While many of us are soaking up the last of summer’s sun and fun, food manufacturing supply chains are readying for the upcoming holiday food rush.

Have you ever noticed a lot of our favorite memories are surrounded by food? When we go to celebrate something like a birthday, anniversary, or special achievement, it usually involves food. It’s no surprise then that over the holiday season, nearly 165 million consumers across the U.S. purchase food and beverages to celebrate, according to a study from Cornell. As the holidays soon approach, food consumption surges, with the average American indulging up to an extra 440 calories per serving!

The increased demand and tight holiday deadlines can present challenges for many food and beverage companies with their logistics. This is in addition to already facing a competitive peak shipping season! However, by understanding the dynamics of this unique period of time, shippers can ensure success is ahead of them. First, let’s dive into some fascinating facts and insights about food during the holiday season. Then, we’ll follow that with some essential tips so your company can be prepared for the holiday food rush!

Holiday Food Supply Timeline & Stats

The Holiday Food Surge Begins with Fall

The holiday food rush first begins with the arrival of fall flavors. Pumpkin spice, now seen as the quintessential flavor of fall, has seen a 47 percent increase in sales, as reported by The Guardian, within the past five years. In 2023 alone, Datassential reported 144 new limited-time offers that featured pumpkin on major restaurant menus. From the infamous Pumpkin Spice Lattes (PSLs) to pumpkin soups and ravioli, this flavor dominates the season. But we can’t forget another fall favorite – apple. Food and beverage items with caramel apple were one of the highest-indexing flavors last fall.

Halloween Signals Significant Holiday Food Consumption Increase

Halloween is a major milestone in the holiday food timeline, with 65 percent of consumers participating in the festivities. In fact, of all 172 million that celebrate the spooky season, 95 percent of them purchase candy. Even more staggering is that a quarter of all the candy sold annually comes from Halloween sales. It’s not all about the sweets, though! Pizza is the most popular dinner staple on All Hallow’s Eve, according to Grubhub. There’s also the annual tradition of carving a pumpkin, with Statista reporting roughly 154 million Americans partaking in the activity in 2023.

Dia de Los Muertos Celebrations Begin to Trend

Datassential reports that 10 percent of consumers in the U.S. report celebrating Dia de Los Muertos, or Day of the Dead. This holiday is gaining popularity, which means so are the celebratory foods associated with it! Pan de Muerto is one traditional sweet bread that’s essential to the celebration.

Thanksgiving Continues to Drive Food Supply Chain Demand

Thanksgiving remains the most popular fall holiday, with 83 percent of Americans celebrating the tradition. A whopping 46 million turkeys are consumed each year, according to the U.S. Department of Agriculture. Other top holiday staples include cranberry sauce, stuffing, green bean casserole, mashed potatoes, macaroni and cheese, sweet potatoes, and pumpkin and apple pies. That’s a lot of food to prepare for a meal, so 23 percent of consumers will buy a full, ready-made meal from a restaurant. Another 22 percent will supplement with some food from restaurants for part of their feasts.

Sweets, Candy & Chocolate Build Holiday Food Demand at Christmas & New Year’s

Leading up to Christmas, many enjoy hot cocoa, cookies, and other treats. 1.76 billion candy canes, a holiday staple, are made annually for this joyous time of the year. 70 percent of Americans make Christmas desserts, with frosted sugar cookies being the top ones consumed annually. Don’t forget the eggnog! 122 million pounds of it is poured and drunk each year.

When it comes to Christmas dinner, pork dishes are the most popular globally, but turkey still trumps all for the U.S. Other winter feast staples include roasted or mashed potatoes, roasted carrots, gravy, stuffing, shrimp, and lots of Christmas pudding, cookies, and pies. Sweet tooths rejoice as 83 percent of consumers fill stockings with treats like candy and chocolate.

Christmas and New Year’s are among the busiest holidays for restaurants. Both holidays also see a spike in alcohol consumption, with New Year’s Eve being the second most alcohol-associated holiday behind Mardi Gras. Champagne is the fan favorite for those ringing in the New Year.

