While many of us are soaking up the last of summer’s sun and fun, food manufacturing supply chains are readying for the upcoming holiday food rush.

Have you ever noticed a lot of our favorite memories are surrounded by food? When we go to celebrate something like a birthday, anniversary, or special achievement, it usually involves food. It’s no surprise then that over the holiday season, nearly 165 million consumers across the U.S. purchase food and beverages to celebrate, according to a study from Cornell. As the holidays soon approach, food consumption surges, with the average American indulging up to an extra 440 calories per serving!

The increased demand and tight holiday deadlines can present challenges for many food and beverage companies with their logistics. This is in addition to already facing a competitive peak shipping season! However, by understanding the dynamics of this unique period of time, shippers can ensure success is ahead of them. First, let’s dive into some fascinating facts and insights about food during the holiday season. Then, we’ll follow that with some essential tips so your company can be prepared for the holiday food rush!

Holiday Food Supply Timeline & Stats

The Holiday Food Surge Begins with Fall

The holiday food rush first begins with the arrival of fall flavors. Pumpkin spice, now seen as the quintessential flavor of fall, has seen a 47 percent increase in sales, as reported by The Guardian, within the past five years. In 2023 alone, Datassential reported 144 new limited-time offers that featured pumpkin on major restaurant menus. From the infamous Pumpkin Spice Lattes (PSLs) to pumpkin soups and ravioli, this flavor dominates the season. But we can’t forget another fall favorite – apple. Food and beverage items with caramel apple were one of the highest-indexing flavors last fall.

Halloween Signals Significant Holiday Food Consumption Increase

Halloween is a major milestone in the holiday food timeline, with 65 percent of consumers participating in the festivities. In fact, of all 172 million that celebrate the spooky season, 95 percent of them purchase candy. Even more staggering is that a quarter of all the candy sold annually comes from Halloween sales. It’s not all about the sweets, though! Pizza is the most popular dinner staple on All Hallow’s Eve, according to Grubhub. There’s also the annual tradition of carving a pumpkin, with Statista reporting roughly 154 million Americans partaking in the activity in 2023.

Dia de Los Muertos Celebrations Begin to Trend

Datassential reports that 10 percent of consumers in the U.S. report celebrating Dia de Los Muertos, or Day of the Dead. This holiday is gaining popularity, which means so are the celebratory foods associated with it! Pan de Muerto is one traditional sweet bread that’s essential to the celebration.

Thanksgiving Continues to Drive Food Supply Chain Demand

Thanksgiving remains the most popular fall holiday, with 83 percent of Americans celebrating the tradition. A whopping 46 million turkeys are consumed each year, according to the U.S. Department of Agriculture. Other top holiday staples include cranberry sauce, stuffing, green bean casserole, mashed potatoes, macaroni and cheese, sweet potatoes, and pumpkin and apple pies. That’s a lot of food to prepare for a meal, so 23 percent of consumers will buy a full, ready-made meal from a restaurant. Another 22 percent will supplement with some food from restaurants for part of their feasts.

Sweets, Candy & Chocolate Build Holiday Food Demand at Christmas & New Year’s

Leading up to Christmas, many enjoy hot cocoa, cookies, and other treats. 1.76 billion candy canes, a holiday staple, are made annually for this joyous time of the year. 70 percent of Americans make Christmas desserts, with frosted sugar cookies being the top ones consumed annually. Don’t forget the eggnog! 122 million pounds of it is poured and drunk each year.

When it comes to Christmas dinner, pork dishes are the most popular globally, but turkey still trumps all for the U.S. Other winter feast staples include roasted or mashed potatoes, roasted carrots, gravy, stuffing, shrimp, and lots of Christmas pudding, cookies, and pies. Sweet tooths rejoice as 83 percent of consumers fill stockings with treats like candy and chocolate.

Christmas and New Year’s are among the busiest holidays for restaurants. Both holidays also see a spike in alcohol consumption, with New Year’s Eve being the second most alcohol-associated holiday behind Mardi Gras. Champagne is the fan favorite for those ringing in the New Year.

Logistics & SHipping Tips for Holiday Food Shipping

The holiday season often brings those in logistics the gift of increased demand and decreased capacity. Like most Americans, truck drivers aim to be home for the holidays, trimming the number of available carriers down. Freight of all kinds can increase during the period, further cutting the number of trucks available. Shippers with more specialized requirements, like temperature control, can find even less capacity. Shippers also have tighter deadlines to meet at this time to make the most of the seasonal business.

Overall, the holiday season can be a time of heightened stress and disruption. Given these unique challenges, it’s crucial for food and beverage shippers to prepare thoroughly to appease customers.

Five Tips for the Best Holiday Food Shipping Logistics Outcomes

Tip 1: Keep Inventory Stocked

Running out of stock during the holiday season is a surefire way to lose customers. Track your inventory levels closely and replenish supplies early to ensure you’re well-stocked. By keeping orders moving consistently, you’ll be able to meet consumer demand and avoid causing any disappointment.

Tip 2: Have Backup Shipping Plans Ready

The chances of any disruptions or delays happening during this season are increased. Having backup shipping plans already prepared is essential to keep your goods moving.

Build relationships with multiple carriers and suppliers, or even a third-party logistics provider (3PL). This way, you’ll have known contacts ready in case you need any help.

Look at alternate modes of transportation and be prepared to quickly shift plans should something happen. Exploring multimodal options can be a great way to diversify risk, add capacity, and protect your freight budget. Having this flexibility available and ready can help you stay on track and your supply chain running smoothly.

Tip 3: Real-Time Visibility is Needed for Success

In today’s supply chains, having access to the visibility you need is crucial. You should either work with a provider that offers it or invest in your own technology, like a Transportation Management System (TMS).

A TMS can be very helpful during the holiday season. It can help you with routing decisions by matching your freight with the best carriers, lanes, and rates. In addition, it will allow you to optimize the in-house processes of your transportation network – which can be helpful during busy and slow seasons. By selecting the best carriers and optimizing your routes, you’ll not only increase your service but reduce your risk.

Using a TMS also gives you data-driven insights to better manage disruptions, reduce downtime, and budget your logistics spend. Data analytics can help you recognize which carriers are most likely to have the capacity, saving you time arranging your shipments.

Tip 4: Communication and Collaboration

Effective communication is key to a successful holiday season. Regularly communicate with all stakeholders, including suppliers, carriers, and customers. Collaborating with your partners during the seasonal planning phase can provide valuable insights and help you identify potential issues before they arise.

Tip 5: Partner with a 3PL

Working with a 3PL can be a game-changer during the holiday season. A 3PL offers access to a larger network of carriers, advanced technology, and expertise in managing complex logistics challenges. With their support, you can ensure your supply chain remains resilient, even in the face of unexpected disruptions.

Treat Yourself with Easier Logistics This Holiday Season

Navigating the holiday food rush can be overwhelming, and that’s why Trinity Logistics is here to be your guide. Like Santa, we’ve been around a while, with 45 years of experience handling logistics during holiday seasons.

Right away, you’ll gain access to our large network of vetted, quality carrier relationships to cover your shipments. But that’s just the start! There are many more benefits to working with Trinity, including:

- Multiple modes of transportation to find the best bang for your buck, support your business growth, or just have a backup plan ready

- Best-in-class technology and customized Managed Transportation solutions available, giving you the exact visibility and data you want

- 24/7/365 support, so no matter what day or time it is, you’ll have the help you need

One benefit that tends to shine above all else? Our exceptional People-Centric service. It’s the trait that makes Trinity different from other 3PLs and keeps our customers returning time and time again. It’s truly our care, compassion, and communication that you’ll notice and appreciate.

