Trinity Logistics, an exceptional third-party logistics provider (3PL), is pleased to share its recent hirings in vital leadership positions across two of its Regional Service Centers (RSC).

Scott Swieca, who recently joined Trinity in April as the Arizona RSC Director of Operations, has been promoted to fulfill the role of Vice President. Swieca brings over 20 years of experience in the logistics industry. He has an extensive background working at other non-asset-based 3PLs, as well as with asset-based carrier companies.

“Stepping into the role of Vice President for the Arizona RSC is an incredible honor,” said Swieca. “I’m excited to work with a talented Team to drive growth and solutions for our shippers and carriers. We’re in growth mode out here in Arizona, and very excited to scale our superior level of service to assist more clients. We’re building our regional brand within Trinity’s core values and aim to deliver exceptional experiences for the Team Members, carriers, shippers, and Agents we work with. I’m very excited to be here and see the growth the Scottsdale, Arizona RSC will bring.”

In addition, Dan Lewis joins Trinity as the Director of Sales at the Iowa RSC. Lewis has worked in the logistics industry since 2015. He has a deep understanding of 3PLs and has held several sales roles, giving the Iowa office a fresh perspective.

“I’m happy to join Team Trinity and experience their well-known company culture,” said Lewis. “It was exciting to have found an organization that felt like such a natural fit already. I look forward to working with the Sales Team to help them reach and develop tailored logistics solutions for new clients, while strengthening the current relationships we already have. I’m set with the intention to help this office exceed expectations!”

Trinity Logistics looks forward to the insight and experience Swieca and Lewis have and bring to the company, as well as their respective offices.

LEARN MORE ABOUT TRINITY LOGISTICSAbout Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 45 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized as a Top Freight Brokerage by Transport Topics and as a Top Company for Women to Work for in Transportation by Women in Trucking.

While many of us are soaking up the last of summer’s sun and fun, food manufacturing supply chains are readying for the upcoming holiday food rush.

Have you ever noticed a lot of our favorite memories are surrounded by food? When we go to celebrate something like a birthday, anniversary, or special achievement, it usually involves food. It’s no surprise then that over the holiday season, nearly 165 million consumers across the U.S. purchase food and beverages to celebrate, according to a study from Cornell. As the holidays soon approach, food consumption surges, with the average American indulging up to an extra 440 calories per serving!

The increased demand and tight holiday deadlines can present challenges for many food and beverage companies with their logistics. This is in addition to already facing a competitive peak shipping season! However, by understanding the dynamics of this unique period of time, shippers can ensure success is ahead of them. First, let’s dive into some fascinating facts and insights about food during the holiday season. Then, we’ll follow that with some essential tips so your company can be prepared for the holiday food rush!

Holiday Food Supply Timeline & Stats

The Holiday Food Surge Begins with Fall

The holiday food rush first begins with the arrival of fall flavors. Pumpkin spice, now seen as the quintessential flavor of fall, has seen a 47 percent increase in sales, as reported by The Guardian, within the past five years. In 2023 alone, Datassential reported 144 new limited-time offers that featured pumpkin on major restaurant menus. From the infamous Pumpkin Spice Lattes (PSLs) to pumpkin soups and ravioli, this flavor dominates the season. But we can’t forget another fall favorite – apple. Food and beverage items with caramel apple were one of the highest-indexing flavors last fall.

Halloween Signals Significant Holiday Food Consumption Increase

Halloween is a major milestone in the holiday food timeline, with 65 percent of consumers participating in the festivities. In fact, of all 172 million that celebrate the spooky season, 95 percent of them purchase candy. Even more staggering is that a quarter of all the candy sold annually comes from Halloween sales. It’s not all about the sweets, though! Pizza is the most popular dinner staple on All Hallow’s Eve, according to Grubhub. There’s also the annual tradition of carving a pumpkin, with Statista reporting roughly 154 million Americans partaking in the activity in 2023.

Dia de Los Muertos Celebrations Begin to Trend

Datassential reports that 10 percent of consumers in the U.S. report celebrating Dia de Los Muertos, or Day of the Dead. This holiday is gaining popularity, which means so are the celebratory foods associated with it! Pan de Muerto is one traditional sweet bread that’s essential to the celebration.

Thanksgiving Continues to Drive Food Supply Chain Demand

Thanksgiving remains the most popular fall holiday, with 83 percent of Americans celebrating the tradition. A whopping 46 million turkeys are consumed each year, according to the U.S. Department of Agriculture. Other top holiday staples include cranberry sauce, stuffing, green bean casserole, mashed potatoes, macaroni and cheese, sweet potatoes, and pumpkin and apple pies. That’s a lot of food to prepare for a meal, so 23 percent of consumers will buy a full, ready-made meal from a restaurant. Another 22 percent will supplement with some food from restaurants for part of their feasts.

Sweets, Candy & Chocolate Build Holiday Food Demand at Christmas & New Year’s

Leading up to Christmas, many enjoy hot cocoa, cookies, and other treats. 1.76 billion candy canes, a holiday staple, are made annually for this joyous time of the year. 70 percent of Americans make Christmas desserts, with frosted sugar cookies being the top ones consumed annually. Don’t forget the eggnog! 122 million pounds of it is poured and drunk each year.

When it comes to Christmas dinner, pork dishes are the most popular globally, but turkey still trumps all for the U.S. Other winter feast staples include roasted or mashed potatoes, roasted carrots, gravy, stuffing, shrimp, and lots of Christmas pudding, cookies, and pies. Sweet tooths rejoice as 83 percent of consumers fill stockings with treats like candy and chocolate.

Christmas and New Year’s are among the busiest holidays for restaurants. Both holidays also see a spike in alcohol consumption, with New Year’s Eve being the second most alcohol-associated holiday behind Mardi Gras. Champagne is the fan favorite for those ringing in the New Year.

Logistics & SHipping Tips for Holiday Food Shipping

The holiday season often brings those in logistics the gift of increased demand and decreased capacity. Like most Americans, truck drivers aim to be home for the holidays, trimming the number of available carriers down. Freight of all kinds can increase during the period, further cutting the number of trucks available. Shippers with more specialized requirements, like temperature control, can find even less capacity. Shippers also have tighter deadlines to meet at this time to make the most of the seasonal business.

Overall, the holiday season can be a time of heightened stress and disruption. Given these unique challenges, it’s crucial for food and beverage shippers to prepare thoroughly to appease customers.

Five Tips for the Best Holiday Food Shipping Logistics Outcomes

Tip 1: Keep Inventory Stocked

Running out of stock during the holiday season is a surefire way to lose customers. Track your inventory levels closely and replenish supplies early to ensure you’re well-stocked. By keeping orders moving consistently, you’ll be able to meet consumer demand and avoid causing any disappointment.

Tip 2: Have Backup Shipping Plans Ready

The chances of any disruptions or delays happening during this season are increased. Having backup shipping plans already prepared is essential to keep your goods moving.

Build relationships with multiple carriers and suppliers, or even a third-party logistics provider (3PL). This way, you’ll have known contacts ready in case you need any help.

Look at alternate modes of transportation and be prepared to quickly shift plans should something happen. Exploring multimodal options can be a great way to diversify risk, add capacity, and protect your freight budget. Having this flexibility available and ready can help you stay on track and your supply chain running smoothly.

Tip 3: Real-Time Visibility is Needed for Success

In today’s supply chains, having access to the visibility you need is crucial. You should either work with a provider that offers it or invest in your own technology, like a Transportation Management System (TMS).

