It’s a simple fact. People can’t survive without food. When times are tough, we can certainly make sacrifices in other parts of our lives, like our online shopping habits or a remodel we wanted, but not food. This makes food manufacturing a reliable and even diverse industry to run a business in. Yet, it doesn’t come without its own set of unique challenges, especially with its logistics.

Today, the demand for fast and reliable shipping is higher than ever. Food and beverage companies need to meet the rising pressure to provide quicker turnarounds and deliver their products at optimal freshness to stay competitive. With already complex supply chains, how can a company keep up? Not to mention, what if there’s an issue found or a delay? Don’t stress. We’ll cover logistics challenges that commonly hurt food manufacturing businesses and how working with a third-party logistics (3PL) company, like Trinity Logistics, can solve and simplify your processes for shipping food.

Common Shipping Challenges Faced by Food Manufacturing

Diversity in Scheduling Applications Introduces Challenges

One of the biggest headaches for food manufacturers is self-imposed. Each shipper or distributor could be using a different scheduling portal or application. Some even just use Excel spreadsheets. Because of this, scheduling conflicts and communication gaps are often seen when shipping food. This can be very frustrating to the logistics departments arranging the shipments.

Furthermore, the carriers they aim to work with may not know how to use the application or might not even have access to it. This inefficiency can cause issues with them scheduling their pickup or delivery appointments. It also can limit access to capacity, something that is truly needed for those requiring temperature control during peak produce season!

Plenty of Time-Sensitive Freight in Food Manufacturing – Beat Must Arrive by Dates

As previously mentioned, food manufacturers face a growing demand for products that are at peak freshness, especially for those needing temperature control. It’s not unusual for these time-sensitive shipments to be last-minute orders requiring immediate action. Some of these can come in just the day before or even the day before and need shipping right away. Sometimes to help manage the influx of shipments, freight can be assigned with a “Must Arrive by Date” (MABD). This can put pressure on food manufacturers, and missed delivery windows can result in costly penalties. These fees, called chargebacks, usually get pushed back onto the customer and impact your bottom line and service.

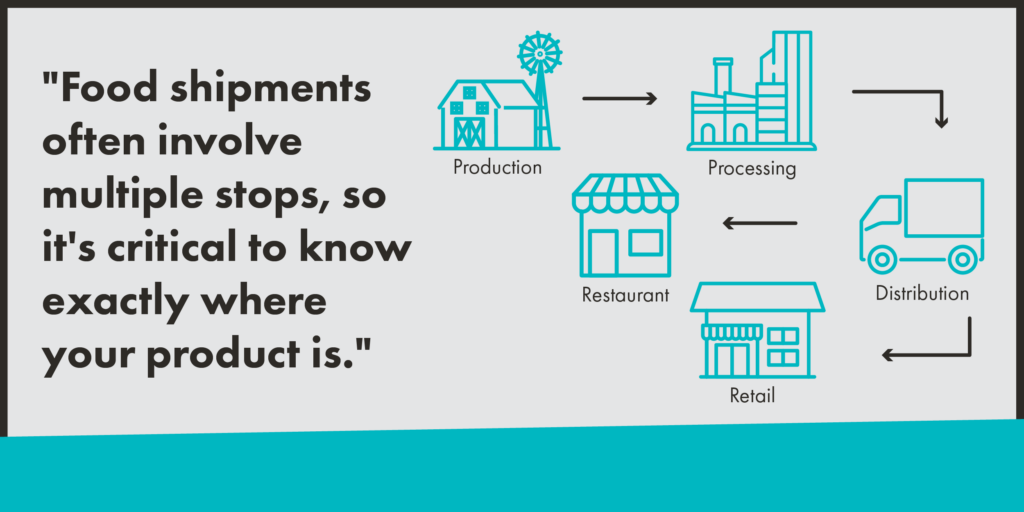

Identify Visibility Gaps When Shipping Food

With many time-sensitive and temperature-control requirements, it’s important for food manufacturers to have complete visibility into their shipments. Food shipments often involve multiple stops, so it’s critical to understand where your product is and when it’s expected to arrive. Even though it is valuable, many food manufacturers find they have limited visibility of their shipments. This creates a lot of uncertainty, causing additional gaps in communication and possible delays or disruptions. Most importantly, it can jeopardize the safety of your food product, an important piece to meet the Food Safety Modernization Act (FSMA) regulation.

Keeping Food Shipping Logistics Budget in Control

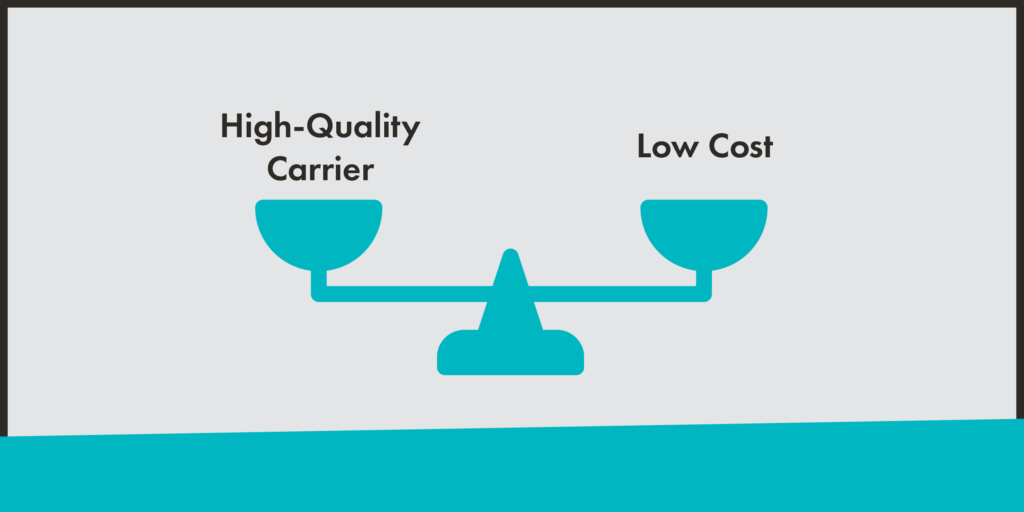

Carrier selection for shipping food products can be a puzzle for food manufacturers to figure out. On one hand, you want to work with high-quality carriers to ensure your food products arrive at peak freshness. On the other hand, they cost more. One certainly wants to budget and find balance. Look to pay too little, and you may not find the quality service your products need. Finding that balance between the two can be difficult.

Market trends can also cause unexpected price fluctuations, further challenging their logistics budget. This can really hurt those needing to meet peak freshness as it’s not like they can’t ship their products as they may perish. Instead, they’ve got to adjust and pay the current price.

Food manufacturers must be creative and find solutions to keep their costs down but their quality up. They can consider other transportation modes as options to manage costs, but understanding which one makes the most sense for their product can be overwhelming.

Embracing Sustainability in Food Shipping

Sustainability is on everyone’s minds, including consumers. With global food and beverage production causing roughly 34 percent of greenhouse gas emissions, consumers are holding food manufacturing companies to higher standards. They’re researching more about the companies they purchase food products from. They want to know what positive practices they implement, such as sustainable fishing, the use of ecological pesticides, reforesting, fair trade, or the use of compostable packaging.

TRINITY Logistics SOLVEs Food Shipping PROBLEMS

With over 45 years of serving customized logistics solutions to thousands of food manufacturers, we’re fairly confident in our ability to help you overcome any of these challenges.

We Speak Your Food Shipping Scheduling Language

We’re in tune with most if not all, scheduling portals that food and beverage shippers use. You don’t have to worry about training us! Yes, we could even say we know how to navigate those scheduling apps “with our eyes closed.” Even if we have a newer Team Member who is unfamiliar with it, we can guarantee that at least one of our 400+ Team Members or 135+ Authorized Agents know it and can assist.

Time-Sensitive Titans: We Deliver Your Food Products When It Matters Most

At Trinity Logistics, we understand the urgency of time-sensitive food deliveries. Our Team excels in handling quick turnarounds, making us the “emergency room” for your time-critical freight. We are acutely aware of the potential repercussions of missed deliveries and leverage our strong carrier relationships to secure the capacity you need. These established partnerships allow for better planning and ensure that carriers are familiar with the specific needs of food commodities, pickup, and delivery locations.