Everyone wants to enjoy the holiday season. Why not let Trinity focus on the logistics for your business, so you can go back to doing what you enjoy – helping consumers savor holiday treats and create memorable moments with your product.

Try out Trinity Logistics for Your Next Shipment Learn How Trinity Supports Food & Beverage Shippers Sample More of the Trinity Culture & Service – Join Our Mailing ListAre you a Freight Agent that stumbled across this article?

Freight Agents, Indulge in an Exceptional 3PL PartnerRefrigerated trucking can be a complex, but rewarding job.

You might be transporting anything from fresh produce, frozen food, or important medicines like biologics. But, no matter what it is, the items you’re hauling are vital to many and there’s great pride that comes with that.

Refrigerated trucking is not only more specialized than dry freight hauling but offers more earning potential, and there are certain times of the year during which you can count on higher freight volumes to keep your company profitable.

Whether you’re new to refrigerated trucking or a veteran, it’s important your company knows how to properly transport temperature-controlled products, from pick-up through delivery. At Trinity Logistics, we sometimes see claims on temperature-controlled shipments, and we want to help you avoid any costly mistakes with a few tips specific to refrigerated trucking. So, we’ve crafted this guide to help you prepare for your hauling your next temperature-controlled shipment.

MOTOR CARRIER REFRIGERATED TRUCKING RESPONSIBILITIES

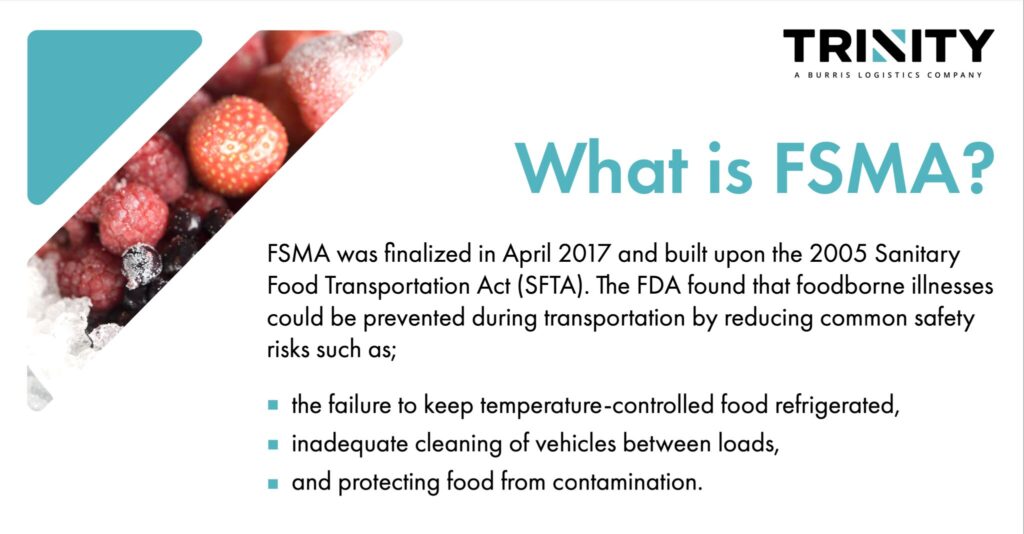

The purpose of the Food and Drug Administration’s (FDA) Food Safety Modernization Act (FSMA) is to prevent foodborne diseases, and FSMA rules contain essential requirements for shippers, loaders, receivers, and carriers like you to follow with refrigerated trucking. FSMA requires those transporting food to follow best practices for sanitary transportation, such as proper personnel training, maintaining shipment records, and following shipper instructions to keep food properly temperature-controlled during transit.

FSMA Responsibilities for Motor Carriers

Keeping Your Equipment Clean and Operable

You must keep your refrigerated trailer clean between loads and make sure it is running efficiently to maintain any required temperatures to keep food safe while transporting.

Your Equipment Must Meet the Shipper’s Needs

Shippers are responsible for communicating any food safety requirements to providers they work with, such as specifying temperature and pre-cooling requirements in writing. It is your responsibility to adhere to those requirements specified by the shipper.

Keeping Records

When it comes to FSMA, verbal confirmations don’t stand. Shippers and providers you work with require records of previous cargo hauled, equipment cleaning, inspection, and temperature records. This includes recording if your reefer fails or containers are compromised, allowing contaminants in, and showing via documentation that you took action to correct the issue. Keeping thorough documentation will help you, in the long run, should you face any potential claims. It’s recommended to keep all records for 12 months, minimum.

Training Employees

Under FSMA, motor carriers must train all drivers and transportation personnel on their role, FSMA rules, the awareness of potential food safety problems like cross-contamination that can occur during transportation, and sanitary transportation practices. It’s also important to keep records of this training and hold refresher training from time to time.

PREPARING FOR REFRIGERATED TRUCKING AND TEMP-CONTROLLED TRANSIT

*This blog content provides suggestions only and is not meant to take the place of your own company procedures.*

Cleaning Your Refrigerated Trailer

1. If the previous receiver cleaned your trailer, request documentation from them to share with the shipper for your upcoming temperature-controlled shipment. It’s important to keep any trailer washout records and receipts to provide to shippers upon request.

2. Open your refrigerated trailer and remove any items that shouldn’t get wet.

3. Sweep out any debris.

4. Prepare a bucket of food-grade detergent and water.

5. Scrub all interior surfaces with a clean cloth and the detergent mix.

6. Use a hose to spray down the inside, including the ceiling and walls. Pay special attention to any cracks and crevices.

7. Keep doors to the trailer open, allowing the inside of the trailer to air dry.

8. If the outside of the truck and your trailer is dirty, wash down the exterior as well.

Pre-trip

1. Review shipping instructions and confirm the cargo is at the required temperature before it is loaded. Refrigerated trailers are meant to maintain temperature, not change it. For fresh produce, verifying temperature usually involves pulping product with a thermometer or probe dial.

2. Run your refrigerated trailer for at least 20 minutes in “high speed cool” mode to remove any residual heat. Pre-cooling may take more than one hour depending on factors such as equipment and ambient temperatures. Therefore, be aware of the temperature requirements in advance to ensure equipment is at the proper temperature before you arrive at the shipper and the loading process starts.

3. Perform an automatic pre-trip test to confirm that your refrigerated trailer is running properly and confirm that it passes the test. Keep a record of this. If your auto pre-trip test fails, refer to your company’s prescribed procedures or contact your maintenance provider for repair.

4. It’s time to set your refrigerated trailer to the required temperature specified by the shipper. Verify the set temperature after adjusting it to its requirement to confirm it is set correctly. Next, confirm that the unit is set to the correct date and time. If this is not done and the shipper requests a reefer download after delivery, the data will be inaccurate. Some drivers will take a picture of the reefer unit dashboard to document settings before they leave the shipper.

5. Confirm that you have the correct mode of operation selected on the reefer unit prior to loading. Again, refer to your shipment instructions for this. Often, the shipper will require perishables to be hauled in continuous mode as opposed to cycle sentry or stop-start cycle.

6. Allow your refrigerated unit adequate time to pre-cool before loading.

7. Document all pre-trip cleaning, inspecting, and pre-cooling to share with the shipper upon request.

Loading

1. Ensure you witness the loading process, visually confirming product temperature, count, and quality match your shipment tender. If a carrier cannot verify loading conditions or discrepancies exist, the carrier notates the issue on the bill of lading and request the shipper to sign this.

2. Carriers are responsible for the final blocking and bracing of product, so make sure items are not over-stacked or loaded in a way that impedes airflow or circulation. As a carrier, if you are not comfortable with the load condition, you have the right to refuse the shipment.

3. Once loaded and final blocking and bracing are completed, immediately close the doors to maintain temperature. Once again, verify that the correct cycle and temperature are set. If a trailer seal is required, its presence should be documented on the bill of lading by the shipper.