A TMS can be very helpful during the holiday season. It can help you with routing decisions by matching your freight with the best carriers, lanes, and rates. In addition, it will allow you to optimize the in-house processes of your transportation network – which can be helpful during busy and slow seasons. By selecting the best carriers and optimizing your routes, you’ll not only increase your service but reduce your risk.

Using a TMS also gives you data-driven insights to better manage disruptions, reduce downtime, and budget your logistics spend. Data analytics can help you recognize which carriers are most likely to have the capacity, saving you time arranging your shipments.

Tip 4: Communication and Collaboration

Effective communication is key to a successful holiday season. Regularly communicate with all stakeholders, including suppliers, carriers, and customers. Collaborating with your partners during the seasonal planning phase can provide valuable insights and help you identify potential issues before they arise.

Tip 5: Partner with a 3PL

Working with a 3PL can be a game-changer during the holiday season. A 3PL offers access to a larger network of carriers, advanced technology, and expertise in managing complex logistics challenges. With their support, you can ensure your supply chain remains resilient, even in the face of unexpected disruptions.

Treat Yourself with Easier Logistics This Holiday Season

Navigating the holiday food rush can be overwhelming, and that’s why Trinity Logistics is here to be your guide. Like Santa, we’ve been around a while, with 45 years of experience handling logistics during holiday seasons.

Right away, you’ll gain access to our large network of vetted, quality carrier relationships to cover your shipments. But that’s just the start! There are many more benefits to working with Trinity, including:

- Multiple modes of transportation to find the best bang for your buck, support your business growth, or just have a backup plan ready

- Best-in-class technology and customized Managed Transportation solutions available, giving you the exact visibility and data you want

- 24/7/365 support, so no matter what day or time it is, you’ll have the help you need

One benefit that tends to shine above all else? Our exceptional People-Centric service. It’s the trait that makes Trinity different from other 3PLs and keeps our customers returning time and time again. It’s truly our care, compassion, and communication that you’ll notice and appreciate.

Everyone wants to enjoy the holiday season. Why not let Trinity focus on the logistics for your business, so you can go back to doing what you enjoy – helping consumers savor holiday treats and create memorable moments with your product.

Try out Trinity Logistics for Your Next Shipment Learn How Trinity Supports Food & Beverage Shippers Sample More of the Trinity Culture & Service – Join Our Mailing ListAre you a Freight Agent that stumbled across this article?

Freight Agents, Indulge in an Exceptional 3PL PartnerIf you’ve worked in the LTL industry for any bit of time, then you know that it’s always changing. Yes, sometimes that means it gets a bit more complicated. Rates adjust. Rules and processes are modified. Despite all this, there is usually one constant – the core LTL carriers we work with. Yet, in 2023, that changed; we saw the departure of the legacy LTL carrier known as Yellow Corporation.

The closing of such a large and well-established LTL carrier is very rare. The industry hadn’t felt the void of such a large company since Consolidated Freightways closed 20 years prior. So, what happened? Considering Yellow Corporation was the third largest LTL carrier, what happened to all the freight they handled?

As someone with a career in LTL, I saw this happen in real-time and have directly seen its ripple effects. I can answer some of those questions and share with you my thoughts, experiences, and observations of this impactful event in LTL history.

The Fall of Yellow Corporation

Yellow Corporation (commonly referred to as YRC) was no stranger to financial turmoil. The company was laden with debt that was worsened with the Great Recession. It almost put them into filing for bankruptcy in 2009.

A stint of other factors after that didn’t put them in a better position when COVID-19 rolled around in 2020. YRC was granted a $700 million COVID-relief loan by the U.S. government, which it used nearly half of to cover past due payments to healthcare and pensions, payments on equipment and properties, and interest accrued by its other debts. Fast forward to 2023, and that’s where their final chapter began.

A few months into 2023, YRC and the Teamsters Union engaged in back-and-forth negotiations. YRC wanted to change operational procedures and sought extra funding to help it pay off its debts. Teamsters disagreed with the proposed changes. We saw news articles and hit pieces about the conflict, week after week. It was nearly impossible for the industry to ignore it.

In July, whispers began of a possible union strike that would effectively halt YRC’s freight network. This was the writing on the wall for many shippers and third-party logistics (3PL) companies. At this point, the hull had been punctured, and water pouring in. Do you stay or do you go?

YRC and its subsidiaries were promptly disabled from countless TMS platforms. No customer wanted their freight stuck in limbo if Teamsters were to go on strike against YRC. Because of this, YRC saw a sharp decline in freight volume and tonnage. A company that was in financial disarray was now losing its primary source of revenue.

On July 30th, Yellow Corporation ceased all operations. The Teamsters had not agreed to the negotiations, and the 11th hour came and went. So, what now?

The Aftermath of YRC’s Closing

YRC’s exit affected two parties: shippers using LTL and other LTL carriers.

For shippers using LTL, they were two buckets: those who had already begun shifting their freight to other carriers in their pricing roster and those unfortunate enough to still have most or all freight with YRC. The latter had a more difficult situation to overcome as they now had to find an LTL carrier to move their freight without paying an arm and a leg.

For LTL carriers, YRC’s existing freight had to go somewhere, so they had to figure out how to absorb it. Carriers such as Estes, FedEx, and XPO and their capabilities were pushed to their limit, now drinking from a firehose of incoming freight. Volumes increased drastically, and with such a rapid rise came decreased capacity.

LTL carriers were making the difficult decision to exclude certain shippers in favor of others just to service accounts and keep their networks moving without bottlenecking. This left many smaller shippers stranded with a shorter list of available LTL carriers.

As carriers became inundated with freight, their operating ratios took a hit, and something had to be done to regain control. A season of atypical general rate increases (GRI) began. LTL carriers needed to remain profitable lest they succumb to a fate like Yellow.

3PLs and shippers alike started getting notifications from their carrier representatives about rates going up. Shipping LTL got more expensive now that the carriers had to pick and choose who they serviced with their finite capacity. The increased rate structures also priced out shippers that were used to YRC’s competitively priced tariffs or couldn’t stomach the increases.

For many shippers and 3PLs, the immediate aftermath of the Yellow Corporation bankruptcy was unlike any they had previously experienced.

Now, that’s the long and short of it, but how are things today? Surely, the disappearance of a significant LTL carrier like that would have lasting, irreversible affects.

Well, yes, but also no.

The Current Impact of YRC’s Closing

Today the LTL industry has mostly stabilized. YRC’s freight volume has dispersed, and the dust has settled. The LTL carriers have course-corrected their capacity concerns.

After the YRC bankruptcy, there were also new questions to answer, one of which was “What happens to their assets?” Those went through the bankruptcy courts, but the LTL carriers were eager to get a piece of it.

The purchased terminals and trailers meant increased footprint and capacity, which can be the difference between being the best and the biggest for LTL carriers. Several carriers bid to acquire the terminals left behind by Yellow Corporation.

Estes Express, a prominent national LTL carrier, was one of the larger victors in the bidding war. As one of Trinity’s carrier relationships, I asked Estes if they could share the impact YRC’s exit had on their company. Here’s what President and COO Webb Estes had to say:

“Estes acquired 29 terminals and a large amount of equipment as a result of Yellow’s exit from the marketplace. I can’t say enough for the dedication and resiliency of our team to work together tirelessly to quickly bring them online and add to our steady capacity growth. In addition we purchased several tractors and trailers, and we were also able to buy many smaller items – such as load bars, airbags, and freight tables – all of which help us do an even better job protecting our customer’s freight,” said Estes. “One other surprising benefit is that the additional freight we’ve taken on has allowed us to add more direct linehaul lanes, and we’re seeing better overall service in 2024 compared to last year.” Estes added, “This is a great example of how Estes continues to invest wisely in assets and capabilities that create capacity, opportunity, and resiliency for our company and those we serve. And that remains a primary reason why customers from coast-to-coast continue to rely on us for their shipping needs.”