Furthermore, in the unfortunate event that fees do arise due to carrier issues, Trinity acts as your advocate. We hold our carriers accountable and ensure that any associated charges are passed along to the responsible party. Our meticulous investigation process guarantees that only the root cause of the problem bears the financial burden.

Expand the View into Your Food Shipments

We’re champions of end-to-end visibility, great communication, and transparency because we know you deserve it. Our commitment to People-Centric service isn’t just our slogan; it’s our philosophy.

We leverage a combination of cutting-edge technology and a dedicated Team Member to keep you informed every step of the way. Use our Customer Portal to see real-time tracking of your shipments. If you’re looking for even more transparency, there’s our Managed Transportation service, offering you a customized Transportation Management System (TMS) solution that works for your business. Between our technology and our Team Members, you’ll find this proactive approach ensures you’re not left in the dark until delivery.

Find Balance in Your Logistics Budget

Starting out, our established carrier relationships not only gain you access to capacity but to leverage our competitive rates. Additionally, we have multiple modes to choose from and our Experts can help you explore which one suits your product and budget.

Now, we understand balance isn’t easy to obtain, so that’s why Trinity Logistics goes a step further in our service to help you find it. For those food manufacturers that build a shipping history with us, we’re able to review your data and conduct a comprehensive review of your logistics. This will give you a clearer insight into your logistics to find room for improvement. We won’t come empty-handed, either. We’ll make recommendations to add efficiencies and see if we’re on the right track for your company’s success.

Adding Sustainability into Your Logistics

We understand the importance of sustainability and are committed to helping you implement it throughout your supply chain. This includes connecting you with carriers that prioritize eco-friendly practices, finding sustainable shipping options, and exploring carbon offsetting programs. If you need further proof, Trinity currently holds a bronze medal rating by EcoVadis, the world’s largest and most trusted provider of sustainability ratings.

Learn more about Trinity's sustainability initiativesBonus Benefit for Food Manufacturers! Trinity’s Relationship with Honor Foods

As a Burris Logistics Company, we have a direct relationship with Honor Foods. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They have access to thousands of reputable brands and can simplify your purchasing process. Honor specializes in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers. Speed up your lead times and increase profitability with no extra storage space needed. Working with Trinity and Honor, you can get the best of both Burris Logistics brands and gain additional success in your business.

Operating in food manufacturing can be complex, but it doesn’t have to be. Try Trinity Logistics for your shipping and see just how easy it can be.

Discover how Trinity exceptionally serves those in food and beverage Get a quote to see if our solutions are right for your businessCraft Beer Logistics: Navigate Complexity, Grow Your Business

Beer, a beloved and timeless beverage. It’s a staple in many cultures and continues to be one of the world’s most popular drinks. A growing subset in beer is the craft beer industry, known for its robustness, variety of flavors, and highlighting regional tastes. According to the Brewers Association, in 2022, craft beer sales increased five percent and now account for almost a quarter of the U.S. beer market. While the demand for craft beer grows, the logistics behind its distribution is increasingly complex.

Craft brewery owners often wear many hats and have lots of tasks to hop on. This can include handling their logistics. This includes more than just the shipping of their beer but the many ingredients and equipment that go into making it. From start to finish, these beer supply chains involve numerous stages and stakeholders, including ingredient manufacturers, distributors, and retailers.

Having effective logistics planning and processes is crucial for craft brewers to meet their growing demand and provide great service to their stakeholders. Managing their supply chains can be difficult to do alone, which is why a third-party logistics (3PL) provider can be a valuable resource to growing craft breweries.

LOGISTICS CHALLENGES FACING THE CRAFT BEER INDUSTRY

Knowing how to legally and efficiently manage their shipping networks is a crucial part of running a successful craft brewery business. There are several challenges craft brewers face such as keeping temperature control throughout transportation, meeting state regulations, and meeting customer demand.

PERISHABLE INGREDIENTS AND PRODUCTS

The need for temperature control in the logistics of craft beer is paramount to preserve the integrity of any needed ingredients or finished products.

Craft brewers also often experiment with ciders, mead, and other malt beverages with specialized flavors, which can include perishable ingredients like fruit. The shelf life of the raw materials and craft beer brings along the element of urgency, placing even more importance on on-time deliveries. Coordinating these shipments to ensure quality beer adds an additional layer of complexity to the logistics process.

REGULATORY COMPLIANCE

Navigating the web of regulations for shipping beer in logistics can be a considerable challenge. Regulations for shipping alcohol vary from state to state, meaning you’ll need to be compliant based on where you are shipping to and from. Additionally, state laws will often change every few years, making it even more difficult.

Craft brewers must also find carriers with the correct licensing, knowledge, and experience to handle the unique requirements of transporting alcoholic beverages. It’s important to work with a logistics provider that knows all the ins and outs of meeting your product’s requirements and state regulations to prevent costly disruptions due to non-compliance.

MEETING CUSTOMER DEMAND

As craft brewers reach more customers, the more need there is for effective logistics planning. Having to juggle keeping track of supplies, determining the most efficient distribution methods, and preparing for any supply chain disruption can be overwhelming. Having a successful craft brewery goes beyond just brewing great beer, but ensuring it reaches the consumer when and where they want it.

Managing costs is on top of rolling out new beverages can be a significant challenge for craft breweries. Having efficient strategies, such as freight consolidation or finding the most cost-effective mode of transportation, can help keep costs in check. This is where an expert third-party logistics company (3PL) can assist with strategy and technology, like a transportation management system (TMS) for visible reporting.

3PL BENEFITS: BREWING SUCCESS WITH TRINITY LOGISTICS

While there may be difficulties to face in the dynamic world of craft brewing, partnering with a 3PL like Trinity Logistics can alleviate the burden. Here’s why working with us for your craft beer shipping and supply chain is the perfect recipe for success:

Our Only Job is Logistics

Logistics is what we handle day in and day out. When you trust us with your freight, you get more time to focus on what you do best – brewing exceptional beer and growing your business.

Experts in Specialized Shipments

Understanding the nuances of transporting freight with specialized requirements, such as temperature control, is our expertise. Whether it’s raw materials or the final product, we ensure everything arrives in optimal condition.

Regulation Compliance

Our dedicated Team and compliance department work diligently to ensure the necessary regulations are meant to provide you peace of mind and reduced risk.

Tracking and Tracing

We understand transparency is key to your success, so we offer several ways to view and keep track of your freight, no matter the time of day.

Effective Logistics Strategies

Whether you need help with something as simple as finding the most cost-effective mode of transportation to freight consolidation, we can help you find and implement strategies to optimize your supply chain and manage costs. It doesn’t matter if it’s just one or 20 pallets of freight, we can arrange full truckload, less-than-truckload (LTL), expedited, or any other mode you may need.

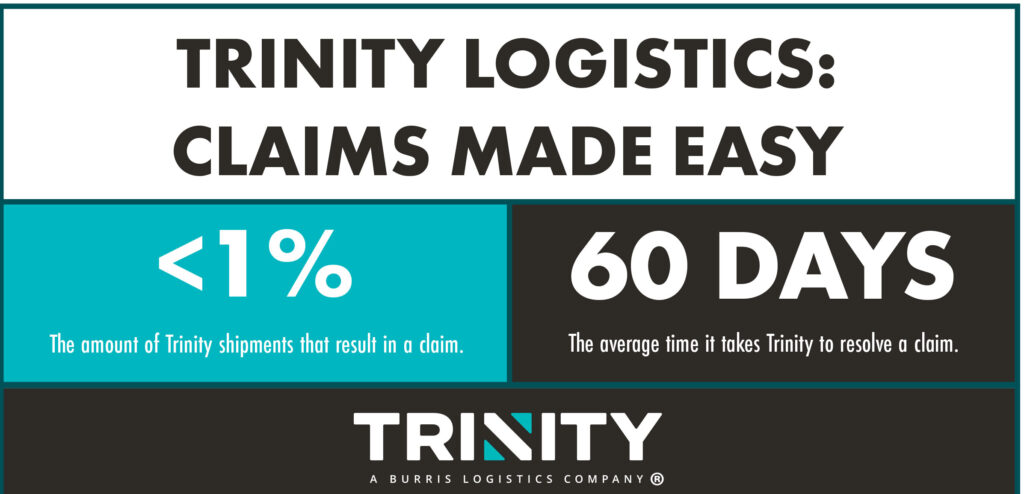

Reduced Risk

At Trinity, we meticulously verify all carrier relationships that we work with, not just during the initial setup but for every shipment. We’re also proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. If something does happen, we have a Cargo Claims Department at the ready to assist you in navigating any issues.

