The food and beverage industry is enormous, including subindustries like grocery, restaurants, bars, catering, and more. The industry continues to evolve and adapt despite frequently changing consumer preferences and new, complex challenges. So, what’s currently affecting those in food and beverage? In this blog, we’re going to dive into some of the latest trends in the food and beverage industry.

TRENDS IN THE FOOD AND BEVERAGE INDUSTRY

LABOR SHORTAGES IN FOODSERVICE

ARTIFICIAL INTELLIGENCE & AUTOMATION

CONTINUED COLD CHAIN GROWTH

One of the well-known trends in the food and beverage industry is the continued growth of cold chains. Recently, a Grand View Research study shows that the cold chain market was estimated at USD $330,680 billion in 2023. Furthermore, it’s estimated to grow at a Compound Annual Growth Rate (CAGR) of 14.8 percent from 2024 to 2030.

Recently, there’s been an increased demand for temperature-controlled pharmaceutical logistics (think vaccines and biologics), rising demand for better food quality, including more fresh and frozen foods, and a surging need to reduce food waste. All this is anticipated to drive the market’s growth.

In light of the pandemic, the risks of COVID-19 have made consumers more interested in healthier, less processed foods that will boost their immune systems. However, less processed foods mean more food products that will need temperature control.

Additionally, the frozen food sector looks to be growing. Besides filling home freezers, frozen foods are growing in restaurants. Restaurants are also providing new menu items for the frozen grocery aisle. In an American Frozen Food Institute report, 72 percent of frozen food consumers said they combine frozen and fresh ingredients in their meals.

Comparatively, shippers are also using more cold chain services to preserve the shelf life of their products, even when temperature-controlled transportation isn’t needed.

SUSTAINABILITY

Growing climate issues are making sustainability a common trend in almost all industries. Consumers are taking notice of the sustainable practices of companies. From ethical sourcing, carbon neutrality, to eco-friendly packaging, consumers want the brands they buy from to be sustainable. Additionally, food waste is a major contributor to greenhouse gas emissions globally, contributing to cold chain issues. This makes sustainability one of the top trends in the food and beverage industry.

Consumers Care About Sustainability

One way consumers can show their support for the environment is by choosing to purchase from sustainable brands. Consumers have shown they’re willing to pay more and be loyal to brands that invest in their sustainability efforts. In a survey by YouGov, more than half of consumers said they would be willing to pay up to 10 percent more on sustainable versions of regular packaged food and drinks. In another consumer survey, 78 percent of respondents agree that sustainability is import, with 63 percent stating they have adopted greener buying habits.

Food Waste Prevention

In fact, an S&P Global Ratings report says food waste contributes to 10 percent of emissions and that $1 trillion of food is wasted each year. Similarly, according to the U.S. Environmental Protection Agency (EPA), between 73 to 152 million metric tons of food get wasted each year in the U.S. The most wasted foods are fruits and vegetables, followed by dairy and eggs, with over half of all waste occurring in households and restaurants. In addition, the food processing sector generates 34 million metric tons of food waste per year. And over the past decade, the total U.S. food waste has increased by 12 percent to 14 percent.

To put it differently, the EPA said halving food waste in the U.S. would save 3.2 trillion gallons of water, 640 million pounds of fertilizer, 262 billion kilowatt-hours of energy, and 92 million metric ton equivalents of carbon dioxide. According to the Agency, reducing the waste of meats, cereals, and fresh fruits and vegetables would have the most significant impact.

Due to this growing issue, governments and businesses have been working hard to improve sustainability efforts. In July 2021, the Zero Food Waste Act was introduced to provide grants to businesses that significantly reduce their food waste. Additionally, in November 2021, the Food Donation Improvement Act was introduced to lower food waste by making it easier for companies to donate food instead of throwing it out.

Cold chain improvements have seen growing importance even outside the food and beverage industry. One example is UPS Healthcare developing a system and opening facilities to move medicines safely. Part of their plan includes using reusable cold chain packaging. In addition, Amazon is working on insulation packaging to reduce material waste and replace 735,000 pounds of plastic film, 3.15 million pounds of cotton fiber, and 15 million pounds of non-recyclable plastic.

