If you’ve worked in the LTL industry for any bit of time, then you know that it’s always changing. Yes, sometimes that means it gets a bit more complicated. Rates adjust. Rules and processes are modified. Despite all this, there is usually one constant – the core LTL carriers we work with. Yet, in 2023, that changed; we saw the departure of the legacy LTL carrier known as Yellow Corporation.

The closing of such a large and well-established LTL carrier is very rare. The industry hadn’t felt the void of such a large company since Consolidated Freightways closed 20 years prior. So, what happened? Considering Yellow Corporation was the third largest LTL carrier, what happened to all the freight they handled?

As someone with a career in LTL, I saw this happen in real-time and have directly seen its ripple effects. I can answer some of those questions and share with you my thoughts, experiences, and observations of this impactful event in LTL history.

The Fall of Yellow Corporation

Yellow Corporation (commonly referred to as YRC) was no stranger to financial turmoil. The company was laden with debt that was worsened with the Great Recession. It almost put them into filing for bankruptcy in 2009.

A stint of other factors after that didn’t put them in a better position when COVID-19 rolled around in 2020. YRC was granted a $700 million COVID-relief loan by the U.S. government, which it used nearly half of to cover past due payments to healthcare and pensions, payments on equipment and properties, and interest accrued by its other debts. Fast forward to 2023, and that’s where their final chapter began.

A few months into 2023, YRC and the Teamsters Union engaged in back-and-forth negotiations. YRC wanted to change operational procedures and sought extra funding to help it pay off its debts. Teamsters disagreed with the proposed changes. We saw news articles and hit pieces about the conflict, week after week. It was nearly impossible for the industry to ignore it.

In July, whispers began of a possible union strike that would effectively halt YRC’s freight network. This was the writing on the wall for many shippers and third-party logistics (3PL) companies. At this point, the hull had been punctured, and water pouring in. Do you stay or do you go?

YRC and its subsidiaries were promptly disabled from countless TMS platforms. No customer wanted their freight stuck in limbo if Teamsters were to go on strike against YRC. Because of this, YRC saw a sharp decline in freight volume and tonnage. A company that was in financial disarray was now losing its primary source of revenue.

On July 30th, Yellow Corporation ceased all operations. The Teamsters had not agreed to the negotiations, and the 11th hour came and went. So, what now?

The Aftermath of YRC’s Closing

YRC’s exit affected two parties: shippers using LTL and other LTL carriers.

For shippers using LTL, they were two buckets: those who had already begun shifting their freight to other carriers in their pricing roster and those unfortunate enough to still have most or all freight with YRC. The latter had a more difficult situation to overcome as they now had to find an LTL carrier to move their freight without paying an arm and a leg.

For LTL carriers, YRC’s existing freight had to go somewhere, so they had to figure out how to absorb it. Carriers such as Estes, FedEx, and XPO and their capabilities were pushed to their limit, now drinking from a firehose of incoming freight. Volumes increased drastically, and with such a rapid rise came decreased capacity.

LTL carriers were making the difficult decision to exclude certain shippers in favor of others just to service accounts and keep their networks moving without bottlenecking. This left many smaller shippers stranded with a shorter list of available LTL carriers.

As carriers became inundated with freight, their operating ratios took a hit, and something had to be done to regain control. A season of atypical general rate increases (GRI) began. LTL carriers needed to remain profitable lest they succumb to a fate like Yellow.

3PLs and shippers alike started getting notifications from their carrier representatives about rates going up. Shipping LTL got more expensive now that the carriers had to pick and choose who they serviced with their finite capacity. The increased rate structures also priced out shippers that were used to YRC’s competitively priced tariffs or couldn’t stomach the increases.

For many shippers and 3PLs, the immediate aftermath of the Yellow Corporation bankruptcy was unlike any they had previously experienced.

Now, that’s the long and short of it, but how are things today? Surely, the disappearance of a significant LTL carrier like that would have lasting, irreversible affects.

Well, yes, but also no.

The Current Impact of YRC’s Closing

Today the LTL industry has mostly stabilized. YRC’s freight volume has dispersed, and the dust has settled. The LTL carriers have course-corrected their capacity concerns.

After the YRC bankruptcy, there were also new questions to answer, one of which was “What happens to their assets?” Those went through the bankruptcy courts, but the LTL carriers were eager to get a piece of it.

The purchased terminals and trailers meant increased footprint and capacity, which can be the difference between being the best and the biggest for LTL carriers. Several carriers bid to acquire the terminals left behind by Yellow Corporation.

Estes Express, a prominent national LTL carrier, was one of the larger victors in the bidding war. As one of Trinity’s carrier relationships, I asked Estes if they could share the impact YRC’s exit had on their company. Here’s what President and COO Webb Estes had to say:

“Estes acquired 29 terminals and a large amount of equipment as a result of Yellow’s exit from the marketplace. I can’t say enough for the dedication and resiliency of our team to work together tirelessly to quickly bring them online and add to our steady capacity growth. In addition we purchased several tractors and trailers, and we were also able to buy many smaller items – such as load bars, airbags, and freight tables – all of which help us do an even better job protecting our customer’s freight,” said Estes. “One other surprising benefit is that the additional freight we’ve taken on has allowed us to add more direct linehaul lanes, and we’re seeing better overall service in 2024 compared to last year.” Estes added, “This is a great example of how Estes continues to invest wisely in assets and capabilities that create capacity, opportunity, and resiliency for our company and those we serve. And that remains a primary reason why customers from coast-to-coast continue to rely on us for their shipping needs.”

While LTL carriers, larger shippers, and 3PLs came out in the black or relatively unscathed, others did not. Smaller shippers with all their freight lanes with YRC had no backup plans except to pay increased, non-discounted LTL rates with other carriers or risk their business operations.

How Did Trinity Logistics Fare?

At Trinity, those first few months after the bankruptcy were interesting! We saw many new shippers start a relationship with us and saw some complications in LTL carrier transit lanes that bottlenecked. Don’t worry, they were quickly resolved. Since Trinity has a broad roster of national and regional LTL carrier contracts in place, our shipper relationships were able to use our rates to course correct from the YRC closure and effectively avoid any critical disruption.

Is the last time we’ll see an industry-shaking event in the LTL space? Likely not. For now, the industry is stable, and many LTL carriers are growing and reporting profitable earnings.

In my 10+ years working in the LTL industry at a 3PL, the Yellow Corporation was always a top LTL carrier for us. Seeing them fade into the wind after decades of LTL service was surreal, and I felt sad for the many YRC employees I’ve grown to know.

Despite such an impactful event, now written in the history books, it’s a year later, and the LTL landscape is still thriving (and volatile), even with one less player at the table.

Final Thoughts

Considering the size of Yellow and the steady decline until evaporation from the industry, I actually expected more disarray from it. Sure, the first weeks after the bankruptcy had the GRIs, shipment delays, and new shipper partnerships for Trinity to handle, but after a month or two, it was relatively smooth sailing back to normal.

I think that speaks volumes to the age we live in. The amount of technology and time-saving efficiencies that LTL carriers invest in year after year. It allowed the industry to absorb the freight volume of one of the largest LTL carriers in the world and it did so in less than 60 days! It’s kind of crazy and a testament to the LTL industry and its controlled chaos.

Working with Yellow for so many years, I grew familiar with some of the names worked there. People we would see at conferences, have calls with or see on emails. People who had been in the industry much longer than I have, had extensive backgrounds, and grew their roots at Yellow.

The bankruptcy landed them in the middle of it all, but many of them went on to other LTL carriers and took their experience, adding value there. I think that’s a silver lining here. Despite the financial decision of Yellow as a company, it had people on its roster that brought purpose to LTL and now these people are creating an impact for other carriers and customers alike. For how vast it is, the LTL industry can be closeknit, so to see those former Yellow employees succeed at other LTL carriers is a bright spot in this saga.

Learn More About Trinity's LTL Services Get More Content Like This In Your InboxABOUT THE AUTHOR

Curt Kouts holds the Director of LTL position at Trinity Logistics. Kouts has been with Trinity and in the logistics industry for 14 years, having held several titles among carrier vetting, account management, and within the LTL Team itself. His main responsibilities as Director focus on elevating Trinity’s LTL customers’ experience, helping the LTL Team support in operations and billing, and aiding the company in overall LTL sales and success. Kouts finds the LTL industry incredibly challenging, presenting him and his Team a ton of problems that they have a passion for solving. He enjoys learning more about LTL whenever possible and overall, making LTL an experience that keeps all his customers, both internal and external, coming back.

Do you feel like you could be spending less on your less-than-truckload (LTL) shipping rates? Most likely, you’re right. LTL shipping rates are affected by many different factors, so it can be pretty easy to make these simple changes and see your shipping costs decrease. While these tips may not be possible for everyone or every shipment, hopefully, you’ll find one you can start implementing to reduce your freight costs.

HOW LTL SHIPPING RATES ARE CALCULATED

Compared to truckload rates, LTL shipping rates can be very confusing. To make it simpler, here’s what goes into your LTL costs.

Absolute Minimum Charge

This is the lowest rate a carrier will charge.

Accessorials

These are extra charges for any services provided by the carrier that are beyond simply shipping from one point to another. Examples of common accessorials include:

- Inside pickup or delivery

- Lift gate service

- Residential delivery

- Detention storage

Base Rates

Each LTL carrier sets its own base rate, often quoted per 100 lbs., and based on the freight classification, weight of the shipment, distance traveled, and the origin and destination zip codes.

Lane

The lane plays a role in the base rate. The further the distance traveled in the lane, the more costly the LTL shipping rate can be.

Freight Classification

The product you ship has its own classification based on the National Motor Freight Classification (NMFC). Freight that is dense and difficult to break is in a lower class, making it the least expensive. Lighter and more fragile freight is at a higher freight class and thus, costs more.

Weight

LTL shipping rates are based on the total weight and number of pallets. The heavier a shipment, the less it costs per hundred pounds, as factored by the base rate calculation.

HOW TO SAVE ON YOUR LTL SHIPPING RATES

Maximize Density

LTL carriers make a profit by fitting as many different LTL shipments into their trailers as safely as possible. So, which do you think they prefer – a shipment that takes up 25 percent of their trailer or a shipment that takes up 10 percent? The less space your shipment can take up, the less it could cost to ship it.

While the weight of your shipment may be out of your control, the density is not. Increasing density starts with how you pack your LTL freight. Experienced shippers know that doing everything they can to compactly pack their freight on pallets will reduce their LTL shipping rates.

So, do everything you can to make your shipment take up less space. If your current pallets are not stackable, find a way to make them, if possible. Reduce any empty space between cases or products on the pallet. If possible, stack an extra row on top of each pallet to eliminate using an extra pallet. Brainstorm all the ways to make your shipment take up less space, and you’ll likely see savings.

*It’s important to note that you should never negate safety or product quality to reduce your shipping rates!

Aim to Avoid Peak Shipping When Possible

While this may not always be possible, avoiding peak shipping times is an easy way to reduce your LTL shipping costs. When you can, plan and ship early or after peak times.

Evaluate Packaging and Product Design for Logistics

Now this tip is more of a hefty task, but it’s certainly one to consider. When in the early stages of product and packaging design, or even when re-evaluating, it’s ideal to get one of your logistics professionals involved. This will help your product and package designers consider details that can make your product easy to ship, stack, and organize. There’s nothing worse than having a great product only to end up with it being too cost-prohibitive to transport.

Consider “Economy Class” LTL Carriers

If your shipment isn’t time-sensitive, using “economy class” LTL carriers is an easy way to reduce your LTL shipping rates. Their rates are often cheaper but their transit times are longer, so you’re trading off higher costs for more time. If you have time to spare, this is a great option for savings.

Ship Larger Loads Less Often

As you likely know, it’s cheaper to ship several pallets at once than one at a time over a few weeks. However, to use this strategy, you’ll have to convince your customers to take on larger orders. You can offer them a price break or agree to share some of the savings you see in shipping to do so.

Consolidate to One Truckload

Eliminating a shipment altogether is a surefire way to reduce your freight costs.

Have you ever considered consolidating your LTL shipments into a multi-stop truckload shipment? Shipping a full truckload of freight is often far less expensive than shipping multiple LTL shipments.

Of course, it depends on where your shipments are delivering. For example, a multi-stop truckload picking up in Maine and delivering in Florida, Minnesota, and California might not make financial sense compared to shipping LTL. But if your delivery points are close to each other, or if they form a line across the country (at least vaguely), getting a quote on a consolidated truckload shipment would be very wise

If you don’t have enough for a full truckload, you could still consolidate and combine two or more LTL shipments into one. It’s worth it to see if any sort of consolidation can reduce your LTL shipping rates.

Negotiate with LTL Carriers

It never hurts to ask or negotiate for a discounted rate with your LTL carrier. Perhaps you can have an accessorial fee waived or reduced based on shipment frequency.

If you ship all kinds of freight, you may be able to negotiate freight of all kinds (FAK) for reduced LTL shipping rates. Rather than getting a rate for different classes of freight (which can be time-consuming and complicated), you negotiate to have all your LTL freight rated in the same class, with FAK, which not only saves you time but money.

You could also negotiate for Customer Specific Pricing (CSP). This is contracted pricing, which could include a FAK structure if needed. LTL CSP allows carriers to have a better picture of your freight which not only results in more efficient, but often cheaper, pricing since the rate contracts are ONLY based on your shipments.

Interested in LTL CSP? Let Trinity negotiate with LTL carriers on your behalf.

Avoid Accessorials When Possible

Accessorials in LTL shipping are common and some may be unavoidable, but many can be avoided when planning ahead. To avoid these extra charges, make sure to educate yourself on your LTL carrier’s guidelines and accessorial fees, aim to avoid weight, dimension, and oversizing adjustments, and ensure your bill of lading (BOL) is accurate. Taking these extra steps will ensure you don’t get hit with unexpected charges and keep your LTL shipping rates low.

Provide Accurate Information

Most shippers are aware that the rate for shipping their LTL freight is highly dependent on the size and weight. For this reason, some people are tempted to slightly underestimate the dimensions or weight of their shipment in the hopes it will result in a slightly lower shipping cost and the LTL carrier will be none the wiser.

Whatever you do, don’t do this! Rather than saving money, you may be opening yourself up to extra charges. Most carriers will double-check that the dimensions and weight of your shipment match what’s on the BOL. If it doesn’t match, you’ll be faced with extra, unexpected charges. Your shipment cost will be raised accordingly, but you’ll also be charged with an inspection or reweigh fee, and it’s possible the carrier will red flag your freight to be inspected every single time you ship with them, meaning you just caused increased LTL shipping rates for the future – the opposite of what you wanted.

Use a TMS for Efficiencies

Controlling your shipping costs can be difficult without having full visibility of your freight spend. So, if you’re really looking to take control of your freight costs, a transportation management system (TMS) is what you need. A TMS can give you clear insight into your logistics with comprehensive reporting so you can find more ways to save on your LTL shipping rates while also finding efficiencies in your operations.