While LTL carriers, larger shippers, and 3PLs came out in the black or relatively unscathed, others did not. Smaller shippers with all their freight lanes with YRC had no backup plans except to pay increased, non-discounted LTL rates with other carriers or risk their business operations.

How Did Trinity Logistics Fare?

At Trinity, those first few months after the bankruptcy were interesting! We saw many new shippers start a relationship with us and saw some complications in LTL carrier transit lanes that bottlenecked. Don’t worry, they were quickly resolved. Since Trinity has a broad roster of national and regional LTL carrier contracts in place, our shipper relationships were able to use our rates to course correct from the YRC closure and effectively avoid any critical disruption.

Is the last time we’ll see an industry-shaking event in the LTL space? Likely not. For now, the industry is stable, and many LTL carriers are growing and reporting profitable earnings.

In my 10+ years working in the LTL industry at a 3PL, the Yellow Corporation was always a top LTL carrier for us. Seeing them fade into the wind after decades of LTL service was surreal, and I felt sad for the many YRC employees I’ve grown to know.

Despite such an impactful event, now written in the history books, it’s a year later, and the LTL landscape is still thriving (and volatile), even with one less player at the table.

Final Thoughts

Considering the size of Yellow and the steady decline until evaporation from the industry, I actually expected more disarray from it. Sure, the first weeks after the bankruptcy had the GRIs, shipment delays, and new shipper partnerships for Trinity to handle, but after a month or two, it was relatively smooth sailing back to normal.

I think that speaks volumes to the age we live in. The amount of technology and time-saving efficiencies that LTL carriers invest in year after year. It allowed the industry to absorb the freight volume of one of the largest LTL carriers in the world and it did so in less than 60 days! It’s kind of crazy and a testament to the LTL industry and its controlled chaos.

Working with Yellow for so many years, I grew familiar with some of the names worked there. People we would see at conferences, have calls with or see on emails. People who had been in the industry much longer than I have, had extensive backgrounds, and grew their roots at Yellow.

The bankruptcy landed them in the middle of it all, but many of them went on to other LTL carriers and took their experience, adding value there. I think that’s a silver lining here. Despite the financial decision of Yellow as a company, it had people on its roster that brought purpose to LTL and now these people are creating an impact for other carriers and customers alike. For how vast it is, the LTL industry can be closeknit, so to see those former Yellow employees succeed at other LTL carriers is a bright spot in this saga.

Learn More About Trinity's LTL Services Get More Content Like This In Your InboxABOUT THE AUTHOR

Curt Kouts holds the Director of LTL position at Trinity Logistics. Kouts has been with Trinity and in the logistics industry for 14 years, having held several titles among carrier vetting, account management, and within the LTL Team itself. His main responsibilities as Director focus on elevating Trinity’s LTL customers’ experience, helping the LTL Team support in operations and billing, and aiding the company in overall LTL sales and success. Kouts finds the LTL industry incredibly challenging, presenting him and his Team a ton of problems that they have a passion for solving. He enjoys learning more about LTL whenever possible and overall, making LTL an experience that keeps all his customers, both internal and external, coming back.

Artificial Intelligence (AI). You see it mentioned all over the news headlines. You overhear your coworkers discussing it in the breakroom. Even your family members bring it up at get-togethers.

Much like when the internet first came to be, people are both amazed and uncertain about it. I often hear and see the same questions come up. What is the history of AI? When did it start? What exactly is AI? Is it just ChatGPT? What kinds of AI are there? Will AI take my job from me? Will AI take over the human race? (Definitely no to the last one!)

As someone who works in the technology field, I’d love to answer those exact questions for you and share some of my own thoughts on AI.

What is Artificial Intelligence?

Let’s answer this question first. Artificial intelligence is the science of making machines think, process, and create like humans. It has become a term applied to applications that can perform tasks a human could do, like analyzing data or replying to customers online.

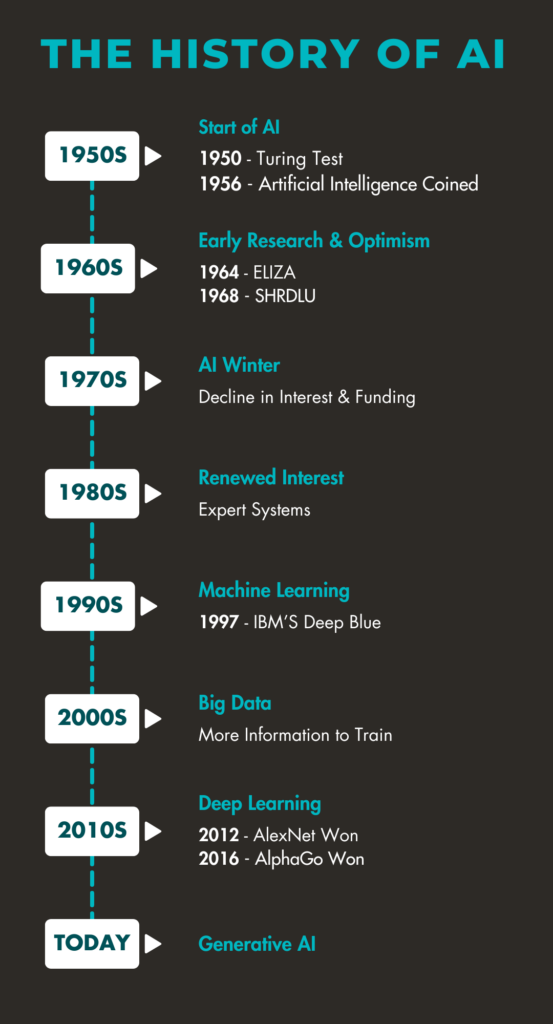

The History of Artificial Intelligence

You might be surprised to learn that AI has existed for a while.

1950s

The Start of AI

The first application of artificial intelligence was the Turing Test. In 1950, Alan Turing tested a machine’s ability to exhibit behavior equal to a human. The test was widely influential and believed to be the start of AI.

In 1956, “Artificial Intelligence” was officially coined by John McCarthy, Marvin Minsky, Nathaniel Rochester, and Claude Shannon at the Dartmouth Conference. The conference is seen as the founding event of AI.

1960s

Early Research and Optimism

Early AI programs began to develop during this time. Computer scientists and researchers eagerly explored methods to create intelligent machines and programs.

Joseph Weizenbaum created ELIZA, a natural language processing program to explore communication between people and machines. Later, Terry Winograd created SHRDLU, a program that understood language in a restricted environment.

1970s

The AI Winter

Early enthusiasm from the 1950s and 1960s fell due to limited computational power and unrealistic expectations. There was a significant decline in interest and funding for AI, so projects fell by the wayside. You’ll often see this time in history called the “AI Winter.”

1980s

Expert Systems Bring Renewed Interest

Despite the slowdown, some projects continued, albeit with slow progress. Expert systems, designed to mimic human decision-making abilities, developed and were a turning point in AI. These systems proved that AI could be used and beneficial in businesses and industries. Many commercial fields, such as medicine and finance, began using expert systems.