Logistics & SHipping Tips for Holiday Food Shipping

The holiday season often brings those in logistics the gift of increased demand and decreased capacity. Like most Americans, truck drivers aim to be home for the holidays, trimming the number of available carriers down. Freight of all kinds can increase during the period, further cutting the number of trucks available. Shippers with more specialized requirements, like temperature control, can find even less capacity. Shippers also have tighter deadlines to meet at this time to make the most of the seasonal business.

Overall, the holiday season can be a time of heightened stress and disruption. Given these unique challenges, it’s crucial for food and beverage shippers to prepare thoroughly to appease customers.

Five Tips for the Best Holiday Food Shipping Logistics Outcomes

Tip 1: Keep Inventory Stocked

Running out of stock during the holiday season is a surefire way to lose customers. Track your inventory levels closely and replenish supplies early to ensure you’re well-stocked. By keeping orders moving consistently, you’ll be able to meet consumer demand and avoid causing any disappointment.

Tip 2: Have Backup Shipping Plans Ready

The chances of any disruptions or delays happening during this season are increased. Having backup shipping plans already prepared is essential to keep your goods moving.

Build relationships with multiple carriers and suppliers, or even a third-party logistics provider (3PL). This way, you’ll have known contacts ready in case you need any help.

Look at alternate modes of transportation and be prepared to quickly shift plans should something happen. Exploring multimodal options can be a great way to diversify risk, add capacity, and protect your freight budget. Having this flexibility available and ready can help you stay on track and your supply chain running smoothly.

Tip 3: Real-Time Visibility is Needed for Success

In today’s supply chains, having access to the visibility you need is crucial. You should either work with a provider that offers it or invest in your own technology, like a Transportation Management System (TMS).

A TMS can be very helpful during the holiday season. It can help you with routing decisions by matching your freight with the best carriers, lanes, and rates. In addition, it will allow you to optimize the in-house processes of your transportation network – which can be helpful during busy and slow seasons. By selecting the best carriers and optimizing your routes, you’ll not only increase your service but reduce your risk.

Using a TMS also gives you data-driven insights to better manage disruptions, reduce downtime, and budget your logistics spend. Data analytics can help you recognize which carriers are most likely to have the capacity, saving you time arranging your shipments.

Tip 4: Communication and Collaboration

Effective communication is key to a successful holiday season. Regularly communicate with all stakeholders, including suppliers, carriers, and customers. Collaborating with your partners during the seasonal planning phase can provide valuable insights and help you identify potential issues before they arise.

Tip 5: Partner with a 3PL

Working with a 3PL can be a game-changer during the holiday season. A 3PL offers access to a larger network of carriers, advanced technology, and expertise in managing complex logistics challenges. With their support, you can ensure your supply chain remains resilient, even in the face of unexpected disruptions.

Treat Yourself with Easier Logistics This Holiday Season

Navigating the holiday food rush can be overwhelming, and that’s why Trinity Logistics is here to be your guide. Like Santa, we’ve been around a while, with 45 years of experience handling logistics during holiday seasons.

Right away, you’ll gain access to our large network of vetted, quality carrier relationships to cover your shipments. But that’s just the start! There are many more benefits to working with Trinity, including:

- Multiple modes of transportation to find the best bang for your buck, support your business growth, or just have a backup plan ready

- Best-in-class technology and customized Managed Transportation solutions available, giving you the exact visibility and data you want

- 24/7/365 support, so no matter what day or time it is, you’ll have the help you need

One benefit that tends to shine above all else? Our exceptional People-Centric service. It’s the trait that makes Trinity different from other 3PLs and keeps our customers returning time and time again. It’s truly our care, compassion, and communication that you’ll notice and appreciate.

Everyone wants to enjoy the holiday season. Why not let Trinity focus on the logistics for your business, so you can go back to doing what you enjoy – helping consumers savor holiday treats and create memorable moments with your product.

Try out Trinity Logistics for Your Next Shipment Learn How Trinity Supports Food & Beverage Shippers Sample More of the Trinity Culture & Service – Join Our Mailing ListAre you a Freight Agent that stumbled across this article?

Freight Agents, Indulge in an Exceptional 3PL PartnerConsumers want more fruits and vegetables in their diets but produce shippers must face these common logistics challenges to keep up with their demand.

