The food and beverage industry is enormous, including subindustries like grocery, restaurants, bars, catering, and more. The industry continues to evolve and adapt despite frequently changing consumer preferences and new, complex challenges. So, what’s currently affecting those in food and beverage? In this blog, we’re going to dive into some of the latest trends in the food and beverage industry.

TRENDS IN THE FOOD AND BEVERAGE INDUSTRY

LABOR SHORTAGES IN FOODSERVICE

ARTIFICIAL INTELLIGENCE & AUTOMATION

CONTINUED COLD CHAIN GROWTH

One of the well-known trends in the food and beverage industry is the continued growth of cold chains. Recently, a Grand View Research study shows that the cold chain market was estimated at USD $330,680 billion in 2023. Furthermore, it’s estimated to grow at a Compound Annual Growth Rate (CAGR) of 14.8 percent from 2024 to 2030.

Recently, there’s been an increased demand for temperature-controlled pharmaceutical logistics (think vaccines and biologics), rising demand for better food quality, including more fresh and frozen foods, and a surging need to reduce food waste. All this is anticipated to drive the market’s growth.

In light of the pandemic, the risks of COVID-19 have made consumers more interested in healthier, less processed foods that will boost their immune systems. However, less processed foods mean more food products that will need temperature control.

Additionally, the frozen food sector looks to be growing. Besides filling home freezers, frozen foods are growing in restaurants. Restaurants are also providing new menu items for the frozen grocery aisle. In an American Frozen Food Institute report, 72 percent of frozen food consumers said they combine frozen and fresh ingredients in their meals.

Comparatively, shippers are also using more cold chain services to preserve the shelf life of their products, even when temperature-controlled transportation isn’t needed.

SUSTAINABILITY

Growing climate issues are making sustainability a common trend in almost all industries. Consumers are taking notice of the sustainable practices of companies. From ethical sourcing, carbon neutrality, to eco-friendly packaging, consumers want the brands they buy from to be sustainable. Additionally, food waste is a major contributor to greenhouse gas emissions globally, contributing to cold chain issues. This makes sustainability one of the top trends in the food and beverage industry.

Consumers Care About Sustainability

One way consumers can show their support for the environment is by choosing to purchase from sustainable brands. Consumers have shown they’re willing to pay more and be loyal to brands that invest in their sustainability efforts. In a survey by YouGov, more than half of consumers said they would be willing to pay up to 10 percent more on sustainable versions of regular packaged food and drinks. In another consumer survey, 78 percent of respondents agree that sustainability is import, with 63 percent stating they have adopted greener buying habits.

Food Waste Prevention

In fact, an S&P Global Ratings report says food waste contributes to 10 percent of emissions and that $1 trillion of food is wasted each year. Similarly, according to the U.S. Environmental Protection Agency (EPA), between 73 to 152 million metric tons of food get wasted each year in the U.S. The most wasted foods are fruits and vegetables, followed by dairy and eggs, with over half of all waste occurring in households and restaurants. In addition, the food processing sector generates 34 million metric tons of food waste per year. And over the past decade, the total U.S. food waste has increased by 12 percent to 14 percent.

To put it differently, the EPA said halving food waste in the U.S. would save 3.2 trillion gallons of water, 640 million pounds of fertilizer, 262 billion kilowatt-hours of energy, and 92 million metric ton equivalents of carbon dioxide. According to the Agency, reducing the waste of meats, cereals, and fresh fruits and vegetables would have the most significant impact.

Due to this growing issue, governments and businesses have been working hard to improve sustainability efforts. In July 2021, the Zero Food Waste Act was introduced to provide grants to businesses that significantly reduce their food waste. Additionally, in November 2021, the Food Donation Improvement Act was introduced to lower food waste by making it easier for companies to donate food instead of throwing it out.

Cold chain improvements have seen growing importance even outside the food and beverage industry. One example is UPS Healthcare developing a system and opening facilities to move medicines safely. Part of their plan includes using reusable cold chain packaging. In addition, Amazon is working on insulation packaging to reduce material waste and replace 735,000 pounds of plastic film, 3.15 million pounds of cotton fiber, and 15 million pounds of non-recyclable plastic.

LABOR SHORTAGES In Foodservice

Labor shortages are common among other industries, making this another relatable trend in the food and beverage industry. As a result, hiring workers in the U.S. is becoming near impossible. According to a recent market report, labor shortages are a top concern for 23 percent of food and beverage businesses. The most difficult positions to fill look to be those in the restaurant and foodservice sectors. It’s not just the hiring of new workers, but retaining them as well.

Workers are leaving the industry due to a combination of burnout, low wages, and a desire for better work-life balance. Because of this, restaurants and foodservice companies have had to reduce their hours or limit their menu, while consumers have felt it in longer wait times and less personalized service. With good customer experiences being paramount to a company’s success, resolving this issue is critical.

For this reason, advanced technology can help remove some redundant tasks and help supplement amidst labor shortages. For example, those in the bar sector are being introduced to self-pour technology, which uses RFID tracking and allows customers to pour their own beverages. .

CONSUMERS ARE MORE COMPLEX

Over the years, consumers and their choices in food and beverage and their preferred shopping habits, have become more complex. Because of this, there is a greater assortment of products than ever, with more items requiring temperature control as consumers move away from processed foods and look for fresher, healthier items. Consequently, the supply chain for grocery continues to evolve as the message from consumers is clear. They want what they want, when they want it, where they want it, and expect businesses to respond to their demands.

Continued Decline of In-Person Shopping

In speaking to consumer shopping preferences, it looks like online grocery shopping, food delivery, and food subscription boxes are here to stay. Many consumers prefer the option to receive food and beverage products at their door. For instance, in recent a study by Drive Research, the use of grocery delivery services in 2024 have risen 56 percent compared to 2022. Additionally, the use of grocery curbside or pickup in 2024 have risen 100 percent compared to 2022, further showing the decline of in-person shopping for food and beverage items.

Cost of Food and Beverage Products a Large Concern

Additionally, inflation and rising costs for everyday items, including food and beverages, have consumers rethinking how much and what brands they buy. For example, a recent study showed 54 percent of respondents stating they’ve reduced how much, and unfortunately, 20 percent said they were skipping meals to save money on food. Data from another survey found that 43 percent of consumers are cooking dishes with less meat to save on grocery costs. Others are choosing to purchase cheaper cuts of meat.

Private label brands continue to see growth as shoppers look to save money whenever possible. In fact, according to Numerator, private label brands hold almost a quarter of sales in the grocery sector. The Private Label Manufacturers Association shows that private label sales saw 2.5 percent growth compared to a decline of 0.8 percent by national brands in 2024.

Taste and Experience is a Must

Consumers want to feel good about what they eat. They want nutritious options that alight with their dietary preferences or health goals. In a survey but the International Food Information Council, 54 percent of consumers consider the healthfulness of food in their purchasing decision. Yet, even with the health benefits, they still want their products to taste good, as Datassential shared 35 percent of them purchase items that sound both delicious and healthy.

Consumers are interested in trends like unprocessed foods, natural ingredients, anti-inflammatory, and hydration. Alcohol-free and non-alcoholic beverages are also a rapidly growing trend, with 2 in 5 consumers abstaining from drinking alcohol.

Consumers generally want a positive experience with food and beverage products. While it’s fuel for the body, it can also serve as a source of community, entertainment, and more. In one study, 53 percent of consumers see experiences as essential to their personal lives, especially among the younger generations since the pandemic. They’re interested in trying to tastes and spices, products that bring a sense of nostalgia, or food and beverages that tie in with a story, as shown by the recent increase in pop-up restaurants and bars.

supply chain Challenges

Since the pandemic, supply chains have been seen more of the limelight. As shown by rising costs faced by consumers, food and beverage supply chains have been challenged by shortages of raw materials, disruptions like strikes or a bridge collapse, and a growing demand by consumers for transparency and speed.

Consumers are also becoming more interested in knowing where the products they buy come from. According to a study by IBM, nearly 70 percent of consumers want to see a brand’s sourcing practices. They want to know how the products they buy were manufactured. They’re looking for companies who show concern to how their manufacturing affects the planet’s life span and how their product is raised or grown. Consumers want to feel like the products they choose to buy will make a difference.

According to a Mckinsey report, food and beverage supply chains see supply chain disruption roughly once every three years. A 2023 risk report shows that supply chain executives are concerned about disruptions from climate change, environmental factors, and geopolitical conflicts. Another risk report shows that 73 percent of companies experienced higher supply chain losses within that past two years. Because of this, building supply chain resiliency is a huge trend for food and beverage companies.

ARTIFICIAL INTELLIGENCE & AUTOMATION

Artificial intelligence (AI) is a buzzword across all industries, but how could it affect food and beverage? One way is through providing clearer insights into shopper preferences, helping companies better market to them to grow brand loyalty. It can help with supply chain optimization, helping businesses better understand consumer demand and optimize production planning and management, reduce overstocking, and minimize waste. Some companies, like Campbell Soup Co., are using AI to help with product development, tracking data and discovering what its customers want next.