1990s

Machine Learning and Real-World Applications

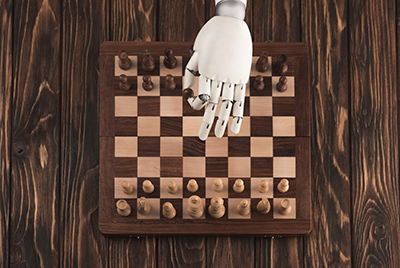

Here’s where AI started gaining momentum. During this time, we shifted from rule-based systems to Machine Learning. Machine Learning is just that – a machine or program that can learn from data. We see a lot of Machine Learning in today’s applications, like self-driving cars or facial recognition.

Machine Learning developed so well that in 1997, IBM’s Deep Blue became the first computer system to defeat world chess champion Gary Kasparov. This moment showcased AI’s potential for complex problem-solving and ability to think like a person.

2000s

Big Data Offers AI Advancements

Up until now, AI was limited by the amount and quality of data it could train and test with Machine Learning. In the 2000s, big data came into play, giving AI access to massive amounts of data from various sources. Machine Learning had more information to train on, increasing its capability to learn complex patterns and make accurate predictions.

Additionally, as advances made in data storage and processing technologies led to the development of more sophisticated Machine Learning algorithms, like Deep Learning.

2010s

Breakthroughs With Deep Learning

Deep Learning was a breakthrough in the current modernization of AI. It enabled machines to learn from large datasets and make predictions or decisions based on that. It’s made significant breakthroughs in various fields and can perform such tasks like classifying images.

In 2012, AlexNet won, no dominated, the ImageNet Large Scale Visual Recognition Challenge. This significant event was the first widely recognized successful application of Deep Learning.

In 2016 Google’s AlphaGo AI played a game of Go against world champion Lee Se-dol and won. Shocked, Se-dol said AlphaGo played a “nearly perfect game.” Creator DeepMind said the machine studied older games and spent a lot of time playing the game, over and over, each time learning from its mistakes and getting better. A notable moment in history, demonstrating the power of reinforcement learning with AI.

2020s

Generative AI

Today’s largest and known impact is Generative AI, able to create new things based on previous data. There’s been a widespread adoption of Generative AI, including in writing, music, photography, even video. We’re also beginning to see AI across industries, from healthcare and finance to autonomous vehicles.

Common Forms of AI

Computer Vision

Computer Vision is a field of AI that enables machines to interpret and make decisions based on visual data. It involves acquiring, processing, analyzing, and understanding images and data to produce numerical or symbolic information. Common applications include facial recognition, object detection, medical image analysis, and autonomous vehicles.

Honestly, Computer Vision is my favorite field of AI. I’ve had the opportunity to work on some extremely interesting use cases of Computer Vision. One was using augmented reality lenses (like virtual reality goggles) to train combat medics using Computer Vision. The Computer Vision with augmented reality added a level of realism to the virtual training, which used to be unattainable. While I would love to go into further detail about what the AI looked like, I signed a non-disclosure agreement. You’ll just have to take my word that it was really cool!

Machine Learning (ML)

Machine Learning is a subset of AI that allows computers to learn from and make predictions or decisions based on data. It encompasses a variety of techniques such as supervised learning, unsupervised learning, reinforcement learning, and semi-supervised learning. Common applications range from recommendation systems (like Netflix), fraud detection, predictive analytics, and personalization.

Deep Learning

Deep Learning is a subset of machine learning. It involves neural networks with many layers (deep neural networks) that can learn from large amounts of data. It enables machines to learn features and representations from raw data automatically. Key components include convolutional neural networks (CNNs), recurrent neural networks (RNNs), and generative adversarial networks (GANs).

Natural Language Processing (NLP)

Natural Language Processing (NLP) is a branch of AI that focuses on the interaction between computers and humans through natural language. It enables machines to understand, interpret, generate, and respond to human language. Common applications include machine translation, sentiment analysis, chatbots, and speech recognition.

Generative AI / ChatGPT

Generative AI refers to AI models that can generate new data like the data its trained on. This includes text, images, music, and more. ChatGPT, a specific (and well known) application of Generative AI, is a language model developed by OpenAI that can generate human-like text based on the input it receives. It uses Deep Learning techniques to produce coherent and contextually relevant responses, making it useful for applications like conversational agents, content creation, and more.

AI is Awesome BUT It Has Some Setbacks

Don’t Worry, AI is Not Going to Take Away Your Job

Artificial intelligence has some great benefits, like processing and analyzing data in minutes, but it’s not perfect. It’s still not HUMAN, it’s not you, and that is exactly why it won’t replace you in your job.

Take a lawyer for example. AI has been known to complete the bar exam in the 90thpercentile. Awesome, right? But that doesn’t mean AI is going to perform better than an actual lawyer in a case. It just means the AI is better at answering the test because of its training with the text.

AI is very good and fast at anything with text, but it’s terrible at motor functions and mimicking a person in a non-scripted environment. Like with Generative AI – at some point I know you’ve seen or heard something created by it and have had the thought, “This is definitely AI.”

Ethical Components

As AI continues to be adopted and widely used, I believe it needs legislation around it. For example, do people need to state they are using AI for their work? Can they still claim it’s something created by them if AI created a part or even all of it? Who gets the credit – the person or the machine?

There’s also the concern with creators being miscredited or violations with copyright. There’s been plenty of cases or news headlines in which AI has learned from artists and essentially recycled their work in a slightly new form. Is that a form of stealing?

AI Can Be Volatile

The development of AI is happening fast. Tomorrow, your current AI platform could be outdated. Things constantly change week to week. The features you might love now could be cut and replaced with something new. It can be hard for people and their own Technology Teams to keep up! And did I mention its hallucinations? Sometimes it likes to make up its own false information, so you should always doublecheck its results!

My Closing Thoughts

AI is real, it’s been here, and is both impressive and scary. It’s also very trendy to mention in any news article or headline, which is why you’re seeing it mentioned a lot. Nor, again, is it coming for your job anytime soon. While some articles may have you believe it will provide us world peace by the end of the year, it is still limited in capability.

This is not to understate the need for legislation so that it is responsibly used, but rather, a presentation of the facts of AI’s impressive feats, and numbered flaws. It’s important to remember that while things like ChatGPT and Generative AI are newer, we have a long history of AI development, going back nearly as far as computers, and likely, further back than many of our lifetimes.

Get More Content Like This In Your Inbox Learn More About Trinity Logistics Learn About Trinity's TechnologyAbout the Author

Michael Adams is a Data Scientist I at Trinity Logistics. Adams holds a Master’s Degree in Data Science and has worked three years in the field, including his 2 years at Trinity. In his current role he focuses on applying Data Science techniques and methodologies to solve difficult problems, using AI to improve business outcomes, and supporting Trinity’s Data Engineering initiatives to improve quality assurance, ETL processes, and data cleanliness.

Outside of his role at Trinity, Adams has a couple of personal Computer Vision and AI projects of his own! When he’s not tinkering away at those, he enjoys being outdoors, either hiking or kayaking!

Severe weather events are the new normal. Can the logistics industry handle more supply chain disruption?

It’s a hot, sunny day, and you’ve found the perfect spot on the beach to sit back, relax, and enjoy the cool breeze of the ocean waves. As you’ve sat down and unpacked your snacks, a thunderstorm rolls in, causing the lifeguards to hop off their chairs, stating the beach is closing. Plans = ruined.

We’ve all been there – when poor weather makes an inconvenient appearance. But severe weather is more than just rain on your wedding day. It’s more extreme, like high winds, flooding from heavy rain, wildfires, or droughts. Severe weather events are becoming more intense and commonplace, causing supply chains to struggle. Logistics professionals often face challenges like disrupted deliveries, product shortages, and skyrocketing costs.