LABOR SHORTAGES In Foodservice

Labor shortages are common among other industries, making this another relatable trend in the food and beverage industry. As a result, hiring workers in the U.S. is becoming near impossible. According to a recent market report, labor shortages are a top concern for 23 percent of food and beverage businesses. The most difficult positions to fill look to be those in the restaurant and foodservice sectors. It’s not just the hiring of new workers, but retaining them as well.

Workers are leaving the industry due to a combination of burnout, low wages, and a desire for better work-life balance. Because of this, restaurants and foodservice companies have had to reduce their hours or limit their menu, while consumers have felt it in longer wait times and less personalized service. With good customer experiences being paramount to a company’s success, resolving this issue is critical.

For this reason, advanced technology can help remove some redundant tasks and help supplement amidst labor shortages. For example, those in the bar sector are being introduced to self-pour technology, which uses RFID tracking and allows customers to pour their own beverages. .

CONSUMERS ARE MORE COMPLEX

Over the years, consumers and their choices in food and beverage and their preferred shopping habits, have become more complex. Because of this, there is a greater assortment of products than ever, with more items requiring temperature control as consumers move away from processed foods and look for fresher, healthier items. Consequently, the supply chain for grocery continues to evolve as the message from consumers is clear. They want what they want, when they want it, where they want it, and expect businesses to respond to their demands.

Continued Decline of In-Person Shopping

In speaking to consumer shopping preferences, it looks like online grocery shopping, food delivery, and food subscription boxes are here to stay. Many consumers prefer the option to receive food and beverage products at their door. For instance, in recent a study by Drive Research, the use of grocery delivery services in 2024 have risen 56 percent compared to 2022. Additionally, the use of grocery curbside or pickup in 2024 have risen 100 percent compared to 2022, further showing the decline of in-person shopping for food and beverage items.

Cost of Food and Beverage Products a Large Concern

Additionally, inflation and rising costs for everyday items, including food and beverages, have consumers rethinking how much and what brands they buy. For example, a recent study showed 54 percent of respondents stating they’ve reduced how much, and unfortunately, 20 percent said they were skipping meals to save money on food. Data from another survey found that 43 percent of consumers are cooking dishes with less meat to save on grocery costs. Others are choosing to purchase cheaper cuts of meat.

Private label brands continue to see growth as shoppers look to save money whenever possible. In fact, according to Numerator, private label brands hold almost a quarter of sales in the grocery sector. The Private Label Manufacturers Association shows that private label sales saw 2.5 percent growth compared to a decline of 0.8 percent by national brands in 2024.

Taste and Experience is a Must

Consumers want to feel good about what they eat. They want nutritious options that alight with their dietary preferences or health goals. In a survey but the International Food Information Council, 54 percent of consumers consider the healthfulness of food in their purchasing decision. Yet, even with the health benefits, they still want their products to taste good, as Datassential shared 35 percent of them purchase items that sound both delicious and healthy.

Consumers are interested in trends like unprocessed foods, natural ingredients, anti-inflammatory, and hydration. Alcohol-free and non-alcoholic beverages are also a rapidly growing trend, with 2 in 5 consumers abstaining from drinking alcohol.

Consumers generally want a positive experience with food and beverage products. While it’s fuel for the body, it can also serve as a source of community, entertainment, and more. In one study, 53 percent of consumers see experiences as essential to their personal lives, especially among the younger generations since the pandemic. They’re interested in trying to tastes and spices, products that bring a sense of nostalgia, or food and beverages that tie in with a story, as shown by the recent increase in pop-up restaurants and bars.

supply chain Challenges

Since the pandemic, supply chains have been seen more of the limelight. As shown by rising costs faced by consumers, food and beverage supply chains have been challenged by shortages of raw materials, disruptions like strikes or a bridge collapse, and a growing demand by consumers for transparency and speed.

Consumers are also becoming more interested in knowing where the products they buy come from. According to a study by IBM, nearly 70 percent of consumers want to see a brand’s sourcing practices. They want to know how the products they buy were manufactured. They’re looking for companies who show concern to how their manufacturing affects the planet’s life span and how their product is raised or grown. Consumers want to feel like the products they choose to buy will make a difference.