According to WifiTalents, 62 percent of food and beverage executives believe AI will have a significant impact on their industry within the next five years. With the uses for AI in the food and beverage industry being so extensive, it will be interesting to see how companies make use of it.

There’s also a lot to be talked about in AI and automation for the customer experience. Companies are looking into AI-driven customer service opportunities and ways to streamline customer interactions. You see a lot of this in the restaurant industry with the use of table side tablets, interactive menus, and mobile ordering and payment. AI is used in mobile apps to personalize menus and promotions based on customer preferences.

Growing Cold Storage Demand

The demand for refrigerated warehouses is continuing to soar to new heights. A report from Skyquest forecasts the U.S. cold storage market to increase with a compound annual growth rate of 13.5 percent through 2031, expecting to reach a value of $118.8 billion.

Temperature-controlled storage is critical to many sectors, from grocery to pharmaceutical companies. The growing demand for cold storage facilities comes the adoption of automation and technology, the popularity of ecommerce and demand for faster delivery, as well as online grocery platforms. There’s also a thriving demand for convenience foods – those that are usually chilled but ready to eat with little to no preparation.

STAY AHEAD OF TRENDS IN THE FOOD & BEVERAGE INDUSTRY

No matter the trends in the food and beverage industry, having a logistics resource, consultant, or expert is one way to stay ahead. Whatever phrase you want to use but ultimately, have support on your side for any complex situation. This is where a third-party logistics company (3PL), such as Trinity Logistics, can come in. We can help you find creative solutions to your logistics challenges.

Now, you’re likely wondering, “why work with Trinity Logistics?” For one, we’ve been serving cold chains for over 45 years! Whether you have a complex challenge or just need help with one shipment, we have the experience and quality carrier relationships to meet your needs.

You can also count on us to stay knowledgeable on what’s going on in your industry so you can stay updated too. We know that even in times of supply chain disruption, your industry doesn’t stop, so neither do we.

And lastly, what makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

If you’re ready to have Trinity Logistics on your side for logistics support and expertise, no matter the industry trends, then let’s get connected.

DISCOVER HOW WORKING WITH TRINITY CAN BENEFIT YOUR COMPANY STAY UP-TO-DATE VIA OUR EMAILWhile many of us are soaking up the last of summer’s sun and fun, food manufacturing supply chains are readying for the upcoming holiday food rush.

Have you ever noticed a lot of our favorite memories are surrounded by food? When we go to celebrate something like a birthday, anniversary, or special achievement, it usually involves food. It’s no surprise then that over the holiday season, nearly 165 million consumers across the U.S. purchase food and beverages to celebrate, according to a study from Cornell. As the holidays soon approach, food consumption surges, with the average American indulging up to an extra 440 calories per serving!

The increased demand and tight holiday deadlines can present challenges for many food and beverage companies with their logistics. This is in addition to already facing a competitive peak shipping season! However, by understanding the dynamics of this unique period of time, shippers can ensure success is ahead of them. First, let’s dive into some fascinating facts and insights about food during the holiday season. Then, we’ll follow that with some essential tips so your company can be prepared for the holiday food rush!

Holiday Food Supply Timeline & Stats

The Holiday Food Surge Begins with Fall

The holiday food rush first begins with the arrival of fall flavors. Pumpkin spice, now seen as the quintessential flavor of fall, has seen a 47 percent increase in sales, as reported by The Guardian, within the past five years. In 2023 alone, Datassential reported 144 new limited-time offers that featured pumpkin on major restaurant menus. From the infamous Pumpkin Spice Lattes (PSLs) to pumpkin soups and ravioli, this flavor dominates the season. But we can’t forget another fall favorite – apple. Food and beverage items with caramel apple were one of the highest-indexing flavors last fall.

Halloween Signals Significant Holiday Food Consumption Increase

Halloween is a major milestone in the holiday food timeline, with 65 percent of consumers participating in the festivities. In fact, of all 172 million that celebrate the spooky season, 95 percent of them purchase candy. Even more staggering is that a quarter of all the candy sold annually comes from Halloween sales. It’s not all about the sweets, though! Pizza is the most popular dinner staple on All Hallow’s Eve, according to Grubhub. There’s also the annual tradition of carving a pumpkin, with Statista reporting roughly 154 million Americans partaking in the activity in 2023.

Dia de Los Muertos Celebrations Begin to Trend

Datassential reports that 10 percent of consumers in the U.S. report celebrating Dia de Los Muertos, or Day of the Dead. This holiday is gaining popularity, which means so are the celebratory foods associated with it! Pan de Muerto is one traditional sweet bread that’s essential to the celebration.

Thanksgiving Continues to Drive Food Supply Chain Demand

Thanksgiving remains the most popular fall holiday, with 83 percent of Americans celebrating the tradition. A whopping 46 million turkeys are consumed each year, according to the U.S. Department of Agriculture. Other top holiday staples include cranberry sauce, stuffing, green bean casserole, mashed potatoes, macaroni and cheese, sweet potatoes, and pumpkin and apple pies. That’s a lot of food to prepare for a meal, so 23 percent of consumers will buy a full, ready-made meal from a restaurant. Another 22 percent will supplement with some food from restaurants for part of their feasts.

Sweets, Candy & Chocolate Build Holiday Food Demand at Christmas & New Year’s

Leading up to Christmas, many enjoy hot cocoa, cookies, and other treats. 1.76 billion candy canes, a holiday staple, are made annually for this joyous time of the year. 70 percent of Americans make Christmas desserts, with frosted sugar cookies being the top ones consumed annually. Don’t forget the eggnog! 122 million pounds of it is poured and drunk each year.

When it comes to Christmas dinner, pork dishes are the most popular globally, but turkey still trumps all for the U.S. Other winter feast staples include roasted or mashed potatoes, roasted carrots, gravy, stuffing, shrimp, and lots of Christmas pudding, cookies, and pies. Sweet tooths rejoice as 83 percent of consumers fill stockings with treats like candy and chocolate.

Christmas and New Year’s are among the busiest holidays for restaurants. Both holidays also see a spike in alcohol consumption, with New Year’s Eve being the second most alcohol-associated holiday behind Mardi Gras. Champagne is the fan favorite for those ringing in the New Year.

Logistics & SHipping Tips for Holiday Food Shipping

The holiday season often brings those in logistics the gift of increased demand and decreased capacity. Like most Americans, truck drivers aim to be home for the holidays, trimming the number of available carriers down. Freight of all kinds can increase during the period, further cutting the number of trucks available. Shippers with more specialized requirements, like temperature control, can find even less capacity. Shippers also have tighter deadlines to meet at this time to make the most of the seasonal business.

Overall, the holiday season can be a time of heightened stress and disruption. Given these unique challenges, it’s crucial for food and beverage shippers to prepare thoroughly to appease customers.

Five Tips for the Best Holiday Food Shipping Logistics Outcomes

Tip 1: Keep Inventory Stocked

Running out of stock during the holiday season is a surefire way to lose customers. Track your inventory levels closely and replenish supplies early to ensure you’re well-stocked. By keeping orders moving consistently, you’ll be able to meet consumer demand and avoid causing any disappointment.

Tip 2: Have Backup Shipping Plans Ready

The chances of any disruptions or delays happening during this season are increased. Having backup shipping plans already prepared is essential to keep your goods moving.

Build relationships with multiple carriers and suppliers, or even a third-party logistics provider (3PL). This way, you’ll have known contacts ready in case you need any help.

Look at alternate modes of transportation and be prepared to quickly shift plans should something happen. Exploring multimodal options can be a great way to diversify risk, add capacity, and protect your freight budget. Having this flexibility available and ready can help you stay on track and your supply chain running smoothly.

Tip 3: Real-Time Visibility is Needed for Success

In today’s supply chains, having access to the visibility you need is crucial. You should either work with a provider that offers it or invest in your own technology, like a Transportation Management System (TMS).

A TMS can be very helpful during the holiday season. It can help you with routing decisions by matching your freight with the best carriers, lanes, and rates. In addition, it will allow you to optimize the in-house processes of your transportation network – which can be helpful during busy and slow seasons. By selecting the best carriers and optimizing your routes, you’ll not only increase your service but reduce your risk.

Using a TMS also gives you data-driven insights to better manage disruptions, reduce downtime, and budget your logistics spend. Data analytics can help you recognize which carriers are most likely to have the capacity, saving you time arranging your shipments.

Tip 4: Communication and Collaboration

Effective communication is key to a successful holiday season. Regularly communicate with all stakeholders, including suppliers, carriers, and customers. Collaborating with your partners during the seasonal planning phase can provide valuable insights and help you identify potential issues before they arise.

Tip 5: Partner with a 3PL

Working with a 3PL can be a game-changer during the holiday season. A 3PL offers access to a larger network of carriers, advanced technology, and expertise in managing complex logistics challenges. With their support, you can ensure your supply chain remains resilient, even in the face of unexpected disruptions.