From intense hurricanes to wildfires, the growing effects of climate change on supply chains are becoming impossible to ignore. In a report by Breakthrough, 39 percent of transportation professionals note severe weather as the biggest challenge to their networks, having primary concerns surrounding climate change and sustainability. With severe weather and its effect of supply chain disruption being a challenge for companies for the foreseeable future, they must take proactive measures to maintain resiliency. Is your supply chain prepared?

CASES OF SUPPLY CHAIN DISRUPTION FROM RECENT SEVERE WEATHER

Climate change has led to an increase in severe weather events. If you’re uncertain as to how much of an increase we’ve seen, let me share an eye-opening fact with you. The U.S. National Climate Assessment estimates that in the 1980’s, a billion-dollar extreme weather event would take place once every four months. Now, they occur once every three weeks! That’s not a lot of downtime in between events for affected supply chains to regroup.

Supply chain disruption from severe weather like the ones mentioned below is no longer a distant worry but a constant concern.

Droughts

In recent years, droughts have been impacting vital waterways. The Panama Canal, a critical path for global shipments, has experienced its worst drought since records began in 1950. Due to low water levels, restrictions were imposed, limiting heights and the number of daily vessels. Similarly, the Mississippi River has faced periods of drought and low water levels, making it difficult to transport goods.

Elevated heat and droughts affect not only waterways for transportation but also the production of goods. For example, coffee, cocoa beans, and olives have all recently faced drought conditions, resulting in a lower output of their respective products.

Wildfires

Often fueled by extreme heat and droughts, wildfires are now an expected annual danger to many parts of the world, like the Western U.S. and parts of Canada. Fire seasons start earlier and last longer while growing in intensity and size. Though the wildfires themselves are one problem, the spread of the smoke coming off them greatly expands their impact. The smoke reduces not only our air quality but also visibility, such as with the wildfires in Canada in 2023, which created widespread smoky conditions and delayed several shipments in populated locations such as Chicago and New York.

Hurricanes

Hurricane Season continues to bring more hurricanes and stronger storms each year. In fact, the National Oceanic and Atmospheric Association (NOAA) forecasts that the 2024 season will see 17 – 25 named storms, with four to seven being a Category 3 or greater. On average, there are 14 named storms with three being a Category 3 storm or greater.

Hurricane Ian was one severe weather event to cause supply chain disruption in the Southeast in 2022. Ian was a Category 4 storm when it made landfall in Florida and resulted in a 75 percent drop in shipments during its course. More than $416 million of citrus crops, a major good grown in the area, were destroyed by Ian.

Another Category 4, Hurricane Harvey, struck Texas in 2017. More than 50 inches of rain fell, breaking previous U.S. records and causing massive flooding, which closed roadways and many facilities. Several ports along the Gulf Coast were closed for nearly a week.

Even a Category 1 hurricane can impact supply chains. In July 2024, Hurricane Beryl hit South Texas, causing major flooding, power outages, and port closures.

Deep Freezes

Several locations have seen unusual deep freezes in recent years. In 2021, Texas saw a widespread freeze that their electric grid was unplanned for, causing a blackout for over two weeks. Many manufacturing businesses had to shut down, and railroads did, too. This caused significant supply chain disruption for transportation between Texas and the Pacific Northwest.

In 2022, New York experienced Winter Storm Elliott, which lasted roughly a week. Heavy snowfall and extreme cold temperatures caused power outages, resulting in a 40 percent decrease in shipment volume.

These are just a few examples of the impact severe weather has had on supply chains in recent years. Scientists believe that supply chain disruption from severe weather events will only intensify in the coming years as extreme temperatures and sea levels continue to rise.

HOW SEVERE WEATHER CAUSES SUPPLY CHAIN DISRUPTION

Severe weather events can wreak havoc on supply chains in many ways!

Infrastructure Damage

Roads, bridges, or ports can become damaged and make routes unavailable.

Shipping and Transportation Delays

The effects of severe weather, such as flooding or wind gusts, can slow or stop transit, causing delays and increased shipping times.

Shortages and Increased Costs

Damages and delays from severe weather can impact production, reducing inventory and capacity. Increased demand then increases the cost of materials, products, or shipping.

HOW SUPPLY CHAINS CAN STAY PROACTIVE

While you can’t control the weather, you can control whether your supply chain is prepared. Now is the time to be proactive and plan so your supply chain survives and thrives when severe weather strikes.

Assess Your Risk

Map out your entire supply chain to find gaps and vulnerabilities. Identify which companies and suppliers are involved and what severe weather events might impact them. If capable, look at previous data on supply chain disruption to learn from it. Are there certain sites that experience frequent disruption? How could you have been better prepared?

Have a Contingency Plan

Now that your supply chain is mapped and risks identified, it’s time to build plans for when disruption hits. Confirm that your supply chain partners have their own plan in place. Determine backup suppliers and partners for when current ones are affected. Find and select alternative transportation methods and routes. Once established, regularly assess this plan to ensure it will operate effectively.

Invest in Extra Insurance

This may seem like simple advice but invest in insurance to protect your business from losses. For example, flood or hurricane insurance will help you restore any damaged assets from a severe storm. Business interruption coverage can offer added protection, covering any lost sales during a disruption from severe weather.

Invest in Technology

There is a lot of technology available to help you be prepared for severe weather. Technology with Artificial Intelligence (AI) and predictive analytics can be useful to help you forecast and respond quickly when issues unfold. Leveraging AI and machine learning can help you reach a level of automation in which decisions can be made from data in a matter of seconds.

Create End-to-End Visibility

One of the most common weaknesses in supply chains is a lack of visibility. With the increase in severe weather and supply chain disruption, visibility is needed now more than ever. Having real-time access to tracking, carriers, suppliers, and inventory can help you identify any issues before disruption takes place.

A transportation management system (TMS) can provide the visibility you need. It provides critical data about your shipments and orders in real-time, giving you an advantage should a problem arise. This can help you make quick decisions to reroute shipments, avoid affected areas, and keep your customers informed.

See how a TMS could help you.Establish Open Communication

Establishing open communication among your supply chain partners now will benefit you when severe weather happens. Be transparent. Share details about when you receive orders, where they go, and when they are due.

Let partners know your backup plans and ensure they are prepared for any severe weather events. When there is a chance of supply chain disruption, send communications right away. The earlier you can make partners aware of the possibility, the more time they have to adjust their plans.

Collaborate with Resilient Partners

Are your supply chain partners prepared for potential disruption? Identify those who are ready to weather the storms and those who are vulnerable. Supply chain disruption isn’t going away, so you’ll want to raise your concerns and highlight your need for resiliency. If the risk is too great for your supply chain, you may consider looking into alternative partners to replace them.

WEATHER ANY STORM WITH TRINITY LOGISTICS

Working with a reliable logistics provider like Trinity Logistics is a great way to build supply chain resiliency and overcome severe weather threats.

Trinity Logistics has been supporting thousands of supply chains through all sorts of supply chain disruption for over 45 years. Severe weather events don’t scare us away, as we thrive on quickly solving issues like those that storms can bring. We also have a dedicated After-Hours Team to support your business at any time. Even if severe weather halts your shipping overnight, on a holiday, or weekend, we’re here to help.

Our nationwide network of trusted carrier relationships will ensure your shipments arrive safely at their delivery locations. You can also count on our multiple transportation options to allow you to keep your goods moving through rain, hail, or snow. Lastly, our customizable Managed Transportation solutions can give you the real-time visibility you need to stay updated and make any changes in a matter of minutes.

Don’t let supply chain disruption fog up your company’s goals. Try Trinity Logistics and see how our People-Centric service can light the way to success.