It’s hard to deny the nutritional value fruits and vegetables bring to our diets. It’s likely why there’s been substantial growth in consumer demand for produce over the past decade. While that’s great for businesses based in produce, there’s also greater pressure for produce shippers to deliver.

The journey from farm to table can be surprisingly complex for fruits and vegetables. Produce shippers face several hurdles that they need to overcome for their products to deliver fresh and meet the growing consumer demand. Let’s explore the intricacies of these difficulties and how they all can be taken care of by working with a third-party logistics (3PL) provider, like Trinity Logistics.

CHALLENGE 1: CHOOSING BEST TRANSPORTATION MODE

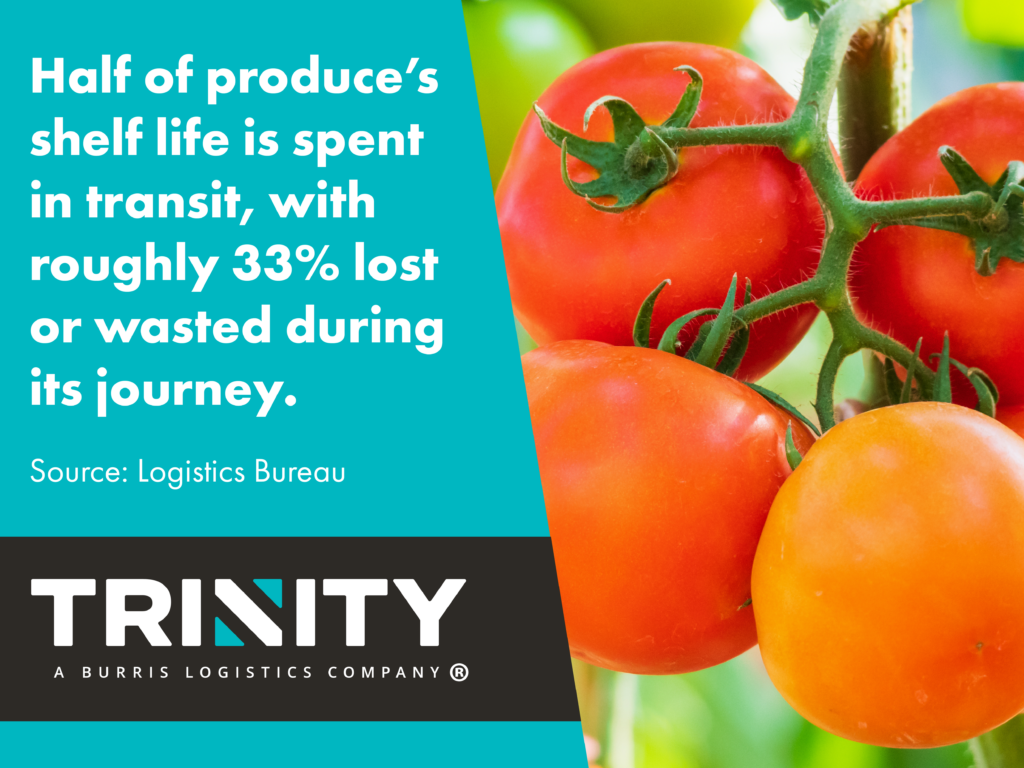

Produce shippers first face the challenge of determining what transportation mode to use for their shipments. With produce, half of its shelf life is spent in transit. It’s also reported that roughly 33 percent of produce is lost or wasted during its journey, according to the Logistics Bureau.

This is why produce shippers must ask themselves these questions to help determine the right transportation mode for their shipment.

What’s best for your product?

What can you afford?

How much time does your produce have?

Air is great for foods that have a very short shelf life and may need expedited shipping. However, air is often the most expensive of your options. Rail can offer you cost savings but requires more travel time, often two to three days. This option is often saved for produce with a longer shelf life. Lastly, there’s truckload shipping, which offers several shipping options and costs, depending on factors like whether you need a full truck, expedited shipping, or freight consolidation.

CHALLENGE 2: SELECTING THE RIGHT CARRIER PARTNER

The next challenge produce shippers need to tackle is choosing the right carrier to pick up and deliver their shipment. This may be the most crucial task of all because the carrier you choose can make or break your shipment. You need to trust the carrier you choose has experience in handling your specific cargo and meeting food safety regulations, especially for those that need temperature control.