According to a Mckinsey report, food and beverage supply chains see supply chain disruption roughly once every three years. A 2023 risk report shows that supply chain executives are concerned about disruptions from climate change, environmental factors, and geopolitical conflicts. Another risk report shows that 73 percent of companies experienced higher supply chain losses within that past two years. Because of this, building supply chain resiliency is a huge trend for food and beverage companies.

ARTIFICIAL INTELLIGENCE & AUTOMATION

Artificial intelligence (AI) is a buzzword across all industries, but how could it affect food and beverage? One way is through providing clearer insights into shopper preferences, helping companies better market to them to grow brand loyalty. It can help with supply chain optimization, helping businesses better understand consumer demand and optimize production planning and management, reduce overstocking, and minimize waste. Some companies, like Campbell Soup Co., are using AI to help with product development, tracking data and discovering what its customers want next.

According to WifiTalents, 62 percent of food and beverage executives believe AI will have a significant impact on their industry within the next five years. With the uses for AI in the food and beverage industry being so extensive, it will be interesting to see how companies make use of it.

There’s also a lot to be talked about in AI and automation for the customer experience. Companies are looking into AI-driven customer service opportunities and ways to streamline customer interactions. You see a lot of this in the restaurant industry with the use of table side tablets, interactive menus, and mobile ordering and payment. AI is used in mobile apps to personalize menus and promotions based on customer preferences.

Growing Cold Storage Demand

The demand for refrigerated warehouses is continuing to soar to new heights. A report from Skyquest forecasts the U.S. cold storage market to increase with a compound annual growth rate of 13.5 percent through 2031, expecting to reach a value of $118.8 billion.

Temperature-controlled storage is critical to many sectors, from grocery to pharmaceutical companies. The growing demand for cold storage facilities comes the adoption of automation and technology, the popularity of ecommerce and demand for faster delivery, as well as online grocery platforms. There’s also a thriving demand for convenience foods – those that are usually chilled but ready to eat with little to no preparation.

STAY AHEAD OF TRENDS IN THE FOOD & BEVERAGE INDUSTRY

No matter the trends in the food and beverage industry, having a logistics resource, consultant, or expert is one way to stay ahead. Whatever phrase you want to use but ultimately, have support on your side for any complex situation. This is where a third-party logistics company (3PL), such as Trinity Logistics, can come in. We can help you find creative solutions to your logistics challenges.

Now, you’re likely wondering, “why work with Trinity Logistics?” For one, we’ve been serving cold chains for over 45 years! Whether you have a complex challenge or just need help with one shipment, we have the experience and quality carrier relationships to meet your needs.

You can also count on us to stay knowledgeable on what’s going on in your industry so you can stay updated too. We know that even in times of supply chain disruption, your industry doesn’t stop, so neither do we.

And lastly, what makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

If you’re ready to have Trinity Logistics on your side for logistics support and expertise, no matter the industry trends, then let’s get connected.

DISCOVER HOW WORKING WITH TRINITY CAN BENEFIT YOUR COMPANY STAY UP-TO-DATE VIA OUR EMAILWhether your product is coming straight from the farm, is moving between processing, or heading off to the consumer, the dairy industry needs first-rate cold chain solutions to meet their complex supply chains.

Dairy products such as milk, cheese, and butter are household staples and essential in many people’s diets. It’s no surprise that the dairy industry is considered one of the fastest-growing industries, almost doubling in value every five years. To keep up with consumer demand, the dairy industry needs exceptional cold chain solutions to keep their products cold and safe for consumption.

