Craft Beer Logistics: Navigate Complexity, Grow Your Business

Beer, a beloved and timeless beverage. It’s a staple in many cultures and continues to be one of the world’s most popular drinks. A growing subset in beer is the craft beer industry, known for its robustness, variety of flavors, and highlighting regional tastes. According to the Brewers Association, in 2022, craft beer sales increased five percent and now account for almost a quarter of the U.S. beer market. While the demand for craft beer grows, the logistics behind its distribution is increasingly complex.

Craft brewery owners often wear many hats and have lots of tasks to hop on. This can include handling their logistics. This includes more than just the shipping of their beer but the many ingredients and equipment that go into making it. From start to finish, these beer supply chains involve numerous stages and stakeholders, including ingredient manufacturers, distributors, and retailers.

Having effective logistics planning and processes is crucial for craft brewers to meet their growing demand and provide great service to their stakeholders. Managing their supply chains can be difficult to do alone, which is why a third-party logistics (3PL) provider can be a valuable resource to growing craft breweries.

LOGISTICS CHALLENGES FACING THE CRAFT BEER INDUSTRY

Knowing how to legally and efficiently manage their shipping networks is a crucial part of running a successful craft brewery business. There are several challenges craft brewers face such as keeping temperature control throughout transportation, meeting state regulations, and meeting customer demand.

PERISHABLE INGREDIENTS AND PRODUCTS

The need for temperature control in the logistics of craft beer is paramount to preserve the integrity of any needed ingredients or finished products.

Craft brewers also often experiment with ciders, mead, and other malt beverages with specialized flavors, which can include perishable ingredients like fruit. The shelf life of the raw materials and craft beer brings along the element of urgency, placing even more importance on on-time deliveries. Coordinating these shipments to ensure quality beer adds an additional layer of complexity to the logistics process.

REGULATORY COMPLIANCE

Navigating the web of regulations for shipping beer in logistics can be a considerable challenge. Regulations for shipping alcohol vary from state to state, meaning you’ll need to be compliant based on where you are shipping to and from. Additionally, state laws will often change every few years, making it even more difficult.

Craft brewers must also find carriers with the correct licensing, knowledge, and experience to handle the unique requirements of transporting alcoholic beverages. It’s important to work with a logistics provider that knows all the ins and outs of meeting your product’s requirements and state regulations to prevent costly disruptions due to non-compliance.

MEETING CUSTOMER DEMAND

As craft brewers reach more customers, the more need there is for effective logistics planning. Having to juggle keeping track of supplies, determining the most efficient distribution methods, and preparing for any supply chain disruption can be overwhelming. Having a successful craft brewery goes beyond just brewing great beer, but ensuring it reaches the consumer when and where they want it.

Managing costs is on top of rolling out new beverages can be a significant challenge for craft breweries. Having efficient strategies, such as freight consolidation or finding the most cost-effective mode of transportation, can help keep costs in check. This is where an expert third-party logistics company (3PL) can assist with strategy and technology, like a transportation management system (TMS) for visible reporting.

3PL BENEFITS: BREWING SUCCESS WITH TRINITY LOGISTICS

While there may be difficulties to face in the dynamic world of craft brewing, partnering with a 3PL like Trinity Logistics can alleviate the burden. Here’s why working with us for your craft beer shipping and supply chain is the perfect recipe for success:

Our Only Job is Logistics

Logistics is what we handle day in and day out. When you trust us with your freight, you get more time to focus on what you do best – brewing exceptional beer and growing your business.

Experts in Specialized Shipments

Understanding the nuances of transporting freight with specialized requirements, such as temperature control, is our expertise. Whether it’s raw materials or the final product, we ensure everything arrives in optimal condition.

Regulation Compliance

Our dedicated Team and compliance department work diligently to ensure the necessary regulations are meant to provide you peace of mind and reduced risk.

Tracking and Tracing

We understand transparency is key to your success, so we offer several ways to view and keep track of your freight, no matter the time of day.

Effective Logistics Strategies

Whether you need help with something as simple as finding the most cost-effective mode of transportation to freight consolidation, we can help you find and implement strategies to optimize your supply chain and manage costs. It doesn’t matter if it’s just one or 20 pallets of freight, we can arrange full truckload, less-than-truckload (LTL), expedited, or any other mode you may need.