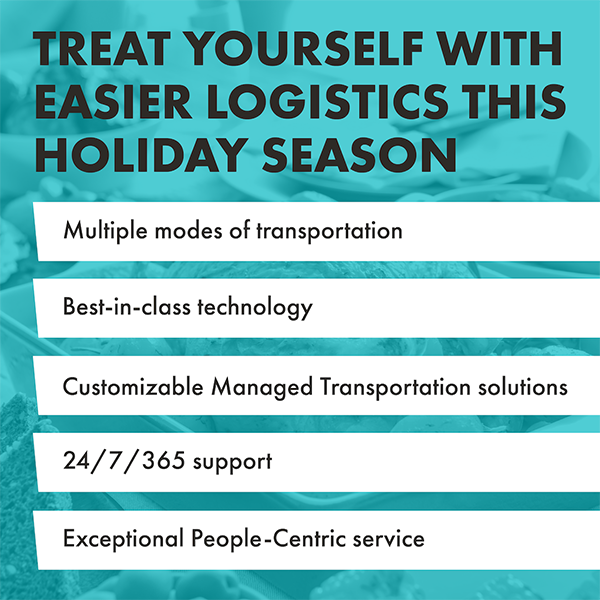

Treat Yourself with Easier Logistics This Holiday Season

Navigating the holiday food rush can be overwhelming, and that’s why Trinity Logistics is here to be your guide. Like Santa, we’ve been around a while, with 45 years of experience handling logistics during holiday seasons.

Right away, you’ll gain access to our large network of vetted, quality carrier relationships to cover your shipments. But that’s just the start! There are many more benefits to working with Trinity, including:

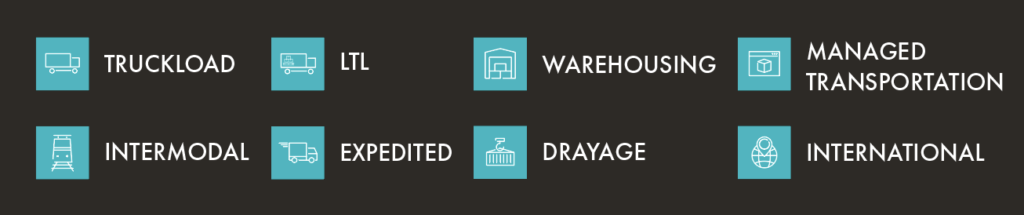

- Multiple modes of transportation to find the best bang for your buck, support your business growth, or just have a backup plan ready

- Best-in-class technology and customized Managed Transportation solutions available, giving you the exact visibility and data you want

- 24/7/365 support, so no matter what day or time it is, you’ll have the help you need

One benefit that tends to shine above all else? Our exceptional People-Centric service. It’s the trait that makes Trinity different from other 3PLs and keeps our customers returning time and time again. It’s truly our care, compassion, and communication that you’ll notice and appreciate.

Everyone wants to enjoy the holiday season. Why not let Trinity focus on the logistics for your business, so you can go back to doing what you enjoy – helping consumers savor holiday treats and create memorable moments with your product.

Try out Trinity Logistics for Your Next Shipment Learn How Trinity Supports Food & Beverage Shippers Sample More of the Trinity Culture & Service – Join Our Mailing ListAre you a Freight Agent that stumbled across this article?

Freight Agents, Indulge in an Exceptional 3PL PartnerIt’s a simple fact. People can’t survive without food. When times are tough, we can certainly make sacrifices in other parts of our lives, like our online shopping habits or a remodel we wanted, but not food. This makes food manufacturing a reliable and even diverse industry to run a business in. Yet, it doesn’t come without its own set of unique challenges, especially with its logistics.

Today, the demand for fast and reliable shipping is higher than ever. Food and beverage companies need to meet the rising pressure to provide quicker turnarounds and deliver their products at optimal freshness to stay competitive. With already complex supply chains, how can a company keep up? Not to mention, what if there’s an issue found or a delay? Don’t stress. We’ll cover logistics challenges that commonly hurt food manufacturing businesses and how working with a third-party logistics (3PL) company, like Trinity Logistics, can solve and simplify your processes for shipping food.

Common Shipping Challenges Faced by Food Manufacturing

Diversity in Scheduling Applications Introduces Challenges

One of the biggest headaches for food manufacturers is self-imposed. Each shipper or distributor could be using a different scheduling portal or application. Some even just use Excel spreadsheets. Because of this, scheduling conflicts and communication gaps are often seen when shipping food. This can be very frustrating to the logistics departments arranging the shipments.

Furthermore, the carriers they aim to work with may not know how to use the application or might not even have access to it. This inefficiency can cause issues with them scheduling their pickup or delivery appointments. It also can limit access to capacity, something that is truly needed for those requiring temperature control during peak produce season!

Plenty of Time-Sensitive Freight in Food Manufacturing – Beat Must Arrive by Dates

As previously mentioned, food manufacturers face a growing demand for products that are at peak freshness, especially for those needing temperature control. It’s not unusual for these time-sensitive shipments to be last-minute orders requiring immediate action. Some of these can come in just the day before or even the day before and need shipping right away. Sometimes to help manage the influx of shipments, freight can be assigned with a “Must Arrive by Date” (MABD). This can put pressure on food manufacturers, and missed delivery windows can result in costly penalties. These fees, called chargebacks, usually get pushed back onto the customer and impact your bottom line and service.

Identify Visibility Gaps When Shipping Food

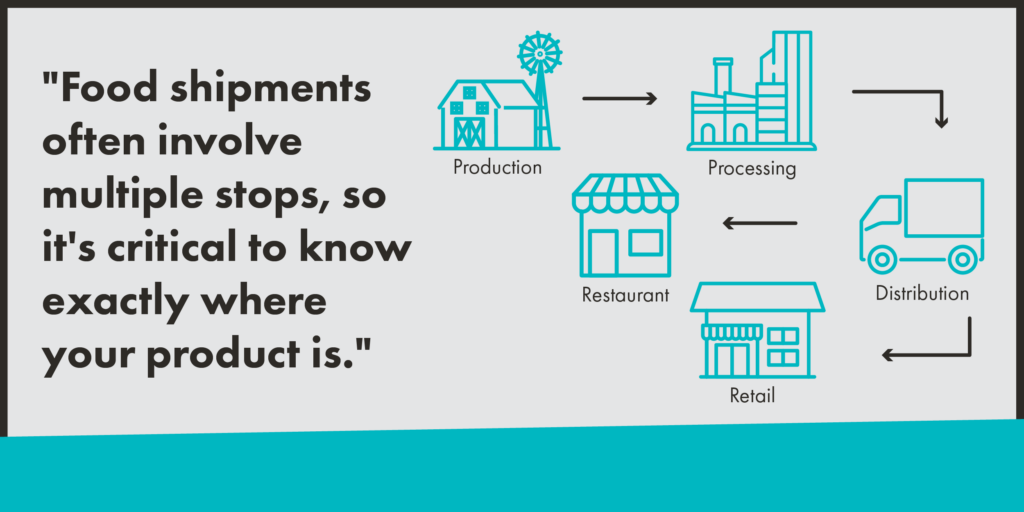

With many time-sensitive and temperature-control requirements, it’s important for food manufacturers to have complete visibility into their shipments. Food shipments often involve multiple stops, so it’s critical to understand where your product is and when it’s expected to arrive. Even though it is valuable, many food manufacturers find they have limited visibility of their shipments. This creates a lot of uncertainty, causing additional gaps in communication and possible delays or disruptions. Most importantly, it can jeopardize the safety of your food product, an important piece to meet the Food Safety Modernization Act (FSMA) regulation.

Keeping Food Shipping Logistics Budget in Control

Carrier selection for shipping food products can be a puzzle for food manufacturers to figure out. On one hand, you want to work with high-quality carriers to ensure your food products arrive at peak freshness. On the other hand, they cost more. One certainly wants to budget and find balance. Look to pay too little, and you may not find the quality service your products need. Finding that balance between the two can be difficult.

Market trends can also cause unexpected price fluctuations, further challenging their logistics budget. This can really hurt those needing to meet peak freshness as it’s not like they can’t ship their products as they may perish. Instead, they’ve got to adjust and pay the current price.

Food manufacturers must be creative and find solutions to keep their costs down but their quality up. They can consider other transportation modes as options to manage costs, but understanding which one makes the most sense for their product can be overwhelming.

Embracing Sustainability in Food Shipping

Sustainability is on everyone’s minds, including consumers. With global food and beverage production causing roughly 34 percent of greenhouse gas emissions, consumers are holding food manufacturing companies to higher standards. They’re researching more about the companies they purchase food products from. They want to know what positive practices they implement, such as sustainable fishing, the use of ecological pesticides, reforesting, fair trade, or the use of compostable packaging.