WORK WITH A 3PL

Probably the quickest and easiest way to save on your LTL shipping rates and your time is working with a third-party logistics company (3PL), like Trinity Logistics.

Because of the high volume of freight that 3PLs arrange for all their customers, means we have lower contracted rates (aka deeper discounts) available that you otherwise wouldn’t be able to access. This will result in significant cost savings, especially over time.

Working with Trinity Logistics also gives you the benefit of working with logistics experts who can help you not only with your LTL shipping but any other modes you may need or be interested in. We’ll help you determine what other modes make sense and what other benefits or savings they could offer your business. We also have a dedicated Team to assist you with Managed Transportation or implementing a TMS if that’s something you may need now, or in the future as you grow.

Whether you simply need help saving on your LTL shipping rates or would like a valuable logistics partner on your side for all your logistics needs, our Team is ready to help you and your business succeed.

LEARN HOW TRINITY CAN HELP YOU WITH LTL SHIPPING START SAVING ON LTL SHIPPING RATES-GET A FREE QUOTEYou can consider drayage service the unsung hero of shipping. It’s crucial to global supply chains, bridging the gap for both intermodal and international shipments.

Growing businesses often develop a need for drayage services but can easily get overwhelmed by it. Unlike truckload or less-than-truckload (LTL), getting your items picked up and delivered with drayage shipping sometimes isn’t a straightforward process. From port congestion to demurrage, it’s easy to get lost in the tangled process of drayage. Yet, with a few quick tips and the right approach, you can make use of drayage services to your supply chain’s advantage.

What ARE COMMON CHALLENGES WITH DRAYAGE? How Can I avoid Them?

Route Planning

One of the primary challenges faced by shippers handling drayage services is route planning. Ports and rail terminals often operate in congested cities with lots of traffic and frequent road closures. Poor route planning can lead to delays, missed appointments, increased fuel consumption, additional fees, and, most of all, frustrated customers.

Chassis/Equipment Shortages

Just like there can be ebbs and flows with truck trailer capacity, drayage brings the concern of its own equipment shortages. Chassis are what the containers sit on when hauled by the carriers. It’s important to mention that drayage carriers don’t own chassis. Instead, they rent the chassis from the port or terminal, thus adding an additional complexity to drayage services. Chassis shortages most often happen during peak shipping seasons and can create delays or additional costs for shippers.

Port or Terminal Delays

Delays can happen at the ports or terminals for several reasons. Unforeseen events like canal blockages (Suez Canal), the Francis Scott Key Bridge collapse, or possible rail strikes have most recently created delays for shippers. Customs clearance is often the most common cause of delays as the process can be intensive, and any improper documentation or misclassified products can cause a holdup. Container reshuffling can also be an issue from time to time when there are too many containers, whether full or empty, at the ports or terminals.

Additional Charges

Additional charges may be the bane of drayage services, second to delays. Drayage can come with many accessorial fees that can catch shippers off guard if not prepared. The most common fee you’ll hear about in drayage services is demurrage.

Once a container is delivered to the port or terminal, you’re given a set number of “free days” for it to be picked up by a drayage carrier. This is called your Last Free Day (LFD), and that’s the date you want to ensure your container is picked up so you won’t face this additional charge.

There are also drop fees. Drop fees are for when the drayage carrier must drop the container and then come back to pick it up and return it empty to the port or terminal.

Lastly, if the empty container is returned late to the port or terminal, that’s an additional fee.

Lack of Transparency or Communication

With drayage services, you really need to have a clear picture of what’s happening if you want to reduce the chance of accruing any additional charges, not to mention any delivery delays or customer dissatisfaction. Effective communication between shippers, carriers, logistics providers, and port or terminal authorities is essential for smooth drayage shipping.

TIPS TO Avoid DRAYAGE SERVICE CHALLENGES

If you’ve experienced any of the previously mentioned challenges with drayage service, the great news is there are really only two tips you need to make it seamless.

Proper Planning and Time Management

Most of the challenges with drayage are caused by improper planning, unforeseen circumstances, or misinterpretation at the port. Proper time management and planning are essential to avoid those challenges in the first place. Ensuring you have properly evaluated and documented your freight, selecting the right drayage carrier based on your needs, and taking into consideration factors like port or terminal timings or traffic.

Additionally, stay in the know of what’s going on in the market. Are there any anticipated delays or disruptions that could change your plans? Do you have a contingency plan in place should an unforeseen event occur? The more planning you’ve made ahead of your drayage shipment, the better your supply chain will operate.

Work with the Right Drayage Provider

Working with the right provider can significantly impact the success of your drayage service. While that tip is easy to state, how do you determine if a provider is the right one for your needs?

When searching for a drayage service provider, you should ensure they:

- Gain you access to reliable capacity with experienced carriers,

- Offer excellent customer service and clear and timely communication,

- Technology tools to provide you with shipment visibility and tracking,

- Accurate billing practice,

- And has a high on-time delivery percentage.

By prioritizing these characteristics when looking for a drayage service provider to work with, you’ll quickly find that selecting the right one will improve your company’s competitiveness and service by helping you overcome these common challenges.

WORK WITH TRINITY FOR The Best DRAYAGE SERVICES

Speaking of reliable drayage service providers, you’re currently hot in your search already!

Trinity Logistics is a nationwide, top-rated third-party logistics (3PL) provider capable of helping you overcome any challenges you’ve been facing with your drayage service. You should consider us because:

Trustworthy Carrier Relationships

We treat and respect our carrier relationships and aim to build a strong partnership with each one to help their businesses be successful. Because of that, we’ve built trusted partnerships with those in our carrier network, gaining you access to the capacity you need and the service you want.

24/7/365 Support

No matter what happens, we’re ready to support you around the clock. We have a dedicated After-Hours Team to continue the monitoring of your freight and are ready to quickly resolve potential challenges, no matter the time of night, holidays, and every weekend.

Tracking and Tracing

We understand transparency is key to your drayage success, so we offer several ways to view and keep track of your freight, no matter the time of day.

Team of Experts

Our only job is logistics. It’s what we handle day in and day out. We’ve been working in this industry for 45 years and have seen all the ups, downs, delays, and disruptions the freight market has thrown at us, so we know how to handle tough situations. Additionally, we stay knowledgeable about what’s going on and keep you informed of anything that could come your way, with a backup plan at the ready.

Clear Communication About Charges

From the start, we are transparent about costs and help you understand all the different charges that you may see or come across with drayage service.

Your Trinity relationship will provide a list of any potential charges that may arise, such as any overweight, drop, or hazmat fees. Our goal is to ensure you know exactly what to expect so there are never any surprises.

An additional benefit to our trusted carrier relationships is our capability of keeping any fees from the port tied to the clearance of any containers from being billed back to you and being able to be competitive with those drayage rates.

Yes, drayage services can be complex and challenging at times, but it doesn’t have to be if you choose to work with Trinity Logistics.

I WANT TO KNOW MORE ABOUT TRINITY’S DRAYAGE SERVICEAt Trinity Logistics, we’ve always believed in doing the right thing. That concept is foundational and woven into the fabric of our company culture, from the services we provide to the impact we aim to make on the world around us. Being sustainable is an important focus for the company. It’s a responsibility we take seriously, so our sustainability initiatives are no afterthought.

Logistics Environmental Sustainability

The United Nations defines sustainability as “meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

Our company takes that message to heart. We recognize the critical part we play in taking care of our communities, making a positive impact, and reducing our environmental footprint. We want to leave a positive legacy behind that extends beyond our logistics services. This includes our part in taking care of our environment and the communities we touch.

Here’s a glimpse into how we take action to be sustainable.

Paving the Way to Less Emissions with SmartWay

The SmartWay program by the Environmental Protection Agency (EPA) helps companies improve supply chain sustainability and reduce transportation emissions by providing a system to track fuel and emissions so companies can select more efficient carriers and logistics strategies.

Trinity invested in a SmartWay partnership in 2008, making this our earliest sustainability initiative. This partnership enables us to access and build relationships with SmartWay-certified carriers that commit to tracking and minimizing their emissions. We’re able to leverage that network, empowering our shipper relationships to make sustainable choices by using these SmartWay-certified carriers whenever possible.

Chemical Safety with Responsible CareⓇ

Responsible CareⓇ is the chemical industry’s environmental, health, safety, and security initiative, hosted by the American Chemical Council.

Since 2009, Trinity has been a proud member of Responsible CareⓇ. Some of the ways we take this sustainability initiative into action include;

- carrying pollution liability coverage to cover costs associated with pollution clean-up or other pollution-related liability claims;

- stringent carrier vetting to select the right carrier with the right requirements, like being hazmat-certified;

- ongoing required Team Member training to maintain knowledge of proper procedures, especially regarding chemical transportation.

Offsetting Carbon Footprint in Logistics with ClimeCo

ClimeCo is a non-profit organization that helps companies offset their emissions by donating funds towards sustainable projects.

Trinity Logistics understands that climate change is a pressing issue, so we’re committed to doing our part. In 2022, we began collaborating with Carbonfund, now known as ClimeCo. At the end of each fiscal year, we calculate the electricity usage of our owned facilities. With that calculation, ClimeCo helps us identify sustainable projects to donate to and offset the emissions we produced that year.

We’ve already made a difference by contributing to the Texas Capricorn Ridge Wind Project and N20 Abatement Project. In 2022 alone, we offset 143 tonnes of carbon emissions, and in 2023, we mitigated another offset of 90 tonnes. That’s a win for the environment and a win for future generations.

Building Sustainability in Our Offices

Sustainability isn’t only about grand gestures; it’s about the everyday choices we make. That’s why we seek out sustainable practices within our own facilities.

We offer convenient battery recycling through a partnered vendor, ensuring they’re disposed of responsibly. We also ensure any used paint gets recycled instead of ending up in landfills.

We offer multi-stream recycling to our Team Members as well. Each Team Member has their own container to recycle any paper documents, while a large bin outside collects glass and recyclable plastics. Knowledge is power, so we educate our Team Members on proper recycling practices, too.

Our Facilities Team also aims to make sustainable purchases as often as possible. They’ve already converted any lighting in our owned offices to energy-efficient LEDs. They also focus on purchasing eco-friendly supplies that are compostable and certified sustainable. For example, they buy compostable paper plates and takeout containers for our weekly lunches.

Recognizing the Power of Remote Work for A Cleaner Environment

We recognize the many benefits of remote work. It fosters a vibrant company culture, empowers our Team Members with greater flexibility, and contributes to a greener future. By embracing remote and hybrid work positions, we help reduce emissions from daily commutes and cut our office space requirements.

Currently, around 50 percent of our positions offer remote or hybrid options, allowing our Team Members to focus on time with their families, contribute to their communities, and be part of this impactful sustainability initiative.

Empowering Shippers with Sustainability

For Trinity, sustainability is about more than our own initiatives. It’s also about helping our relationships find sustainable options in their supply chains.

For each shipment, we’re able to offer guidance on the most efficient transportation modes available. We offer regular business reviews to analyze our shipper relationship’s unique logistics profiles to find and suggest efficiencies. Our Team also works closely with shippers and carriers to tackle deadheading, a large contributor to carbon in the trucking industry.

Additionally, we’re always looking to explore new ways to push the sustainability envelope for our relationships. Currently, we’re looking into platforms that can help us provide our shipper relationships an extra avenue to offset their carbon emissions, too, like Patch.io.

Ecovadis – Recognition of Trinity’s Commitment to Sustainability

EcoVadis, a trusted and globally recognized provider of business sustainability ratings, recognizes our dedication. In 2023, they awarded us a bronze medal, placing us within the top 50 percent of companies assessed. While we acknowledge this is a significant achievement, at Trinity, we aim to continuously improve. Our sights are set on achieving a silver rating in 2024, reflecting our ongoing commitment to continuous improvement.

The Trinity Logistics Difference

As our mission statement says, we’re dedicated to “improving lives and supply chains by solving tough problems.” Sustainability is undeniably a complicated challenge. The good news is that our passionate Team Members at Trinity Logistics thrive on tackling tough problems and overcoming obstacles. We’re relentless in our pursuit of solutions, and we won’t stop until we’re satisfied with the results.

We understand sustainability is a never-ending journey of improvement. That’s why you can count on Trinity Logistics to remain a leader in sustainable practices. We’re constantly expanding our sustainability initiatives and deepening our commitment to a greener future.

Our dedication to sustainability is just one facet of the Trinity difference. If this is how seriously we take environmental responsibility, imagine the level of commitment we bring to solving your logistics challenges.

DISCOVER HOW WE CAN HELP YOU ACHIEVE YOUR LOGISTICS GOALSAfter several record setting years, 2023 saw shifts to the freight market. How did the 2023 freight market affect shipper and carrier businesses? Did other businesses have the same struggles as yours? Are they expecting to face similar difficulties in 2024? How are their partner relationships?

Trinity Logistics wanted to get answers to these questions for you, so we asked a random sample of our shipper and carrier relationships to gauge the effect 2023 had on their business and what their expectations for 2024 in our first Freight Market Survey. Here’s what we found out:

2023 SHipper & Carrier Data: Freight Market Survey Results

Past Challenges – Same, But Different

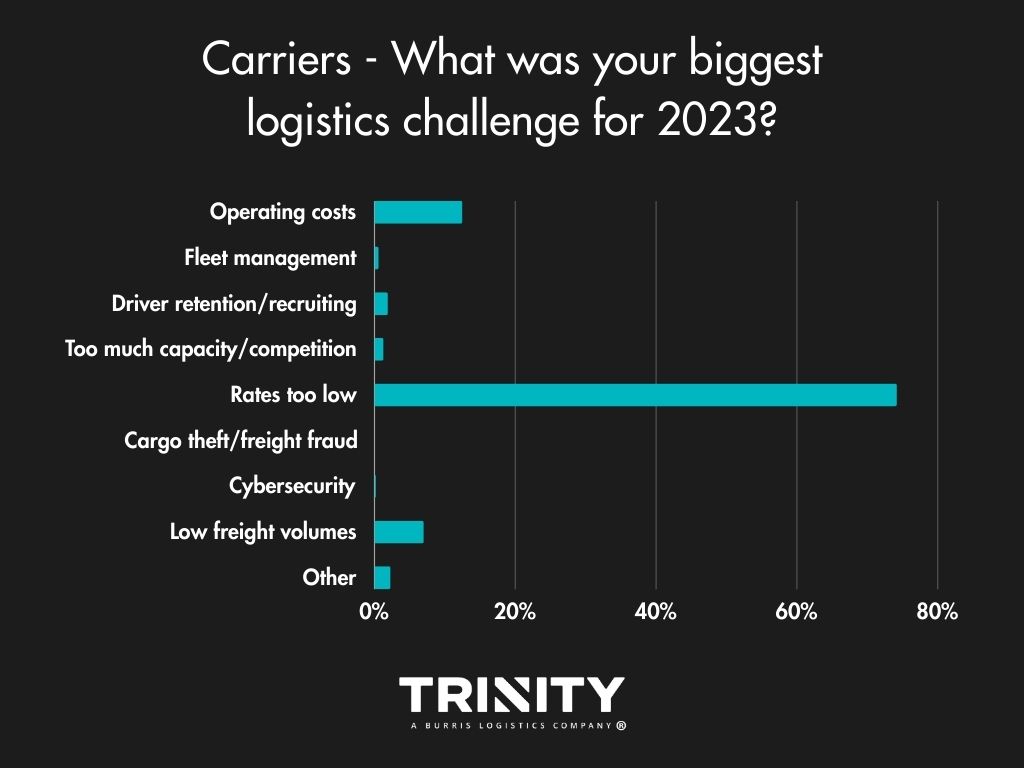

Considering the recent turndown of demand and the freight market, it’s not a big surprise that money was the biggest issue for shippers and carriers alike. Shippers answered that transportation costs were their biggest challenge in 2023, with supply chain delays/disruption and capacity not far behind. Low rates and increasing operating costs were the main challenges facing carriers.