24/7/365 Support

No matter what happens, we’re ready to support you around the clock. We have a dedicated After-Hours Team to continue the monitoring of your freight and are ready to quickly resolve potential challenges, no matter the time of night, holidays, and every weekend.

Trustworthy Carrier Relationships

We treat and respect our carrier relationships just as much as our shipper ones. We aim to build a strong partnership with each one to help their businesses be successful. Because of that, we’ve built strong and trusted partnerships with those in our carrier network, providing you further confidence that your freight will arrive safely.

Managed Transportation

Whether you solely need a TMS for your transportation management, you’re looking for a fully outsourced solution, or something in between, we can help. We understand companies don’t come one-size-fits-all, and neither should the services you need to optimize your logistics. Our Managed Transportation services cater to businesses of all sizes and needs, capable of growing right alongside your brewing venture.

Partnering with Trinity Logistics offers you more than just transportation services. We’re a trusted, strategic ally that’s invested in seeing your business succeed. Leave the logistics to the seasoned experts, so you can focus on creatively and passionately brewing while we ensure your craft brews reach your consumers right when they want it.

LET US HELP WHAT ALES YOU IN LOGISTICSRefrigerated trucking can be a complex, but rewarding job.

You might be transporting anything from fresh produce, frozen food, or important medicines like biologics. But, no matter what it is, the items you’re hauling are vital to many and there’s great pride that comes with that.

Refrigerated trucking is not only more specialized than dry freight hauling but offers more earning potential, and there are certain times of the year during which you can count on higher freight volumes to keep your company profitable.

Whether you’re new to refrigerated trucking or a veteran, it’s important your company knows how to properly transport temperature-controlled products, from pick-up through delivery. At Trinity Logistics, we sometimes see claims on temperature-controlled shipments, and we want to help you avoid any costly mistakes with a few tips specific to refrigerated trucking. So, we’ve crafted this guide to help you prepare for your hauling your next temperature-controlled shipment.

MOTOR CARRIER REFRIGERATED TRUCKING RESPONSIBILITIES

The purpose of the Food and Drug Administration’s (FDA) Food Safety Modernization Act (FSMA) is to prevent foodborne diseases, and FSMA rules contain essential requirements for shippers, loaders, receivers, and carriers like you to follow with refrigerated trucking. FSMA requires those transporting food to follow best practices for sanitary transportation, such as proper personnel training, maintaining shipment records, and following shipper instructions to keep food properly temperature-controlled during transit.

FSMA Responsibilities for Motor Carriers

Keeping Your Equipment Clean and Operable

You must keep your refrigerated trailer clean between loads and make sure it is running efficiently to maintain any required temperatures to keep food safe while transporting.

Your Equipment Must Meet the Shipper’s Needs

Shippers are responsible for communicating any food safety requirements to providers they work with, such as specifying temperature and pre-cooling requirements in writing. It is your responsibility to adhere to those requirements specified by the shipper.

Keeping Records

When it comes to FSMA, verbal confirmations don’t stand. Shippers and providers you work with require records of previous cargo hauled, equipment cleaning, inspection, and temperature records. This includes recording if your reefer fails or containers are compromised, allowing contaminants in, and showing via documentation that you took action to correct the issue. Keeping thorough documentation will help you, in the long run, should you face any potential claims. It’s recommended to keep all records for 12 months, minimum.

Training Employees

Under FSMA, motor carriers must train all drivers and transportation personnel on their role, FSMA rules, the awareness of potential food safety problems like cross-contamination that can occur during transportation, and sanitary transportation practices. It’s also important to keep records of this training and hold refresher training from time to time.

PREPARING FOR REFRIGERATED TRUCKING AND TEMP-CONTROLLED TRANSIT

*This blog content provides suggestions only and is not meant to take the place of your own company procedures.*

Cleaning Your Refrigerated Trailer

1. If the previous receiver cleaned your trailer, request documentation from them to share with the shipper for your upcoming temperature-controlled shipment. It’s important to keep any trailer washout records and receipts to provide to shippers upon request.

2. Open your refrigerated trailer and remove any items that shouldn’t get wet.

3. Sweep out any debris.

4. Prepare a bucket of food-grade detergent and water.

5. Scrub all interior surfaces with a clean cloth and the detergent mix.

6. Use a hose to spray down the inside, including the ceiling and walls. Pay special attention to any cracks and crevices.

7. Keep doors to the trailer open, allowing the inside of the trailer to air dry.

8. If the outside of the truck and your trailer is dirty, wash down the exterior as well.

Pre-trip

1. Review shipping instructions and confirm the cargo is at the required temperature before it is loaded. Refrigerated trailers are meant to maintain temperature, not change it. For fresh produce, verifying temperature usually involves pulping product with a thermometer or probe dial.

2. Run your refrigerated trailer for at least 20 minutes in “high speed cool” mode to remove any residual heat. Pre-cooling may take more than one hour depending on factors such as equipment and ambient temperatures. Therefore, be aware of the temperature requirements in advance to ensure equipment is at the proper temperature before you arrive at the shipper and the loading process starts.

3. Perform an automatic pre-trip test to confirm that your refrigerated trailer is running properly and confirm that it passes the test. Keep a record of this. If your auto pre-trip test fails, refer to your company’s prescribed procedures or contact your maintenance provider for repair.

4. It’s time to set your refrigerated trailer to the required temperature specified by the shipper. Verify the set temperature after adjusting it to its requirement to confirm it is set correctly. Next, confirm that the unit is set to the correct date and time. If this is not done and the shipper requests a reefer download after delivery, the data will be inaccurate. Some drivers will take a picture of the reefer unit dashboard to document settings before they leave the shipper.

5. Confirm that you have the correct mode of operation selected on the reefer unit prior to loading. Again, refer to your shipment instructions for this. Often, the shipper will require perishables to be hauled in continuous mode as opposed to cycle sentry or stop-start cycle.

6. Allow your refrigerated unit adequate time to pre-cool before loading.

7. Document all pre-trip cleaning, inspecting, and pre-cooling to share with the shipper upon request.

Loading

1. Ensure you witness the loading process, visually confirming product temperature, count, and quality match your shipment tender. If a carrier cannot verify loading conditions or discrepancies exist, the carrier notates the issue on the bill of lading and request the shipper to sign this.

2. Carriers are responsible for the final blocking and bracing of product, so make sure items are not over-stacked or loaded in a way that impedes airflow or circulation. As a carrier, if you are not comfortable with the load condition, you have the right to refuse the shipment.

3. Once loaded and final blocking and bracing are completed, immediately close the doors to maintain temperature. Once again, verify that the correct cycle and temperature are set. If a trailer seal is required, its presence should be documented on the bill of lading by the shipper.

During Transit

1. Make use of the strip curtains as this helps keep temperature-controlled air in and any outside air out.

2. Limit the number of door openings throughout transit to keep temperature-controlled air in and outside air out. Only allow doors to be opened by verified shippers or receivers.

3. Keeping proper airflow is critical. Even with adequate running equipment, poor air distribution can cause spoilage. Verify all sides of the cargo have proper airflow before your trip and any time you make a stop.

PULPING FOR REFRIGERATED PRODUCE SHIPMENTS

Pulping is an essential task when hauling produce with your refrigerated trucking. Pulping is the act of taking the product’s temperature before and upon delivering the shipment.

How to Pulp Produce

For produce that is unbagged, one must insert a pulp thermometer into a piece of produce, inserting for three to four minutes to get the most accurate reading.

If the produce is bagged, like salad mixes, fold the bag in half and place the probe between the two sides, with the produce as close to the thermometer as possible.

Why Pulping is Important

Before loading, it is the shipper’s responsibility to pulp the product, and should be done in the presence of the driver. However, it is the carrier’s responsibility to confirm the proper temperature of the product before allowing it to be loaded on the truck, so there may be the case you need to pulp the product.

Pulping temperatures should be recorded on the shipment’s bill of lading and signed by both the shipper and driver. This can help protect both the shipper and motor carrier from claims if the product arrives at its destination off temperature.

Throughout transit, it is the carrier’s responsibility to monitor the refrigerated trailer temperature, usually with some sort of sensor technology providing real-time information, or with older refrigerated trailers, a temperature download that is available upon delivery.