TRINITY Logistics SOLVEs Food Shipping PROBLEMS

With over 45 years of serving customized logistics solutions to thousands of food manufacturers, we’re fairly confident in our ability to help you overcome any of these challenges.

We Speak Your Food Shipping Scheduling Language

We’re in tune with most if not all, scheduling portals that food and beverage shippers use. You don’t have to worry about training us! Yes, we could even say we know how to navigate those scheduling apps “with our eyes closed.” Even if we have a newer Team Member who is unfamiliar with it, we can guarantee that at least one of our 400+ Team Members or 135+ Authorized Agents know it and can assist.

Time-Sensitive Titans: We Deliver Your Food Products When It Matters Most

At Trinity Logistics, we understand the urgency of time-sensitive food deliveries. Our Team excels in handling quick turnarounds, making us the “emergency room” for your time-critical freight. We are acutely aware of the potential repercussions of missed deliveries and leverage our strong carrier relationships to secure the capacity you need. These established partnerships allow for better planning and ensure that carriers are familiar with the specific needs of food commodities, pickup, and delivery locations.

Furthermore, in the unfortunate event that fees do arise due to carrier issues, Trinity acts as your advocate. We hold our carriers accountable and ensure that any associated charges are passed along to the responsible party. Our meticulous investigation process guarantees that only the root cause of the problem bears the financial burden.

Expand the View into Your Food Shipments

We’re champions of end-to-end visibility, great communication, and transparency because we know you deserve it. Our commitment to People-Centric service isn’t just our slogan; it’s our philosophy.

We leverage a combination of cutting-edge technology and a dedicated Team Member to keep you informed every step of the way. Use our Customer Portal to see real-time tracking of your shipments. If you’re looking for even more transparency, there’s our Managed Transportation service, offering you a customized Transportation Management System (TMS) solution that works for your business. Between our technology and our Team Members, you’ll find this proactive approach ensures you’re not left in the dark until delivery.

Find Balance in Your Logistics Budget

Starting out, our established carrier relationships not only gain you access to capacity but to leverage our competitive rates. Additionally, we have multiple modes to choose from and our Experts can help you explore which one suits your product and budget.

Now, we understand balance isn’t easy to obtain, so that’s why Trinity Logistics goes a step further in our service to help you find it. For those food manufacturers that build a shipping history with us, we’re able to review your data and conduct a comprehensive review of your logistics. This will give you a clearer insight into your logistics to find room for improvement. We won’t come empty-handed, either. We’ll make recommendations to add efficiencies and see if we’re on the right track for your company’s success.

Adding Sustainability into Your Logistics

We understand the importance of sustainability and are committed to helping you implement it throughout your supply chain. This includes connecting you with carriers that prioritize eco-friendly practices, finding sustainable shipping options, and exploring carbon offsetting programs. If you need further proof, Trinity currently holds a bronze medal rating by EcoVadis, the world’s largest and most trusted provider of sustainability ratings.

Learn more about Trinity's sustainability initiativesBonus Benefit for Food Manufacturers! Trinity’s Relationship with Honor Foods

As a Burris Logistics Company, we have a direct relationship with Honor Foods. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They have access to thousands of reputable brands and can simplify your purchasing process. Honor specializes in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers. Speed up your lead times and increase profitability with no extra storage space needed. Working with Trinity and Honor, you can get the best of both Burris Logistics brands and gain additional success in your business.

Operating in food manufacturing can be complex, but it doesn’t have to be. Try Trinity Logistics for your shipping and see just how easy it can be.

Discover how Trinity exceptionally serves those in food and beverage Get a quote to see if our solutions are right for your businessCraft Beer Logistics: Navigate Complexity, Grow Your Business

Beer, a beloved and timeless beverage. It’s a staple in many cultures and continues to be one of the world’s most popular drinks. A growing subset in beer is the craft beer industry, known for its robustness, variety of flavors, and highlighting regional tastes. According to the Brewers Association, in 2022, craft beer sales increased five percent and now account for almost a quarter of the U.S. beer market. While the demand for craft beer grows, the logistics behind its distribution is increasingly complex.

Craft brewery owners often wear many hats and have lots of tasks to hop on. This can include handling their logistics. This includes more than just the shipping of their beer but the many ingredients and equipment that go into making it. From start to finish, these beer supply chains involve numerous stages and stakeholders, including ingredient manufacturers, distributors, and retailers.

Having effective logistics planning and processes is crucial for craft brewers to meet their growing demand and provide great service to their stakeholders. Managing their supply chains can be difficult to do alone, which is why a third-party logistics (3PL) provider can be a valuable resource to growing craft breweries.

LOGISTICS CHALLENGES FACING THE CRAFT BEER INDUSTRY

Knowing how to legally and efficiently manage their shipping networks is a crucial part of running a successful craft brewery business. There are several challenges craft brewers face such as keeping temperature control throughout transportation, meeting state regulations, and meeting customer demand.

PERISHABLE INGREDIENTS AND PRODUCTS

The need for temperature control in the logistics of craft beer is paramount to preserve the integrity of any needed ingredients or finished products.

Craft brewers also often experiment with ciders, mead, and other malt beverages with specialized flavors, which can include perishable ingredients like fruit. The shelf life of the raw materials and craft beer brings along the element of urgency, placing even more importance on on-time deliveries. Coordinating these shipments to ensure quality beer adds an additional layer of complexity to the logistics process.

REGULATORY COMPLIANCE

Navigating the web of regulations for shipping beer in logistics can be a considerable challenge. Regulations for shipping alcohol vary from state to state, meaning you’ll need to be compliant based on where you are shipping to and from. Additionally, state laws will often change every few years, making it even more difficult.

Craft brewers must also find carriers with the correct licensing, knowledge, and experience to handle the unique requirements of transporting alcoholic beverages. It’s important to work with a logistics provider that knows all the ins and outs of meeting your product’s requirements and state regulations to prevent costly disruptions due to non-compliance.

MEETING CUSTOMER DEMAND

As craft brewers reach more customers, the more need there is for effective logistics planning. Having to juggle keeping track of supplies, determining the most efficient distribution methods, and preparing for any supply chain disruption can be overwhelming. Having a successful craft brewery goes beyond just brewing great beer, but ensuring it reaches the consumer when and where they want it.

Managing costs is on top of rolling out new beverages can be a significant challenge for craft breweries. Having efficient strategies, such as freight consolidation or finding the most cost-effective mode of transportation, can help keep costs in check. This is where an expert third-party logistics company (3PL) can assist with strategy and technology, like a transportation management system (TMS) for visible reporting.

3PL BENEFITS: BREWING SUCCESS WITH TRINITY LOGISTICS

While there may be difficulties to face in the dynamic world of craft brewing, partnering with a 3PL like Trinity Logistics can alleviate the burden. Here’s why working with us for your craft beer shipping and supply chain is the perfect recipe for success:

Our Only Job is Logistics

Logistics is what we handle day in and day out. When you trust us with your freight, you get more time to focus on what you do best – brewing exceptional beer and growing your business.

Experts in Specialized Shipments

Understanding the nuances of transporting freight with specialized requirements, such as temperature control, is our expertise. Whether it’s raw materials or the final product, we ensure everything arrives in optimal condition.

Regulation Compliance

Our dedicated Team and compliance department work diligently to ensure the necessary regulations are meant to provide you peace of mind and reduced risk.

Tracking and Tracing

We understand transparency is key to your success, so we offer several ways to view and keep track of your freight, no matter the time of day.

Effective Logistics Strategies

Whether you need help with something as simple as finding the most cost-effective mode of transportation to freight consolidation, we can help you find and implement strategies to optimize your supply chain and manage costs. It doesn’t matter if it’s just one or 20 pallets of freight, we can arrange full truckload, less-than-truckload (LTL), expedited, or any other mode you may need.

Reduced Risk

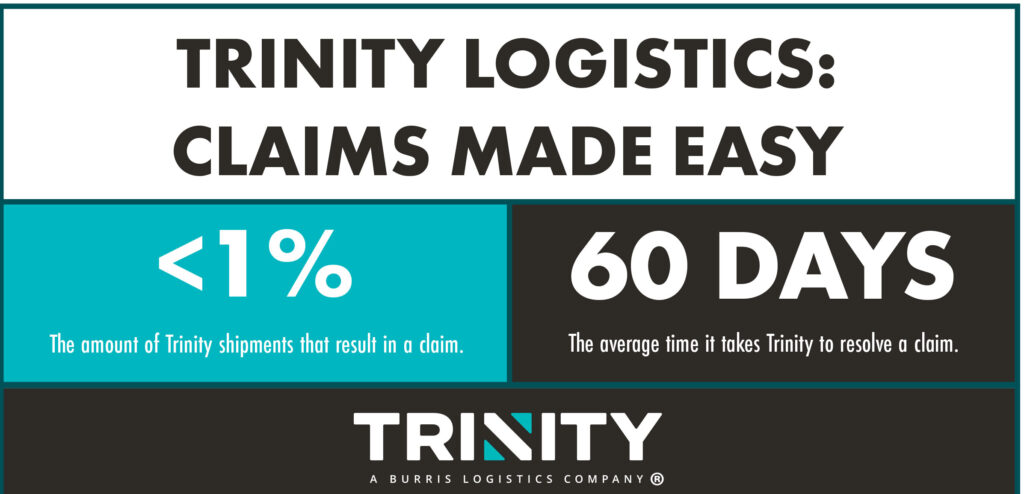

At Trinity, we meticulously verify all carrier relationships that we work with, not just during the initial setup but for every shipment. We’re also proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. If something does happen, we have a Cargo Claims Department at the ready to assist you in navigating any issues.