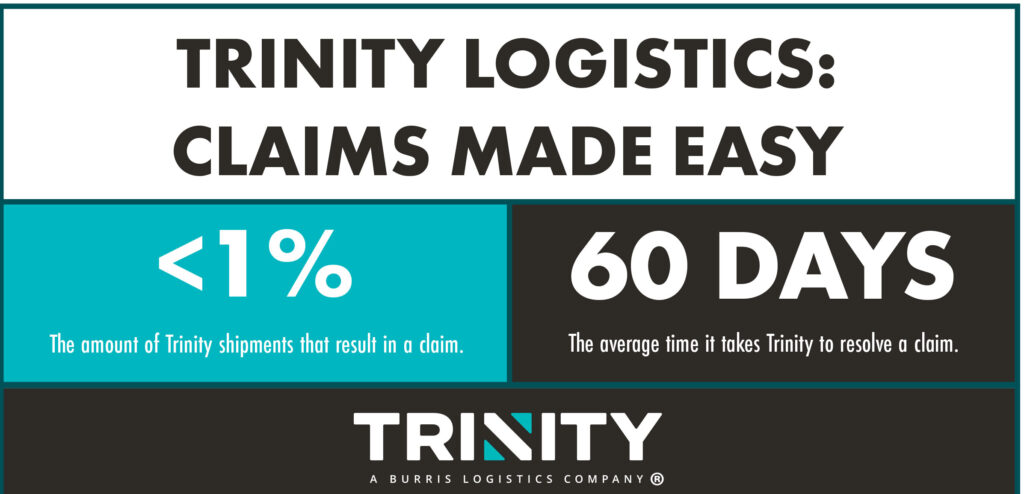

Reduced Risk

At Trinity, we meticulously verify all carrier relationships that we work with, not just during the initial setup but for every shipment. We’re also proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. If something does happen, we have a Cargo Claims Department at the ready to assist you in navigating any issues.

24/7/365 Support

No matter what happens, we’re ready to support you around the clock. We have a dedicated After-Hours Team to continue the monitoring of your freight and are ready to quickly resolve potential challenges, no matter the time of night, holidays, and every weekend.

Trustworthy Carrier Relationships

We treat and respect our carrier relationships just as much as our shipper ones. We aim to build a strong partnership with each one to help their businesses be successful. Because of that, we’ve built strong and trusted partnerships with those in our carrier network, providing you further confidence that your freight will arrive safely.

Managed Transportation

Whether you solely need a TMS for your transportation management, you’re looking for a fully outsourced solution, or something in between, we can help. We understand companies don’t come one-size-fits-all, and neither should the services you need to optimize your logistics. Our Managed Transportation services cater to businesses of all sizes and needs, capable of growing right alongside your brewing venture.

Partnering with Trinity Logistics offers you more than just transportation services. We’re a trusted, strategic ally that’s invested in seeing your business succeed. Leave the logistics to the seasoned experts, so you can focus on creatively and passionately brewing while we ensure your craft brews reach your consumers right when they want it.

LET US HELP WHAT ALES YOU IN LOGISTICSConsumers want more fruits and vegetables in their diets but produce shippers must face these common logistics challenges to keep up with their demand.

It’s hard to deny the nutritional value fruits and vegetables bring to our diets. It’s likely why there’s been substantial growth in consumer demand for produce over the past decade. While that’s great for businesses based in produce, there’s also greater pressure for produce shippers to deliver.

The journey from farm to table can be surprisingly complex for fruits and vegetables. Produce shippers face several hurdles that they need to overcome for their products to deliver fresh and meet the growing consumer demand. Let’s explore the intricacies of these difficulties and how they all can be taken care of by working with a third-party logistics (3PL) provider, like Trinity Logistics.

CHALLENGE 1: CHOOSING BEST TRANSPORTATION MODE

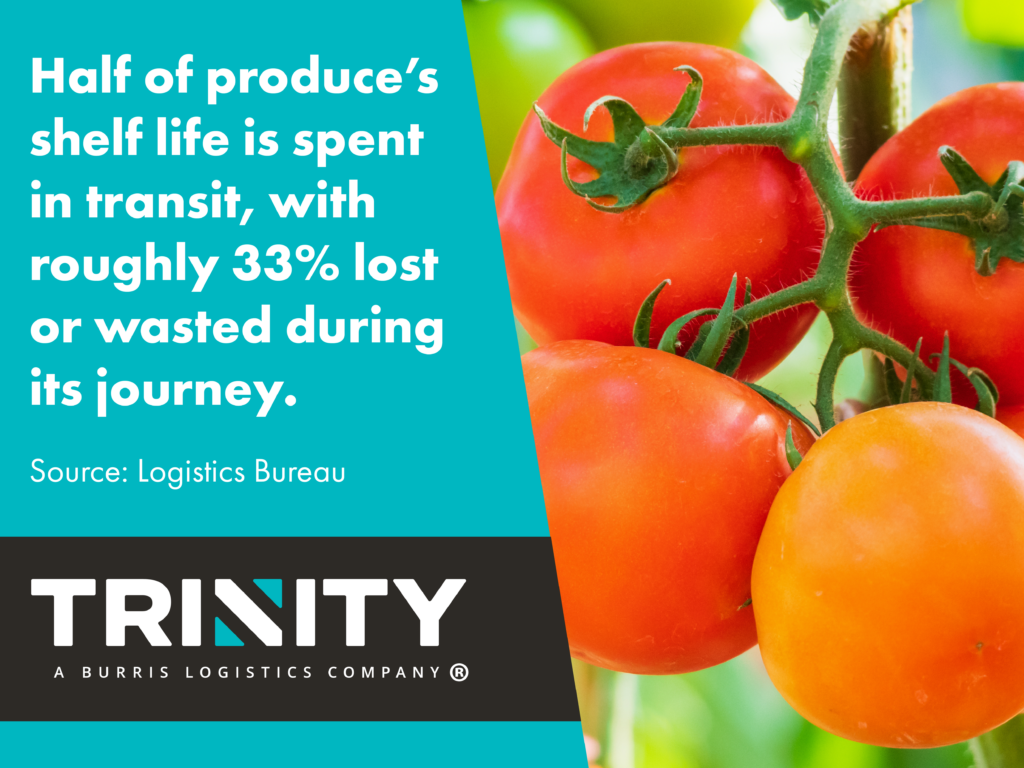

Produce shippers first face the challenge of determining what transportation mode to use for their shipments. With produce, half of its shelf life is spent in transit. It’s also reported that roughly 33 percent of produce is lost or wasted during its journey, according to the Logistics Bureau.