Upon delivery, it is the receiver’s responsibility to pulp the product for a temperature read and to determine if the shipment will be accepted.

Under FSMA, be prepared to provide a record of temperatures in transit via reefer download. Failure of a carrier to provide a record of unit temperatures in transit will prevent a carrier from disputing temperature deviations should there be a claim.

TEMP VARIANCES – HOW MUCH IS TOO MUCH?

One thing you may be asking with your refrigerated trucking is, how much is too much when it comes to temperature variances? Well, that can depend on several factors.

One factor is the type of product. For example, there are some perishable products that are very sensitive to temperature variances, where even a two-degree difference could reduce the shelf life by 50 percent.

Another cause could be the location where the temperature was taken in the trailer or the recording device’s accuracy. Or if a shipment has multiple stops versus one that goes right to the destination.

Temperature variances are usually expected, so it’s important to determine when a variation is tolerable versus when it places the product at risk for spoilage.

It’s also important to note the amount of time the product has been off temperature. For example, frozen goods might be subjected to some temperature variance without much effect on the shipment, whereas refrigerated goods often spoil at a quicker rate.

When it comes to claims due to temperature variances, there simply is no one-size-fits-all for processing these. Shipment claims due to temperature variances are treated on a case-by-case basis depending on the above-mentioned factors. Verifying temperature prior to loading, maintaining proper temperature in transit, and the ability to provide a reefer download documenting transit conditions are ways for carriers to prevent temperature damage.

WHAT IF THERE’S AN ISSUE AT DELIVERY?

First and foremost, be sure to communicate your transportation status and any issues to your point of contact in real time. If there are any overage, shortage, or damage issues at delivery, the receiver should document it on your bill of lading (BOL). If there is a reported issue and you are unclear about the next steps, contact your insurance agent to report the issue and request direction.

If the product is produce, a USDA inspection may be requested to document the condition of the product.

Whenever a temperature problem is reported, get a reefer download for the trailer used for the shipment to document the temperature conditions for the time the cargo was on your truck.

Your cargo policy will not pay for temperature damage if it is caused by an incorrect reefer setpoint or driver negligence. However, if your refrigerated trailer experiences issues during transit, your cargo insurance may step in to pay a cargo claim related to any temperature damage. However, be prepared to provide supporting documentation. To be proactive in the prevention of any issues caused by your equipment, it’s important to perform regular maintenance according to your cargo insurance requirements and company guidelines.

REFRIGERATED TRUCKING – SHIPPER RED FLAGS TO LOOK FOR

There are a few shipper red flags to look out for before accepting a refrigerated trucking shipment or having your trailer loaded.

Mixed temperature shipments can be a red flag. Sometimes shippers will want to try to ship products together that need vastly different temperature requirements to reduce costs, like fresh and frozen products. These types of shipments are “high risk” and not recommended. Whether a shipper is using a bulkhead or not, to keep your company safe, it’s recommended to avoid shipments that combine frozen, fresh, or dry loads on the same truck.

Now, let’s say you’ve accepted a refrigerated trucking shipment but when you arrive at the shipper you notice one of these things:

- There is food labeled improperly (no USDA logo),

- Spoiled or overripe food products or evidence of spillage, such as juices or blood in the cargo area,

- Food products being shipped with chemicals,

- Evidence of product tampering, like a broken seal or cut tape on boxes.

If you notice any of these things, do not get loaded and immediately contact the Food Safety Inspection Service (FSIS).

EASILY FIND THE TEMP-CONTROLLED SHIPMENTS YOU’RE LOOKING FOR

Now that you’re prepared to handle the complexities of refrigerated trucking, it’s time to find available shipments. Here’s where Trinity’s Carrier Portal is beneficial.

Our online load board allows you to search for available shipments, filtering by equipment, lanes, and more. Many of our available shipments even allow digital freight matching, providing you the opportunity to Quote Now or Book Now, saving you time from calling or emailing in. Additionally, new shipments get directed to our Carrier Portal first, meaning you’ll have access to exclusive Trinity loads before they get posted to the public load boards!

Find my next refrigerated trucking shipment*This article provides information only and should not be construed as advice. It is provided without warranty of any kind.*

It’s produce season. That time of the year when produce shipments are at their peak and so are produce shipment rejections. According to DAT, up to 12 percent of shipments are rejected or delayed. Produce shipments are most often rejected because of the complexities of fresh food logistics. Because of their perishability, they are more likely to experience damage in transit due to improper handling, temperature variances, or delays.

A produce shipment rejection can cause lost time, added fuel and shipping costs, wasted product, and sometimes even a strained relationship with your customer. In addition, these rejections can cause a domino effect of added issues, costs, paperwork, and make everyone’s day longer than it needs to be. Yet, with attention to detail, planning, and effective communication, you can prevent produce shipment rejections and manage your costs. Here’s some advice on preventing shipment refusal during produce season.

| ARTICLE CONTENTS |

| REASONS TO REJECT PRODUCE |

| WHAT TO DO WHEN PRODUCE IS REFUSED |

| PRODUCE SHIPMENT REJECTION PREVENTION |

| HAVING HELP WITH PRODUCE SEASON |

REASONS TO REJECT PRODUCE

With fresh produce being on average, 90 percent water, it’s a volatile product to ship. It can develop issues at any stage, during growth, harvest, storage, packing, or shipping. This makes the logistics of shipping produce that much more complicated. As a result, there can be many more reasons for produce shipment rejections to happen. So, what are some reasons for a produce shipment rejection?

Paperwork Errors/Wrong Product

The Bill of Lading (BOL) must match the shipment delivered. When the receiver checks the BOL to verify the purchase order (PO) number, skid, case count, and weight of the freight delivered, and it doesn’t line up, then the shipment may be rejected. This could happen for several reasons. For example, the product could be what they asked for but the wrong amount, or the product could be completely different. However, any discrepancy between what they ordered and what arrived will mean a rejected shipment.

*Important to note: A produce shipment should not be rejected if there is less than 50 percent of the product short or damaged.*

Pallet Configuration

Some customers require that the product arrives according to their specific guidelines for packaging. If their requested guidelines are not followed, or anything shifted, fell, or ripped while in transit, then they may refuse the shipment.

Improper Temperature Range

Maintaining integrity and freshness is serious when it comes to a perishable product like produce. If your produce shipment falls out of its needed temperature range, even by one degree, the receiver may reject your shipment. Unlike other types of freight, the chance for spoilage with produce is too high, so a receiver won’t often take on the liability with any temperature variances.

Delivered Late

Often, retail and grocery distributing centers operate on tight schedules, so a delay could impact their other appointments. Unfortunately, this means they rarely make exceptions when it comes to late shipments and your produce will be rejected.

Equipment Issues

The trailer could have been unable to keep the temperature in the range needed for your produce shipment or perhaps the trailer was not washed thoroughly before loading. Maybe the carrier showed up with a van and you needed a refrigerated trailer. There are several issues in which the trailer your shipment is delivered in can have the receiver refusing your product.

Reasonable Time to Reject

One important thing to know about produce shipment rejections is that there is a reasonable time for the receiver to reject the shipment. When shipping by truck, the receiver must not exceed eight hours to inspect and reject. When shipping by rail, the receiver must not exceed 24 hours to inspect and reject.

AS A SHIPPER, WHAT TO DO WHEN PRODUCE IS REFUSED

Many issues associated with rejected produce shipments can often be resolved quickly with extra communication and planning.

You’ll first need to figure out why the receiver rejected your produce shipment, so start with asking your receiver that. Ask for pictures showing any damage and a copy of the BOL. Next, ask for the report by the USDA inspector or another qualified individual, as it’s required for the receiver to have the shipment inspected, note any issues, and detail what the cause of damage was. Additionally, ask your carrier for a reefer unit download or a temperature recorder download so you can see if there were any temperature fluctuations during transit.

If you’re considering filing a cargo claim, you must know that cargo claims for produce will only be paid for proven physical damage.

Now, if a produce shipment is rejected and not unloaded, there are a couple of options for you to try to recoup the loss. You can reroute the shipment to a different facility that will accept it, donate the shipment, or have the carrier dispose of it. Regardless of which option you choose, you are responsible for handling where the shipment will go next.