GET A FREE QUOTE ON YOUR NEXT SHIPMENT SUBSCRIBE & STAY IN THE KNOW LEARN MORE ABOUT TRINITY'S SOLUTIONSStay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

GOOD NEWS, BUT…

Consumer spending is the biggest driver of the U.S. economy, accounting for roughly two-thirds of the nation’s Gross Domestic Product (GDP). One measurement of that consumer spending is the Redbook index, which compares year-over-year growth for large domestic general retailers (think Walmart, Amazon, Target). The index has averaged just over 3.5 percent for the past 20 years, so the recent year-over-year (YoY) growth in the four-plus percent range speaks to the strength of consumer spending (Figure 1.1). This index alone certainly gives reason for optimism, however there is a cautionary tale with regards to consumer debt.

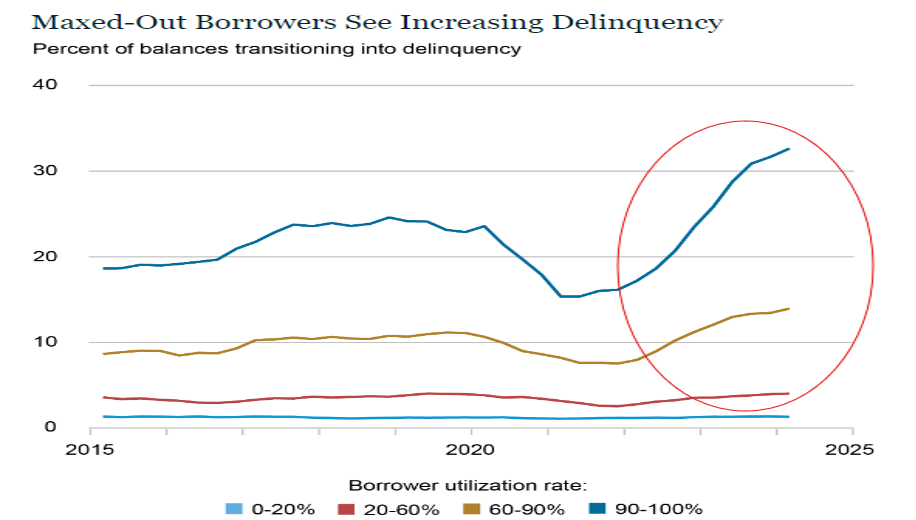

After years of next to zero interest rates to keep the economy on its legs, consumers have seen interest rates on the rise, with the federal funds rate at its highest level since the early 2000’s. With the increase in interest to borrow funds, combined with the increased costs of essentials (food, housing, energy), many households have turned to credit cards to fill the gap for funding of these necessities. Figure 1.2 from the New York Fed Consumer Credit Panel shows the rise in consumer delinquency particularly in those groups that utilize more than half of their available credit line.

While there appears to be relief on the horizon with the impending reduction in interest rates, it appears a portion of active consumers may be pulling back on purchases for those items that are not mission critical. This, in turn, will have an impact on restocking of inventories and trucking activity.

While it is not approaching the levels seen in 2021, the volume index is quickly approaching levels seen in 2022. This has buoyed optimism in the industry.

JUST SOME GOOD LUCK? TIME WILL TELL

The uptick in consumer spending, restocking of inventories and the threat of labor strife in the fourth quarter of this year has been to the benefit of those involved with the rail and import business.

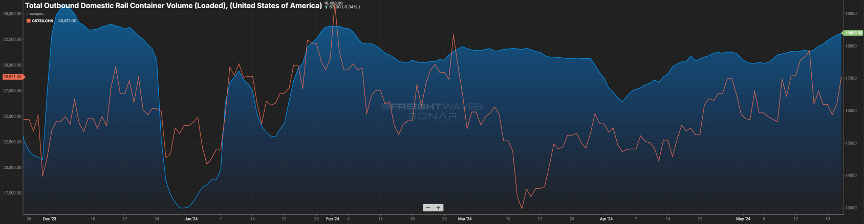

In Figure 2.1 below, the blue line represents loaded container rail volume in the U.S. and the past three months have seen the volume grow. Similarly, container volumes to the U.S. have been on the rise.

The orange line represents container volume from China over the past six months. While some of that traditional volume is now flowing through other countries, like Mexico, there is still a great deal of activity with U.S.-China trade. Will this continue or is it fool’s gold? That is something we will continue to keep an eye on as a pullback in consumer spending will dictate how the needle moves.

STAYING RIGHT WHERE WE ARE

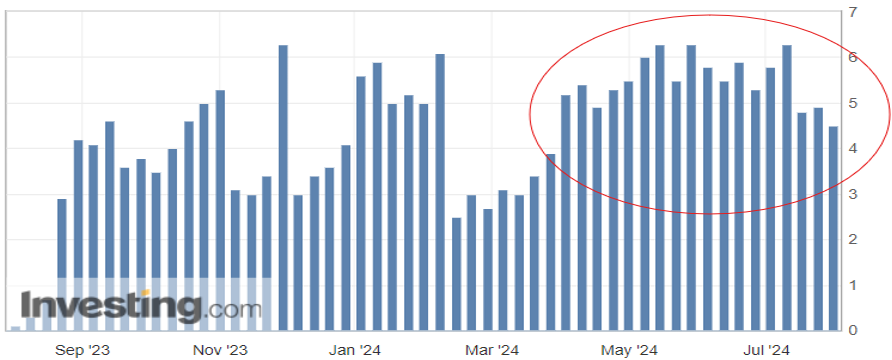

Finally, looking at domestic over-the-road volume (blue line) compared with carrier rejection rates (green line). The slight upward trend continues with volumes and rejection rates (Figure 3.1). Rejection rates continue to inch towards 2022 levels, but a five-to-six rejection rate is about half of what one would see in a balanced freight market.

This has yet to manifest itself in the way of increased freight rates, as capacity still exists in the market.Shippers and carriers should anticipate little change in conditions (although hurricane season is looming) until early 2025.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive the top five logistics articles of the week every Friday morning by selecting “Weekly News Update” when you select your preferences.

Get Weekly News Updates in Your InboxTrinity Logistics, a leading third-party logistics (3PL) provider, proudly welcomes Jimmy Bryant as its new Director of Agent Support.

Hosting a wealth of experience in the logistics industry, Bryant previously held a Senior Director position at Rockfarm Supply Chain Solutions, where he successfully managed and developed their Agency Program for the past six years. Previously, he served as a Sales Director for a large brokerage in Indianapolis.

“Trinity has always stood out for its exceptional agency program,” said Bryant. “What truly sets Trinity apart is its unwavering commitment to staff development and the overall growth of everyone involved. I chose Trinity because of its strong culture and supportive environment. I’m excited about the opportunities to advance our Freight Agent Program.”

“Jimmy’s ability to understand the unique challenges faced by Freight Agents quickly impressed me,” said Greg Massey, Senior Vice President of Agent Development. “His track record of achieving sustained growth while providing top-notch service and support aligns perfectly with Trinity’s mission of being the best, not necessarily the biggest.”

Trinity is enthusiastic for the insight and experience Bryant brings to the company and its Freight Agent program.

LEARN MORE ABOUT TRINITY LOGISTICS'S FREIGHT AGENT PROGRAMAbout Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 45 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized as a Top Freight Brokerage by Transport Topics and as a Top Company for Women to Work for in Transportation by Women in Trucking.

June 1st through the end of November is considered Hurricane Season for the Atlantic and Gulf Coast, with heightened chances of storms occurring from early August to October. According to the National Weather Service, there’s an average of six hurricanes each year, with two typically becoming major storms hosting winds of 110-plus mph.