Business Impact – Could Have Been Better

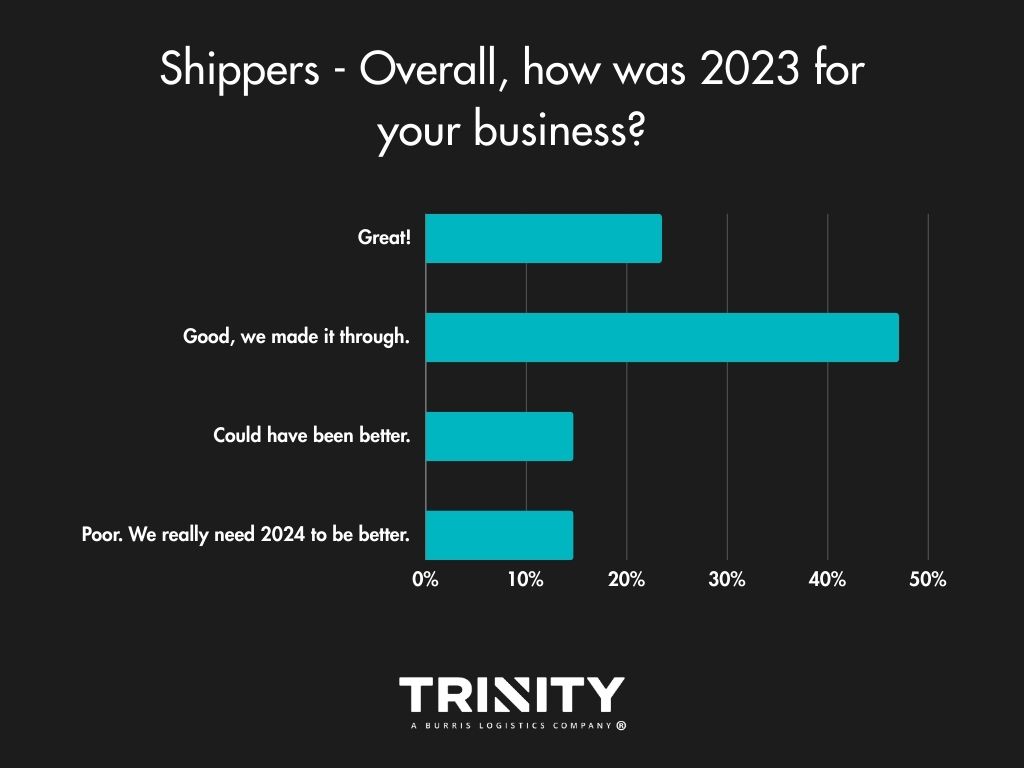

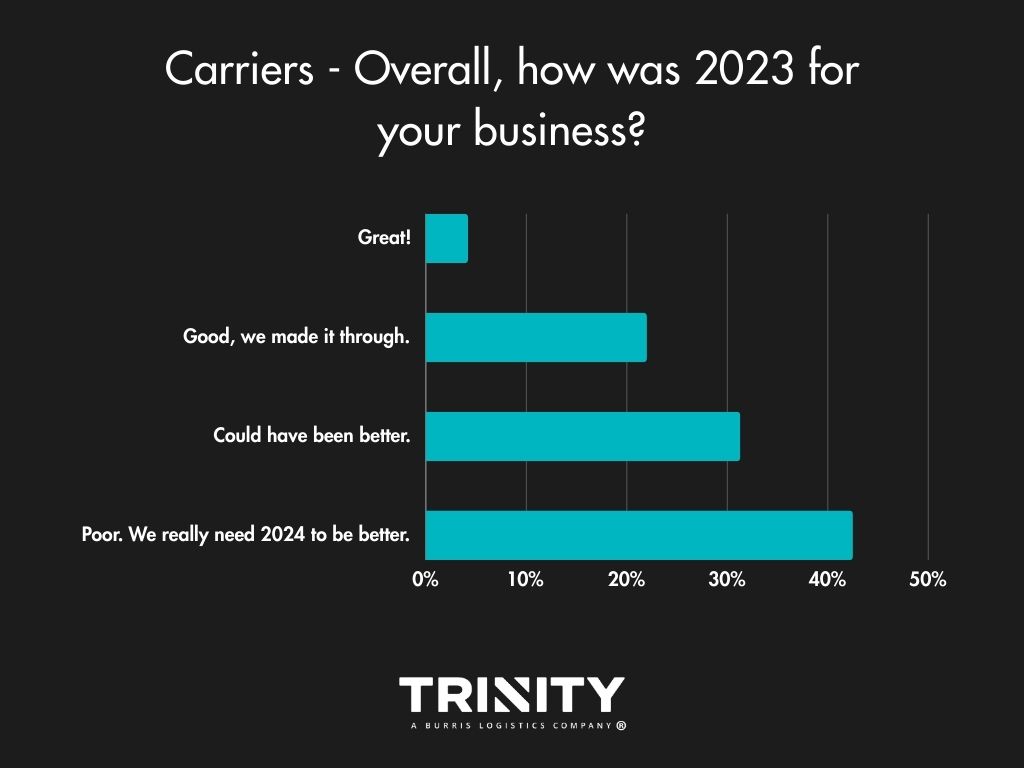

Even with the change in consumer demand trending downwards throughout 2023, most shippers answered that their year was good overall. Carriers on the other hand seemed to face a rougher year in business with over half of them stating their year could have been better or was poor.

A LOOK INTO 2024

Future Challenges – Money Problems

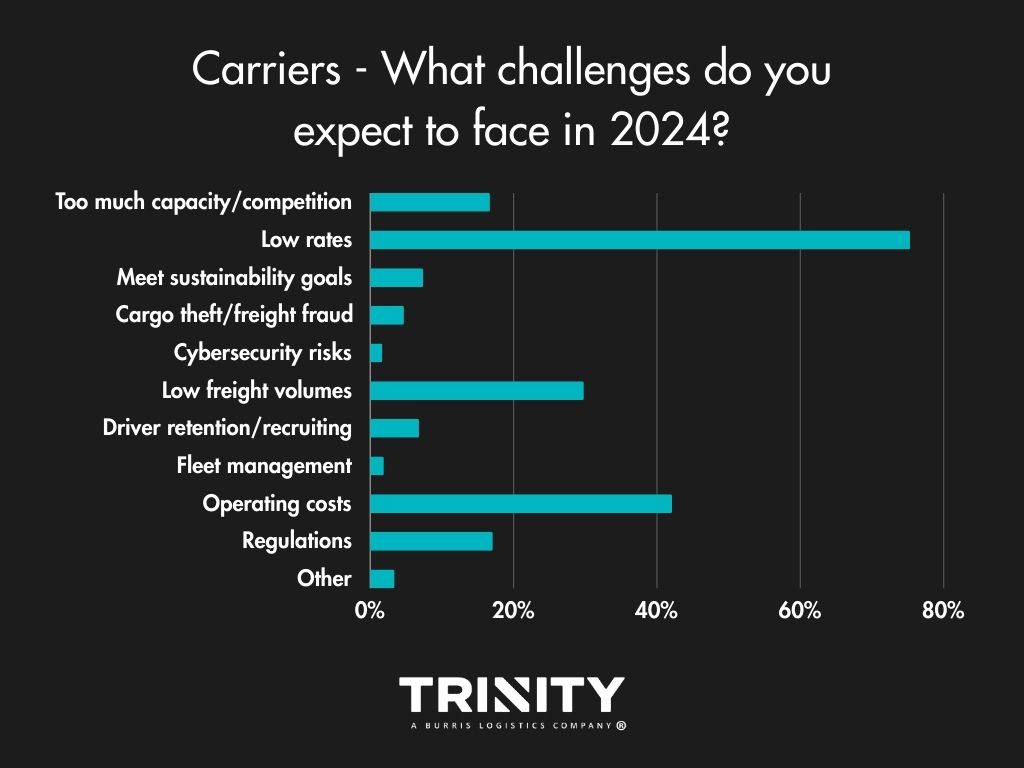

2024 isn’t looking much different in terms of challenges compared to 2023. Shippers look to have the same financial challenges as they did in 2023 with transportation costs, supply chain delays/disruption, and decreased demand being the top concerns selected. Carriers are still concerned about low rates, operating costs, and low freight volumes hurting their businesses.

Hot Trends

Even though transportation costs are shippers’ strongest concerns in their previous answers, it seems the increased amount of supply chain disruptions and delays we’ve all experienced in these recent years have hit a nerve, with the majority answering that supply chain resilience is the trend their business is most interested in. Cybersecurity also looks to be a growing interest.

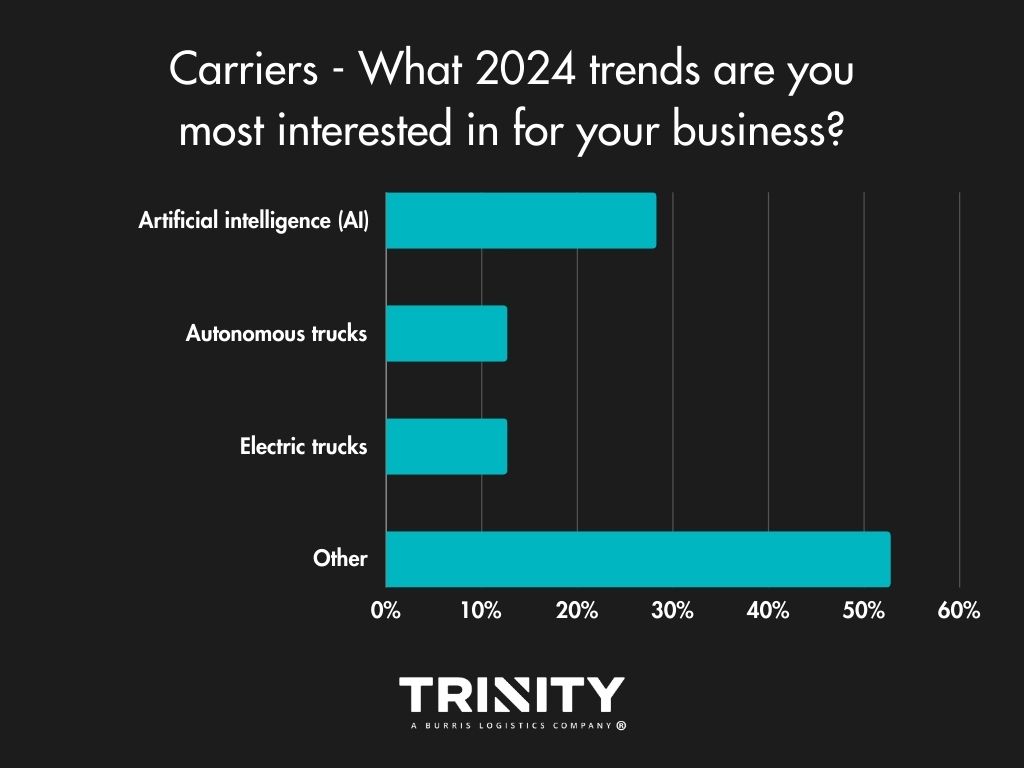

Carriers on the other hand, interestingly enough, look to the recent trend of Artificial Intelligence (AI). Also, as noted in the comment boxes of our “Other” option, increased rates and better fuel prices were trends they’d like to see in 2024.

Load Volumes & Capacity – Slightly Positive Outlook

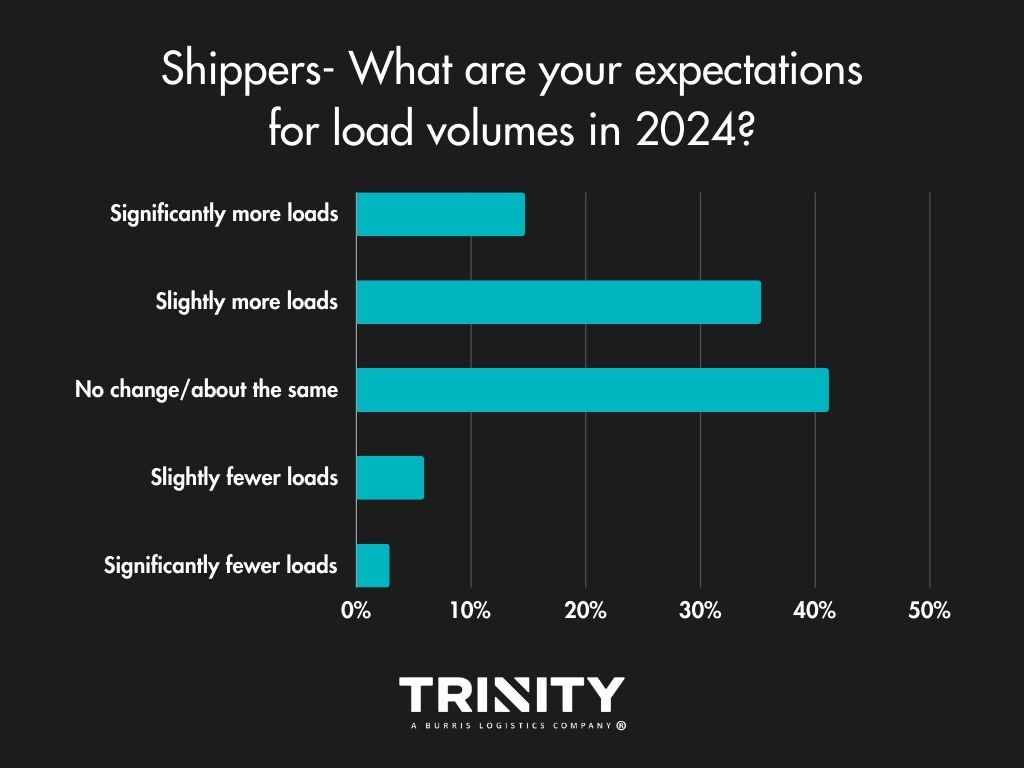

Overall, shippers are slightly more optimistic for 2024, thinking it won’t bring any change or the change it brings will be positive. Most think load volumes will stay the same or there will be a little more in freight volumes this year. As for truck capacity, they think it will be the same as 2023 or slightly tighter.