CHALLENGE 3: MAINTAINING FRESHNESS/QUALITY

Maintaining freshness is one of the primary logistics challenges for produce shippers. Millions of dollars are wasted each year on produce that didn’t maintain freshness by delivery.

Produce begins to deteriorate the moment it’s harvested, so the risk of decomposition is equal to, or perhaps even greater, to produce shippers than those of theft or delay. Fresh or frozen produce needs to be stored and transported at specific temperatures to ensure its quality when bought and eaten by the consumer. Even the amount of humidity, light, or kind of packaging can affect a produce product, so produce shippers face this challenge in every segment of their shipping.

Every kind of produce also has different needs. Some need very specific environments to maintain freshness. Others can stay at room temperature or take on more handling. Shelf life is also something to consider. Produce with short shelf lives will need quick transit from farm to store. This also means several kinds of produce often can’t ship together. Since there is no one-size-fits-all process for produce, it’s important for produce shippers and their logistics partners to understand what’s needed for the specific product to deliver at peak quality.

CHALLENGE 4: SHIPMENT VISIBILITY

Tracking and shipment visibility is essential for produce shippers to be able to reduce risk. Without a clear look into your shipments, you’re left in the dark and uncertain whether your product will arrive on time or in acceptable condition.

This can challenge more than just produce shippers, but all stakeholders in a company’s supply chain. Miscommunication can happen between retailers and sellers as well, causing miscalculations in capacity planning or undependable forecasts. Real-time visibility and data are absolutely needed for produce shippers to enhance transparency with their business partners and gain more control over their supply chains.

CHALLENGE 5: REGULATIONS

Navigating regulations is a huge challenge for produce shippers. Failure to meet those regulations can lead to severe and often costly consequences. For example, in the U.S., produce shippers must comply with the Food Safety Modernization Act (FSMA), which entails specific guidelines for food safety.

There are also quality standards and labeling requirements to be met. The U.S. Department of Agriculture (USDA) has a strict grading system to determine the quality of produce, considering its size, shape, color, and defects.

CHALLENGE 6: HANDLING ANY CLAIMS

There’s always a risk for claims in shipping, but claims can happen more often for produce shippers compared to other industries, due to its shorter shelf life. The majority of claims we see in produce shipping are the result of spoilage, which can happen for many different reasons.

Handling claims for produce is slightly more difficult due to the Perishable Agricultural Commodities Act (PACA). When handling produce claims, it’s important you and your transportation provider understand and follow PACA.

HOW TRINITY LOGISTICS HELPS PRODUCE SHIPPERS OVERCOME THEIR CHALLENGES

All those challenges listed above that you may face – we know how and are prepared to handle them.

After 45 years of serving shippers in the food and beverage industry, we’re experts in its logistics requirements and regulations. We also take part in industry organizations, like the International Fresh Produce Association, so we stay knowledgeable about what may affect produce shippers.

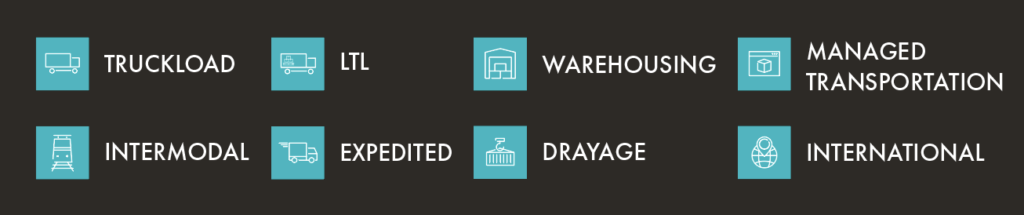

When it comes to choosing your transportation mode, we have a multitude of options available to support you, whether you’re looking for help with one shipment or a fully outsourced logistics solution.

Additionally, we work with trusted carrier relationships that have been fully vetted to ensure your product travels safely and delivers on time. This includes vetting that reefer equipment is not older than 2012 and a temp-reading or download can be made readily available for any refrigerated or frozen produce shipments.

No matter where your freight is in its journey, we provide you with several real-time tracking options to stay fully informed. Through our Managed Transportation service and the use of a transportation management system (TMS), you can find more visibility and data to improve your supply chain processes and communication.