During Transit

1. Make use of the strip curtains as this helps keep temperature-controlled air in and any outside air out.

2. Limit the number of door openings throughout transit to keep temperature-controlled air in and outside air out. Only allow doors to be opened by verified shippers or receivers.

3. Keeping proper airflow is critical. Even with adequate running equipment, poor air distribution can cause spoilage. Verify all sides of the cargo have proper airflow before your trip and any time you make a stop.

PULPING FOR REFRIGERATED PRODUCE SHIPMENTS

Pulping is an essential task when hauling produce with your refrigerated trucking. Pulping is the act of taking the product’s temperature before and upon delivering the shipment.

How to Pulp Produce

For produce that is unbagged, one must insert a pulp thermometer into a piece of produce, inserting for three to four minutes to get the most accurate reading.

If the produce is bagged, like salad mixes, fold the bag in half and place the probe between the two sides, with the produce as close to the thermometer as possible.

Why Pulping is Important

Before loading, it is the shipper’s responsibility to pulp the product, and should be done in the presence of the driver. However, it is the carrier’s responsibility to confirm the proper temperature of the product before allowing it to be loaded on the truck, so there may be the case you need to pulp the product.

Pulping temperatures should be recorded on the shipment’s bill of lading and signed by both the shipper and driver. This can help protect both the shipper and motor carrier from claims if the product arrives at its destination off temperature.

Throughout transit, it is the carrier’s responsibility to monitor the refrigerated trailer temperature, usually with some sort of sensor technology providing real-time information, or with older refrigerated trailers, a temperature download that is available upon delivery.

Upon delivery, it is the receiver’s responsibility to pulp the product for a temperature read and to determine if the shipment will be accepted.

Under FSMA, be prepared to provide a record of temperatures in transit via reefer download. Failure of a carrier to provide a record of unit temperatures in transit will prevent a carrier from disputing temperature deviations should there be a claim.

TEMP VARIANCES – HOW MUCH IS TOO MUCH?

One thing you may be asking with your refrigerated trucking is, how much is too much when it comes to temperature variances? Well, that can depend on several factors.

One factor is the type of product. For example, there are some perishable products that are very sensitive to temperature variances, where even a two-degree difference could reduce the shelf life by 50 percent.

Another cause could be the location where the temperature was taken in the trailer or the recording device’s accuracy. Or if a shipment has multiple stops versus one that goes right to the destination.

Temperature variances are usually expected, so it’s important to determine when a variation is tolerable versus when it places the product at risk for spoilage.

It’s also important to note the amount of time the product has been off temperature. For example, frozen goods might be subjected to some temperature variance without much effect on the shipment, whereas refrigerated goods often spoil at a quicker rate.

When it comes to claims due to temperature variances, there simply is no one-size-fits-all for processing these. Shipment claims due to temperature variances are treated on a case-by-case basis depending on the above-mentioned factors. Verifying temperature prior to loading, maintaining proper temperature in transit, and the ability to provide a reefer download documenting transit conditions are ways for carriers to prevent temperature damage.

WHAT IF THERE’S AN ISSUE AT DELIVERY?

First and foremost, be sure to communicate your transportation status and any issues to your point of contact in real time. If there are any overage, shortage, or damage issues at delivery, the receiver should document it on your bill of lading (BOL). If there is a reported issue and you are unclear about the next steps, contact your insurance agent to report the issue and request direction.

If the product is produce, a USDA inspection may be requested to document the condition of the product.

Whenever a temperature problem is reported, get a reefer download for the trailer used for the shipment to document the temperature conditions for the time the cargo was on your truck.

Your cargo policy will not pay for temperature damage if it is caused by an incorrect reefer setpoint or driver negligence. However, if your refrigerated trailer experiences issues during transit, your cargo insurance may step in to pay a cargo claim related to any temperature damage. However, be prepared to provide supporting documentation. To be proactive in the prevention of any issues caused by your equipment, it’s important to perform regular maintenance according to your cargo insurance requirements and company guidelines.

REFRIGERATED TRUCKING – SHIPPER RED FLAGS TO LOOK FOR

There are a few shipper red flags to look out for before accepting a refrigerated trucking shipment or having your trailer loaded.

Mixed temperature shipments can be a red flag. Sometimes shippers will want to try to ship products together that need vastly different temperature requirements to reduce costs, like fresh and frozen products. These types of shipments are “high risk” and not recommended. Whether a shipper is using a bulkhead or not, to keep your company safe, it’s recommended to avoid shipments that combine frozen, fresh, or dry loads on the same truck.

Now, let’s say you’ve accepted a refrigerated trucking shipment but when you arrive at the shipper you notice one of these things:

- There is food labeled improperly (no USDA logo),

- Spoiled or overripe food products or evidence of spillage, such as juices or blood in the cargo area,

- Food products being shipped with chemicals,

- Evidence of product tampering, like a broken seal or cut tape on boxes.

If you notice any of these things, do not get loaded and immediately contact the Food Safety Inspection Service (FSIS).

EASILY FIND THE TEMP-CONTROLLED SHIPMENTS YOU’RE LOOKING FOR

Now that you’re prepared to handle the complexities of refrigerated trucking, it’s time to find available shipments. Here’s where Trinity’s Carrier Portal is beneficial.

Our online load board allows you to search for available shipments, filtering by equipment, lanes, and more. Many of our available shipments even allow digital freight matching, providing you the opportunity to Quote Now or Book Now, saving you time from calling or emailing in. Additionally, new shipments get directed to our Carrier Portal first, meaning you’ll have access to exclusive Trinity loads before they get posted to the public load boards!

Find my next refrigerated trucking shipment*This article provides information only and should not be construed as advice. It is provided without warranty of any kind.*

Trinity Logistics, a Burris Logistics company, is proud to share that Food Logistics has named the company as a recipient of the 2022 Top 3PL & Cold Storage Providers Award.

Food Logistics is the only publication exclusively dedicated to covering the movement of products and information through the cold food and beverage supply chain. The Top 3PL & Cold Storage Providers list recognizes leading third-party logistics and cold storage providers in the food and beverage industry. Companies on the list play a pivotal role in keeping the food and beverage industry’s products stored, transported, and stocked while maintaining the product’s quality.

“These past 18 months have been so challenging for U.S. supply chains. It’s the continuous bottlenecks that require fleets to re-tool and pivot accordingly. But it’s the drivers, the fleet, the warehouses, and software/technologies that really keep today’s supply chains in line,” says Marina Mayer, Editor-in-Chief of Food Logistics and Supply & Demand Chain Executive. “These 3PLs and cold storage providers have collaborated on all facets of their operations to achieve full visibility, complete forecasting, end-to-end leverage, and the ultimate in sustainability. Now is the time to honor and celebrate those companies making magic happen behind the frontlines.”

Trinity works with thousands of shippers in the food and beverage industry, making the company well-versed in its requirements and regulations. Equipped with state of industry technology and with Burris Logistics, one of the top cold storage providers in North America, as its parent company, Trinity provides exceptional service to those in the cold chain.

“We are honored to be named a Top 3PL & Cold Storage Provider, and very fortunate to be part of the Burris Logistics family,” said Mark Peterson, SVP of Sales at Trinity Logistics. “Having a parent company with 90+ years of cold storage & food distribution experience gives us a distinct advantage. From the 3PL viewpoint, our focus is on optimizing the efficiency of our distribution network. The pillars of that effort are gathering and analyzing the right data; clear and consistent communication with our partners; and the highly educated and motivated team of professionals at Trinity Logistics.”