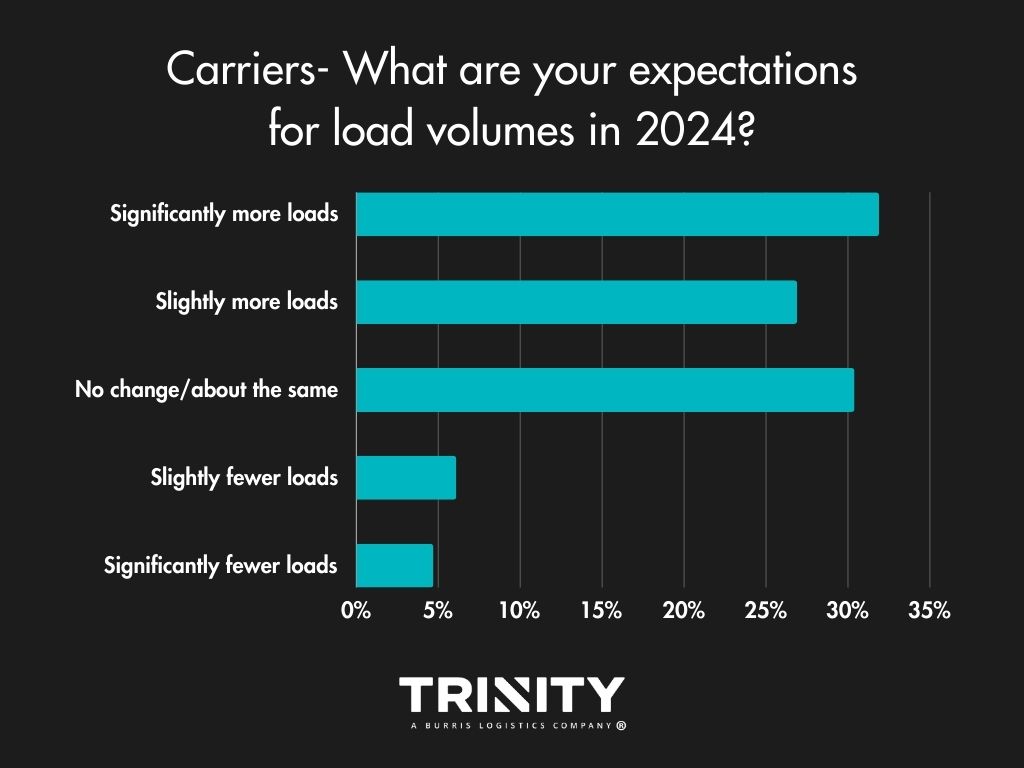

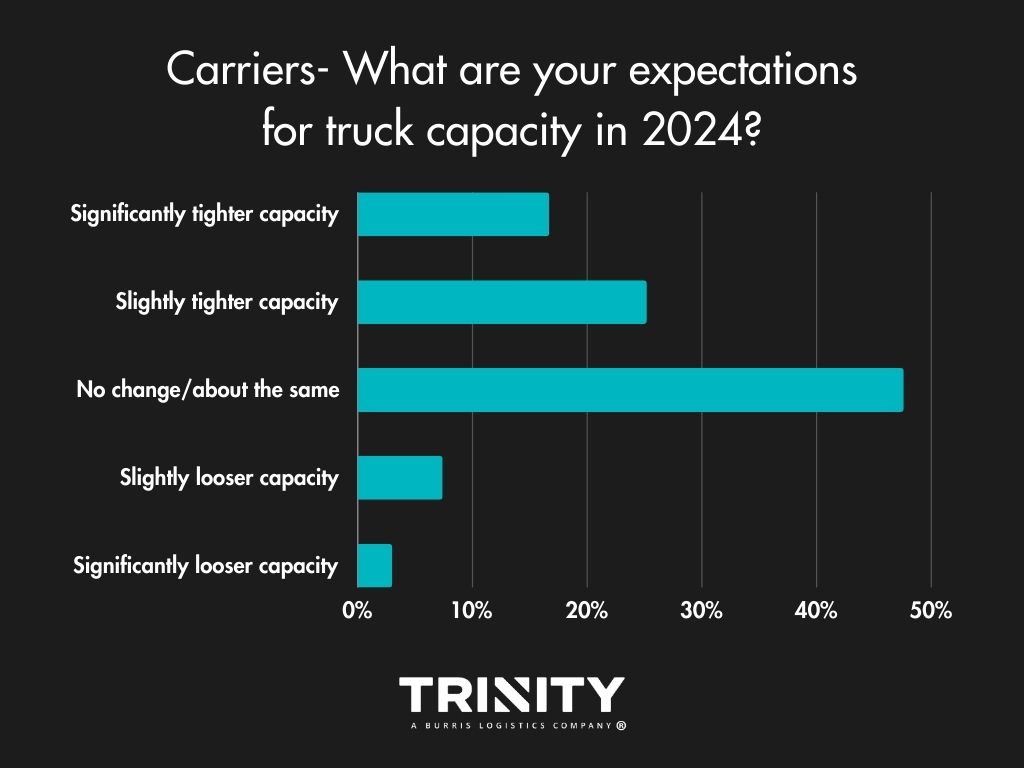

Carriers also think 2024 will bring more freight volumes and that capacity will likely stay the same or get tighten slightly versus 2023.

Spot or Contract?

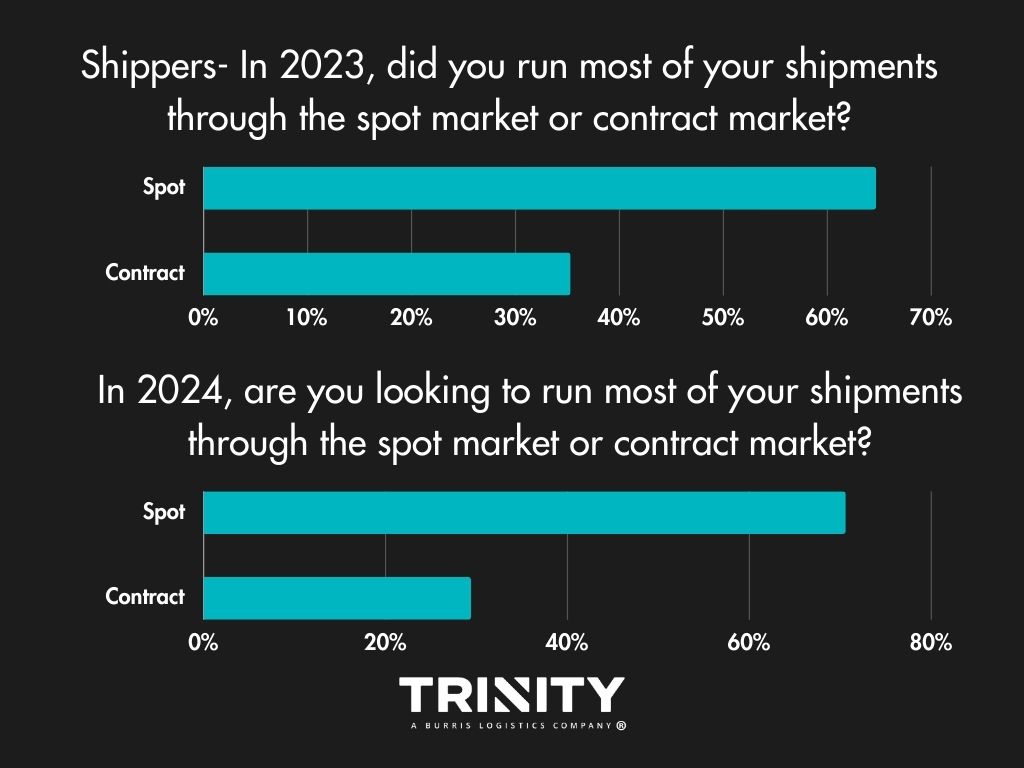

Year-over-year, shippers aren’t looking to change much in terms of which market they turn to. Most look to continue to put most of their freight on the spot market.

For carriers, there looks to be some change anticipated. In 2023, most carriers ran spot market freight but in 2024, over half of them look to haul contracted freight.

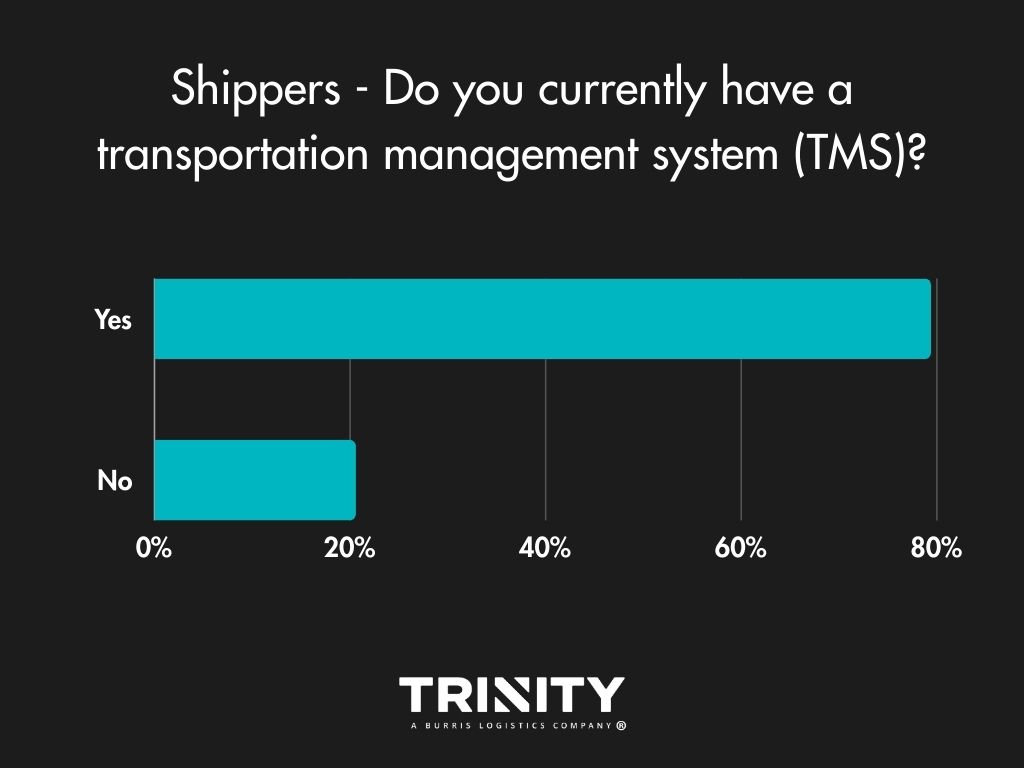

Do Shippers Have a TMS?

It’s 2024, so you’d think most shippers would have a transportation management system (TMS), and no surprise, they do. For those that don’t and answered, it seems they did not have a good experience with one in the past or don’t know enough about them.

Brokers Are the Way to Go

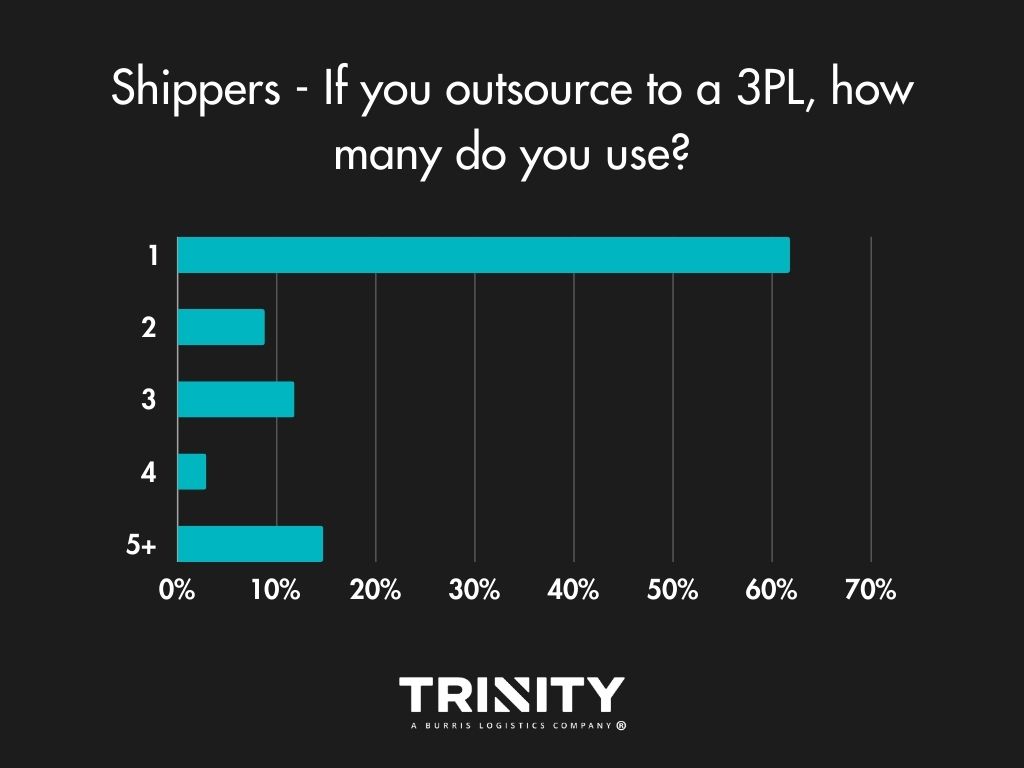

When asked how they like to move their shipments, most shippers use a mix of carriers and third-party logistics providers (3PLs) or just 3PLs. A few do use their own trucks. For those that do outsource to 3PLs, they usually just stick to one provider.