24/7/365 Support

No matter what happens, we’re ready to support you around the clock. We have a dedicated After-Hours Team to continue the monitoring of your freight and are ready to quickly resolve potential challenges, no matter the time of night, holidays, and every weekend.

Trustworthy Carrier Relationships

We treat and respect our carrier relationships just as much as our shipper ones. We aim to build a strong partnership with each one to help their businesses be successful. Because of that, we’ve built strong and trusted partnerships with those in our carrier network, providing you further confidence that your freight will arrive safely.

Managed Transportation

Whether you solely need a TMS for your transportation management, you’re looking for a fully outsourced solution, or something in between, we can help. We understand companies don’t come one-size-fits-all, and neither should the services you need to optimize your logistics. Our Managed Transportation services cater to businesses of all sizes and needs, capable of growing right alongside your brewing venture.

Partnering with Trinity Logistics offers you more than just transportation services. We’re a trusted, strategic ally that’s invested in seeing your business succeed. Leave the logistics to the seasoned experts, so you can focus on creatively and passionately brewing while we ensure your craft brews reach your consumers right when they want it.

LET US HELP WHAT ALES YOU IN LOGISTICSConsumers want more fruits and vegetables in their diets but produce shippers must face these common logistics challenges to keep up with their demand.

It’s hard to deny the nutritional value fruits and vegetables bring to our diets. It’s likely why there’s been substantial growth in consumer demand for produce over the past decade. While that’s great for businesses based in produce, there’s also greater pressure for produce shippers to deliver.

The journey from farm to table can be surprisingly complex for fruits and vegetables. Produce shippers face several hurdles that they need to overcome for their products to deliver fresh and meet the growing consumer demand. Let’s explore the intricacies of these difficulties and how they all can be taken care of by working with a third-party logistics (3PL) provider, like Trinity Logistics.

CHALLENGE 1: CHOOSING BEST TRANSPORTATION MODE

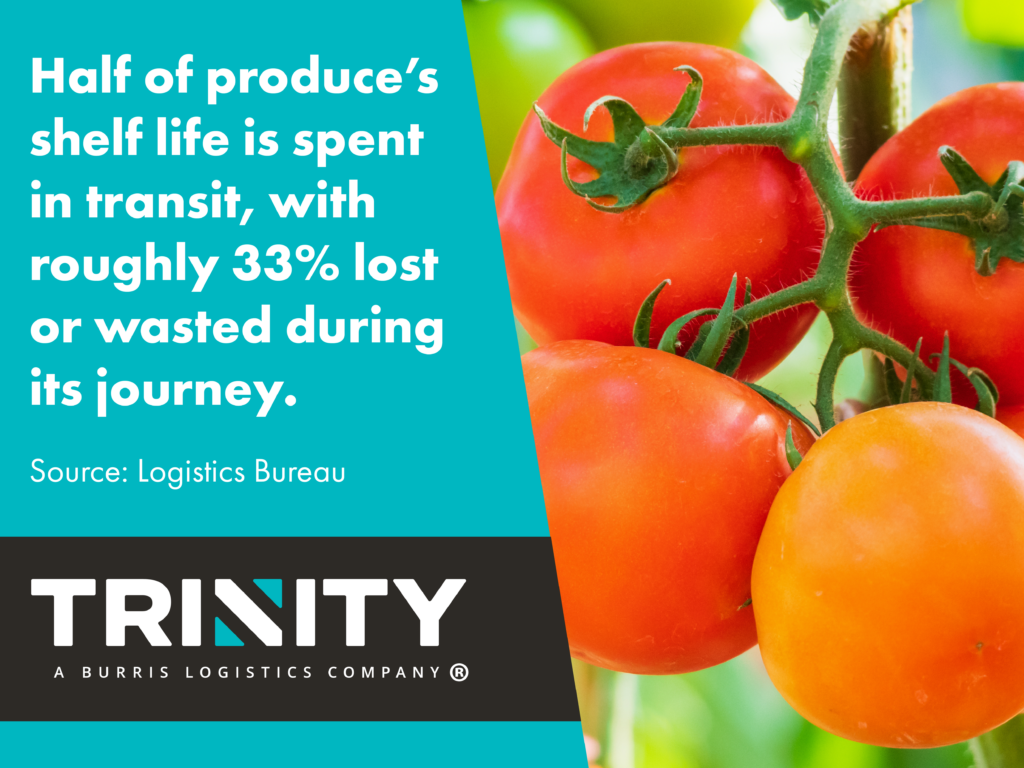

Produce shippers first face the challenge of determining what transportation mode to use for their shipments. With produce, half of its shelf life is spent in transit. It’s also reported that roughly 33 percent of produce is lost or wasted during its journey, according to the Logistics Bureau.

This is why produce shippers must ask themselves these questions to help determine the right transportation mode for their shipment.

What’s best for your product?

What can you afford?

How much time does your produce have?

Air is great for foods that have a very short shelf life and may need expedited shipping. However, air is often the most expensive of your options. Rail can offer you cost savings but requires more travel time, often two to three days. This option is often saved for produce with a longer shelf life. Lastly, there’s truckload shipping, which offers several shipping options and costs, depending on factors like whether you need a full truck, expedited shipping, or freight consolidation.

CHALLENGE 2: SELECTING THE RIGHT CARRIER PARTNER

The next challenge produce shippers need to tackle is choosing the right carrier to pick up and deliver their shipment. This may be the most crucial task of all because the carrier you choose can make or break your shipment. You need to trust the carrier you choose has experience in handling your specific cargo and meeting food safety regulations, especially for those that need temperature control.

CHALLENGE 3: MAINTAINING FRESHNESS/QUALITY

Maintaining freshness is one of the primary logistics challenges for produce shippers. Millions of dollars are wasted each year on produce that didn’t maintain freshness by delivery.

Produce begins to deteriorate the moment it’s harvested, so the risk of decomposition is equal to, or perhaps even greater, to produce shippers than those of theft or delay. Fresh or frozen produce needs to be stored and transported at specific temperatures to ensure its quality when bought and eaten by the consumer. Even the amount of humidity, light, or kind of packaging can affect a produce product, so produce shippers face this challenge in every segment of their shipping.

Every kind of produce also has different needs. Some need very specific environments to maintain freshness. Others can stay at room temperature or take on more handling. Shelf life is also something to consider. Produce with short shelf lives will need quick transit from farm to store. This also means several kinds of produce often can’t ship together. Since there is no one-size-fits-all process for produce, it’s important for produce shippers and their logistics partners to understand what’s needed for the specific product to deliver at peak quality.

CHALLENGE 4: SHIPMENT VISIBILITY

Tracking and shipment visibility is essential for produce shippers to be able to reduce risk. Without a clear look into your shipments, you’re left in the dark and uncertain whether your product will arrive on time or in acceptable condition.

This can challenge more than just produce shippers, but all stakeholders in a company’s supply chain. Miscommunication can happen between retailers and sellers as well, causing miscalculations in capacity planning or undependable forecasts. Real-time visibility and data are absolutely needed for produce shippers to enhance transparency with their business partners and gain more control over their supply chains.

CHALLENGE 5: REGULATIONS

Navigating regulations is a huge challenge for produce shippers. Failure to meet those regulations can lead to severe and often costly consequences. For example, in the U.S., produce shippers must comply with the Food Safety Modernization Act (FSMA), which entails specific guidelines for food safety.

There are also quality standards and labeling requirements to be met. The U.S. Department of Agriculture (USDA) has a strict grading system to determine the quality of produce, considering its size, shape, color, and defects.

CHALLENGE 6: HANDLING ANY CLAIMS

There’s always a risk for claims in shipping, but claims can happen more often for produce shippers compared to other industries, due to its shorter shelf life. The majority of claims we see in produce shipping are the result of spoilage, which can happen for many different reasons.

Handling claims for produce is slightly more difficult due to the Perishable Agricultural Commodities Act (PACA). When handling produce claims, it’s important you and your transportation provider understand and follow PACA.

HOW TRINITY LOGISTICS HELPS PRODUCE SHIPPERS OVERCOME THEIR CHALLENGES

All those challenges listed above that you may face – we know how and are prepared to handle them.