The full list of 2022’s Top 3PL & Cold Storage Providers will appear in Food Logistics’ August issues, as well as online at www.FoodLogistics.com.

Learn how Trinity supports food and beverage companies.About Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 40 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized on Transport Topics’ Top 100 Freight Brokerage List, a Top 3PL and Cold Storage Provider by Food Logistics, and a Top Company for Women to Work for in Transportation by Women in Trucking.

With cold chain logistics, every product that you deal with has very specific temperature requirements that you need to adhere to. These products are ending up on tables across the entire country, so you want to make your product arrives precisely the way it needs to be so it’s safe for human consumption. Because of this, cold chain logistics can be challenging to manage, and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. It would undoubtedly be helpful to find one provider that could offer you end-to-end cold chain management, from production to delivery. And that’s what we’re here to talk about today. Burris Logistics and Trinity Logistics working together could be the solutions you’ve been looking for to simplify your cold chain management. Keep reading to find out how we work better together to serve your complete cold chain.

BURRIS LOGISTICS CAPABILITIES

Let’s start with Burris Logistics. What do they offer that can enable cold chain shippers and their businesses to thrive in the face of its complexities?

Quick Background

Burris Logistics has been around for 96 years. The company started as a produce hauler from southern Delmarva to Philadelphia. They quickly grew and expanded into the frozen food business and found their purpose as a driven food logistics provider. Today, they own 14 cold storage sites up and down the east coast and out into Midwest. Burris Logistics currently has a family of brands including Burris PRW Plus, Honor Foods, and Trinity Logistics.

Burris Logistics offers you logistics technology solutions that never sleep. With a Technology Team of over 100 Team Members, they work around the clock to provide you with technology resources designed to meet your specific needs.

From a Burris asset standpoint, they’re able to track all their trailers with ELD and reefer tracking, with the ability to ping the tractor and trailers to see where each of their assets are in real time. In addition, they have access to technology that can start and stop the units, reset them, or check temps on them, no matter the distance. With the complexities of cold chain transit and the current driver shortage, Burris works hard to put in place any technology that can make a driver’s job easier. They want to cut any obstacles drivers may face on the road while having any data be transparent to help both them and ultimately, any customers.

Burris also has technology for their cold storage warehouses. They focus on providing their customers with freshness, clarity, and visibility. They offer real-time monitoring and any differentiation from setpoints gets recorded. They make sure to get real-time data to those who need it should meaningful decisions need action, and have secondary and tertiary backups available.

Some of their other logistics technology offered are:

· Warehouse management system software

· Enterprise resource management

· Produce inspection tool

· External integrations

· Supply chain portal

· Demand planning

· Order status

· Delivery status

Burris Logistics works with you to create the best possible warehousing and distribution solutions. They’ll support you with a network of strategically located warehouses, 96 years of expertise, and a solution customized for your unique needs.

In a reflection of national trends, the newest and fastest-growing business line within Burris Logistics is their direct-to-consumer to support those in the cold chain e-commerce space. Through current resources and expertise in temperature-controlled logistics, Burris can deliver a premier frozen fulfillment network with cutting-edge technology, thought leadership, and warehouses across the country. Burris’s knowledge of shipping supplies, coolant technology, and two-day parcel shipping capability ensures quality is delivered with every package.

Facility Design is the process of considering new construction via greenfield facility sites or the re-purposing of an existing operation. Many companies are facing changing business needs, including the need for multi-channel execution. This makes the ability to scale up and scale down with various capabilities an essential part of planning. With partners who increase their dependency on Burris Logistics, they’ve been able to scale their operations to accommodate their programs with new locations, modifications to existing assets, and technology to keep the supply chain efficient.

Your customers desire the right products, in place, at the right time. Honor Foods, a Burris Logistics company understands how important it is to have on-menu and on-shelf products available while also minimizing food waste. They can help you plan inbound and outbound freight, using logistics technology and their warehouses to maintain food quality and safety.

With one of their other brands, Honor Foods, Burris offers Private Label In-house brands that have developed into trusted names amongst food service operators. These products undergo scrutinous selection and quality assurance knowing that our restaurant partners only accept the best. Your customers want what is trending, and Burris can help you meet this demand. Their brands come sourced from trusted shippers and can be a noticeable cost saving for you.

Burris Logistics understands that products need different environments, which is why their facilities can provide different temperatures and humidity, depending on your product. Newer warehouses are purposefully being built with ambient/dry storage space to accommodate increased partner needs. Additionally, their warehouses and distribution centers are in strategic locations near major transportation hubs and ports, making it easy to get your freight on the move quickly.

TRINITY LOGISTICS CAPABILITIES

Quick Background

Trinity Logistics has been around for over 40 years. The company was started by the Banning family in Cambridge, Maryland. Throughout the years, the company grew and expanded as a non-asset-based third-party logistics company (3PL) and was acquired by Burris in 2019. The two companies saw similarities in company culture and future goals, deciding to unite for greater opportunities and offer more supply chain solutions for our customers.

Burris + Trinity = Better TogetherURRIS

What’s great for Trinity being part of the Burris Logistics family of brands is being able to offer more help to Burris customers. Trinity’s support helps Burris better assist some of the existing freight business they have for customers either coming back into their buildings or going to other places.

The addition of Trinity also offers Burris customers a wider variety of options in modes and technology, or even help outside of the cold chain. Trinity is very experienced in heavy haul moves or more complicated hazardous moves for the chemical industry. So, no matter the size of your company or freight, we have a solution for you. But, we’re here to talk about the cold chain, so let’s focus on refrigerated and frozen freight.

While it’s not always hard to find a refrigerated carrier, you do want to be selective. There are a lot of carriers out there, but Trinity has a robust vetting process in place. We make sure carriers hauling your freight have the right amount of insurance, requirements, and experience. In addition, we make sure these drivers are representing Burris and Trinity the way we need to and that our customers are getting their products delivered safely.

You might ask, how do we guarantee safety with our carrier network? Well, these carriers mean as much to us as our shipper customers do, so we build just as strong carrier relationships. We offer our carriers many different kinds of technologies for location tracking, temperature tracking, and so on. We make sure to continue to evolve our technology solutions to keep the shipping process easy and safe for both carriers and customers. Additionally, we have our communication. Our communication is one of our strongest assets to ensure both parties have their needs and solutions met. Our bottom line is bringing value and if we can do that, we’ll be successful.

We offer and use several different technologies like Macropoint or Fourkites, so we can ping shipments and know exactly where they are and what the temperature of the product is, giving our customers instant access to look at their freight. That’s just one piece of the technology puzzle.

Even with the technology available, we never lose contact with our customers. We strive to stay very People-Centric. Our technology only helps make it easier for our customers to view information, especially with our Customer Portal, giving them the ability to trace loads without having to reach out. It gives them access to see updates at any time of day and offers backend access to their invoices to answer billing questions, make payments online, or provide them with a breakdown of what each load costs, lumper fees, accessorials, or pallet exchanges. Our Customer Portal allows you to manage that piece of business on your own time and at your own speed. We’ll always be available, but the Portal and any of our technologies are there to bring you even more value and efficiency.

Current logistics technology available:

· Carrier Portal

· My Carrier Packet

· TriumphPay

· FourKites

· Trucker Tools

· MacroPoint

· Customer Portal

· Customized Transportation Management Solutions

· Banyan LTL

· DAT Book Now

· Trucker Tools Book It Now

WAREHOUSING

We know that one size does not fit all when it comes to warehousing. That’s why we have warehouse providers with locations across the nation to allow you to scale your business at your own pace, plus our cold storage solutions with Burris Logistics. Our growing network supports reliable service and premier dry, refrigerated, or frozen solutions so you can focus on what you do best.