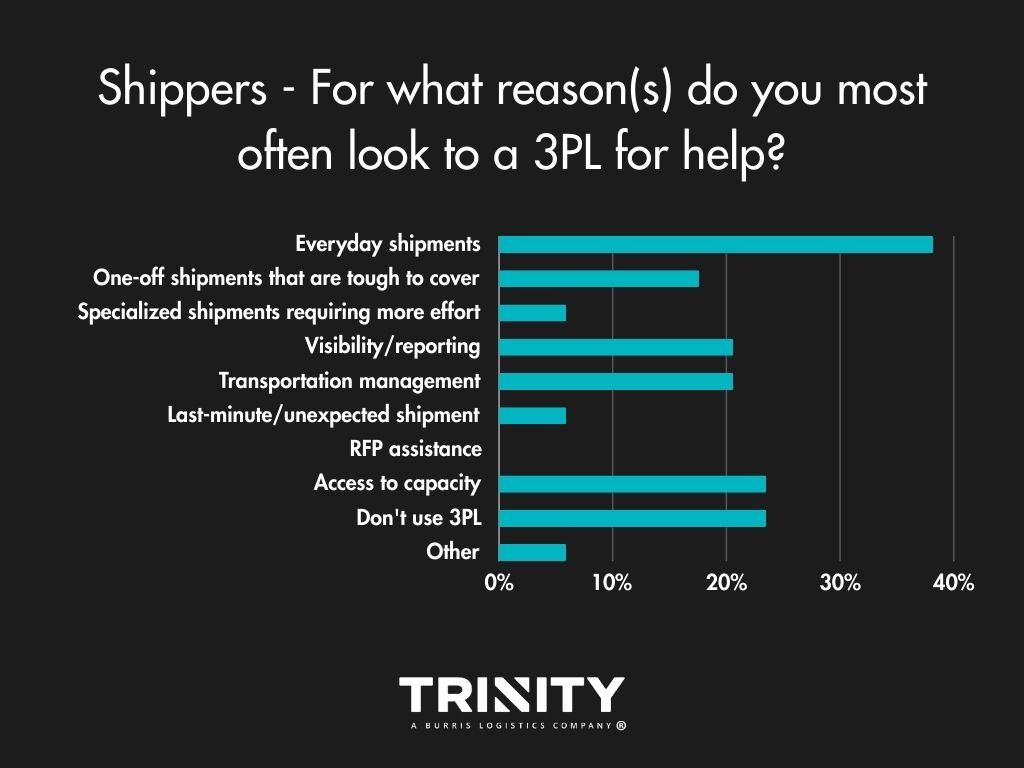

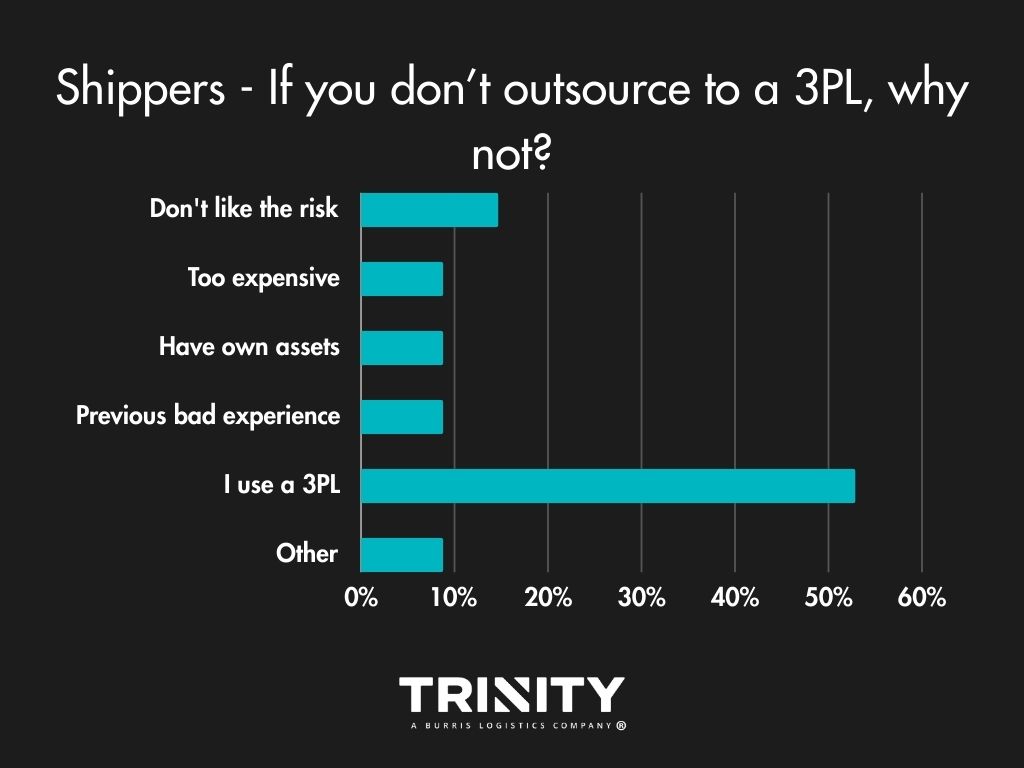

Shippers most often look to a 3PL for help with their everyday shipments, for transportation management, visibility, and access to their capacity. The main reason shippers choose not to work a 3PL for their logistics? They don’t like the risk.

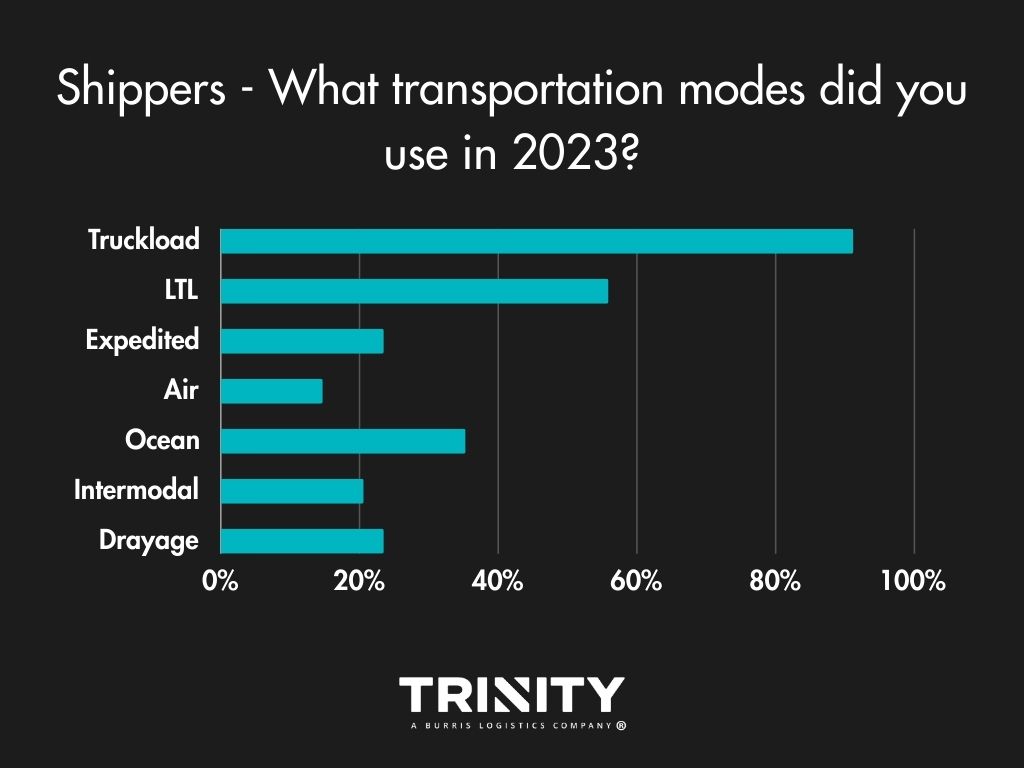

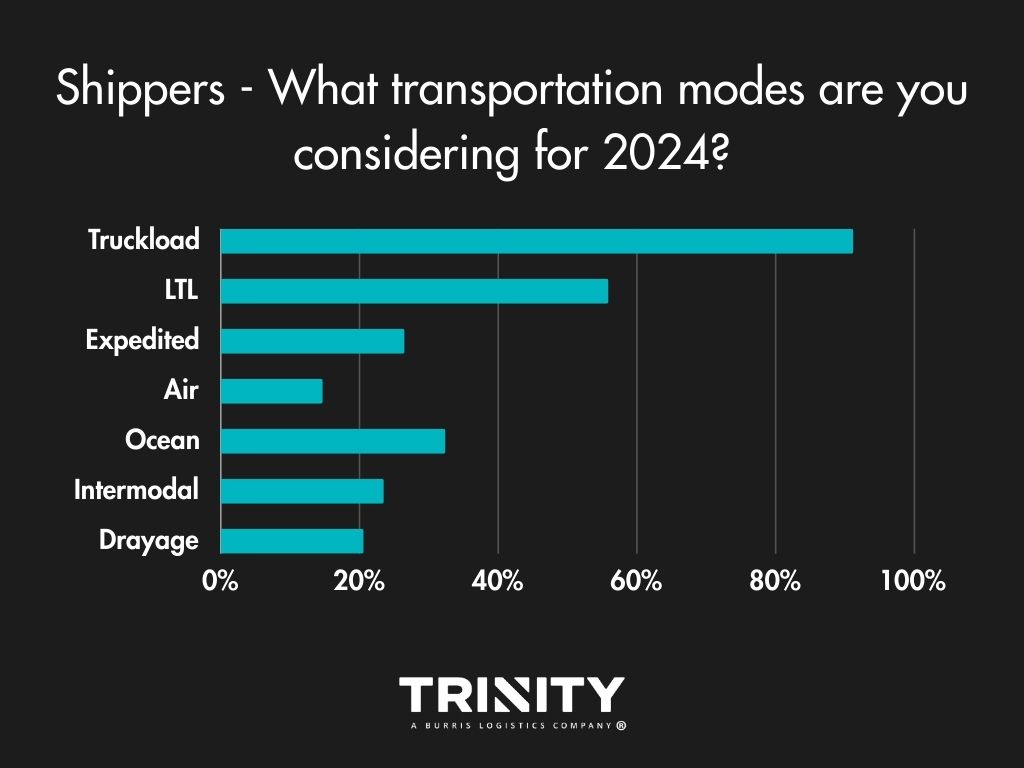

Transportation Modes – Staying Consistent

Overall, shippers aren’t looking to change what transportation modes they use for their shipments. Truckload and less-than-truckload (LTL) are the primary modes they like to use, with a little diversification sprinkled in.

Exceptional Service Stands the Test of Time

When it comes to their logistics partners, shippers find the most value in receiving exceptional service, with costs coming in as a close second.

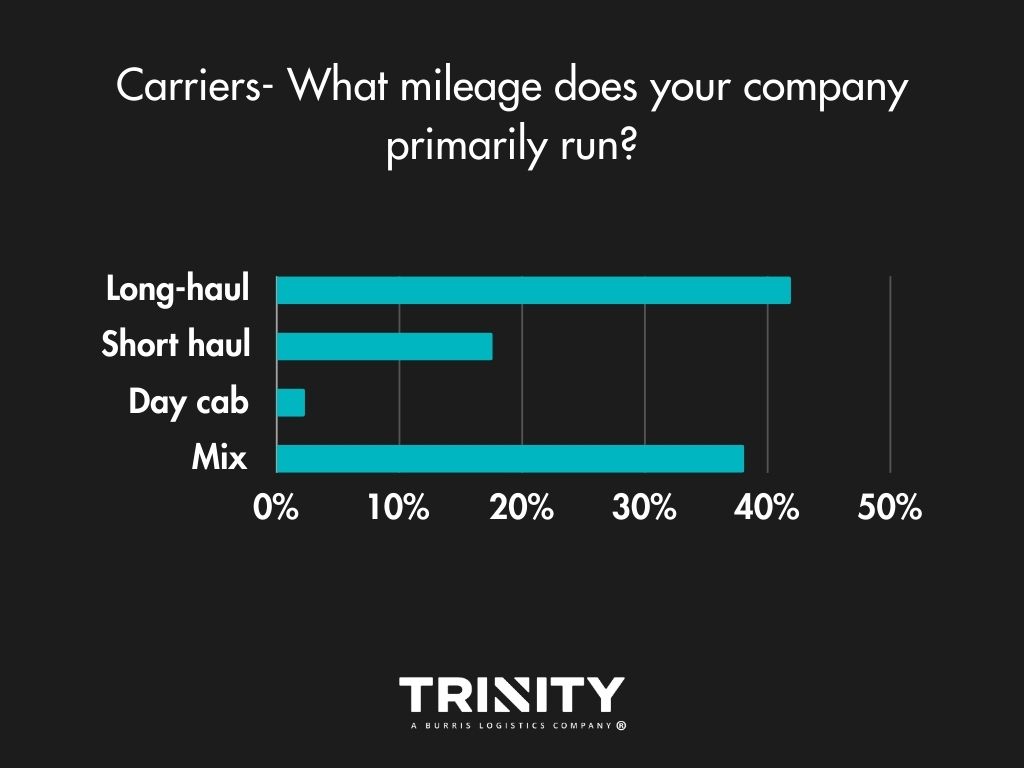

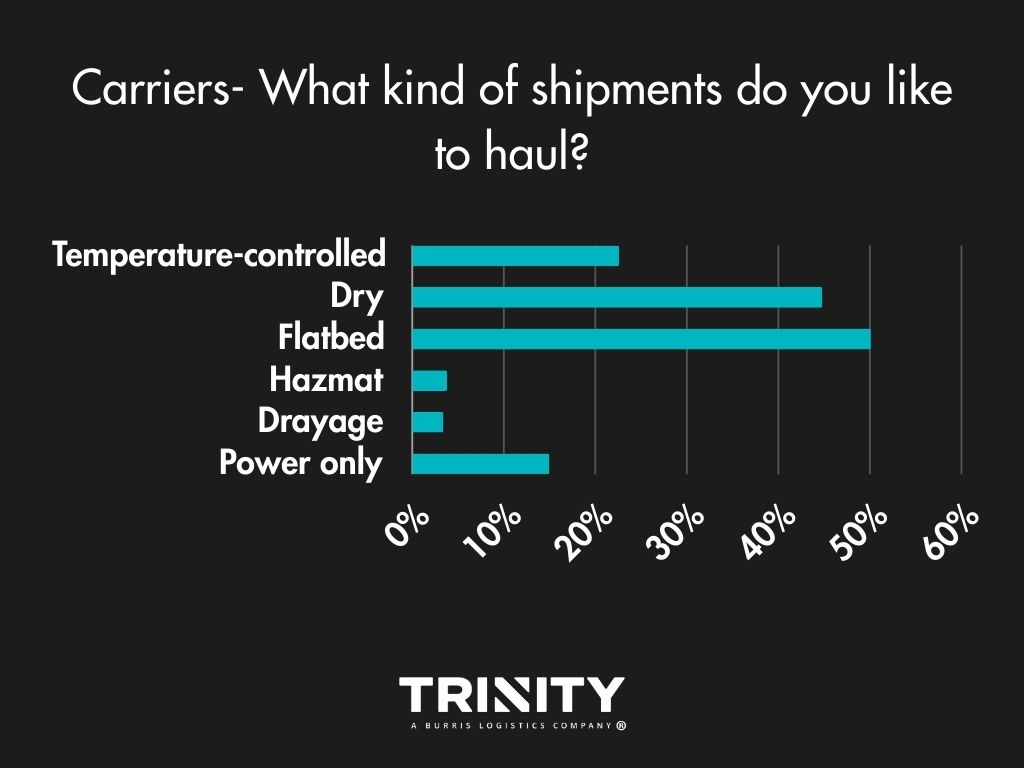

Most Wanted: Long Mileage, Flatbed Shipments

When it comes to mileage, most carrier companies tend to run long-hauls or a mix of short and long shipments. Flatbed hauls are the type of shipments most carriers like to haul with dry van coming in as a close second.