What are any secondary markets the produce can go to if messed up? What’s the disposition? You’ll be the best resource for the area’s market. Be familiar with your shipping lanes and the secondary markets within your location to best salvage the produce if refused.

Secondary Facility

As long as your produce is still safe for consumption and solely rejected for the way it looks, you might be able to sell the shipment to a secondary facility. For example, a sauce maker or a french fry company might be willing to buy a shipment of tomatoes or potatoes that are still edible but visually unappealing.

Donation

It can be possible to reuse a rejected produce shipment through local donation, though there are still high standards for products if donated. Any food and beverage products donated must be safe enough to consume. Donations can be optimal as your produce can still be used, and you can receive tax credits for your donation.

Disposal

If your produce shipment is rejected due to a temperature violation or clear spoilage during transit, disposal may be your solution. When your produce is determined to be unsalvageable, it may be best to dispose of it. Although the other two options are better for the environment and your bottom line, it’s sometimes a necessary evil to dispose of the product. While recycling and reusing are ideal, they may not be workable due to compliance and safety standards. One of the benefits of disposal is that scheduling disposals are often quicker than scheduling to another facility.

Maintaining a Good Customer Relationship

Shipment rejections can stress even the best relationships. It’s best to keep in mind that you are in it for the long haul and produce shipment rejections that can happen even to the best of shippers due to its complexity.

It’s best to acknowledge the rejection, replace the product as soon as possible, and find the source of the issue to help reduce the chance of another produce rejection happening anytime soon. Take ownership of the problem and control of your shipment so you can manage your money from the salvage. Taking control over the disposition will help you maximize your return, reduce claimed damages, and reduce your risk of customer relationship loss.

While these are all great solutions for handling produce shipment rejections, it’s ideal to prevent them in the first place. For companies looking to focus on their bottom line, it’s important to know all necessary prevention measures for produce shipment rejections and plan for when they do happen.

PRODUCE SHIPMENT REJECTION PREVENTION

Paperwork and Communication

The first step to preventing produce shipment rejections is to have your paperwork and communication in order. Your agreement must be clear on the condition of the produce your buyer will receive. Being able to present your buyer with evidence that your produce is safe and of the quality you stated it’s in before transit will prevent most cases of rejection.

Communication with your buyer and your logistics team on how your produce is being handled before loading, during loading, and during transit must be done effectively and properly. This is especially crucial because of the Food Safety Modernization Act (FSMA). Be sure to provide photos, diagrams, or any other examples of proper pallet configuration to your warehouse and trucking partners. This kind of communication will help them pack and load your freight correctly from the start.

Carrier Selection

Produce shipments, especially during produce season, often pay a lot. This means you’ll have a lot of carriers bidding to haul for you. Therefore, quality carrier selection and additional insurance requirements, like reefer breakdown, are crucial aspects to prevent rejected produce shipments.

Make sure you confirm with your motor carrier that they are both authorized and experienced to haul your produce.

Additionally, make sure they understand all your shipments requirements, including FSMA. For example, do they need washout receipts? Do they have a good quality truck, updated trailer, or a quality reefer? Do they have or need temperature-monitoring devices or other technology to ensure the temperature is controlled and the cold chain uninterrupted? Can they pull a reefer download if required?

By finding a quality carrier and building a strong relationship with them, you’ll gain a dependable carrier to use regularly. This can help you reduce any transportation-related issues that could later result in a shipment rejection.

Loading

Don’t Overstack

When it comes to produce season, the number one cause of claims that we see comes from over-stacking your boxes or bins of produce when loading them onto the trailer. An example of this would be triple or quadruple stacking your boxes when they need to be double-stacked. While this depends on each shipping location, not all may be aware that each box has a maximum capacity it can withstand and not damage your produce. You need to know the weight-bearing amount of your boxes so you can place no more than that. When you over-stack, it’s will increase the risk of your produce getting squished and damaged. Certain produce can be very fragile, like berries, tomatoes, asparagus, or bananas. They tend to bruise easily, so single-stacking boxes are even more ideal for them.

No Hot Loads

Industry experts say that as much as 32 percent of all cargo is loaded at the wrong temperature.

This is often due to poor loading practices, like loading from a hot field. When it comes to produce, loading from a hot field is a HUGE NO. This causes the driver to start traveling with your produce at the wrong temperature, which puts compliance and financial pressure on carriers, as the load is at a high risk of spoiling. Your produce should be safely brought down to its required transit temperature before loading to prevent any spoilage.

Have the Proper Equipment

While this may seem silly, it still needs to be said: If a motor carrier shows up with a dry van and your produce requires a refrigerated trailer, DO NOT LOAD. While losing some time or causing a bit of a delay is not ideal, it’s better to have the proper trailer needed to keep your risk of shipment rejection from spoilage or damage low. Additionally, make sure your carrier’s refrigerated temperature monitoring system has the proper temperature, date, and time set. If there is a rejection due to temperature variance and the date and time are wrong, you’ll take the blame due to current regulations.

When it comes to your motor carrier and loading, it’s also ideal to allow them to inspect and pulp your product before loading. They have the right to do so, and the opportunity can give your carrier the confidence to haul your product safely. It also helps build a strong and loyal relationship, while helping you gain more insight that your product is okay before it’s in transit.

Keep Clean of Debris

Another way to help prevent produce rejections is to have a shipping platform that can be cleaned without leaving any splinters or debris in vehicles. Food-grade plastic pallets are ideal for solving many hygiene issues while helping reduce product damage during transport. Unlike wooden pallets, they don’t splinter or leave behind debris, and their nonabsorbent surface can be easily cleaned and dried.

Transit and Delivery

As mentioned during loading, make sure you have a way to track temperatures throughout the shipment and be able to receive notifications in real time. By getting early warning signs of issues, temperature variations can be quickly detected and dealt with right away instead of learning about them later at delivery.

Additionally, make sure you have a qualified inspector on-site at delivery. This will help should the receiver decide to reject your produce shipment to determine if your product is salvageable for you to recoup costs.

Before transit, it’s best that you set up the potential for rework facilities to accept your produce should the receiver refuse it. Talk to nearby receiving facilities to establish accounts, processes, and pricing ahead of time. This way, if there has been some visual damage or slight shifting, it can quickly reroute to the other location and be reworked, being proactive rather than reactive. This is especially important when it comes to produce since time is of the essence.

HAVING HELP

Produce shipment rejections can be complex and confusing at times. This is where working with a third-party logistics company (3PL), like Trinity, can come in handy. We have Teams to help you with the prevention of rejections as well as when one does happen.

Carrier Compliance

Our Carrier Compliance Team is here to vet our carrier network and make sure they have what you need to get your shipment delivered safely. Not only do we have a rigorous vetting process, but depending on your shipment requirements, we’ll make checks for extra insurance needs like reefer breakdown and make sure they are FSMA compliant.

Claims

No matter how prepared one can be, unexpected things can still happen. Shipments may get refused and so that’s why we have a Claims Team here ready to assist you. It can be a real lifesaver to have a Team of certified professionals to help take the stress out of the claims process. Should it be needed, our Claims Team will help you start the process, be there to track progress, and assist until a resolution is met between all involved parties.

DON’T GO THROUGH PRODUCE SEASON ALONE

With proper prevention, compliance, and planning, produce shipment rejections can become less of a thorn in your side during produce season. Even still, they can and will happen at times. Make sure you’re ready and have the support you need by working with an experienced provider such as Trinity.

You’ll have the advantage of working with and trusting our risk departments, who work hard to help mitigate any risk to your shipments. In addition, you can trust that each of our carrier relationships is properly vetted for things like reefer breakdown coverage. Should you need it, you’ll have a whole Claims Team ready to help you sort through any unexpected shipment issues.

Gain the support you need to navigate the complexity of produce season with less stress.

LEARN HOW WE SUPPORT PRODUCE SHIPPERS HELP ME WITH PRODUCE SHIPMENTSInterruptions to the cold chain create problems such as spoilage, changes in the appearance, taste, or smell of a product, growth of harmful bacteria, or lost potency. Preventing any interruption of the cold chain is one of the main responsibilities of a logistics manager. Let’s look at some of the significant cold chain challenges you may have to face, and how you can keep issues at bay.