Why the Dairy Industry Needs Cold Chain Solutions

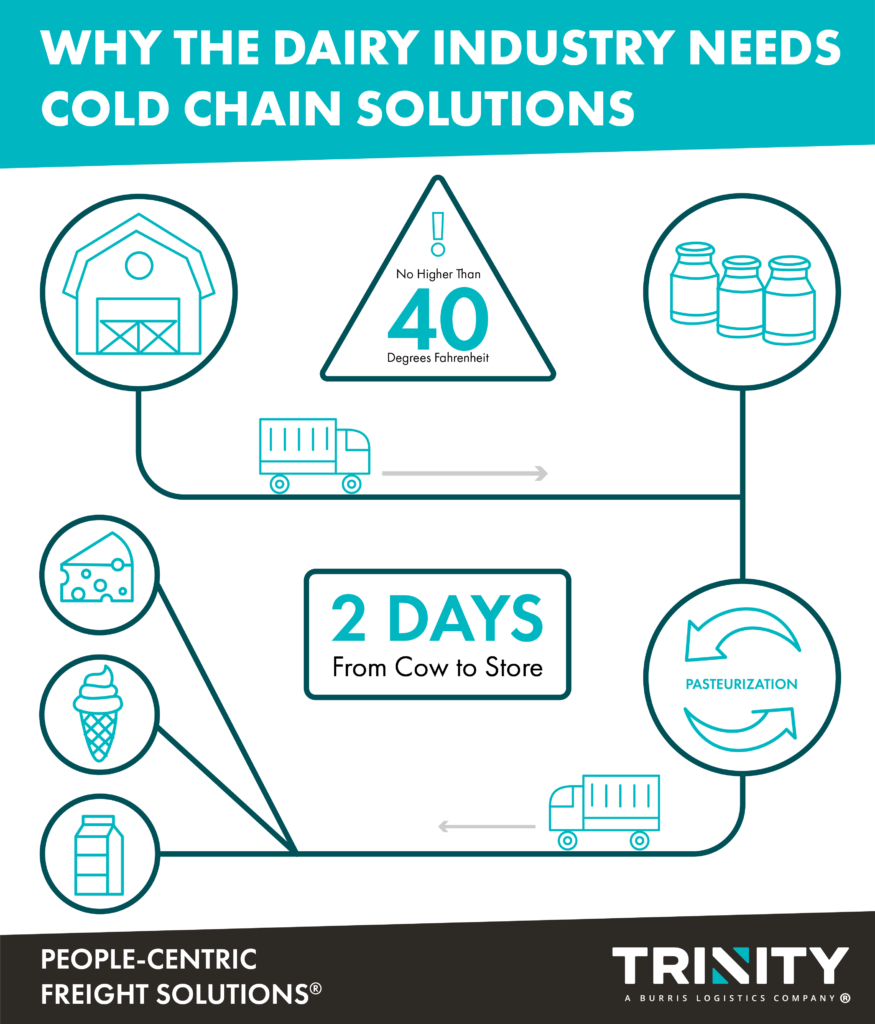

Dairy products all start with milk, and it has a short shelf life. After the cows have been milked, it immediately transports to cooling storage tanks or a chilled trailer. To ensure the milk doesn’t spoil, it must be stored at a temperature no higher than 40 degrees Fahrenheit. It’s then transported to a processing facility, pasteurized, and transported again to consumers.

Usually, this process alone, from cow to store, takes place in about two days. Now, milk is often a starting point for the many diverse dairy products available. Depending on the final product, dairy supply chains have more steps and complexities added.

Common Issues Requiring Cold Chain Solutions

- Temperature Control Needed for Most Dairy Products

- Capacity During Peak Shipping Seasons

- Managing Milk Production with Dairy Demand

- Supply Chain Disruptions

- Dairy is Highly Regulated

- Supply Chain Visibility

- Potential High Value Dairy Products

Temperature Control Needed for Most Dairy Products

Most dairy products need storage at specific temperatures to keep from spoiling. Dairy products need strict attention because of the risk posed to consumers if the cold chain is broken. If not consistently kept cold and free of humidity, bacteria in the dairy can cultivate and dairy products can become harmful.

Capacity During Peak Shipping Seasons

While some dairy products can seek out alternative transportation modes, most find shipping truckload is the most viable option. It’s usually the fastest and cheapest way to move the product because of its weight. It’s also the most viable due to freight security and nature of the product, and because it reduces the risk of claims due to temperature fluctuations or shifting. Since most dairy products need refrigerated trucks for their shipments this can make capacity an issue at times, such as produce season, when reefer capacity can be tighter. It can not only be more difficult to secure a refrigerated truck, but more expensive to do so.