Load Boards are the Way

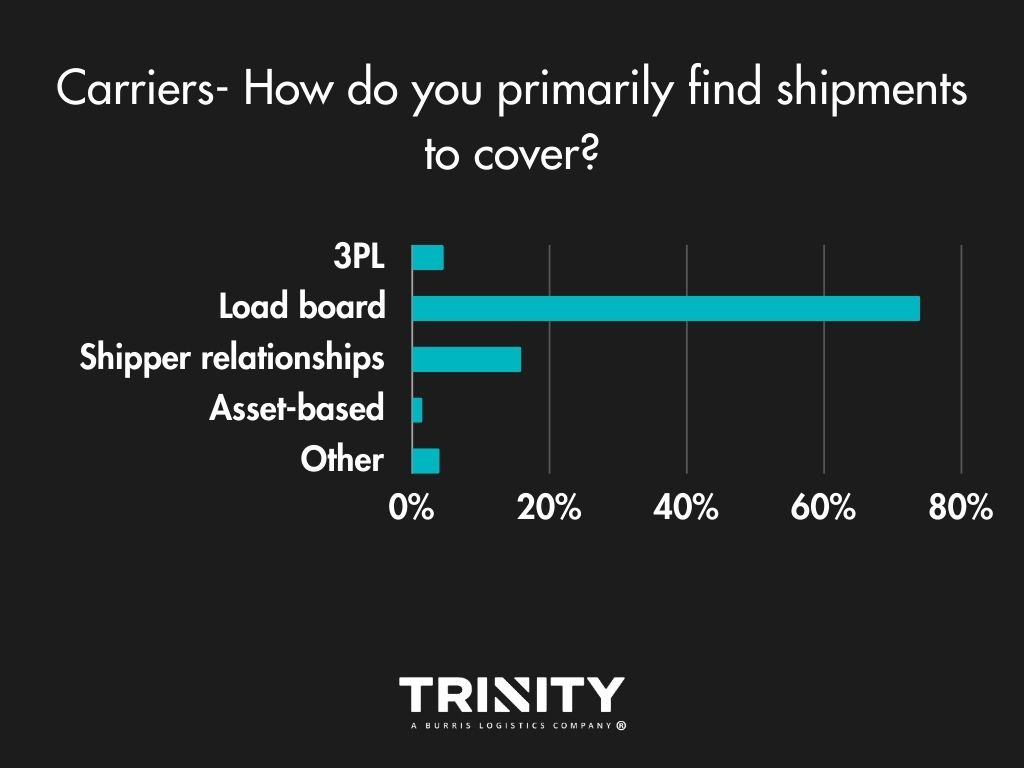

With 74 percent selecting this option, load boards are the norm for carriers to find available shipments. Sometimes they use their shipper relationships, and occasionally they make use of a 3PL.

3PLs – Expanding a Carrier’s Reach

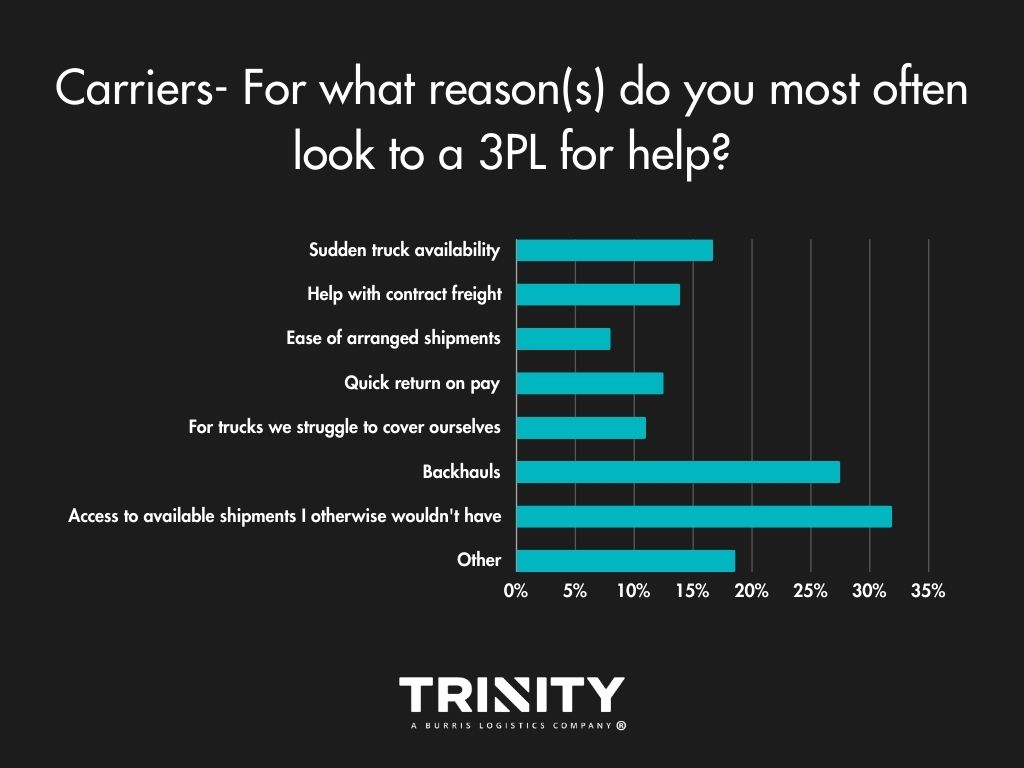

Carriers most often look to a 3PL for help with gaining access to available shipments that they wouldn’t have otherwise. Covering backhauls are another big reason carriers reach out to a 3PL.

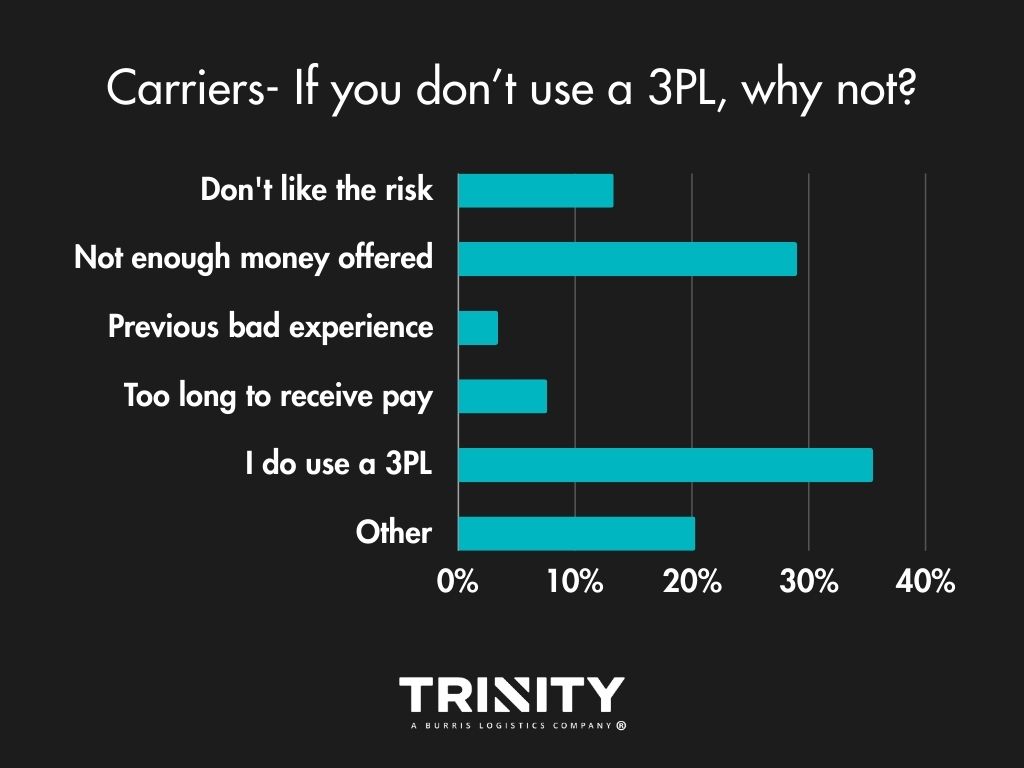

For those that choose to not work with a 3PL, it’s often because of money; rates not being high enough. Surprisingly in the comments, many are not familiar with what a 3PL or freight broker is as well.

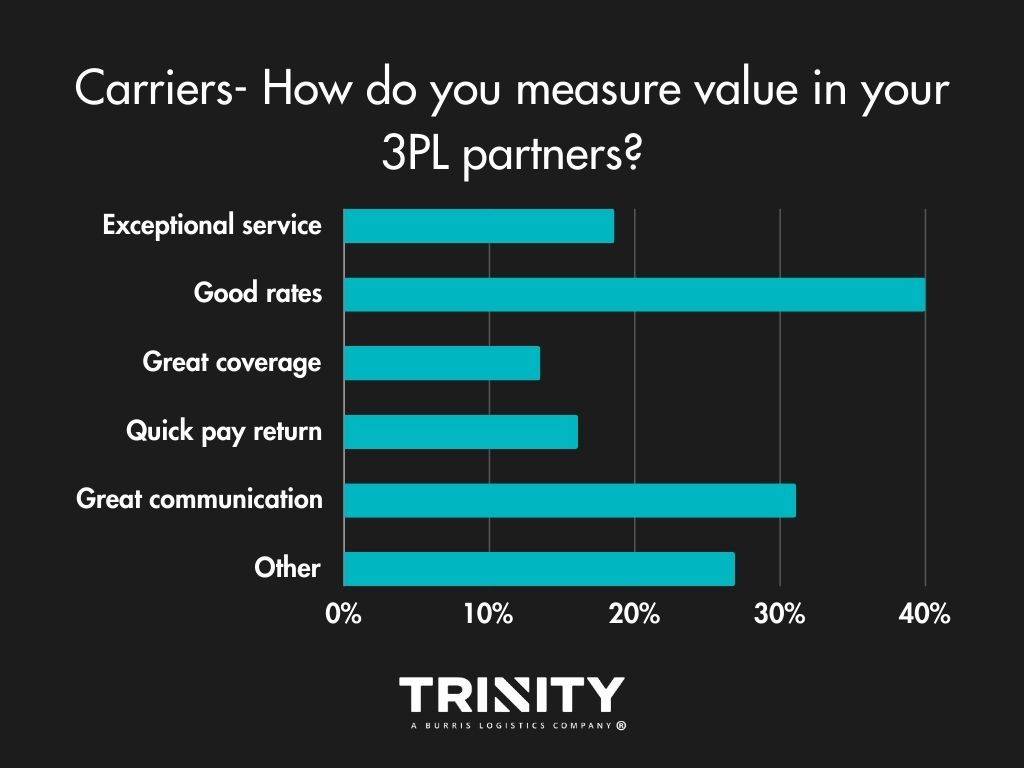

When it comes to measuring value in their 3PL partners, most carriers want good rates and great communication.

Fraud Concerns Growing

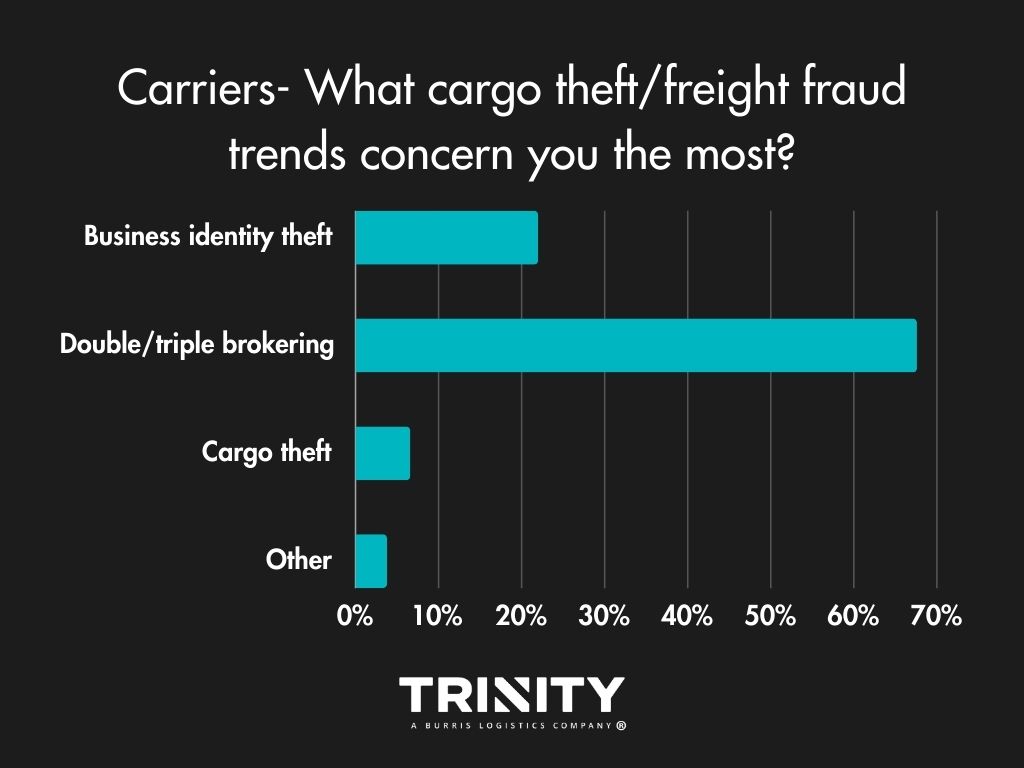

Fraud and scams have been growing in the industry, so we wanted to know what carriers think about it. Carriers are most worried about double and triple brokering affecting their businesses compared to concerns of identity theft or cargo theft.

Craft Beer Logistics: Navigate Complexity, Grow Your Business

Beer, a beloved and timeless beverage. It’s a staple in many cultures and continues to be one of the world’s most popular drinks. A growing subset in beer is the craft beer industry, known for its robustness, variety of flavors, and highlighting regional tastes. According to the Brewers Association, in 2022, craft beer sales increased five percent and now account for almost a quarter of the U.S. beer market. While the demand for craft beer grows, the logistics behind its distribution is increasingly complex.

Craft brewery owners often wear many hats and have lots of tasks to hop on. This can include handling their logistics. This includes more than just the shipping of their beer but the many ingredients and equipment that go into making it. From start to finish, these beer supply chains involve numerous stages and stakeholders, including ingredient manufacturers, distributors, and retailers.

Having effective logistics planning and processes is crucial for craft brewers to meet their growing demand and provide great service to their stakeholders. Managing their supply chains can be difficult to do alone, which is why a third-party logistics (3PL) provider can be a valuable resource to growing craft breweries.

LOGISTICS CHALLENGES FACING THE CRAFT BEER INDUSTRY

Knowing how to legally and efficiently manage their shipping networks is a crucial part of running a successful craft brewery business. There are several challenges craft brewers face such as keeping temperature control throughout transportation, meeting state regulations, and meeting customer demand.

PERISHABLE INGREDIENTS AND PRODUCTS

The need for temperature control in the logistics of craft beer is paramount to preserve the integrity of any needed ingredients or finished products.

Craft brewers also often experiment with ciders, mead, and other malt beverages with specialized flavors, which can include perishable ingredients like fruit. The shelf life of the raw materials and craft beer brings along the element of urgency, placing even more importance on on-time deliveries. Coordinating these shipments to ensure quality beer adds an additional layer of complexity to the logistics process.

REGULATORY COMPLIANCE

Navigating the web of regulations for shipping beer in logistics can be a considerable challenge. Regulations for shipping alcohol vary from state to state, meaning you’ll need to be compliant based on where you are shipping to and from. Additionally, state laws will often change every few years, making it even more difficult.