TRUCKLOAD

Our truckload service provides you with the means to get your freight moving quickly. Truckload is faster than traditional LTL or intermodal shipments which means your shipments can arrive on time and on schedule.

LESS-THAN-TRUCKLOAD (LTL)

Our LTL service provides you with the means to get your freight hauled through a range of options. By leveraging our volume and extensive network of LTL carriers, we can provide you with lower rates for LTL shipments consisting of 1-10 pallets of either dry or temperature-controlled products.

INTERMODAL

You can add value to your supply chain by using this cost and environmentally-friendly shipping option. By shipping intermodal, you’ll reduce your carbon footprint and have reliable and consistent capacity when over-the-road capacity can be tight.

EXPEDITED

Sometimes your freight is time-sensitive or needs less handling. When this happens, we can arrange over-the-road or air-expedited shipping. We’ll make sure your freight arrives on time and without stopping at terminals in between.

DRAYAGE

Your freight can be delivered from the port or rail right to your door, or from your door to the port or rail. Either way, we’ll save you money in the process. From servicing imports and exports, returning empty or full containers, helping you avoid unnecessary fees, long drayage options, or more, our Team is ready to help.

INTERNATIONAL

Arranging international shipments can be tricky and requires a lot of communication. If you are looking for help with arranging your Full Container Load, Less Than Container Load, door-to-door, or port-to-port services, we can help. We’ll be your intermediary with freight forwarders to arrange your air and ocean freight international shipments.

MANAGED SERVICES

In this service, we combine our experienced account management and best-in-class transportation management technology to deliver you a customized solution that helps your company achieve its unique supply chain goals.

HOW WE CAN SERVE YOUR COLD CHAIN BETTER TOGETHER

Experience in Cold Chain

For many reasons, Burris Logistics and Trinity work well together for cold chain shippers. First off is our combined years of experience. There are certain things in cold chain you can only learn from the experience of working with temperature-controlled shipments. For example, things like picking and loading fresh produce, understanding what those temperatures are and what they need to be for storage and transit, and keeping track of those temperatures. Or understanding how to move ice cream from the West Coast and knowing that you can’t go over the mountains; that you must travel around them so as not to cause shrinkage. By having years of experience and understanding of those complex situations and small details that make or break a cold chain shipment, you can trust your temperature-controlled freight is handled safely and correctly with Burris and Trinity.

Technology

Between both Burris and Trinity, we have incredible logistics technology available, but what differentiates us from others is that we keep in mind that logistics is still a “people” business. Technology will always be a tool for our Teams to use and bring logistics solutions to other people who need them. Therefore, we try to stay away from technology just for technology’s sake and make sure what we use and offer is always a valuable solution.

Communication

Because of our years of experience, we are well-versed and experienced in many different situations. We know when and how to pivot quickly and keep business moving forward. When issues arise, we work until they are resolved and keep open communication every step of the way. Having a solid relationship with experts like Burris and Trinity will prove to be your largest asset no matter what supply chain bottlenecks you may face

Flexible, Customized Solutions

Because our two businesses offer many options while keeping business People-Centric, it means you can find a solution that’s customized for your growing business and needs and your solution can be flexible. We know the cold chain and solutions aren’t static, they are ever-changing, so you need a provider that can keep up. By working with Burris and Trinity, you’ll never have to worry about changing up your logistics plan as we’re readily equipped to accommodate any changes you may need. In addition, we can help you stay flexible as one sole provider instead of working with several.

Visibility and End-to-End Cold Chain Management

As the cold chain sector continues to grow, there’s been a growing demand for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the logistics of their temperature-controlled freight. Working with Burris and Trinity can not only give you a wide range of technology to gain visibility and provide you with all the logistics services you may need, thus making your cold chain efficient and transparent. We’ll provide you with dedicated, knowledgeable experts, increased productivity and workflows, and reduced complexity by working with Burris Logistics and their family of brands instead of several different providers.

HAVE YOUR COLD CHAIN LOGISTICS TAKEN CARE OF, END-TO-END

Between Trinity and Burris, we have a substantial Team with a lot of experience in cold chain and knowledge about its potential pitfalls. As a result, we’ve created processes and different services so that we get it right the first time, every time we handle a cold chain shipment.

You can find value in our combined companies’ sizes and services offered. Cold chain logistics can be complicated and trying to do it all alone can be frustrating. That’s why we’re here to help you simplify it. You can count on Burris Logistics and Trinity to serve and support your cold chain all the way from production to delivery, and every step between.

FIND YOUR END-TO-END SOLUTION WITH BURRIS LOGISTICS GET A SHIPPING QUOTE FROM TRINITY LOGISTICSIt’s produce season. That time of the year when produce shipments are at their peak and so are produce shipment rejections. According to DAT, up to 12 percent of shipments are rejected or delayed. Produce shipments are most often rejected because of the complexities of fresh food logistics. Because of their perishability, they are more likely to experience damage in transit due to improper handling, temperature variances, or delays.

A produce shipment rejection can cause lost time, added fuel and shipping costs, wasted product, and sometimes even a strained relationship with your customer. In addition, these rejections can cause a domino effect of added issues, costs, paperwork, and make everyone’s day longer than it needs to be. Yet, with attention to detail, planning, and effective communication, you can prevent produce shipment rejections and manage your costs. Here’s some advice on preventing shipment refusal during produce season.

| ARTICLE CONTENTS |

| REASONS TO REJECT PRODUCE |

| WHAT TO DO WHEN PRODUCE IS REFUSED |

| PRODUCE SHIPMENT REJECTION PREVENTION |

| HAVING HELP WITH PRODUCE SEASON |

REASONS TO REJECT PRODUCE

With fresh produce being on average, 90 percent water, it’s a volatile product to ship. It can develop issues at any stage, during growth, harvest, storage, packing, or shipping. This makes the logistics of shipping produce that much more complicated. As a result, there can be many more reasons for produce shipment rejections to happen. So, what are some reasons for a produce shipment rejection?

Paperwork Errors/Wrong Product

The Bill of Lading (BOL) must match the shipment delivered. When the receiver checks the BOL to verify the purchase order (PO) number, skid, case count, and weight of the freight delivered, and it doesn’t line up, then the shipment may be rejected. This could happen for several reasons. For example, the product could be what they asked for but the wrong amount, or the product could be completely different. However, any discrepancy between what they ordered and what arrived will mean a rejected shipment.

*Important to note: A produce shipment should not be rejected if there is less than 50 percent of the product short or damaged.*

Pallet Configuration

Some customers require that the product arrives according to their specific guidelines for packaging. If their requested guidelines are not followed, or anything shifted, fell, or ripped while in transit, then they may refuse the shipment.

Improper Temperature Range

Maintaining integrity and freshness is serious when it comes to a perishable product like produce. If your produce shipment falls out of its needed temperature range, even by one degree, the receiver may reject your shipment. Unlike other types of freight, the chance for spoilage with produce is too high, so a receiver won’t often take on the liability with any temperature variances.

Delivered Late

Often, retail and grocery distributing centers operate on tight schedules, so a delay could impact their other appointments. Unfortunately, this means they rarely make exceptions when it comes to late shipments and your produce will be rejected.

Equipment Issues

The trailer could have been unable to keep the temperature in the range needed for your produce shipment or perhaps the trailer was not washed thoroughly before loading. Maybe the carrier showed up with a van and you needed a refrigerated trailer. There are several issues in which the trailer your shipment is delivered in can have the receiver refusing your product.

Reasonable Time to Reject

One important thing to know about produce shipment rejections is that there is a reasonable time for the receiver to reject the shipment. When shipping by truck, the receiver must not exceed eight hours to inspect and reject. When shipping by rail, the receiver must not exceed 24 hours to inspect and reject.