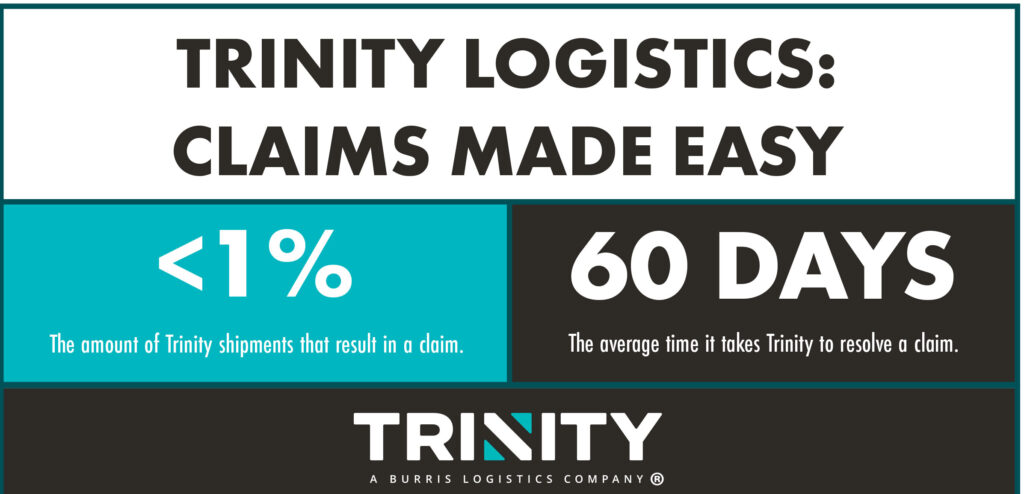

And then there are claims. While we wish every situation could go smoothly, there can still be mishaps. Even so, we’re proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. That’s likely because we work with shippers and receivers to monitor load and unload times, checking to ensure trailer doors are not left open, causing temperatures to fluctuate outside of any required ranges.

Now, fear not, because if something does happen, we’re able to help with that too. We have an in-house expert Claims Team to help negotiate any produce claims on your behalf, with an average rate of 60 days in resolving cargo claims.

By working with Trinity Logistics for your produce shipments, you’ll also gain an extra benefit – experiencing our acclaimed People-Centric service. It’s what our customers praise the most about our services and keeps them returning to Trinity Logistics for their logistics needs.

If you’re tired of tackling these produce shipping challenges alone, it may be time to get connected and join the thousands of shippers that choose to make their logistics easy with Trinity Logistics. You won’t be-leaf our exceptional service until you try it!

Get Out of Your Produce Shipping Pickle

Check Out Trinity's Solutions Request a Free Shipping QuoteThe chemical industry faces complexities every day. From safety regulations to handling and shipping these products, making, and delivering chemicals is no easy task. One of the significant challenges facing the chemical industry today is the pressure for sustainability. With climate change in the spotlight, consumers are taking notice, and sustainability is molding the chemical industry.

Changing the Old Ways

While safety, service, and costs are still important aspects of the chemical industry, sustainability is becoming an important detail. The industry faces pressure from activists, lawmakers, and the public to become more sustainable to help battle climate change.

A big issue arising for the chemical industry is that most people have trouble putting the words “green” with “chemicals.” This idea is something progressive, and future chemists are trying to help the industry adapt.

And while it’s not ideal to pay more money for creating products, it’s the path we’re headed. Studies show that more than three-quarters of consumers are willing to change their shopping habits to reduce their own carbon footprint. Additionally, more than one-third are willing to spend more money on products that help with sustainability.

Sustainability Issues within the Chemical Industry

With over 881 million tons of chemicals transported in previous years, this industry is growing and on the rise. Yet, with its growth comes an increase of challenges on the chemical industry to meet sustainability goals.

One major goal for sustainability is reducing one’s carbon footprint in the world. For the chemical industry, abiding by modern environmental standards like replacing petroleum-based combustion engines with electronic vehicles, or manufacturing with plant-based materials over oil-based, can help achieve carbon reduction. However, the chemical industry has several issues to resolve to meet this goal.