Managing Milk Production with Dairy Demand

Dairy product demand can fluctuate. Yet, even when consumers want fewer dairy products, the cows don’t stop making milk. They can’t be turned on and off like machines, giving the dairy industry a unique balancing act to handle.

Additionally, when it comes to shipping milk, most of that is kept regional given the short shelf life and cost to ship, making dairy demand management even trickier.

Supply Chain Disruptions

As we’ve learned in recent years, there’s always the chance for supply chain disruption to happen. Whether that’s a truck breaking down, a roadblock, or some other instance that would cause delays. With several dairy products (like milk) having a short shelf life, any delays can risk product spoiling and going to waste. Companies in the dairy industry need to be able to act quickly if any disruption happens.

Dairy is Highly Regulated

Dairy products are associated with foodborne illnesses, so it’s no surprise that they’re highly regulated. Right from the start, milk is tested to ensure it’s of safe quality to consume and make other products from. There’s also the Food Safety Modernization Act (FSMA), which places strict requirements on sanitary transportation and the handling of dairy products.

Supply Chain Visibility

Because of so many factors mentioned above, it’s important for dairy companies to have full, real-time visibility of their supply chains. Additionally, many wholesale food distributors and grocery warehouses hold very strict requirements for appointments with very strict product quality inspections to be accepted into their inventory. Without it, dairy companies are at risk of losing products and money due to spoilage, disruptions, delays, or regulation requirements.

Potential High Value Products

Certain dairy products can be high value, like some cheeses for example. This can make the overall value of the load to be costly should there be any potential claims. It’s best for shippers to work with expert providers who have the experience and knowledge to handle any high value dairy products.

Leading Cold Chain Solutions from Trinity Logistics

Shippers in the dairy industry looking for first-rate cold chain solutions can find all they need with Trinity Logistics. We’re a leading third-party logistics (3PL) provider with over 40 years of experience serving logistics solutions to some of the top-known brands in the food and beverage sector.

Standard Operating Procedures for Temperature-Controlled Shipments

One of the reasons we excel in cold chain solutions is our standard operating procedures in place for every temperature-controlled shipment we arrange. This includes:

- Only working with carrier relationships that have downloadable reefer units

- Requiring carriers to pre-cool trailers a minimum of one to two hours before pickup

- Requiring carriers to run their reefer units on continuous

- If necessary, requiring carriers to pulp product before loading

- Requiring carriers to use one of our tracking and tracing partners for real-time shipment visibility

- Only using carriers that have refrigerated trailers that are 2015 or newer

We understand just how critical it is that your product stays at its required temperature. That’s why we work with our trusted, experienced carrier relationships to ensure your product arrives fresh.

Multi-Modal Cold Chain Solutions

No matter what transportation mode you need your product to ship, we have the logistics solutions to support your business now and in the future, including;

- Truckload

- Expedited

- International

- Cross-broder

- Air or ocean shipping

- Drayage

- Less-than-truckload

- Managed Transportation

This enables your business to seamlessly run regardless of what change or growth you experience.

In-Depth Transportation Management

Whether you need a transportation management system (TMS), to fully outsource your logistics, or your own customized managed transportation solution, we can help. We know each business is unique, which is why our system is highly configurable so we can meet your exact needs. Our Trinity experts will work as part of your business, offering in-depth reporting and data to help get you ahead of your competitors.

No Need to Worry About Disruptions

Did I mention that Trinity has been serving cold chains for over 40 years? We’ve seen it all when it comes to supply chain disruptions and delays. We know how to quickly adapt plans to keep your freight moving. While you’ll have your sole Trinity relationship to lean on for updates, we also have a 24/7 Team in case we need any additional support. You can learn to rest easy whenever your shipment is in our care.

Experts in Temp-Controlled Logistics and Dairy

Trinity Logistics has been serving cold chains for 40-plus years, in addition to our parent company, Burris Logistics, that was built on its expertise of handling temperature-controlled commodities.

There’s also Honor Foods, another Burris Logistics company you can lean on for food redistribution if needed. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They specialize in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers.

Our People-Centric Service

What makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

I’D LIKE LEARN MORE ABOUT TRINITY'S COLD CHAIN SOLUTIONS