AS A SHIPPER, WHAT TO DO WHEN PRODUCE IS REFUSED

Many issues associated with rejected produce shipments can often be resolved quickly with extra communication and planning.

You’ll first need to figure out why the receiver rejected your produce shipment, so start with asking your receiver that. Ask for pictures showing any damage and a copy of the BOL. Next, ask for the report by the USDA inspector or another qualified individual, as it’s required for the receiver to have the shipment inspected, note any issues, and detail what the cause of damage was. Additionally, ask your carrier for a reefer unit download or a temperature recorder download so you can see if there were any temperature fluctuations during transit.

If you’re considering filing a cargo claim, you must know that cargo claims for produce will only be paid for proven physical damage.

Now, if a produce shipment is rejected and not unloaded, there are a couple of options for you to try to recoup the loss. You can reroute the shipment to a different facility that will accept it, donate the shipment, or have the carrier dispose of it. Regardless of which option you choose, you are responsible for handling where the shipment will go next.

What are any secondary markets the produce can go to if messed up? What’s the disposition? You’ll be the best resource for the area’s market. Be familiar with your shipping lanes and the secondary markets within your location to best salvage the produce if refused.

Secondary Facility

As long as your produce is still safe for consumption and solely rejected for the way it looks, you might be able to sell the shipment to a secondary facility. For example, a sauce maker or a french fry company might be willing to buy a shipment of tomatoes or potatoes that are still edible but visually unappealing.

Donation

It can be possible to reuse a rejected produce shipment through local donation, though there are still high standards for products if donated. Any food and beverage products donated must be safe enough to consume. Donations can be optimal as your produce can still be used, and you can receive tax credits for your donation.

Disposal

If your produce shipment is rejected due to a temperature violation or clear spoilage during transit, disposal may be your solution. When your produce is determined to be unsalvageable, it may be best to dispose of it. Although the other two options are better for the environment and your bottom line, it’s sometimes a necessary evil to dispose of the product. While recycling and reusing are ideal, they may not be workable due to compliance and safety standards. One of the benefits of disposal is that scheduling disposals are often quicker than scheduling to another facility.

Maintaining a Good Customer Relationship

Shipment rejections can stress even the best relationships. It’s best to keep in mind that you are in it for the long haul and produce shipment rejections that can happen even to the best of shippers due to its complexity.

It’s best to acknowledge the rejection, replace the product as soon as possible, and find the source of the issue to help reduce the chance of another produce rejection happening anytime soon. Take ownership of the problem and control of your shipment so you can manage your money from the salvage. Taking control over the disposition will help you maximize your return, reduce claimed damages, and reduce your risk of customer relationship loss.

While these are all great solutions for handling produce shipment rejections, it’s ideal to prevent them in the first place. For companies looking to focus on their bottom line, it’s important to know all necessary prevention measures for produce shipment rejections and plan for when they do happen.

PRODUCE SHIPMENT REJECTION PREVENTION

Paperwork and Communication

The first step to preventing produce shipment rejections is to have your paperwork and communication in order. Your agreement must be clear on the condition of the produce your buyer will receive. Being able to present your buyer with evidence that your produce is safe and of the quality you stated it’s in before transit will prevent most cases of rejection.

Communication with your buyer and your logistics team on how your produce is being handled before loading, during loading, and during transit must be done effectively and properly. This is especially crucial because of the Food Safety Modernization Act (FSMA). Be sure to provide photos, diagrams, or any other examples of proper pallet configuration to your warehouse and trucking partners. This kind of communication will help them pack and load your freight correctly from the start.

Carrier Selection

Produce shipments, especially during produce season, often pay a lot. This means you’ll have a lot of carriers bidding to haul for you. Therefore, quality carrier selection and additional insurance requirements, like reefer breakdown, are crucial aspects to prevent rejected produce shipments.

Make sure you confirm with your motor carrier that they are both authorized and experienced to haul your produce.

Additionally, make sure they understand all your shipments requirements, including FSMA. For example, do they need washout receipts? Do they have a good quality truck, updated trailer, or a quality reefer? Do they have or need temperature-monitoring devices or other technology to ensure the temperature is controlled and the cold chain uninterrupted? Can they pull a reefer download if required?

By finding a quality carrier and building a strong relationship with them, you’ll gain a dependable carrier to use regularly. This can help you reduce any transportation-related issues that could later result in a shipment rejection.

Loading

Don’t Overstack

When it comes to produce season, the number one cause of claims that we see comes from over-stacking your boxes or bins of produce when loading them onto the trailer. An example of this would be triple or quadruple stacking your boxes when they need to be double-stacked. While this depends on each shipping location, not all may be aware that each box has a maximum capacity it can withstand and not damage your produce. You need to know the weight-bearing amount of your boxes so you can place no more than that. When you over-stack, it’s will increase the risk of your produce getting squished and damaged. Certain produce can be very fragile, like berries, tomatoes, asparagus, or bananas. They tend to bruise easily, so single-stacking boxes are even more ideal for them.

No Hot Loads

Industry experts say that as much as 32 percent of all cargo is loaded at the wrong temperature.

This is often due to poor loading practices, like loading from a hot field. When it comes to produce, loading from a hot field is a HUGE NO. This causes the driver to start traveling with your produce at the wrong temperature, which puts compliance and financial pressure on carriers, as the load is at a high risk of spoiling. Your produce should be safely brought down to its required transit temperature before loading to prevent any spoilage.

Have the Proper Equipment

While this may seem silly, it still needs to be said: If a motor carrier shows up with a dry van and your produce requires a refrigerated trailer, DO NOT LOAD. While losing some time or causing a bit of a delay is not ideal, it’s better to have the proper trailer needed to keep your risk of shipment rejection from spoilage or damage low. Additionally, make sure your carrier’s refrigerated temperature monitoring system has the proper temperature, date, and time set. If there is a rejection due to temperature variance and the date and time are wrong, you’ll take the blame due to current regulations.

When it comes to your motor carrier and loading, it’s also ideal to allow them to inspect and pulp your product before loading. They have the right to do so, and the opportunity can give your carrier the confidence to haul your product safely. It also helps build a strong and loyal relationship, while helping you gain more insight that your product is okay before it’s in transit.

Keep Clean of Debris

Another way to help prevent produce rejections is to have a shipping platform that can be cleaned without leaving any splinters or debris in vehicles. Food-grade plastic pallets are ideal for solving many hygiene issues while helping reduce product damage during transport. Unlike wooden pallets, they don’t splinter or leave behind debris, and their nonabsorbent surface can be easily cleaned and dried.

Transit and Delivery

As mentioned during loading, make sure you have a way to track temperatures throughout the shipment and be able to receive notifications in real time. By getting early warning signs of issues, temperature variations can be quickly detected and dealt with right away instead of learning about them later at delivery.

Additionally, make sure you have a qualified inspector on-site at delivery. This will help should the receiver decide to reject your produce shipment to determine if your product is salvageable for you to recoup costs.

Before transit, it’s best that you set up the potential for rework facilities to accept your produce should the receiver refuse it. Talk to nearby receiving facilities to establish accounts, processes, and pricing ahead of time. This way, if there has been some visual damage or slight shifting, it can quickly reroute to the other location and be reworked, being proactive rather than reactive. This is especially important when it comes to produce since time is of the essence.

HAVING HELP

Produce shipment rejections can be complex and confusing at times. This is where working with a third-party logistics company (3PL), like Trinity, can come in handy. We have Teams to help you with the prevention of rejections as well as when one does happen.

Carrier Compliance

Our Carrier Compliance Team is here to vet our carrier network and make sure they have what you need to get your shipment delivered safely. Not only do we have a rigorous vetting process, but depending on your shipment requirements, we’ll make checks for extra insurance needs like reefer breakdown and make sure they are FSMA compliant.