REGULATIONS

Regulations for the cold chain are ever-changing and complex, which is why they are one of the major challenges faced today. If your cold chain is worldwide, it can be more complicated as there is no one entity to regulate on a global scale. Each region has its own regulations, compliance mandates, and enforcement agencies. Some examples of these are:

U.S. Food and Drug Administration (FDA)

In the U.S., the federal regulatory agency for food and pharmaceuticals is the FDA.

Most cold chain food regulations come from the FDA’s Food Safety Modernization Act (FSMA) of 2017. This regulation covers the cleanliness and function of equipment, protocols set in place for transportation, employee training on the proper handling of food in cold chains, and records of all FSMA compliance.

When it comes to pharmaceutical products, many regulations affect the cold chain. Some of those include:

- 21 CFR 203.32

- Addresses the need for maintaining drugs under stable conditions and meeting manufacturer’s specifications.

- 21 CFR 211.150

- Provides guidance on the written procedures for managing expirations and a reliable system for identifying the distribution of drug samples in the event of a recall.

- 21 CFR 203.36

- Outlines the responsibilities of manufacturers and authorized distributors.

- 21 CFR 205.50

- Minimum requirements for storage and handling of prescription drugs and maintenance of distribution records

Canadian Food and Drugs Act

In Canada, the regulatory authority is the Government of Canada. The Canadian Food and Drugs Act was passed in 1920 and revised in 1985. It regards the production, import, export, and transport across provinces for food, drugs, and cosmetics including products like soap and toothpaste. It ensures products are safe, ingredients disclosed, and drugs are effective.

International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH)

Many other countries, refer to ICH guidelines gathering data on a product’s safety and efficacy to establish a cold chain strategy. ICH brings together many regulatory authorities to discuss data and establish those guidelines. Gathered data is used to consider the duration of temperature excursions that can occur across distribution channels.

Regulations can be complex and demanding at times, but they all have the same goals of retaining the safety, quality, transparency, and efficacy of cold chain commodities. The biggest key to keeping compliance with cold chain regulations is increasing end-to-end visibility in your cold chain. Keeping proper documentation of data throughout your supply chain can seem difficult but modern technology like a transportation management system (TMS), can simplify this cold chain challenge. Current technology applications like GPS tracking, ELD data, Internet of Things (IoT), and a TMS can give you advanced analytics and reporting that would otherwise be comprised of manual processes. Not only does technology offer you savings in time but of human error as many processes become automated.

SUSTAINABILITY

Another significant cold chain challenge is the increasing spotlight on sustainability. The distribution and transportation of temperature-controlled products have shown to be major causes of greenhouse gas emissions. In comparison to other supply chain transportation, cold chain transport consumes 20 percent more fuel than other heavy vehicle types due to the refrigeration equipment. The biggest issue facing sustainability is the high-power consumption or combustion of fossil fuels necessary to power the cold chain’s cooling systems.

There are also growing issues and increasing regulations on refrigerant gases used in cooling systems like hydrofluorocarbons (HFCs) as they are responsible for high greenhouse gas emissions. In 2015, the European Union set strict limits on the production and sale of high global warming potential HFC refrigerants. In the U.S., the Manufacturing Act of 2019 was passed which established a timeline of phasing down the use of HFCs by 2036.

Because of the increasing pressure of sustainability and its regulations enacted on the cold chain, many large food and pharmaceutical companies have plans in place to reduce their carbon emissions. In 2015, more than 150 businesses in the U.S. signed the Business Act on Climate Pledge which launched for private sector businesses to express their support on international action on climate change. Also, in 2015, the Paris Agreement was created, signed by 195 countries at the United Nations climate change summit. This agreement aims to reduce greenhouse gas emissions to prevent the planet from warming by more than 2 degrees Celsius.

Being sustainable in the cold chain is also something you can be recognized for now with awards such as the Supply & Demand Chain Executive Green Supply Chain Award or the Council of Supply Chain Management Professionals’ Supply Chain Sustainability Award. Some ways to consider in adding sustainability to your cold chain is improving your cold chain management to reduce waste and your carbon footprint or considering alternative transportation modes like intermodal versus truckload when shipping your products. While you’re working on improving sustainability in your cold chain, make sure the providers you work with are equally interested in sustainability as well. Here at Trinity, we are proud of our sustainability efforts and to be recognized as a SDCE Green Supply Chain Award winner and as a Food Logistics’ Top Green Provider.

TEMPERATURE VARIANCES

It’s one of the biggest and most common cold chain challenges: maintaining the required temperature of the product throughout the entire supply chain. Any temperature that is higher than the set temperature can affect a product’s quality. Not all products that get exposed to a temperature past their threshold will spoil right away, as it depends on how steep and frequent the exposure was. Once a product has begun to thaw, it is considered contaminated. Depending on the product and temperature, that window of time can be very short. There are many times during cold chain in which a product can be exposed to a temperature variance: during unloading and loading of the product, from poor packaging, handling, or broken equipment.

Loading and Unloading

As your product moves through the cold chain, it can get exposed to temperatures outside its set temp. Whenever loading and unloading your product, handling should be as quick as possible. Preventing prolonged exposure to temperature changes prevents having problems with quality.

Poor packaging or handling

There are many different ways to package your cold chain freight so it can keep its cool. If it’s not done right or in mind of your transit time, your goods can spoil before arrival. When handled poorly, they can become damaged, causing lost product.

Equipment problems

One way the cold chain can be interrupted is when your equipment breaks down. Refrigeration equipment can malfunction due to damage, inadequate maintenance, or losing power.

In cold storage, doors becoming damaged are one of the common challenges they face. When cold storage doors become damaged, they can’t maintain their specified temperatures.

Due to inadequate maintenance, there can be a buildup of condensation in coolers and freezers, causing slippery surfaces and unsafe conditions for workers, as well as a spoiled product. Another maintenance challenge is handling the growth of mold or mildew, which can happen with poorly maintained temperatures. Should this happen, the freezer will need to be cleaned thoroughly and inspected for any problems.

Transportation Breaks Down

Vehicles can break down at any time. Any hold-up in your cold chain shipment could mean more than just a time delay, it can mean a spoiled product. Make sure you’re working with a qualified carrier who inspects their truck or other modes of freight before the journey begins.

Keeping track of the temperature throughout your cold chain is another way to combat having your products exposed to changes in temperature. Temperature monitoring systems are quickly replacing any manual processes of collecting temperature information, saving time, and preventing spoiled products. This also allows cold chain managers insight into their problem areas and being able to fix them.

Some of these temperature monitoring systems are RFID or wireless sensor network, thermal imaging, and temperature loggers. RFID or other wireless sensor networks are the most common in the cold chain. These sensors capture the location and temperature, communicating the information back to a database and allowing parameters like an estimated shelf life to be calculated. You’ll often find these in warehousing and cold storage. Thermal imaging is exactly what you think it is; imaging that is taken showing the different temperatures of everything in the photo. Thermal imaging uses a sensor to convert the radiation given off at different temperatures into a visible light picture. This is also often used in warehousing and cold storage. Lastly, temperature loggers are another type of sensor placed next to cargo in transportation. They can be set to record as frequently as every second, minute, or hour. Once removed, they can be plugged into a computer so the temperature data can be transferred and analyzed.

TEMPERATURE-CONTROLLED SHIPPING CAPACITY

Another significant cold chain challenge is available capacity. Capacity is always a challenge for any industry, but even more so for the cold chain, especially right now. With freight in high demand across all industries and capacity slim, drivers can pick and choose what shipments they want to take based on (already) high rates. Reefer trailers are already limited with the increased demand on cold chain, but when rates for moving other high-demand commodities such as lumber or retail keep increasing, those drivers can choose to utilize their reefer trailer as a dry van to haul should those rates be better paying, further reducing cold chain capacity. Cold storage warehousing is seeing the strain as well because of the growing freight demand. More storage space is needed in the supply chain and new buildings are being built, but those currently in production or needing their building supplies (which are also in high demand), puts yet another strain on shipping capacity until that demand has decreased. With the cold chain demand increasing and available equipment and drivers doing quite the opposite, can the logistics sector keep up? Read more in our current whitepaper.

DON’T LET THE COLD CHAIN SCARE YOU

There is a lot of juggling to do when managing the cold chain. If even one ball is dropped, it can affect the whole cold chain. You can prepare as best as you can for these cold chain challenges, but sometimes it’s nice to know you have backup when you need it most.