One of those issues is plastic. Over one-third of the plastic we use is single-use, meaning that after one use of a water bottle, zip lock bag, or straw, for example, these items are thrown away. The “Plastic Waste Markers Index,” published by the Minderoo Foundation, calculated that energy and chemical companies are the sources of half of the world’s single-use plastic waste. Single-use plastic accounts for most of the waste harming marine life and seeping into land when burned. This issue is not taken lightly. Many lawmakers and activists are acting to introduce a new form of recyclable and reusable plastic.

Major oil spills in recent years have become a rising issue as well. One major oil spill was the Exxon Valdez off the coast of Alaska in 1989, with over eleven million gallons of oil spilled in the ocean. Some more recent ones were the True Oil pipeline in 2020, the tanker truck rollover in 2020, and more.

Finding Sustainable Solutions

The chemical industry is working hard to find new solutions to be more sustainable. One of the significant changes being made is reducing the rise of fossil fuels.

The use of hybrid or electric vehicles has been on the rise, and we’ve seen significant sales growth for these types of vehicles. People are turning away from pumping gasoline to plug their cars into an electric outlet. While these electric vehicles are not yet popular in the trucking industry, many companies are working to build new electronic trucks. Not to mention, President Biden’s recent executive order aimed at making half of all new vehicles (including semitrailers) sold in 2030 electric.

Fossil fuels also play a part in plastics. Single-use plastics are made from polymers, with their base material from fossil fuels. As companies strive to reduce their plastic use or manufacturing, it simultaneously reduces fossil fuel use.

However, with new rules to reduce single-use plastic items, the logistics field will need to find new sustainable ways to package shipments. Currently, products are packaged and shipped in some sort of plastic.

Although these seem like small changes that one person can easily make, the companies that use or manufacture these products face major changes to their business. As severe weather and climate change continue to be front and center worldwide, chemical companies feel the pressure to make these changes towards sustainability.

We’re Here to Help You

Sustainability affects all practices for the chemical industry, including their logistics. Here at Trinity, we’re here to help you reach your logistics goals, including those on sustainability. We offer several modes of transportation, including intermodal, which can reduce your carbon footprint. Our Team of experts can help recommend customized solutions like freight consolidation as another way to be more sustainable with your freight transportation. Or you can consider using technology, like our best-in-class transportation management system, to gain efficiencies and data-driven insights into your logistics, which can also help you with sustainability in your logistics.

We know sustainability practices are necessary for every business. This is why we take pride in our efforts and are proud of our earned recognition as both an SDCE Green Supply Chain Award winner and as a Food Logistics Top Green Provider.

If you’ve been looking for a like-minded logistics partner to reach your goals, we’re here and ready to help.

See how we can help you with sustainability in your logistics.Author: Turner Lee

When was the last time you reviewed your logistics network and technology? If it’s been more than six months, then you’ve stumbled upon the right article. Now, you might be thinking, “I don’t feel like our process is necessarily broken. Is it really worth trying to fix it? Do I really need a transportation management system?” Yet, what if you could strategically reduce your overall spend while transforming your team from being reactive and task-oriented to proactive and customer-oriented. What kind of impact would that have on your company’s bottom line?

If your business;

- has a freight spend of $1M or more,

- utilizes a mix of transportation modes,

- has multiple locations that utilize their own mix of broker and asset providers,

- procures a majority of freight via the spot market, or

- manages most of your data via Excel spreadsheets;

Then keep reading as we’re going to take a look at some common areas of improvement you could see with a Managed Transportation approach.

You’ll learn how Trinity’s unique solutions focus on finding the right mix of people, process, and technology. Through this, we can help leverage your supply chain into a competitive advantage for your organization.

Let’s dive in.

PAIN POINT 1: LACK OF EFFICIENCY

Lack of efficiency in your business is a direct result of a decentralized and very manual approach. Programs like Outlook and Excel were just never intended to handle a freight spend of $1M or more. If your freight spend is $1M or more, you’re probably working with a couple of hundred orders a month, with who knows how many stakeholders to help micromanage quotes, tenders, tracking, and tracing of shipments.

How much time is being wasted across your organization with overwhelming manual processes?

Does this process save you any money when it comes to freight spend?