Craft brewers must also find carriers with the correct licensing, knowledge, and experience to handle the unique requirements of transporting alcoholic beverages. It’s important to work with a logistics provider that knows all the ins and outs of meeting your product’s requirements and state regulations to prevent costly disruptions due to non-compliance.

MEETING CUSTOMER DEMAND

As craft brewers reach more customers, the more need there is for effective logistics planning. Having to juggle keeping track of supplies, determining the most efficient distribution methods, and preparing for any supply chain disruption can be overwhelming. Having a successful craft brewery goes beyond just brewing great beer, but ensuring it reaches the consumer when and where they want it.

Managing costs is on top of rolling out new beverages can be a significant challenge for craft breweries. Having efficient strategies, such as freight consolidation or finding the most cost-effective mode of transportation, can help keep costs in check. This is where an expert third-party logistics company (3PL) can assist with strategy and technology, like a transportation management system (TMS) for visible reporting.

3PL BENEFITS: BREWING SUCCESS WITH TRINITY LOGISTICS

While there may be difficulties to face in the dynamic world of craft brewing, partnering with a 3PL like Trinity Logistics can alleviate the burden. Here’s why working with us for your craft beer shipping and supply chain is the perfect recipe for success:

Our Only Job is Logistics

Logistics is what we handle day in and day out. When you trust us with your freight, you get more time to focus on what you do best – brewing exceptional beer and growing your business.

Experts in Specialized Shipments

Understanding the nuances of transporting freight with specialized requirements, such as temperature control, is our expertise. Whether it’s raw materials or the final product, we ensure everything arrives in optimal condition.

Regulation Compliance

Our dedicated Team and compliance department work diligently to ensure the necessary regulations are meant to provide you peace of mind and reduced risk.

Tracking and Tracing

We understand transparency is key to your success, so we offer several ways to view and keep track of your freight, no matter the time of day.

Effective Logistics Strategies

Whether you need help with something as simple as finding the most cost-effective mode of transportation to freight consolidation, we can help you find and implement strategies to optimize your supply chain and manage costs. It doesn’t matter if it’s just one or 20 pallets of freight, we can arrange full truckload, less-than-truckload (LTL), expedited, or any other mode you may need.

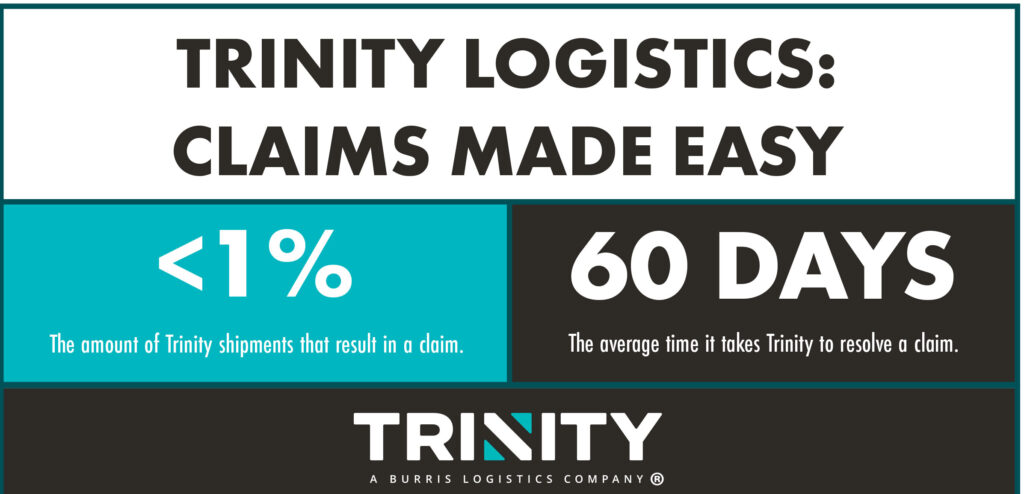

Reduced Risk

At Trinity, we meticulously verify all carrier relationships that we work with, not just during the initial setup but for every shipment. We’re also proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. If something does happen, we have a Cargo Claims Department at the ready to assist you in navigating any issues.

24/7/365 Support

No matter what happens, we’re ready to support you around the clock. We have a dedicated After-Hours Team to continue the monitoring of your freight and are ready to quickly resolve potential challenges, no matter the time of night, holidays, and every weekend.

Trustworthy Carrier Relationships

We treat and respect our carrier relationships just as much as our shipper ones. We aim to build a strong partnership with each one to help their businesses be successful. Because of that, we’ve built strong and trusted partnerships with those in our carrier network, providing you further confidence that your freight will arrive safely.

Managed Transportation

Whether you solely need a TMS for your transportation management, you’re looking for a fully outsourced solution, or something in between, we can help. We understand companies don’t come one-size-fits-all, and neither should the services you need to optimize your logistics. Our Managed Transportation services cater to businesses of all sizes and needs, capable of growing right alongside your brewing venture.

Partnering with Trinity Logistics offers you more than just transportation services. We’re a trusted, strategic ally that’s invested in seeing your business succeed. Leave the logistics to the seasoned experts, so you can focus on creatively and passionately brewing while we ensure your craft brews reach your consumers right when they want it.

LET US HELP WHAT ALES YOU IN LOGISTICSConsumers want more fruits and vegetables in their diets but produce shippers must face these common logistics challenges to keep up with their demand.

It’s hard to deny the nutritional value fruits and vegetables bring to our diets. It’s likely why there’s been substantial growth in consumer demand for produce over the past decade. While that’s great for businesses based in produce, there’s also greater pressure for produce shippers to deliver.

The journey from farm to table can be surprisingly complex for fruits and vegetables. Produce shippers face several hurdles that they need to overcome for their products to deliver fresh and meet the growing consumer demand. Let’s explore the intricacies of these difficulties and how they all can be taken care of by working with a third-party logistics (3PL) provider, like Trinity Logistics.

CHALLENGE 1: CHOOSING BEST TRANSPORTATION MODE

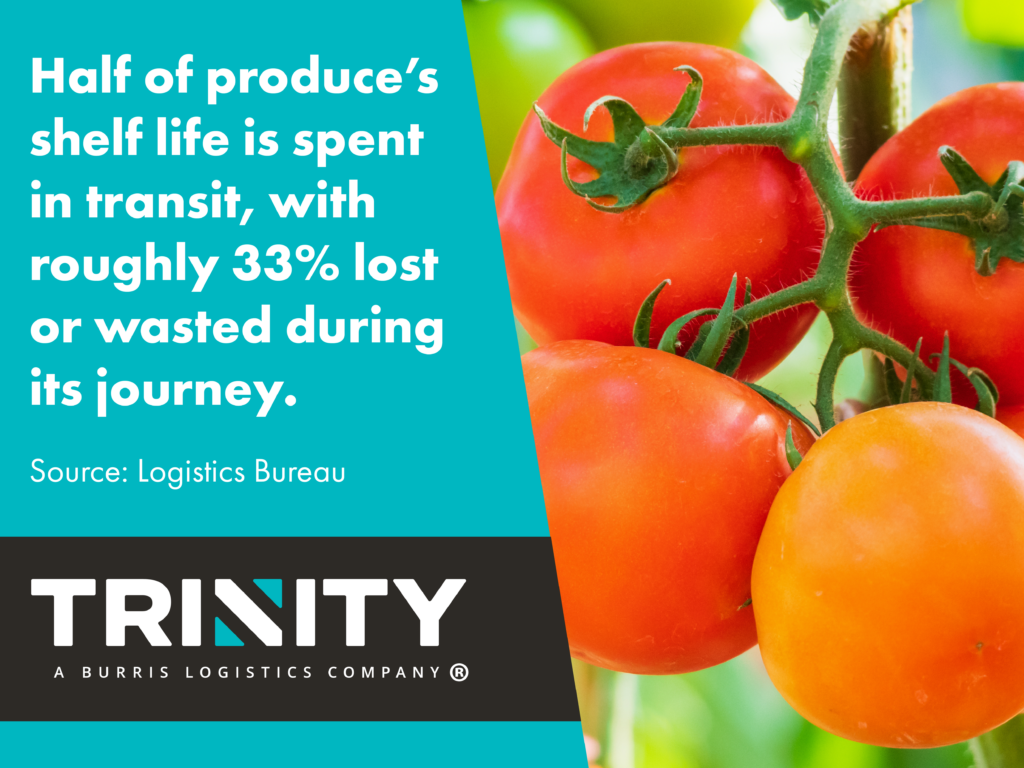

Produce shippers first face the challenge of determining what transportation mode to use for their shipments. With produce, half of its shelf life is spent in transit. It’s also reported that roughly 33 percent of produce is lost or wasted during its journey, according to the Logistics Bureau.

This is why produce shippers must ask themselves these questions to help determine the right transportation mode for their shipment.

What’s best for your product?

What can you afford?

How much time does your produce have?

Air is great for foods that have a very short shelf life and may need expedited shipping. However, air is often the most expensive of your options. Rail can offer you cost savings but requires more travel time, often two to three days. This option is often saved for produce with a longer shelf life. Lastly, there’s truckload shipping, which offers several shipping options and costs, depending on factors like whether you need a full truck, expedited shipping, or freight consolidation.

CHALLENGE 2: SELECTING THE RIGHT CARRIER PARTNER

The next challenge produce shippers need to tackle is choosing the right carrier to pick up and deliver their shipment. This may be the most crucial task of all because the carrier you choose can make or break your shipment. You need to trust the carrier you choose has experience in handling your specific cargo and meeting food safety regulations, especially for those that need temperature control.

CHALLENGE 3: MAINTAINING FRESHNESS/QUALITY

Maintaining freshness is one of the primary logistics challenges for produce shippers. Millions of dollars are wasted each year on produce that didn’t maintain freshness by delivery.

Produce begins to deteriorate the moment it’s harvested, so the risk of decomposition is equal to, or perhaps even greater, to produce shippers than those of theft or delay. Fresh or frozen produce needs to be stored and transported at specific temperatures to ensure its quality when bought and eaten by the consumer. Even the amount of humidity, light, or kind of packaging can affect a produce product, so produce shippers face this challenge in every segment of their shipping.

Every kind of produce also has different needs. Some need very specific environments to maintain freshness. Others can stay at room temperature or take on more handling. Shelf life is also something to consider. Produce with short shelf lives will need quick transit from farm to store. This also means several kinds of produce often can’t ship together. Since there is no one-size-fits-all process for produce, it’s important for produce shippers and their logistics partners to understand what’s needed for the specific product to deliver at peak quality.

CHALLENGE 4: SHIPMENT VISIBILITY

Tracking and shipment visibility is essential for produce shippers to be able to reduce risk. Without a clear look into your shipments, you’re left in the dark and uncertain whether your product will arrive on time or in acceptable condition.

This can challenge more than just produce shippers, but all stakeholders in a company’s supply chain. Miscommunication can happen between retailers and sellers as well, causing miscalculations in capacity planning or undependable forecasts. Real-time visibility and data are absolutely needed for produce shippers to enhance transparency with their business partners and gain more control over their supply chains.

CHALLENGE 5: REGULATIONS

Navigating regulations is a huge challenge for produce shippers. Failure to meet those regulations can lead to severe and often costly consequences. For example, in the U.S., produce shippers must comply with the Food Safety Modernization Act (FSMA), which entails specific guidelines for food safety.

There are also quality standards and labeling requirements to be met. The U.S. Department of Agriculture (USDA) has a strict grading system to determine the quality of produce, considering its size, shape, color, and defects.

CHALLENGE 6: HANDLING ANY CLAIMS

There’s always a risk for claims in shipping, but claims can happen more often for produce shippers compared to other industries, due to its shorter shelf life. The majority of claims we see in produce shipping are the result of spoilage, which can happen for many different reasons.

Handling claims for produce is slightly more difficult due to the Perishable Agricultural Commodities Act (PACA). When handling produce claims, it’s important you and your transportation provider understand and follow PACA.

HOW TRINITY LOGISTICS HELPS PRODUCE SHIPPERS OVERCOME THEIR CHALLENGES

All those challenges listed above that you may face – we know how and are prepared to handle them.

After 45 years of serving shippers in the food and beverage industry, we’re experts in its logistics requirements and regulations. We also take part in industry organizations, like the International Fresh Produce Association, so we stay knowledgeable about what may affect produce shippers.

When it comes to choosing your transportation mode, we have a multitude of options available to support you, whether you’re looking for help with one shipment or a fully outsourced logistics solution.

Additionally, we work with trusted carrier relationships that have been fully vetted to ensure your product travels safely and delivers on time. This includes vetting that reefer equipment is not older than 2012 and a temp-reading or download can be made readily available for any refrigerated or frozen produce shipments.

No matter where your freight is in its journey, we provide you with several real-time tracking options to stay fully informed. Through our Managed Transportation service and the use of a transportation management system (TMS), you can find more visibility and data to improve your supply chain processes and communication.

And then there are claims. While we wish every situation could go smoothly, there can still be mishaps. Even so, we’re proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. That’s likely because we work with shippers and receivers to monitor load and unload times, checking to ensure trailer doors are not left open, causing temperatures to fluctuate outside of any required ranges.

Now, fear not, because if something does happen, we’re able to help with that too. We have an in-house expert Claims Team to help negotiate any produce claims on your behalf, with an average rate of 60 days in resolving cargo claims.

By working with Trinity Logistics for your produce shipments, you’ll also gain an extra benefit – experiencing our acclaimed People-Centric service. It’s what our customers praise the most about our services and keeps them returning to Trinity Logistics for their logistics needs.

If you’re tired of tackling these produce shipping challenges alone, it may be time to get connected and join the thousands of shippers that choose to make their logistics easy with Trinity Logistics. You won’t be-leaf our exceptional service until you try it!

Get Out of Your Produce Shipping Pickle

Check Out Trinity's Solutions Request a Free Shipping QuoteWhether your product is coming straight from the farm, is moving between processing, or heading off to the consumer, the dairy industry needs first-rate cold chain solutions to meet their complex supply chains.

Dairy products such as milk, cheese, and butter are household staples and essential in many people’s diets. It’s no surprise that the dairy industry is considered one of the fastest-growing industries, almost doubling in value every five years. To keep up with consumer demand, the dairy industry needs exceptional cold chain solutions to keep their products cold and safe for consumption.