Even on its best days, the logistics industry is considered complicated. Throw a hurricane in the mix, and you can have straight-up chaos. Hurricane Season means supply chains should prepare for the worst in weather, like heavy rain, dangerous gusts of wind, limited visibility, and flooding. Shipping setbacks such as impassable roadways, stranded trucks and drivers, loss of cargo, and extended deliveries are just some of what can be experienced. Here’s what your organization needs to know to prepare during peak Hurricane Season so your company can avoid delays and a loss in revenue.

Supply Chain Tips for Peak Hurricane Season

Stay Informed

A hurricane’s path and level of impact can change very quickly. It’s crucial you stay informed of potential storms that could impact your supply chain during Hurricane Season.

Set up alerts to be notified of newly formed storms and hurricanes. When a potential storm is in your path find a trusted weather news source and check it often for updates. Don’t just follow the updates before the storm, but also during and after. You may also adopt and use advanced weather tracking systems to get up-to-date information to make informed, real-time decisions.

Maintain Communication

Natural disasters, like hurricanes, can have a huge impact on your company’s supply chain. An easy way to stay ahead is to be transparent and communicate openly throughout. Transparency builds trust and helps manage expectations during a crisis.

If a potential hurricane threatens your business, acknowledge it immediately. Then, start communicating with your customers and partners about the potential effects. Regular updates on potential disruptions and recovery efforts can go a long way in maintaining strong business relationships.

Have an Emergency Plan Ready

You should have a company-wide plan that outlines its actions during a hurricane. Your emergency plan should include important details like;

- an evacuation route for buildings affected

- a crisis communication plan

- assigned employee emergency roles and responsibilities

- instructions on how to protect inventory and equipment

- where emergency supplies are located and how best to use them

- how capable facilities will support when others are affected

When planning, make safety your company’s top priority during a hurricane. Once established, your plan should be reviewed often and updated as needed to ensure it remains effective. Additionally, running practice drills can help everyone know their roles and responsibilities.

Consider Alternatives

Consider what alternative workspaces and methods of transport you could use in the event of a hurricane. Are there temporary warehouse solutions where inventory could be stored? Could intermodal replace a truckload shipment that’s in the path of the storm? Are there alternative routes? How can facilities outside of the storm’s path support those affected? These alternative options should be included in your emergency plan.

While you may not have all the answers when planning, the more you include, the quicker you can make strategic decisions when needed. Having room for flexibility and adaptability is key to minimizing disruptions.

Have Visibility in Your Supply Chain

Visibility is needed now more than ever for supply chains. Having visibility not only helps you on good days but especially during hurricane season.

A transportation management system (TMS) can provide the necessary visibility during a hurricane. It provides critical data about your shipments and orders in real-time, giving you an advantage should a problem arise. This can help you make quick decisions to reroute shipments, avoid affected areas, and keep your customers informed.

See how a TMS could help youThink About Recovery

According to the Federal Emergency Management Agency (FEMA), almost 40 percent of businesses that have to shut down for 24 hours due to a natural disaster never open again.

Ensure your business won’t be in that 40 percent if it happens. Have a plan ready to roll for the aftermath of a hurricane. Prepare for the worst and then plan how to recover from it quickly. This will help prevent any potentially steep revenue loss.

Recovery Team, assemble! It’s time to identify the key employees and providers to get your business back to normal operations. An initial assessment will need to take place and your team’s sole responsibility should be to restore and resume processes. Having those alternative solutions and backup suppliers or providers will be handy here.

Weather the Storm with a Reliable Logistics Partner

Sometimes, you just need extra help. A relationship with a reliable logistics provider, like Trinity Logistics, can help your supply chain overcome the threats of Hurricane Season.

Hurricanes can roll in a cloudy overcast of unknowns, but Trinity shines a light toward safety and security. We have over 45 years of experience helping thousands of supply chains through ups and downs. We thrive on problem-solving and handling issues like the ones hurricanes can bring. We also have a dedicated After-Hours Team to support and quickly resolve any potential challenges – no matter the time of night, holidays, or weekend.

Our nationwide network of trusted carrier relationships ensures your shipments arrive safely at their delivery locations. Additionally, multiple transportation options offer the flexibility to keep your goods moving. Lastly, we’ll help you find real-time visibility with our customizable Managed Transportation solutions. Our dedicated Team (comprised of six Regional offices across the nation) is ready to help you maintain continuity and resilience in your supply chain.

Partner with Trinity logistics so your supply chain can stay afloat, no matter the weather. (Our exceptional service might just blow you away, though!)

GET A FREE QUOTE ON YOUR NEXT SHIPMENT SUBSCRIBE & STAY IN THE KNOW LEARN MORE ABOUT TRINITY LOGISTICS

Stay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

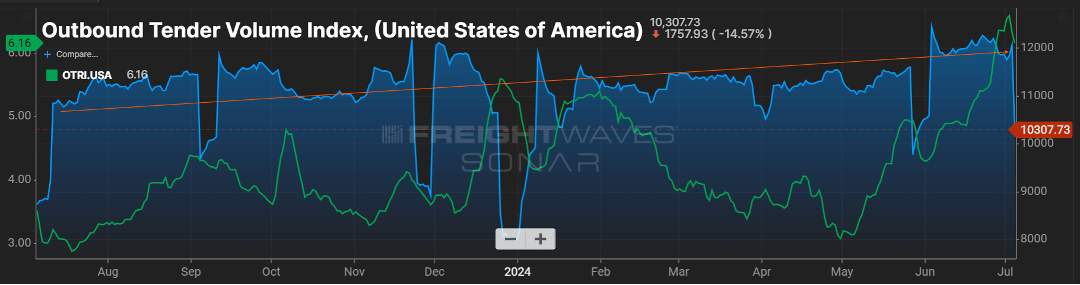

UP AND TO THE RIGHT

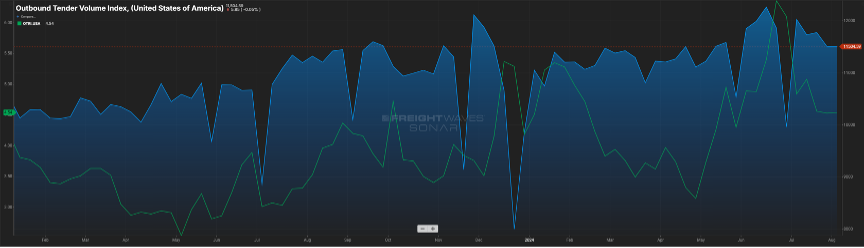

For the past year, the general direction of the Outbound Tender Volume Index (OTVI) has been on an upward trajectory as seen in Figure 1.1.

While it is not approaching the levels seen in 2021, the volume index is quickly approaching levels seen in 2022. This has buoyed optimism in the industry.

Another rise we’re keeping an eye on is the Outbound Tender Rejection Index, the rate at which carriers are saying “no” to freight where they have paper rates with a shipper. A six percent rejection rate may not sound important, but considering the rejection rate has stagnated in the three-to-four percent range for the past year plus, it’s another sign that the freight pendulum may be nearing more of a balanced market.

In 2021, rejection rates hovered in the 20-30 percent range. This was more a product of increased freight volumes and carriers realizing they could get higher rates in the spot market versus the contracted rates they had in place. The uptick in rejection now appears to be more of a limit of capacity in certain markets versus carriers hedging their bets on the open load board.