Do you know if you are utilizing the right carriers?

Would contract pricing cost you less than the spot market in the long run?

The bottom line is this is a reactive strategy focused on individuals’ tasks. To optimize your team and freight, you need a major shift towards being more proactive and customer-focused. This is where Trinity’s technology can help you. All of our Managed Transportation features a cloud-based TMS platform that creates a centralized freight command center, replacing your redundant manual processes with automation. Our TMS helps you manage the entire life cycle of an order and we can even integrate with your order management system to truly optimize your workflow. This means no more phone calls, typing out shipment details, or wondering where your freight is or when it’s going to deliver. Technology is one of the critical aspects of our solutions here at Trinity and also a major catalyst to transforming your supply chain.

PAIN POINT 2: PERFORMANCE

Efficiency isn’t just about getting faster; it’s about getting better. Finding and creating better team performance, better carrier performance, and ultimately improving your bottom-line company performance. So, is there room for improvement in these areas for you? Are your current strategies effective? Can they be measured? You may have answers to these questions that vary from location to location. You’ll usually find some of your distribution centers are better at procuring freight than others.

While a siloed strategy may have made sense for you at one point, companies grow and change. Considering change is a constant, a more wholistic approach will typically yield a better overall cost and carrier performance for you. This is what we consider to be the process part of our solutions. Data is a key driver for the strategy on this one.

On the surface level, it will appear that you simply are spreading your freight too thin across too many carriers or brokers. At Trinity, our Team of Logistics Consultants can quickly diagnose if you are leveraging your overall volumes to the best of your ability. Through strategic sourcing and customer-specific pricing, you can yield savings of six to ten percent, sometimes even more. It can also have a significant effect on improving on-time performance. Best of all, with Trinity’s Managed Transportation, you’ll always be able to track these metrics. You’ll be able to know exactly how your teams compare to the market and are able to adapt quickly when things change.

PAINT POINT 3: VISIBILITY

It’s hard to overstate the importance of real-time visibility in today’s supply chain. When a customer or sales rep asks for a delivery ETA or if the warehouse needs to know what trucks are scheduled to come in; that can all fall back on your outdated and manual processes. Things like picking up the phone, back and forth emails, creating and sharing spreadsheets, that’s just your day-to-day visibility. What about those overall performance metrics and being able to measure your team or your carriers? Unfortunately for many shippers, there can be too many roadblocks for effective communication and a lack of overall supply chain awareness.

However, with the right strategy and technology, visibility can shift from a challenge to a strength. Having access to a TMS takes over a lot of the heavy lifting for you, acting as a virtual control tower for all logistics updates and communication. With Trinity’s solutions, we included unlimited users who can access updates and data 24/7 via the cloud. We can even create push notifications where your team, your warehouse, and your customers can receive updates for their specific tasks automatically. For most shippers, real-time visibility has fully transitioned from an optional benefit to a business necessity – which is why Trinity brings all of this valuable information right to your fingertips.

PAIN POINT 4: BUSINESS INTELLIGENCE

Data has quickly become one of the world’s most valuable resources. In order to make effective decisions, proper data and analysis are needed, especially for logistics strategy or more enterprise-level decisions that reach far beyond the supply chain.

Now let’s say you do have access to good, tangible data. Even still, most likely your data is spread out among various laptops, email accounts, and carrier portals. Trying to compile complete and accurate information is difficult in itself this way, but the greater challenge is what can you do with this data?

That’s where working with Trinity comes in hand. We help compile and present a key analysis in a way that is easy for you to understand and collaborate on action steps for your company’s continuous improvement. Our customers are able to successfully leverage their data to lower costs, improve performance, and drive their company forward. There are many types of helpful reports you can expect to see such as carrier scorecards, customer profitability reports, to network analysis, and distribution projects.

From Surviving to Thriving

Whether or not your challenges have already been identified, through a Managed Transportation Discovery Call with our people-centric approach, you can learn how to take your business from surviving to thriving. Your consultation is free and the only thing you have to learn is how your business can operate more efficiently and strategically.

What do you have to lose?

Intrigued?

Request a consultationNot quite ready for a consultation but still interested in learning more about Trinity’s TMS? Register for a brief presentation specifically focused on our TMS.

Register