Luckily here at Trinity, we’re experts in complex situations. In fact, I would say it’s our specialty. We’ve seen every possible problem there could be and are happy to help. By working with Trinity, you can gain access to the data you need to improve your performance and output, find equipment and capacity when you’re finding it difficult, and work with someone who understands current regulations, no matter the region or type of commodity you work with. We’re here to have your back regardless of what cold chain challenge comes your way.

Simplify your cold chain challenges.Not ready to request a quote? Subscribe to our YouTube channel and watch our latest State of the Industry and Freight Market Update videos to stay on top of what’s going on in cold chain.

Author: Christine Morris

Frozen food is considered one of the safest forms of food preservation because the freezing temperatures prevent harmful bacteria. This doesn’t necessarily mean that frozen food is foolproof. Several situations that could cause your frozen food to go bad and ways to prevent them from happening. If you’re new to shipping frozen food, or you’re a seasoned veteran staying up to date with the ever-changing world of cold chain logistics, here are a few things to keep in mind that can impact your company’s bottom line.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

Improper Packaging

Improper packaging is the most common mistake in frozen food shipping. It may also be the most involved part of your process. Multiple layers of packaging and ensuring an airtight seal to eliminate any heat or humidity penetration is critical. Your packaging’s inner layer should be waterproof to prevent any leakage from melting refrigerant causing damage to your outer packaging.

The person responsible for packaging your frozen food should have a strong understanding of dry ice and how to store it in proper containers. Although it a great source for cold chain packaging, it could be detrimental to your shipment if misused. If dry ice is packaged in an airtight container, there could be a pressure build up and cause that entire container to burst.

Package your frozen food with the proper amount of dry ice or frozen gel packs to prevent temperature fluctuations from happening. You should also ensure that you have the proper sized box to store your products. Too large with extra space means your goods could become damaged in the process of moving.

To prevent improper packaging, ensure that you have full knowledge of the temperatures required for that shipment and what type of insulation you want to use. Partnering with a 3PL that works with vetted carriers that have a strong understanding of how to transport frozen food will also save your shipment from spoiling or getting damaged.

Underestimating Shipping Times

When you underestimate shipment times, the result could impact your bottom line. If your product arrives to its destination melted or spoiled, you’ll end up with rejected products. This means money lost.

Plan your frozen food shipments ahead and research estimated transit times so you can pack enough coolant material. This will also provide insight on which refrigerant choice would work better for that shipment. One to two blocks of dry ice will last between 18-36 hours in a small Styrofoam shipping container. In a larger shipping container, dry ice can last between two to three days. It’s never a bad idea to make sure you have enough refrigerant packed so that it could last an extra day or two should your shipment have some unforeseen delay. Communicate the estimated transit time with your third-party logistics provider to ensure that the carrier shipping your frozen food has all the necessary information.

Not Properly Recording Information

Keep record of every detail about your shipment. This is paramount to staying compliant with the Food Safety Modernization Act (FSMA) and proving that your business has done everything possible to prevent the spread of foodborne illness. This includes the proper labeling of packaging, any providers used, and temperature records from before, during, and after transit.

The FDA Food Safety Modernization Act (FSMA) is transforming the nation’s food safety system into one that is based on the prevention of foodborne illnesses. Our team stays updated on these regulations and have processes in place to stay compliant.

Not Using a Qualified Provider

Maintaining the correct temperatures when shipping frozen food means maintaining its quality. You should make sure you choose a provider who is experienced with your frozen food product. Don’t make the mistake in trying to lower shipping costs by shipping mixed temperature goods together, which if not done properly, can compromise their quality and result in rejection of your product. Shipping mixed loads can be done, but you need to make sure it’s with a provider that has trucks with separate compartments capable of holding different temperatures, and the experience to handle it.

Finding and building a relationship with a qualified, experienced carrier to haul your frozen food products can be a long and time-consuming process. At Trinity, we have a network of over 70,000 qualified carrier relationships to help you.

Why not choose to save some time?

Request a QuoteShipping produce can be a bit tricky. Produce is time-sensitive to make sure consumers at its freshest. Certain produce can be sensitive to pressure, like peaches, that bruise easily. Other produce requires certain temperatures to keep it at its freshest. It’s a juggling act to make sure your produce is at its highest quality when delivered to your customer.

When shipping produce, you need to consider temperature, shelf life, and transit times. Here are three tips to making the process as easy as possible.

Tip #1:

Give as much lead time as you can for orders.

Normally more time means better shipping capacity. Not every truck can haul fresh produce. Refrigerated trucks or reefers are ideal to transport produce because they can adjust and keep temperatures where they need to be for your product. Especially during produce season, the more lead time, the better chance of finding an available reefer at a decent shipping rate.

Tip #2:

Make sure the carrier or transportation partner you select is FSMA (Food Safety Modernization Act) compliant.

Passed in 2011 and implemented in 2017, this regulation focuses on maintaining food safety during transportation. Its goal is to prevent illnesses from contaminated food. If found in violation of FSMA, you can be subjected to large fines and even imprisonment.

Tip #3:

Have detention rules clearly laid out.

Communication is key in your part of shipping produce. In the case of a delay at the farm or pick-up location, drivers can be notified ahead of time, keeping everyone on the same page. This also helps build up your reputation as a shipper of choice, so more quality carriers and transportation partners want to work with you.

Shipping produce is one of Trinity’s specialties. With Burris Logistics as our parent company, we have the warehousing, handling, tracking, and shipping solutions to accommodate you. Shipping produce can be complicated, but it doesn’t have to be. We can help you simplify it.

Looking for a transportation solution for your produce?

Check out our Temperature Shipping Guide.

Food manufacturers have to stay on top of changes, so they don’t fall behind or lose loyal customers. Consumer trends and interests often change, or other market disruptions come out of nowhere. Consumers today care more about health, fast shipping, and the environment. Food safety regulations and unexpected disruptions like the coronavirus have changed the market. Food manufacturers benefit when they choose an experienced 3PL provider who stays informed and can adapt to any changes quickly. This makes for less stress and reduced or no losses in business.

Health Conscious Consumers

Consumers are becoming more health-conscious with their food. They want fewer additives and more natural, organic products. Consumers are buying vegan or plant-based alternatives; food that fits their diet such as Keto, carnivore, or macro-counting. Fewer additives and healthier food mean fresher food with shorter shelf lives. This means quick shipping to keep food fresh and your consumers happy.

Faster Shipping

Due to the Amazon Effect, consumers expect even quicker shipping on everything. Shopping at brick and mortar shops is declining and consumers want to order everything online. According to studies by both Neilson and the Food Market Institute, fifty percent of Americans now buy all of their grocery products online. They want subscription boxes, such as ButcherBox, or meal subscriptions, like HelloFresh, delivered to their doorsteps. Direct to Consumer (D2C) is growing across all industries, especially the food industry.

Environmentally Mindful

With climate change being a hot topic, consumers are more aware of their carbon footprint now more than ever. They want less packaging used for the products they order. They want to know how the brands they shop from stay green and reduce their environmental impact; starting with how the product is made, to the packaging, the shipping, and more. Consumers worry more about how their impact on the environment and that falls back on the manufacturer as well.

Federal Regulations

On top of consumers’ changing demands, there are regulations to keep on top of as well. In recent years, food safety in transportation became a concern, so the Food Safety Modernization Act (FSMA) was created. FSMA is still a newer regulation that was put in place April 2017. Food safety in transportation is important, so there could still be changes to the regulation in the future.

Unexpected Disruptions

The novel coronavirus (COVID-19) rapidly made an impact on food manufacturers in 2020. Uncertainty from the virus caused consumers to buy out grocery stores, creating a high demand for those products. Restaurants shut down or switched to take-out only, causing a reduction in sales. Food manufacturers and the transportation providers they work with had to adapt fast. Hopefully, a crisis like COVID-19 does not happen again, but it is good to be ready for anything and be able to make changes quickly when needed.

Choosing a 3PL provider who stays on top of consumer trends, regulations, and other changes in the food manufacturing industry is important. Having someone who understands your challenges makes working to meet your customer’s demands an easier task.

Trinity Logistics stays informed about what goes on in the food manufacturing industry to better serve you. Concerning the changes mentioned above, Trinity Logistics;

• Makes use of many modes to arrange timely shipping for your natural and organic products.

• Through our parent company, Burris Logistics, we are able to offer you D2C services for faster shipping.

• Is SmartWay certified and has shipping arrangements that are better for the environment.