After 45 years of serving shippers in the food and beverage industry, we’re experts in its logistics requirements and regulations. We also take part in industry organizations, like the International Fresh Produce Association, so we stay knowledgeable about what may affect produce shippers.

When it comes to choosing your transportation mode, we have a multitude of options available to support you, whether you’re looking for help with one shipment or a fully outsourced logistics solution.

Additionally, we work with trusted carrier relationships that have been fully vetted to ensure your product travels safely and delivers on time. This includes vetting that reefer equipment is not older than 2012 and a temp-reading or download can be made readily available for any refrigerated or frozen produce shipments.

No matter where your freight is in its journey, we provide you with several real-time tracking options to stay fully informed. Through our Managed Transportation service and the use of a transportation management system (TMS), you can find more visibility and data to improve your supply chain processes and communication.

And then there are claims. While we wish every situation could go smoothly, there can still be mishaps. Even so, we’re proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. That’s likely because we work with shippers and receivers to monitor load and unload times, checking to ensure trailer doors are not left open, causing temperatures to fluctuate outside of any required ranges.

Now, fear not, because if something does happen, we’re able to help with that too. We have an in-house expert Claims Team to help negotiate any produce claims on your behalf, with an average rate of 60 days in resolving cargo claims.

By working with Trinity Logistics for your produce shipments, you’ll also gain an extra benefit – experiencing our acclaimed People-Centric service. It’s what our customers praise the most about our services and keeps them returning to Trinity Logistics for their logistics needs.

If you’re tired of tackling these produce shipping challenges alone, it may be time to get connected and join the thousands of shippers that choose to make their logistics easy with Trinity Logistics. You won’t be-leaf our exceptional service until you try it!

Get Out of Your Produce Shipping Pickle

Check Out Trinity's Solutions Request a Free Shipping QuoteWhether your product is coming straight from the farm, is moving between processing, or heading off to the consumer, the dairy industry needs first-rate cold chain solutions to meet their complex supply chains.

Dairy products such as milk, cheese, and butter are household staples and essential in many people’s diets. It’s no surprise that the dairy industry is considered one of the fastest-growing industries, almost doubling in value every five years. To keep up with consumer demand, the dairy industry needs exceptional cold chain solutions to keep their products cold and safe for consumption.

Why the Dairy Industry Needs Cold Chain Solutions

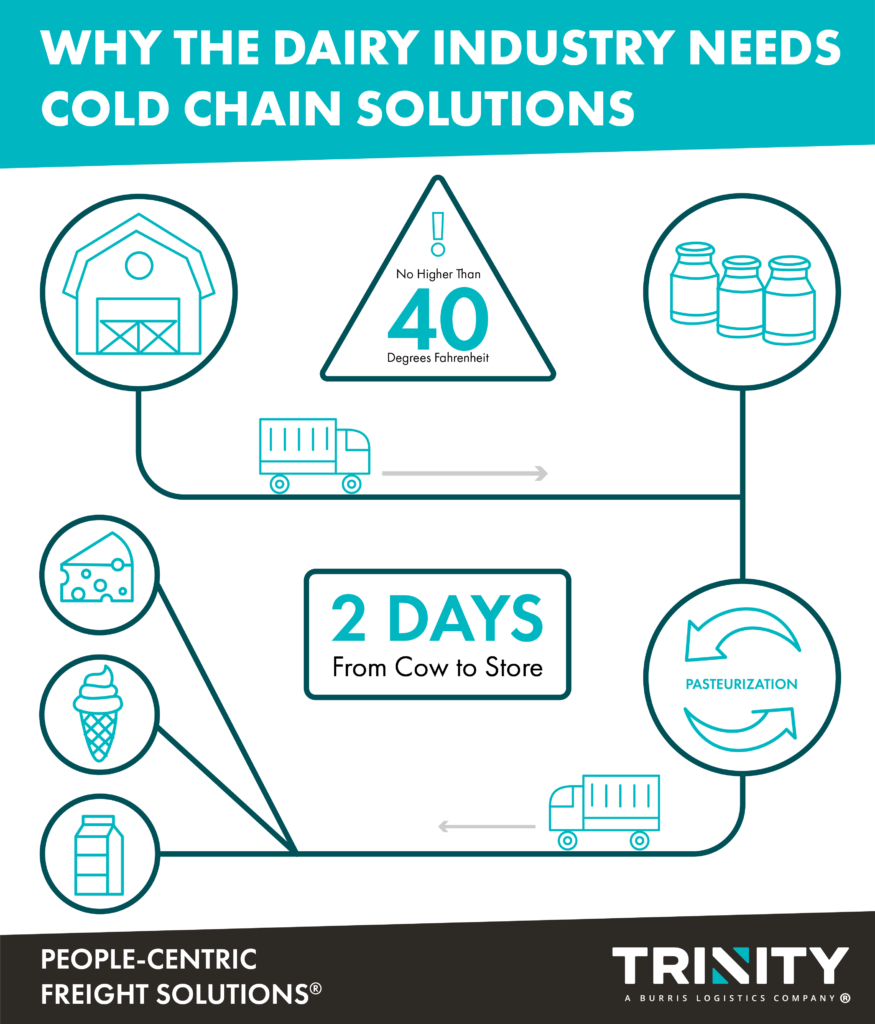

Dairy products all start with milk, and it has a short shelf life. After the cows have been milked, it immediately transports to cooling storage tanks or a chilled trailer. To ensure the milk doesn’t spoil, it must be stored at a temperature no higher than 40 degrees Fahrenheit. It’s then transported to a processing facility, pasteurized, and transported again to consumers.

Usually, this process alone, from cow to store, takes place in about two days. Now, milk is often a starting point for the many diverse dairy products available. Depending on the final product, dairy supply chains have more steps and complexities added.

Common Issues Requiring Cold Chain Solutions

- Temperature Control Needed for Most Dairy Products

- Capacity During Peak Shipping Seasons

- Managing Milk Production with Dairy Demand

- Supply Chain Disruptions

- Dairy is Highly Regulated

- Supply Chain Visibility

- Potential High Value Dairy Products

Temperature Control Needed for Most Dairy Products

Most dairy products need storage at specific temperatures to keep from spoiling. Dairy products need strict attention because of the risk posed to consumers if the cold chain is broken. If not consistently kept cold and free of humidity, bacteria in the dairy can cultivate and dairy products can become harmful.

Capacity During Peak Shipping Seasons

While some dairy products can seek out alternative transportation modes, most find shipping truckload is the most viable option. It’s usually the fastest and cheapest way to move the product because of its weight. It’s also the most viable due to freight security and nature of the product, and because it reduces the risk of claims due to temperature fluctuations or shifting. Since most dairy products need refrigerated trucks for their shipments this can make capacity an issue at times, such as produce season, when reefer capacity can be tighter. It can not only be more difficult to secure a refrigerated truck, but more expensive to do so.

Managing Milk Production with Dairy Demand

Dairy product demand can fluctuate. Yet, even when consumers want fewer dairy products, the cows don’t stop making milk. They can’t be turned on and off like machines, giving the dairy industry a unique balancing act to handle.

Additionally, when it comes to shipping milk, most of that is kept regional given the short shelf life and cost to ship, making dairy demand management even trickier.

Supply Chain Disruptions

As we’ve learned in recent years, there’s always the chance for supply chain disruption to happen. Whether that’s a truck breaking down, a roadblock, or some other instance that would cause delays. With several dairy products (like milk) having a short shelf life, any delays can risk product spoiling and going to waste. Companies in the dairy industry need to be able to act quickly if any disruption happens.

Dairy is Highly Regulated

Dairy products are associated with foodborne illnesses, so it’s no surprise that they’re highly regulated. Right from the start, milk is tested to ensure it’s of safe quality to consume and make other products from. There’s also the Food Safety Modernization Act (FSMA), which places strict requirements on sanitary transportation and the handling of dairy products.

Supply Chain Visibility

Because of so many factors mentioned above, it’s important for dairy companies to have full, real-time visibility of their supply chains. Additionally, many wholesale food distributors and grocery warehouses hold very strict requirements for appointments with very strict product quality inspections to be accepted into their inventory. Without it, dairy companies are at risk of losing products and money due to spoilage, disruptions, delays, or regulation requirements.

Potential High Value Products

Certain dairy products can be high value, like some cheeses for example. This can make the overall value of the load to be costly should there be any potential claims. It’s best for shippers to work with expert providers who have the experience and knowledge to handle any high value dairy products.

Leading Cold Chain Solutions from Trinity Logistics

Shippers in the dairy industry looking for first-rate cold chain solutions can find all they need with Trinity Logistics. We’re a leading third-party logistics (3PL) provider with over 40 years of experience serving logistics solutions to some of the top-known brands in the food and beverage sector.