Drip, Drip, Drip

Speaking of that capacity, there is a reduction happening, albeit a slow drip. As shown in Figure 1.2, for the past year and a half, almost two years, the biggest reduction in capacity has been from the owner-operator segment. Most likely, the carriers in this group that have exited the market are those that rushed in when freight and rates were plentiful, and now are finding more normalized rates combined with high overhead to be unsustainable.

As shippers continue to look ahead, not having reliability among this segment of carriers could prove problematic as volumes escalate and more freight flows to the spot market, which is supported heavily by owner-operator drivers. This is a good reason for shippers to ensure they have a good mix of carrier and broker partners.

Baltimore Still Recovering

Finally, it has been just over three months since the bridge collapsed near Baltimore, MD. The waterways in the surrounding area appear to be returning to normal, and the need for traffic that populated the bridge to divert to alternate routes seems to be no worse for the wear on drivers.

Looking at volume in that market in Figure 1.3 since the end of March when the event occurred, after a slight dip when freight had to be re-routed, volumes as measured by the OTVI have increased just over 10 percent. Certainly, there is still work to be done, short- and long-term, but the Baltimore area appears to have powered through an unfortunate event.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive the top five logistics articles of the week every Friday morning by selecting “Weekly News Update” when you select your preferences.

Get Weekly News Updates in Your InboxNearshoring to Mexico is the hottest trend in supply chains.

With Mexico now the top trading partner of the U.S., two-way trade hit a whopping $68.5 billion, according to data from the Census Bureau. In the first quarter of 2024 alone, trade has grown two percent between the U.S. and Mexico year-over-year (YoY).

This growth in shipping to and from Mexico is truly just the tip of the iceberg as companies invest in nearshoring strategies. According to Mexico’s Secretary of the Economy, there have been 378 foreign direct investments within the last year, and private sector businesses from the U.S. account for nearly 40 percent of it.

This surge is driven by companies moving parts or all their supply chains to Mexico, thanks to geopolitical tensions and disruptions like the COVID-19 pandemic. These have shone light on the gaps and difficulties faced by globally distributed supply chains. Companies seek more stability and budget-friendly solutions, finding hope in Mexico. While nearshoring to Mexico offers such benefits, there are common cross border shipping snags you should aim to avoid.

What are the Benefits of Nearshoring to Mexico?

Location, Location, Location!

One of the largest benefits of nearshoring to Mexico is its location. Mexico’s proximity to the U.S. means faster shipping times and lower costs. It also offers more reliability, making supply chains less susceptible to disruptions.

Potential for Savings

Labor costs in Mexico are currently among the lowest in North America, even cheaper than in China. This can be a major draw for companies looking to reduce operational expenses. Shorter lead times also offer the potential for enhanced productivity and further cost savings.

Positive Economic Impact

Cutting costs and sped-up deliveries mean smoother operations, happier customers, and a boost in productivity. This isn’t just good for your business but beneficial for the Mexican economy, too. Businesses established in Mexico create new jobs and economic growth. The U.S. benefits, too, with stronger, more resilient supply chains that are less vulnerable to global disruptions.

But There Can Be Cross Border Shipping Snags

Many business owners don’t realize the complexities that come with shipping across the U.S.- Mexico border. Working with the right provider can make all the difference in whether you’ll face these common challenges.

Here are four major cross border shipping challenges you should be aware of with your nearshoring strategy.

Security Concerns

Cargo theft is a major concern in Mexico, with hijackings being the primary tactic. In April 2024, Mexico averaged about five cargo thefts per day, according to the National Association of Vehicle Tracking and Protection Companies. Unfortunately, that’s trending up compared to the previous year, that’s a 7.7 percent rise in activity. Most hijackings involve some type of violence and often involve food and beverage goods, household items, electronics, and auto parts.

Another security obstacle is Mexico’s poor highway infrastructure. The quality of Mexico’s roadways is significantly lower than in the U.S. According to the 2019 Global Competitiveness Report, Mexico ranks 49th out of 141 economies in its road quality. In comparison, the U.S. ranks 17th. Mexico’s lacking infrastructure increases the potential risk of delays and accidents, as well as cargo theft with any truck breakdowns.

Despite all this, Mexican carriers are not required by law to carry cargo insurance. Many choose to opt out of having it and this often results in inadequate coverage of freight. Because of this, it’s recommended to look into securing your own extra coverage and aim to work with carriers that are certified with the Customs Trade Partnership Against Terrorism (CTPAT).

Lost in Translation?

When working with those in other countries, it’s important to know how they operate. This includes Mexico. Understanding the language and business culture is essential to achieving success.

This fact may be well-known, but not everyone in Mexico speaks English! Spanish is the official language, spoken by about 90 percent of its people. According to a 2023 report, only five percent of Mexicans speak English. While larger businesses may have more bilingual employees on hand, dealing with smaller ones can be challenging if you do not have someone who speaks Spanish. Also, much technical or industry-specific jargon doesn’t often translate accurately. Without bilingual representatives available, it can be easy to have miscommunication issues.

Unlike the U.S., where we often like to get straight to business, Mexicans often prioritize building personal relationships before even discussing any professional matters. Due to this, negotiations can often be more indirect. Working with Mexican businesses means you’ll need to invest time in building strong relationships to foster trust and rapport with your contacts.

Facing Cross Border Complexities

Getting your freight across the U.S.–Mexico border can be complex. Many parties are involved, including several carriers and the customs broker. There are also several touchpoints during the shipping process, and disruption can happen at any of them.

Another hurdle shippers must deal with in cross border shipping is the lengthy transit time. Due to inspections, typical wait times for trucks crossing the border, especially from Mexico to the U.S., can range anywhere from three to 10 hours on certain days. Choosing the right crossing point can greatly affect the transit time vastly, and there are 48 points to consider!

Paperwork Troubles

Freight most often gets detained at the border for incomplete documentation.

Shippers are required to fill out many, often repetitive documents. It’s common for this paperwork to get misplaced or for shippers to not even be aware of the exact procedures required by authorities. When any of this important paperwork is left blank or filled out incorrectly, the carrier gets detained at the border until it is resolved. This can add extra days or costs to your shipment.

Ensure all necessary documents are in order, including:

- Commercial invoice (in Spanish)

- Bill of lading

- USMCA certificate of origin (if needed)

- Packing list

- Sales contract

- Proforma commercial invoice

- AES filing

- Customs declaration

- Insurance policy

Having these documents in both Spanish and English can prevent delays and misunderstandings.

Trinity Logistics: The Perfect Partner for Your Nearshoring Strategy

Navigating the complexities of shipping to and from Mexico can be overwhelming! One simple mistake is all it takes to cause delays and additional costs. That’s where finding a reliable logistics provider comes in.

Sure, perhaps you can do it all on your own, but trust us, it’s easier with help. You can outright avoid these four common mistakes when shipping to and from Mexico when you’ve chosen to work with a reputable logistics provider like Trinity Logistics.

We’ve been navigating the waters of cross border shipping for over 45 years, so we understand all the nuances. Our bilingual Team Members and Authorized Agents (some even based in Mexico) get the business culture and fluently speak the language, so there won’t be any miscommunication concerns. Not to mention, our People-Centric service always puts relationships first, regardless of nationality.

We’re customs process experts and have trusted carrier relationships ready to roll. Whether it’s Laredo, El Paso, San Diego, or another major U.S.-Mexico border, we have a variety of transportation modes available.

If nearshoring is part of your supply chain strategy but you’re concerned about shipping to and from Mexico, worry no longer. Instead, consider Trinity Logistics as your cross border copilot. We’ll handle the logistics so you can meet your business goals.

Get a FREE Quote Discover Effortless Cross Border Shipping