Why the Dairy Industry Needs Cold Chain Solutions

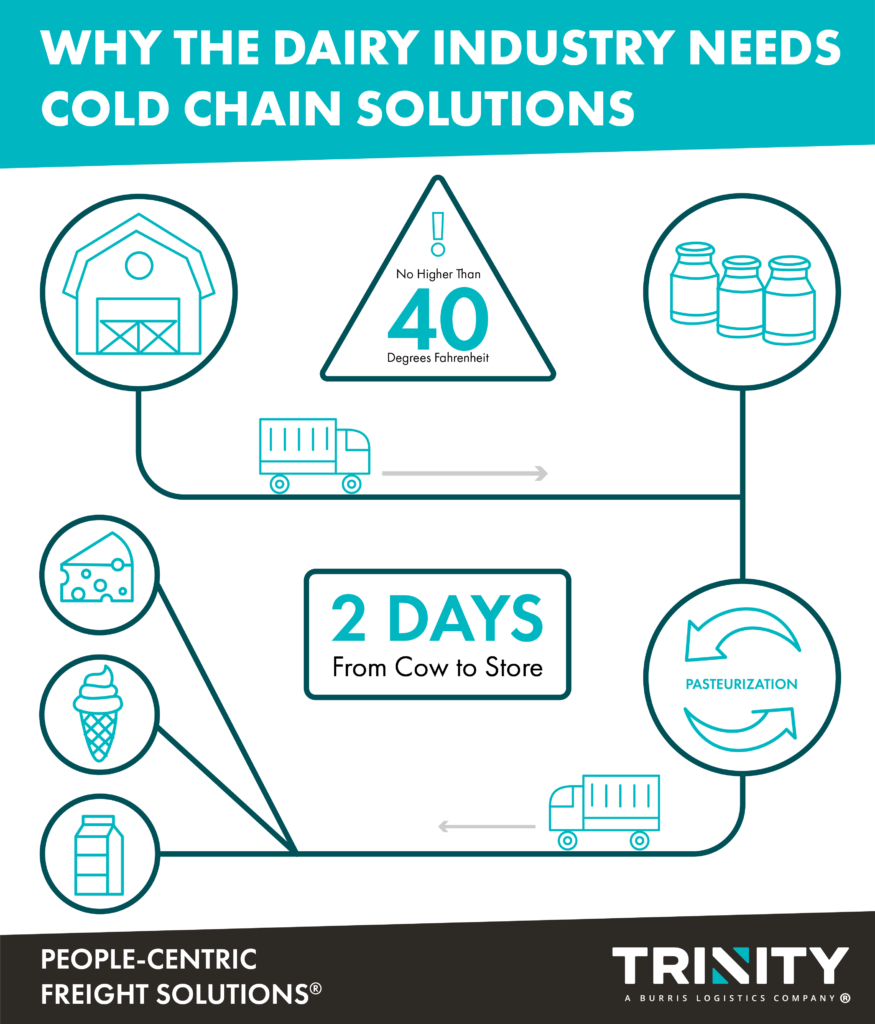

Dairy products all start with milk, and it has a short shelf life. After the cows have been milked, it immediately transports to cooling storage tanks or a chilled trailer. To ensure the milk doesn’t spoil, it must be stored at a temperature no higher than 40 degrees Fahrenheit. It’s then transported to a processing facility, pasteurized, and transported again to consumers.

Usually, this process alone, from cow to store, takes place in about two days. Now, milk is often a starting point for the many diverse dairy products available. Depending on the final product, dairy supply chains have more steps and complexities added.

Common Issues Requiring Cold Chain Solutions

- Temperature Control Needed for Most Dairy Products

- Capacity During Peak Shipping Seasons

- Managing Milk Production with Dairy Demand

- Supply Chain Disruptions

- Dairy is Highly Regulated

- Supply Chain Visibility

- Potential High Value Dairy Products

Temperature Control Needed for Most Dairy Products

Most dairy products need storage at specific temperatures to keep from spoiling. Dairy products need strict attention because of the risk posed to consumers if the cold chain is broken. If not consistently kept cold and free of humidity, bacteria in the dairy can cultivate and dairy products can become harmful.

Capacity During Peak Shipping Seasons

While some dairy products can seek out alternative transportation modes, most find shipping truckload is the most viable option. It’s usually the fastest and cheapest way to move the product because of its weight. It’s also the most viable due to freight security and nature of the product, and because it reduces the risk of claims due to temperature fluctuations or shifting. Since most dairy products need refrigerated trucks for their shipments this can make capacity an issue at times, such as produce season, when reefer capacity can be tighter. It can not only be more difficult to secure a refrigerated truck, but more expensive to do so.

Managing Milk Production with Dairy Demand

Dairy product demand can fluctuate. Yet, even when consumers want fewer dairy products, the cows don’t stop making milk. They can’t be turned on and off like machines, giving the dairy industry a unique balancing act to handle.

Additionally, when it comes to shipping milk, most of that is kept regional given the short shelf life and cost to ship, making dairy demand management even trickier.

Supply Chain Disruptions

As we’ve learned in recent years, there’s always the chance for supply chain disruption to happen. Whether that’s a truck breaking down, a roadblock, or some other instance that would cause delays. With several dairy products (like milk) having a short shelf life, any delays can risk product spoiling and going to waste. Companies in the dairy industry need to be able to act quickly if any disruption happens.

Dairy is Highly Regulated

Dairy products are associated with foodborne illnesses, so it’s no surprise that they’re highly regulated. Right from the start, milk is tested to ensure it’s of safe quality to consume and make other products from. There’s also the Food Safety Modernization Act (FSMA), which places strict requirements on sanitary transportation and the handling of dairy products.

Supply Chain Visibility

Because of so many factors mentioned above, it’s important for dairy companies to have full, real-time visibility of their supply chains. Additionally, many wholesale food distributors and grocery warehouses hold very strict requirements for appointments with very strict product quality inspections to be accepted into their inventory. Without it, dairy companies are at risk of losing products and money due to spoilage, disruptions, delays, or regulation requirements.

Potential High Value Products

Certain dairy products can be high value, like some cheeses for example. This can make the overall value of the load to be costly should there be any potential claims. It’s best for shippers to work with expert providers who have the experience and knowledge to handle any high value dairy products.

Leading Cold Chain Solutions from Trinity Logistics

Shippers in the dairy industry looking for first-rate cold chain solutions can find all they need with Trinity Logistics. We’re a leading third-party logistics (3PL) provider with over 40 years of experience serving logistics solutions to some of the top-known brands in the food and beverage sector.

Standard Operating Procedures for Temperature-Controlled Shipments

One of the reasons we excel in cold chain solutions is our standard operating procedures in place for every temperature-controlled shipment we arrange. This includes:

- Only working with carrier relationships that have downloadable reefer units

- Requiring carriers to pre-cool trailers a minimum of one to two hours before pickup

- Requiring carriers to run their reefer units on continuous

- If necessary, requiring carriers to pulp product before loading

- Requiring carriers to use one of our tracking and tracing partners for real-time shipment visibility

- Only using carriers that have refrigerated trailers that are 2015 or newer

We understand just how critical it is that your product stays at its required temperature. That’s why we work with our trusted, experienced carrier relationships to ensure your product arrives fresh.

Multi-Modal Cold Chain Solutions

No matter what transportation mode you need your product to ship, we have the logistics solutions to support your business now and in the future, including;

- Truckload

- Expedited

- International

- Cross-broder

- Air or ocean shipping

- Drayage

- Less-than-truckload

- Managed Transportation

This enables your business to seamlessly run regardless of what change or growth you experience.

In-Depth Transportation Management

Whether you need a transportation management system (TMS), to fully outsource your logistics, or your own customized managed transportation solution, we can help. We know each business is unique, which is why our system is highly configurable so we can meet your exact needs. Our Trinity experts will work as part of your business, offering in-depth reporting and data to help get you ahead of your competitors.

No Need to Worry About Disruptions

Did I mention that Trinity has been serving cold chains for over 40 years? We’ve seen it all when it comes to supply chain disruptions and delays. We know how to quickly adapt plans to keep your freight moving. While you’ll have your sole Trinity relationship to lean on for updates, we also have a 24/7 Team in case we need any additional support. You can learn to rest easy whenever your shipment is in our care.

Experts in Temp-Controlled Logistics and Dairy

Trinity Logistics has been serving cold chains for 40-plus years, in addition to our parent company, Burris Logistics, that was built on its expertise of handling temperature-controlled commodities.

There’s also Honor Foods, another Burris Logistics company you can lean on for food redistribution if needed. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They specialize in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers.

Our People-Centric Service

What makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

I’D LIKE LEARN MORE ABOUT TRINITY'S COLD CHAIN SOLUTIONSSEAFORD, DE, July 18th, 2023 – Trinity Logistics, a leading third-party logistics (3PL) provider, is proud to share that the company has been named a Top 100 3PL by Inbound Logistics.

Every year, Inbound Logistics publishes its annual 3PL edition including its Top 100 3PL list. The theme of this year’s edition surrounds growth. Outsourcing supply chain, logistics, and transportation solutions to a trusted partner is important to prepare or position companies for times of growth. Hundreds of 3PL companies submitted credentials to be considered this year and IL selected the top 100 3PLs to help companies manage growth, efficiently meet demand, and improve service while holding down costs, with Trinity Logistics selected in that list.

Trinity Logistics has a long history of providing innovative and customer-focused solutions, offering a wide range of services, including warehousing, multiple modes of transportation, technology, and transportation management.

“Trinity is committed to providing our customers with the best possible experience to help them grow and succeed,” said Sarah Ruffcorn, President of Trinity Logistics. “This award is a wonderful recognition of the commitment our Team makes to our shipper and carrier relationships. We are honored to be known as a 3PL partner that companies can depend on to support their growth.”

This is the third year Trinity Logistics has earned recognition as a Top 100 3PL by Inbound Logistics. The recognition is a testament to the company’s growing brand of People-Centric service and customized logistics solutions available to businesses of all sizes and growth goals.

Learn how Trinity Logistics helped these companies grow their business.

Read MW Supply's Case Study Read Cometeer's Case Study Read Albaugh's Case StudyThinking Trinity Logistics might be the 3PL partner to support your company’s growth?

Get a Free, No-Obligation Quote

Freight is always on the move, every single day, seven days a week, 24/7. There are different types of ways to move freight, whether it’s shipping international, drayage, truckload, or intermodal, all have different paths to the same destination. But what about those last-minute shipments or freight that has a quick turnaround?

Throughout this article we will discuss:

- The basics

- The difference between this and standard shipping

- The importance and benefits of shipping freight expedited

- The different forms of expedited shipping

- How to partner with the right company

WHAT IS EXPEDITED SHIPPING?

Expedited shipping sounds just like what it is, a means to move freight as quickly as possible from point A to point B. This shipping mode is for those time-sensitive shipments you may have.

It’s also an option when the freight is high-value or fragile, and you would like for it to go in a dedicated truck instead of using truckload or less-than-truckload (LTL) shipping. Or for when you might just need a sprinter van or straight truck for your freight.

Any freight requiring expedited is on a single truck and typically has one driver, but team drivers can be made available upon request. This helps reduce long transit times by having the drivers take turns to keep the truck moving without any stops.

Expedited shipping can be between one and twelve pallets and under 10,000 pounds. This shipping method can be over-the-road (OTR), less-than-truckload (LTL), or air international shipping. While this mode of transportation is often used for perishable goods, many also use it for dedicated or tradeshow freight.

While expedited shipping is not as popular as some other modes of transportation, its use is on the rise, due to the “Amazon Effect”. Amazon, known for its fast delivery of products, has caused people to expect other packages and goods to be delivered at this rapid pace. With, consumer demand growing to expect goods shipped faster, expedited shipping has become more popular.

EXPEDITED VS. STANDARD SHIPPING

How does expedited shipping differ from standard shipping? Let’s look at some of the differences between the two.

Cost

One of the biggest differences between standard and expedited shipping is the cost associated with it. Expedited shipping is higher in price because it has a strict deadline and moves at an above-average pace.

Standard shipping transports at a slower pace, so often it’s less costly due to the less strict delivery deadline. However, it’s important to note that the cost for any shipment varies depending on the nuances of each shipment.

Time Frame

Expedited shipping delivers anywhere from the same day to three days. Standard shipping time frames are going to vary greatly. They can be anywhere from a week to as high as a month, depending on the pick-up and delivery locations.

Types of Shipments

Expedited shipments often include goods like tradeshow materials, perishable goods, new product launches, or just those last-minute shipment needs. Standard shipments transport goods of all kinds.

Unlike expedited shipping, standard shipping can consist of multiple trucks, drivers, pick-up and delivery locations, and stops in between.

IMPORTANCE & BENEFITS OF EXPEDITED SHIPPING

Expedited shipping has many benefits outside of having your freight delivered faster. It allows you to meet tight deadlines, like if you run out of a product in a store and need to restock quickly, then expedited is the solution for you.

While expedited may not be the most popular mode, it’s an important tool to have in case of emergencies with your freight. Also, with e-commerce demand consistently growing, expedited shipments are here to stay and become more commonplace.

YOUR EXPEDITED SHIPPING OPTIONS

Expedited shipping can take many different forms. Below are some examples:

Dedicated LTL Shipments

These are your normal LTL shipments; however, no other freight is on the truck besides yours. Thus, it eliminates the need to drop off other shipments along the way to the destination.

Airport Recoveries

When freight arrives from shipping in the air, airport recoveries mean the freight is being picked up directly from the airport where the freight has landed.

Liftgate assistance

This machinery loads and offloads the freight on a truck, usually when the shipper or receiver doesn’t have a dock, when delivering to a storefront location, or when a truck is broken down and need to transload the freight to another truck.

Next day option

This option is when goods are ordered, and they are available for delivery immediately and will arrive at the destination the following day.

Tradeshow freight

Any items, booths, collateral, promotional items, and televisions for tradeshow events.

STRATEGICALLY PARTNER WITH A 3PL

It can be difficult to navigate supply chains. Every company has unique needs and looks for custom-tailored logistics solutions to meet them. Your solution could be as simple as partnering with a trusted third-party logistics company (3PL) to handle all your shipments for you.

A 3PL can offer you real-time visibility and updates on your shipments and can adapt quickly to delays and disruptions that may occur. 3PLs understand the nuances of each shipment and the urgency for on-time delivery while having the tools, experience, and expertise to provide you with the best logistics solutions.

IS TRINITY LOGISTICS THE RIGHT PARTNER FOR YOU?

At Trinity Logistics, we handle all types of shipments and have years of experience handling expedited shipments. With our network of relationship carriers, we ensure your freight is taken care of from receiving to destination.

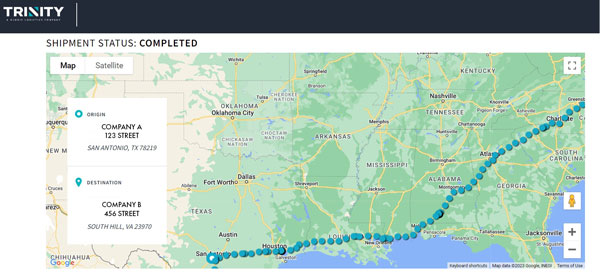

Our Team of Experts is here 24/7, day or night to help you. We also provide you with the Customer Portal where you can track and trace your freight any time of day, see its status, and its estimated time of arrival.

If Trinity sounds like the 3PL for you, click below to connect with our Team of Experts by requesting a free, no-obligated freight quote.

CONNECT WITH OUR TEAMOr, if you’d like to learn more about our expedited shipping solutions, click here.

LEARN MORE ABOUT TRINITY'S EXPEDITED SHIPPING SOLUTIONS