Standard Operating Procedures for Temperature-Controlled Shipments

One of the reasons we excel in cold chain solutions is our standard operating procedures in place for every temperature-controlled shipment we arrange. This includes:

- Only working with carrier relationships that have downloadable reefer units

- Requiring carriers to pre-cool trailers a minimum of one to two hours before pickup

- Requiring carriers to run their reefer units on continuous

- If necessary, requiring carriers to pulp product before loading

- Requiring carriers to use one of our tracking and tracing partners for real-time shipment visibility

- Only using carriers that have refrigerated trailers that are 2015 or newer

We understand just how critical it is that your product stays at its required temperature. That’s why we work with our trusted, experienced carrier relationships to ensure your product arrives fresh.

Multi-Modal Cold Chain Solutions

No matter what transportation mode you need your product to ship, we have the logistics solutions to support your business now and in the future, including;

- Truckload

- Expedited

- International

- Cross-broder

- Air or ocean shipping

- Drayage

- Less-than-truckload

- Managed Transportation

This enables your business to seamlessly run regardless of what change or growth you experience.

In-Depth Transportation Management

Whether you need a transportation management system (TMS), to fully outsource your logistics, or your own customized managed transportation solution, we can help. We know each business is unique, which is why our system is highly configurable so we can meet your exact needs. Our Trinity experts will work as part of your business, offering in-depth reporting and data to help get you ahead of your competitors.

No Need to Worry About Disruptions

Did I mention that Trinity has been serving cold chains for over 40 years? We’ve seen it all when it comes to supply chain disruptions and delays. We know how to quickly adapt plans to keep your freight moving. While you’ll have your sole Trinity relationship to lean on for updates, we also have a 24/7 Team in case we need any additional support. You can learn to rest easy whenever your shipment is in our care.

Experts in Temp-Controlled Logistics and Dairy

Trinity Logistics has been serving cold chains for 40-plus years, in addition to our parent company, Burris Logistics, that was built on its expertise of handling temperature-controlled commodities.

There’s also Honor Foods, another Burris Logistics company you can lean on for food redistribution if needed. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They specialize in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers.

Our People-Centric Service

What makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

I’D LIKE LEARN MORE ABOUT TRINITY'S COLD CHAIN SOLUTIONSRefrigerated trucking can be a complex, but rewarding job.

You might be transporting anything from fresh produce, frozen food, or important medicines like biologics. But, no matter what it is, the items you’re hauling are vital to many and there’s great pride that comes with that.

Refrigerated trucking is not only more specialized than dry freight hauling but offers more earning potential, and there are certain times of the year during which you can count on higher freight volumes to keep your company profitable.

Whether you’re new to refrigerated trucking or a veteran, it’s important your company knows how to properly transport temperature-controlled products, from pick-up through delivery. At Trinity Logistics, we sometimes see claims on temperature-controlled shipments, and we want to help you avoid any costly mistakes with a few tips specific to refrigerated trucking. So, we’ve crafted this guide to help you prepare for your hauling your next temperature-controlled shipment.

MOTOR CARRIER REFRIGERATED TRUCKING RESPONSIBILITIES

The purpose of the Food and Drug Administration’s (FDA) Food Safety Modernization Act (FSMA) is to prevent foodborne diseases, and FSMA rules contain essential requirements for shippers, loaders, receivers, and carriers like you to follow with refrigerated trucking. FSMA requires those transporting food to follow best practices for sanitary transportation, such as proper personnel training, maintaining shipment records, and following shipper instructions to keep food properly temperature-controlled during transit.

FSMA Responsibilities for Motor Carriers

Keeping Your Equipment Clean and Operable

You must keep your refrigerated trailer clean between loads and make sure it is running efficiently to maintain any required temperatures to keep food safe while transporting.

Your Equipment Must Meet the Shipper’s Needs

Shippers are responsible for communicating any food safety requirements to providers they work with, such as specifying temperature and pre-cooling requirements in writing. It is your responsibility to adhere to those requirements specified by the shipper.

Keeping Records

When it comes to FSMA, verbal confirmations don’t stand. Shippers and providers you work with require records of previous cargo hauled, equipment cleaning, inspection, and temperature records. This includes recording if your reefer fails or containers are compromised, allowing contaminants in, and showing via documentation that you took action to correct the issue. Keeping thorough documentation will help you, in the long run, should you face any potential claims. It’s recommended to keep all records for 12 months, minimum.

Training Employees

Under FSMA, motor carriers must train all drivers and transportation personnel on their role, FSMA rules, the awareness of potential food safety problems like cross-contamination that can occur during transportation, and sanitary transportation practices. It’s also important to keep records of this training and hold refresher training from time to time.

PREPARING FOR REFRIGERATED TRUCKING AND TEMP-CONTROLLED TRANSIT

*This blog content provides suggestions only and is not meant to take the place of your own company procedures.*

Cleaning Your Refrigerated Trailer

1. If the previous receiver cleaned your trailer, request documentation from them to share with the shipper for your upcoming temperature-controlled shipment. It’s important to keep any trailer washout records and receipts to provide to shippers upon request.

2. Open your refrigerated trailer and remove any items that shouldn’t get wet.

3. Sweep out any debris.

4. Prepare a bucket of food-grade detergent and water.

5. Scrub all interior surfaces with a clean cloth and the detergent mix.

6. Use a hose to spray down the inside, including the ceiling and walls. Pay special attention to any cracks and crevices.

7. Keep doors to the trailer open, allowing the inside of the trailer to air dry.

8. If the outside of the truck and your trailer is dirty, wash down the exterior as well.

Pre-trip

1. Review shipping instructions and confirm the cargo is at the required temperature before it is loaded. Refrigerated trailers are meant to maintain temperature, not change it. For fresh produce, verifying temperature usually involves pulping product with a thermometer or probe dial.

2. Run your refrigerated trailer for at least 20 minutes in “high speed cool” mode to remove any residual heat. Pre-cooling may take more than one hour depending on factors such as equipment and ambient temperatures. Therefore, be aware of the temperature requirements in advance to ensure equipment is at the proper temperature before you arrive at the shipper and the loading process starts.

3. Perform an automatic pre-trip test to confirm that your refrigerated trailer is running properly and confirm that it passes the test. Keep a record of this. If your auto pre-trip test fails, refer to your company’s prescribed procedures or contact your maintenance provider for repair.

4. It’s time to set your refrigerated trailer to the required temperature specified by the shipper. Verify the set temperature after adjusting it to its requirement to confirm it is set correctly. Next, confirm that the unit is set to the correct date and time. If this is not done and the shipper requests a reefer download after delivery, the data will be inaccurate. Some drivers will take a picture of the reefer unit dashboard to document settings before they leave the shipper.

5. Confirm that you have the correct mode of operation selected on the reefer unit prior to loading. Again, refer to your shipment instructions for this. Often, the shipper will require perishables to be hauled in continuous mode as opposed to cycle sentry or stop-start cycle.

6. Allow your refrigerated unit adequate time to pre-cool before loading.

7. Document all pre-trip cleaning, inspecting, and pre-cooling to share with the shipper upon request.

Loading

1. Ensure you witness the loading process, visually confirming product temperature, count, and quality match your shipment tender. If a carrier cannot verify loading conditions or discrepancies exist, the carrier notates the issue on the bill of lading and request the shipper to sign this.

2. Carriers are responsible for the final blocking and bracing of product, so make sure items are not over-stacked or loaded in a way that impedes airflow or circulation. As a carrier, if you are not comfortable with the load condition, you have the right to refuse the shipment.

3. Once loaded and final blocking and bracing are completed, immediately close the doors to maintain temperature. Once again, verify that the correct cycle and temperature are set. If a trailer seal is required, its presence should be documented on the bill of lading by the shipper.

During Transit

1. Make use of the strip curtains as this helps keep temperature-controlled air in and any outside air out.

2. Limit the number of door openings throughout transit to keep temperature-controlled air in and outside air out. Only allow doors to be opened by verified shippers or receivers.

3. Keeping proper airflow is critical. Even with adequate running equipment, poor air distribution can cause spoilage. Verify all sides of the cargo have proper airflow before your trip and any time you make a stop.

PULPING FOR REFRIGERATED PRODUCE SHIPMENTS

Pulping is an essential task when hauling produce with your refrigerated trucking. Pulping is the act of taking the product’s temperature before and upon delivering the shipment.

How to Pulp Produce

For produce that is unbagged, one must insert a pulp thermometer into a piece of produce, inserting for three to four minutes to get the most accurate reading.

If the produce is bagged, like salad mixes, fold the bag in half and place the probe between the two sides, with the produce as close to the thermometer as possible.

Why Pulping is Important

Before loading, it is the shipper’s responsibility to pulp the product, and should be done in the presence of the driver. However, it is the carrier’s responsibility to confirm the proper temperature of the product before allowing it to be loaded on the truck, so there may be the case you need to pulp the product.

Pulping temperatures should be recorded on the shipment’s bill of lading and signed by both the shipper and driver. This can help protect both the shipper and motor carrier from claims if the product arrives at its destination off temperature.