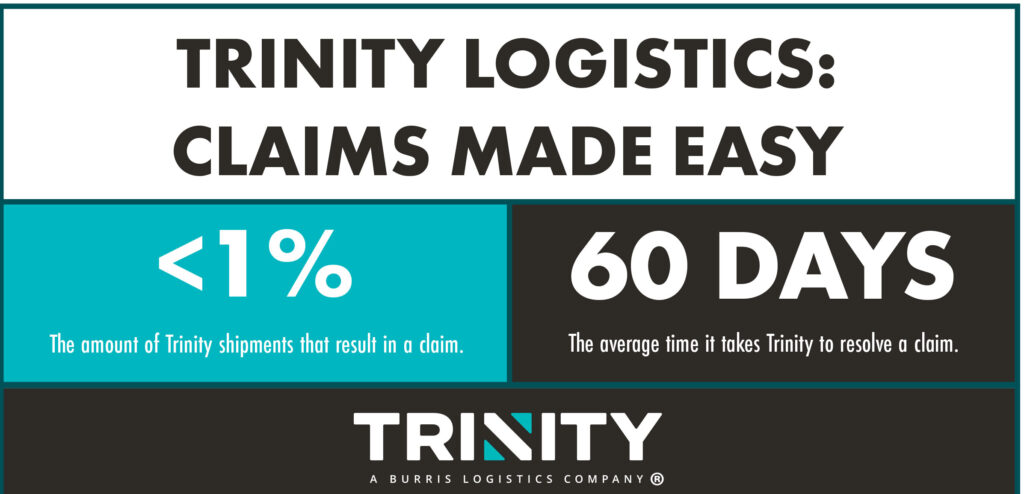

Claims

No matter how prepared one can be, unexpected things can still happen. Shipments may get refused and so that’s why we have a Claims Team here ready to assist you. It can be a real lifesaver to have a Team of certified professionals to help take the stress out of the claims process. Should it be needed, our Claims Team will help you start the process, be there to track progress, and assist until a resolution is met between all involved parties.

DON’T GO THROUGH PRODUCE SEASON ALONE

With proper prevention, compliance, and planning, produce shipment rejections can become less of a thorn in your side during produce season. Even still, they can and will happen at times. Make sure you’re ready and have the support you need by working with an experienced provider such as Trinity.

You’ll have the advantage of working with and trusting our risk departments, who work hard to help mitigate any risk to your shipments. In addition, you can trust that each of our carrier relationships is properly vetted for things like reefer breakdown coverage. Should you need it, you’ll have a whole Claims Team ready to help you sort through any unexpected shipment issues.

Gain the support you need to navigate the complexity of produce season with less stress.

LEARN HOW WE SUPPORT PRODUCE SHIPPERS HELP ME WITH PRODUCE SHIPMENTSThis year, Trinity Logistics was named one of Food Logistics’ Top Green Providers. Food Logistics’ annual awards program showcases individual and corporate leaders in the food and beverage industry. The Top Green Provider award recognizes companies whose products, services, or exemplary leadership enhances sustainability within the cold food and beverage industry.

“Everyone has a role to play when it comes to sustainability, and Trinity has always taken theirs very seriously,” said Sarah Ruffcorn, President of Trinity Logistics. “We are honored to receive this award in consideration of our initiatives towards something so important. Our recognition as a Top Green Provider for 2021 is yet another reason why we are proud to be Trinity Logistics.”

We are honored to be noticed as a company with environmental, economic, and ethical sustainability practices. Going green is something that is very important to us. Since 2008, Trinity Logistics has participated in the Environmental Protection Agency’s SmartWay Program. This program sets initiatives to reduce greenhouse gas emissions and air pollution that is caused by freight transportation. We have been partners with Responsible Care® since 2009. This partnership is committed to improving company performance through community awareness, security, distribution, and pollution prevention. Additionally, one of Trinity’s Guiding Values is integrity. We do the right thing. We are grateful for this award and will continue to uphold our sustainability initiatives to help keep our carbon footprint low.

If you haven’t already noticed, cold chain logistics is currently a hot topic. The demand for fresh products and quality supply chain processes are at an all-time high. Recognizing these trends in cold chain and taking action will help you fulfill your customer’s needs. Let’s look at five trends going on in the cold chain industry.

1. An Increased Demand on Quality Products

Big trends in cold chain, specifically the food industry, has been the demand for fresher and higher-quality products. Consumers want their peaches to be juicier and their avocados to be riper. To satisfy the customers’ wants, you need to make sure the carrier that is shipping your product is well versed in cold chain management. They need to know how to avoid changes in the texture and taste of the produce when a shipment fluctuates beyond the required temperature. The focus on quality products means that refrigerated warehouses will need to maintain temperature zones.

Quality products don’t stop at fresh food. With the COVID-19 vaccine being administered, people want to make sure that what they’re getting injected into their bodies is safe. In addition, the amount of biological drugs and gene therapies is growing. Because of this, logistics companies are also widening their capacity for temperature-controlled transportation to meet the demand.

As we’ve stated in our Shipping Pharmaceuticals blog, cold chain logistics play significant role in the pharmaceutical supply chain. Manufacturers of these vaccines and medications need the cold chain to run smoothly to prevent any damage to the expensive drugs. Pharmaceuticals also need to arrive as good as new because medicine that has sat in incorrect temperatures for an extended period can be ineffective or detrimental to a patient’s health.

2. The Global Cold Chain Market is Booming

A recent report by Grand View Research shows that the global cold chain market size is expected to grow 14.8 percent from 2021 to 2028. Many nations have recognized a rising need to avoid food waste and loss of healthcare products due to spoilage. Moreover, the demand for fresher products is on the rise. Nations such as China and India are boosting their global cold chain efforts to meet the demand for their exports. International trade liberalization has also boosted the use of cold chain, globally. Because it is the global cold chain is rising, manufacturers need to become more specialized in their products so they can ship their goods to a wider variety of customers across the globe.

3. Stronger Regulations

Another trend in the cold chain has been stricter regulations on shipped products. Both globalization and the recent rise of food and pharma counterfeit incidences have caused production and cold chain rules to be reevaluated. The beginning of these rules started with the Food and Drug Administration’s Food Safety Modernization Act. This act requires anyone in the food supply chain to document every step of the process. Certain products like fruit must be traced all the way back to the point of origin.

Being proactive with these firm rules and regulations has also been a common trend across cold chain logistics. Manufacturers are strengthening their processes in-house to help mitigate any issues with their cold chain. Safety should be a top priority for the manufacturer when shipping through cold chain.

4. Innovative Packaging

Specialized packaging has been a trending topic in the cold chain industry. Whether it be for pharmaceuticals or food and beverages, manufacturers have been more specific on how they want their products packaged.

For pharmaceutical companies, there has been a conflict between packaging and transportation costs. For smaller shipments moving through the supply chain, a company can choose either a 24, 48, or 72-hour packaging that will protect the products from becoming ineffective. The more insulated the packaging is, the higher the cost. Globalization is also a major factor in this dilemma. If the U.S. ships cold chain products like pharmaceuticals overseas, it is imperative that the carrier knows to re-ice the shipment if any delays occur.

Companies that specialize in temperature-controlled packaging are making single-use or reusable packaging for all your cold chain needs. There are new refrigerated shipping systems that don’t require gel coolants, and they weigh much less than typical cold chain packages. These systems use evaporative, reactive cooling technology that responds and adjusts to fluctuating temperatures.

Whether it be significant innovations such as evaporative cooling technology or something as simple as adding handles and straps to your packaging, traditional packaging is starting to become a thing of the past. Companies are trying to gain that competitive advantage of being the most innovative packaging company for your cold chain needs.