• Stays knowledgeable on federal regulations that may change shipping practices.

• Are ready to adapt to any huge industry disruption to keep your freight and supply chain moving.

Arranging the shipment of food has become a specialty of Trinity Logistics. When you come to us with problems, we’ll be there ready to offer you solutions. You can count on us.

Ready to work with a 3PL provider you can rely on?

Foodborne diseases are preventable and the reason why the Food and Drug Administration (FDA) put the Food Safety Modernization Act (FSMA) in place.

According to the Centers for Disease Control (CDC) each year foodborne illnesses cause;

- 48 million or 1 in 6, people in the U.S. get sick,

- 128,000 to get hospitalized,

- and 3,000 deaths.

The above statistics made the FDA realize how big of a deal foodborne illness has become and that something needed to change. Thus, came the addition of FSMA to regulations.

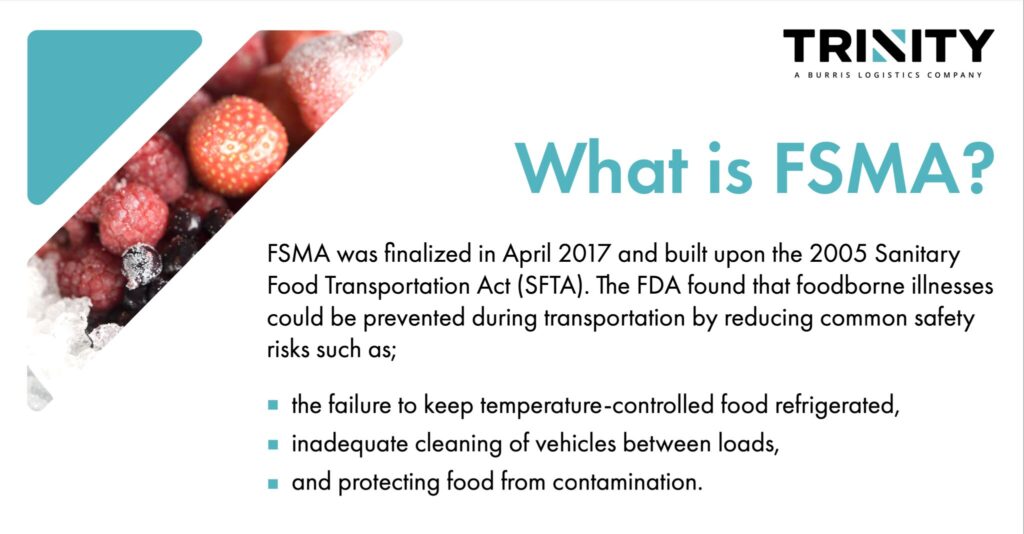

What is FSMA?

FSMA was finalized in April 2017 and built upon the 2005 Sanitary Food Transportation Act (SFTA). There were concerns about the regulations for the transportation of food in a safe manner. Foodborne illnesses could be prevented during transportation by reducing common safety risks such as;

- the failure to keep temperature-controlled food refrigerated,

- inadequate cleaning of vehicles between loads,

- and protecting food from contamination.

How Does FSMA Apply to…..

…Transportation and Logistics?

Food manufacturers and transportation companies that they work with must operate compliant and clean equipment, have operational processes in place, training to prevent food contamination, and keep records of anything on food safety measures.

…Shippers?

Under FSMA, shippers are the ones who arrange the transportation of the food product(s). This includes food manufacturers and the freight brokers they may work with. Shippers must understand the regulation, partner with a transportation company that is compliant, and communicate any food safety requirements with the companies they work with. They are responsible to ensure vehicles and equipment are in sanitary conditions deemed acceptable by the FDA. They must specify temperature and pre-cooling requirements in writing to the carrier and ensure that their cargo doesn’t make food unsafe for bulk shipments.

…Carriers?

Motor carriers must determine that their vehicles and equipment are sanitary. Carriers are responsible for making sure the equipment meets the shipper’s requirements and is able to maintain the temperatures needed to keep food safe. Refrigerated cold storage has to work and be pre-cooled to the correct temperature as instructed before loading. They need to maintain temperature records and proof of equipment cleaning for all cargo that has been on their equipment.

…To Receivers?

Receivers must provide washing facilities to motor carriers if they are handling, loading, or unloading any foods that are not enclosed. Additionally, they must request proof of proper temperature-control records before accepting.

Having Well-Trained Staff

Training on FSMA regulations and processes should make staff aware of the role they play in food safety. FSMA compliance needs to be part of the company’s culture and day-to-day operations.

Record Everything

The FDA requires that accurate records are kept. This includes processes in place to stay compliant and prevent contamination, training, agreements including FSMA, or temperature-control records.

Violations Are a Serious Matter

Companies can face criminal penalties if food is not handled safely and are not compliant with the FDA’s regulations. Criminal violations can include fines of up to $250,000 for an individual or double that for organizations, as well as one year of imprisonment. It is critical to stay FSMA compliant to keep recalls at a minimum.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

Choose Like-Minded Transportation Partners

Food safety issues still occur on a regular basis, so it is important to stay FSMA compliant. Part of that is in choosing a transportation partner that stays on top of regulations and focused on food safety.

Trinity Logistics understands the requirements that are necessary to be FMSA compliant and we verify that our vetted and selected carriers meet those standards as well. We strive to remain ahead of the curve and stay up-to-date when it comes to food safety in transportation. If you are looking for a 3PL provider you can trust when it comes to food safety regulations, such as FSMA, connect with us.

GET HELP WITH YOUR FSMA SHIPMENTSThis time of year in the United States, the weather gets a little warmer, people start daydreaming about trips to the beach or vacations to the mountains, and farmers are gearing up for their busiest work season. Not only does produce need to be harvested at peak freshness, it also needs to be shipped; thus the world of fresh produce logistics. When it comes to fresh produce, the most impactful time for any area in the United States is March through June.

With new food safety in transportation regulations, like the Food Safety Modernization Act, and decreased capacity due to supply and demand, finding a reliable carrier who can pick-up and deliver your fresh produce at peak freshness can be time-consuming, and quite frustrating.

The fresh produce logistics team at Trinity Logistics has the resources and industry expertise to arrange your shipment, regardless of how specialized your requirements may be. So if you’re shipping cucumbers, berries, broccoli, apples, or bananas, know that we love coordinating it all.

Produce by Region

The U.S. has different produce harvest times based on region and climate, so we’ll go over some of the top crops and time frames to get an idea of what’s being transported and when.

Texas, Arizona, and New Mexico

The most impactful time for produce harvest in Texas is March to June, but produce can be found here year-round as it is brought over from Mexico. In surrounding states, New Mexico and Arizona, there’s another push for produce that occurs October through November. Some of the top crops you’ll see out of this area include broccoli, cabbage, cauliflower, grapefruit, cucumbers, onions, lettuce, pumpkins, and peppers (especially the spicy variety).

California

In California, produce season kicks in around the southern part of the state in March to June, and slowly creeps its way up north of the state, ending in September. Some of the top fresh produde from California during these times include carrots, clementines, nectarines, artichokes, lemons, green leafy vegetables, avocados, and kiwi.

The East Coast

Produce season along the East Coast, like California, starts in the south and slowly creeps its way North. Florida begins its big harvest around May, while the harvest in Maine ends in the fall. From south to north, some of the most popular crops from the East Coast include oranges, peaches, tomatoes, watermelon, corn, cucumbers, apples, cherries, and blueberries.

Shipping Produce

There are a lot of factors that go into making sure fresh produce arrives in the same fresh condition for grocery stores, markets, and restaurants relying on it for their business. Total transit time, proper refrigeration, and shipper’s documents in line with the Food Safety Modernization Act all have to be taken into consideration.

We have 35 plus years of experience arranging refrigerated truckload shipments, so we know that no detail can be left out when it comes to these time-sensitive products. We help arrange produce shipments with dedicated full truckload services, port services, and even supply chain consulting and Transportation Management System solutions. Basically – no matter what scale operation you need, we have a solution that can help.

Our dedicated teams handle the careful transportation of your produce and are available to answer your questions 24/7.

Need a Produce Shipping Quote?

If you’re a produce shipper and you’re looking for a freight quote, it’s simple!

Give us a little bit of information about your shipment via our “Request a Quote” form by clicking below, or give us a call at 1-866-603-5679.

Request a Quote!