Throughout transit, it is the carrier’s responsibility to monitor the refrigerated trailer temperature, usually with some sort of sensor technology providing real-time information, or with older refrigerated trailers, a temperature download that is available upon delivery.

Upon delivery, it is the receiver’s responsibility to pulp the product for a temperature read and to determine if the shipment will be accepted.

Under FSMA, be prepared to provide a record of temperatures in transit via reefer download. Failure of a carrier to provide a record of unit temperatures in transit will prevent a carrier from disputing temperature deviations should there be a claim.

TEMP VARIANCES – HOW MUCH IS TOO MUCH?

One thing you may be asking with your refrigerated trucking is, how much is too much when it comes to temperature variances? Well, that can depend on several factors.

One factor is the type of product. For example, there are some perishable products that are very sensitive to temperature variances, where even a two-degree difference could reduce the shelf life by 50 percent.

Another cause could be the location where the temperature was taken in the trailer or the recording device’s accuracy. Or if a shipment has multiple stops versus one that goes right to the destination.

Temperature variances are usually expected, so it’s important to determine when a variation is tolerable versus when it places the product at risk for spoilage.

It’s also important to note the amount of time the product has been off temperature. For example, frozen goods might be subjected to some temperature variance without much effect on the shipment, whereas refrigerated goods often spoil at a quicker rate.

When it comes to claims due to temperature variances, there simply is no one-size-fits-all for processing these. Shipment claims due to temperature variances are treated on a case-by-case basis depending on the above-mentioned factors. Verifying temperature prior to loading, maintaining proper temperature in transit, and the ability to provide a reefer download documenting transit conditions are ways for carriers to prevent temperature damage.

WHAT IF THERE’S AN ISSUE AT DELIVERY?

First and foremost, be sure to communicate your transportation status and any issues to your point of contact in real time. If there are any overage, shortage, or damage issues at delivery, the receiver should document it on your bill of lading (BOL). If there is a reported issue and you are unclear about the next steps, contact your insurance agent to report the issue and request direction.

If the product is produce, a USDA inspection may be requested to document the condition of the product.

Whenever a temperature problem is reported, get a reefer download for the trailer used for the shipment to document the temperature conditions for the time the cargo was on your truck.

Your cargo policy will not pay for temperature damage if it is caused by an incorrect reefer setpoint or driver negligence. However, if your refrigerated trailer experiences issues during transit, your cargo insurance may step in to pay a cargo claim related to any temperature damage. However, be prepared to provide supporting documentation. To be proactive in the prevention of any issues caused by your equipment, it’s important to perform regular maintenance according to your cargo insurance requirements and company guidelines.

REFRIGERATED TRUCKING – SHIPPER RED FLAGS TO LOOK FOR

There are a few shipper red flags to look out for before accepting a refrigerated trucking shipment or having your trailer loaded.

Mixed temperature shipments can be a red flag. Sometimes shippers will want to try to ship products together that need vastly different temperature requirements to reduce costs, like fresh and frozen products. These types of shipments are “high risk” and not recommended. Whether a shipper is using a bulkhead or not, to keep your company safe, it’s recommended to avoid shipments that combine frozen, fresh, or dry loads on the same truck.

Now, let’s say you’ve accepted a refrigerated trucking shipment but when you arrive at the shipper you notice one of these things:

- There is food labeled improperly (no USDA logo),

- Spoiled or overripe food products or evidence of spillage, such as juices or blood in the cargo area,

- Food products being shipped with chemicals,

- Evidence of product tampering, like a broken seal or cut tape on boxes.

If you notice any of these things, do not get loaded and immediately contact the Food Safety Inspection Service (FSIS).

EASILY FIND THE TEMP-CONTROLLED SHIPMENTS YOU’RE LOOKING FOR

Now that you’re prepared to handle the complexities of refrigerated trucking, it’s time to find available shipments. Here’s where Trinity’s Carrier Portal is beneficial.

Our online load board allows you to search for available shipments, filtering by equipment, lanes, and more. Many of our available shipments even allow digital freight matching, providing you the opportunity to Quote Now or Book Now, saving you time from calling or emailing in. Additionally, new shipments get directed to our Carrier Portal first, meaning you’ll have access to exclusive Trinity loads before they get posted to the public load boards!

Find my next refrigerated trucking shipment*This article provides information only and should not be construed as advice. It is provided without warranty of any kind.*

It’s no secret that capacity gets tighter and freight rates higher for all shippers during produce season. While the increased freight demand during produce season affects all markets, produce shippers and those with other temperature-controlled products are hit the hardest. Yet, produce shippers that make use of these suggested tips have a better chance of finding capacity and keeping their costs manageable.

TABLE OF CONTENTS

- When is produce season?

- Tips for produce shippers during produce season

- Make your produce easy to work with

- Have your produce truck ready

- Make sure your carriers are vetted

- Find providers that run temp-controlled year-round

- Make use of technology

- Be the produce shipper all the carriers want to work with

- Look into multimodal solutions

- Measure carrier performance

- Consider a 3PL

- It’s not too late!

When is Produce Season?

Produce season is impactful because it puts pressure on freight shipping rates, which affects shippers both inside and outside the produce sector. To simplify, it’s the rise in crop volumes and heightened demand for trucks to transport these crops that impact capacity during this season. These factors lead to an increase in rates, not only for the shippers who need trucks with temperature control but for a majority of shippers across other modes and regions as well.

It’s vital for produce shippers and all others impacted by produce season to know exactly when the spike in shipping begins. Generally, produce season begins sometime around February and runs through early fall. The main regional areas shipping increased produce are Florida and the East Coast, Texas and surrounding states, and California.

Texas Produce Season

The most impactful time is from March through June however, produce can be found year-round coming from over the border out of Mexico. In Arizona and New Mexico, there is a push for produce that usually occurs in October or November.

Florida Produce Season

Starting as early as March, southeastern states like Florida begin to see an uptick in produce shipping. As temperatures warm up, produce season creeps its way up the East Coast with northeastern states’ produce shippers slowing down sometime in early fall.

California Produce Season

Like the East Coast, produce season starts in the southern part of the state around March and creeps its way up to the northern region, ending in early fall.

Tips for Produce Shippers During Produce Season

Produce shippers facing challenges with capacity during produce season isn’t new. But there are things produce shippers can do to make shipping during produce season easier. Here are some tips you should consider to make it through this tough season.

Make Your Produce Easy to Work With

When capacity is tight and rates are high, carriers get to pick and choose what load they want. Make your produce shipments more desirable by making the job easy to complete.

One way to do this is through freight consolidation. Regional consolidation makes freight easier for carriers to work with. Simply put, instead of using a long-haul truck to make many pick-ups or deliveries in a regional area, hire a regional short-haul expert to do that part. They make all the pick-ups and deliver to one spot so that your long-haul carrier can make one easy pick-up and drive onward. Vice versa is that the long-haul carrier would drop off at one regional facility, and then you use the regional carrier to make the many deliveries.

We’ve found that consolidating the freight this way increases the percentage of on-time delivery, increasing your product’s shelf life and customer satisfaction.

Make Sure Your Produce is Truck Ready

This goes hand in hand with making your produce easy to work with. Often, produce vendors will work with many packing house facilities. Make sure you confirm with the produce shipper where the truck needs to pick up. It’s never a great start to a shipment when a driver has to search location after location for their pick-up. Not only does the driver get frustrated, but with it being a time-sensitive shipment, you want to make sure there are no hang-ups, so it’s picked up on time, delivered on time, and your product’s shelf life is as long as possible.

Make Sure Your Carriers are Vetted

This may be your most important piece of advice. Make sure your selected carriers are properly vetted.

What exactly do we mean by that? This means making sure they have reefer breakdown coverage. Or making sure they have the right amount of insurance coverage in case something goes wrong.

For example, cherries are hard to come by and based on market conditions, their value can change. Does your carrier have that coverage should there be a problem?

There’s also FSMA compliance to consider now. Does your carrier know how to work with produce shipments? Do they have that experience? Do they carry pulp thermometers in their trucks and understand that process to ensure they are not loading produce that is too hot or too cold, making sure it will be in good shape when it’s delivered? All these factors are something to keep in mind regardless of market conditions.

When selecting and vetting your carriers, remember there is a big difference between the cheapest truck and the RIGHT truck.

Find Providers that Run Temp-Controlled Year-Round

Finding and building a relationship with providers that execute year-round temperature-controlled freight across the country can give produce shippers a competitive advantage. By having that relationship, you’ll know and better trust your provider because they have the proven experience and understanding of working with your perishable freight. Additionally, having that reliable relationship can help you keep your costs down during peak produce season.

Make Use of Technology

Making use of transportation management (TMS) technology can help during this season. A TMS can help you with routing decisions by matching freight with the best carriers, lanes, rates, and transit service. In addition, it will allow you to optimize the in-house processes of your transportation network – which can help in both times of disruption and easier times. By selecting the best carriers and optimizing your routes, you’ll not only increase your service levels but reduce your risk.