5. Outsourcing to a Third-Party Logistics Company

Another demand in the cold chain has been for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the transportation of their products. That is why a 3PL provides a wide range of technology services to promote transparency within the supply chain.

Consumers today are becoming more conscientious about their needs. No one wants to settle for spoiled milk or ineffective pharmaceuticals. It is imperative that manufacturers stay up to date on these current trends in the cold chain in order to satisfy their customers. Doing research and staying in the know are both imperative ways for your business to be successful. Being proactive and listening to what customers want is the best way to stay on top in the cold chain industry.

Interested in learning more about Trinity’s experience in cold chain?

Speak With an expertThe economic and operational effects of COVID-19 on the trucking industry have been challenging and devastating. Many have warned the true storm for the trucking sector has yet to arrive, and the effects witnessed to date have been warning signs of what’s yet to come.

Not all operations have been equally affected, but tough times are on the horizon for some trucking companies. The early impacts of the pandemic were at ports, as containers shipped in from China were affected there first.

As lockdowns happened and with events canceled, companies that specialize in moving concert and trade show exhibit items were affected the most. Some fleets dedicated to hauling equipment for events have noted that economic hardship. Others in similar sectors have reported equal occurrences.

THE HARDEST-HIT SECTORS

The food industry has been especially hit hard. Many restaurants and bars have had to close, except for takeout outlets that have stayed afloat. This has left food-service trucks with dwindling sources of income. The International Foodservice Distributors Association predicts the industry will lose $24 billion during the last three months of 2020as the pandemic closes eateries, hotels, and schools.

Another group affected are those who service the automotive industry. Many manufacturers have enacted temporary shutdowns, which affects fleets in more than just their shipments. This limits their supply of new parts for trucks when they need repairs.

Those servicing some of the retail sectors may also struggle. Malls and retail stores are closing at an astounding rate worldwide, slashing demand for the transportation of various goods. While online shopping and delivery could offset the losses faced by trucking companies to a degree, it will take a while for the playing field to level.

THE SECTORS BENEFITING FROM THE PANDEMIC

Of course, fleets who haul sanitizer, toilet paper, groceries, and home office supplies are staying exceptionally busy. Some fleets are even adding more freight to their rosters to keep their trucks running, while others are expanding their operations to keep up with demand.

DAT Solutions has noted that urgent retail orders continue to drive up spot rates for reefer and van equipment. The company says nervous shoppers buy as much as they can for every trip, and retailers are relying more on spot market providers to restock shelves rapidly when other truckers face delays.

Now that a significant part of the world’s population is home, families are also cooking more often. This means that freight demand for grocery and food-related truckers will continue to soar, creating a new market trend many can capitalize on if they’re quick on the uptake.

As retail takes a downward turn, an increasing number of people are shopping online and relying on curbside pickups. Amazon has reportedly been so busy that it’s hired another 100,000 staff members to keep up, while Walmart has enlisted the help of another 150,000 employees.

PREPARING FOR THE UPCOMING RECESSION

While many experts are hailing these changes as a ‘new normal’, it’s important to remember that a recession is looming. If countries put in place secondary lockdowns as the second wave of COVID-19 hits, freight won’t be flowing at the same time. The trucking industry will eventually recover if this proves to be the case, but the time frame for this recovery will depend on how long the virus takes to peak, and how long the recession will last.

WHAT TRUCKING COMPANIES CAN DO

What can fleets do to counteract the potential effects of a second wave? That will depend on the sectors they operate in. Trucking industry professionals have warned some companies may struggle to keep their drivers busy while others will be rushed off their feet in the face of an upswing in demand.

Those in the grocery and refrigerated goods sectors aren’t likely to feel the pinch, even once the recession has arrived. Those in the general freight space may have fewer tons, fewer route miles, and fewer loads to haul. It’s realistic to expect that some carriers will not survive.

In the meantime, trucking companies should work to keep their drivers busy in any way they can. They should remain financially prudent and cut costs where necessary without compromising on safety or service quality. On the other end of the pandemic, there will be many companies that will need to restock their supply chains and they’ll need partners to help them achieve this.

If you’re a trucking company owner or associated professional, get out there, network, talk to your customers and determine what their needs will be once the outbreak has died down. Even if business is not booming right now, you need to find a way to keep drivers in the short term so that your company does not emerge with under-used equipment and a lack of drivers.

Keep your business alive and kicking and be prepared for a decline in business and revenues. We are sitting on the precipice of some major changes in both the world’s economy and the trucking sector. It will be possible to survive, but only with the right approach and strategic partnerships.

FIND A GREAT PARTNER IN TRINITYGuest Author: Lori Dodson

These days consumers are searching for food items in stores that come from all across the world. To keep products fresh, on shelves, and at peak quality, there needs to be good communication among food and beverage supply chain partners.

Food & Beverage Challenges

Unlike other industries, the food and beverage industry face unique challenges with their shipping, such as;

- Deliveries needed before expiration dates

- items needing temperature-control,

- and items needing extra-careful handling

These are just some obstacles you have to face when shipping food products. These challenges closely connect the food manufacturing industry with logistics and transportation partners.

Shipping temperature-sensitive items? Check our our Temperature Shipping Guide.

Logistics & Transportation Partners

With freight transportation, communication begins right from the start. Not all freight travels the same, so setting expectations is the best way to get started. Additionally, having a partner who understands the challenges of shipping your products will prove to be beneficial. Due to this, many food and beverage companies choose to outsource their logistics with a third-party logistics company (3PL).

3PLs have experience quickly solving complex freight solutions every day. You can feel relief when working with a 3PL to arrange your freight transportation. 3PLs have a vetted carrier network with experience in transporting food products and many modes to offer you shipping solutions. You can gain the use of their cutting-edge technology to track your freight.

Sometimes you can experience trouble with communication when outsourcing work to a third party. But you can feel confident when choosing to work with Trinity Logistics. You are kept in the know thanks to the communication processes and technology we have in place.

How Trinity Communicates

When you choose Trinity Logistics, you will work with an Account Representative you can trust as your daily point of contact. They quickly communicate your shipping options, the carrier(s) selected, and provide any solutions to problems that may arise throughout your shipment.

You get to choose from several options for tracing on your shipment, including FourKites, MacroPoint, or Trucker Tools. Your Account Representative keeps an open line of communication with access to our portal, emails, or phone calls to give you real-time visibility of your shipment’s whereabouts and estimated delivery time. You are never left in the dark and unsure of where your product is.

Just as a lack of communication can be a problem, in certain cases so can over-communication. Through the use of these applications, we can relieve the calling, emailing, and texting our carriers. This keeps them safe and focused on the goal at hand: delivering your product on time.

Sometimes you need solutions to problems outside of the typical 9-5 workday. No need to worry. You have access to Trinity’s 24/7 Team to accommodate your needs at any time of the day or night.

All Around Communication

If you are looking for an all-around solution to your problem of communication in your supply chain, a transportation management system (TMS) could be your answer. A TMS can help act as a communication hub for all partners in your supply chain. You can gain end-to-end visibility by working in one place, rather than across various sources. Looking to learn more about a TMS and its functions? Download our Guide to Transportation Management Systems.

All relationships need open communication to work well. That is no different for supply chain partners in food and beverage. Each partner in the supply chain should keep in communication as needed to provide full visibility and keep everyone in the loop. This can prevent damaged product, recalls, extra costs, and frustration. You don’t need to worry about communication issues when choosing Trinity Logistics as a partner in your supply chain. We are more than just a 3PL for shipping, but a 3PL for data and communication.

From arranging your freight shipments or setting up a TMS. Trinity is here to help.

AUTHOR: Christine Griffith