This is why produce shippers must ask themselves these questions to help determine the right transportation mode for their shipment.

What’s best for your product?

What can you afford?

How much time does your produce have?

Air is great for foods that have a very short shelf life and may need expedited shipping. However, air is often the most expensive of your options. Rail can offer you cost savings but requires more travel time, often two to three days. This option is often saved for produce with a longer shelf life. Lastly, there’s truckload shipping, which offers several shipping options and costs, depending on factors like whether you need a full truck, expedited shipping, or freight consolidation.

CHALLENGE 2: SELECTING THE RIGHT CARRIER PARTNER

The next challenge produce shippers need to tackle is choosing the right carrier to pick up and deliver their shipment. This may be the most crucial task of all because the carrier you choose can make or break your shipment. You need to trust the carrier you choose has experience in handling your specific cargo and meeting food safety regulations, especially for those that need temperature control.

CHALLENGE 3: MAINTAINING FRESHNESS/QUALITY

Maintaining freshness is one of the primary logistics challenges for produce shippers. Millions of dollars are wasted each year on produce that didn’t maintain freshness by delivery.

Produce begins to deteriorate the moment it’s harvested, so the risk of decomposition is equal to, or perhaps even greater, to produce shippers than those of theft or delay. Fresh or frozen produce needs to be stored and transported at specific temperatures to ensure its quality when bought and eaten by the consumer. Even the amount of humidity, light, or kind of packaging can affect a produce product, so produce shippers face this challenge in every segment of their shipping.

Every kind of produce also has different needs. Some need very specific environments to maintain freshness. Others can stay at room temperature or take on more handling. Shelf life is also something to consider. Produce with short shelf lives will need quick transit from farm to store. This also means several kinds of produce often can’t ship together. Since there is no one-size-fits-all process for produce, it’s important for produce shippers and their logistics partners to understand what’s needed for the specific product to deliver at peak quality.

CHALLENGE 4: SHIPMENT VISIBILITY

Tracking and shipment visibility is essential for produce shippers to be able to reduce risk. Without a clear look into your shipments, you’re left in the dark and uncertain whether your product will arrive on time or in acceptable condition.

This can challenge more than just produce shippers, but all stakeholders in a company’s supply chain. Miscommunication can happen between retailers and sellers as well, causing miscalculations in capacity planning or undependable forecasts. Real-time visibility and data are absolutely needed for produce shippers to enhance transparency with their business partners and gain more control over their supply chains.

CHALLENGE 5: REGULATIONS

Navigating regulations is a huge challenge for produce shippers. Failure to meet those regulations can lead to severe and often costly consequences. For example, in the U.S., produce shippers must comply with the Food Safety Modernization Act (FSMA), which entails specific guidelines for food safety.

There are also quality standards and labeling requirements to be met. The U.S. Department of Agriculture (USDA) has a strict grading system to determine the quality of produce, considering its size, shape, color, and defects.

CHALLENGE 6: HANDLING ANY CLAIMS

There’s always a risk for claims in shipping, but claims can happen more often for produce shippers compared to other industries, due to its shorter shelf life. The majority of claims we see in produce shipping are the result of spoilage, which can happen for many different reasons.

Handling claims for produce is slightly more difficult due to the Perishable Agricultural Commodities Act (PACA). When handling produce claims, it’s important you and your transportation provider understand and follow PACA.

HOW TRINITY LOGISTICS HELPS PRODUCE SHIPPERS OVERCOME THEIR CHALLENGES

All those challenges listed above that you may face – we know how and are prepared to handle them.

After 45 years of serving shippers in the food and beverage industry, we’re experts in its logistics requirements and regulations. We also take part in industry organizations, like the International Fresh Produce Association, so we stay knowledgeable about what may affect produce shippers.

When it comes to choosing your transportation mode, we have a multitude of options available to support you, whether you’re looking for help with one shipment or a fully outsourced logistics solution.

Additionally, we work with trusted carrier relationships that have been fully vetted to ensure your product travels safely and delivers on time. This includes vetting that reefer equipment is not older than 2012 and a temp-reading or download can be made readily available for any refrigerated or frozen produce shipments.

No matter where your freight is in its journey, we provide you with several real-time tracking options to stay fully informed. Through our Managed Transportation service and the use of a transportation management system (TMS), you can find more visibility and data to improve your supply chain processes and communication.

And then there are claims. While we wish every situation could go smoothly, there can still be mishaps. Even so, we’re proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. That’s likely because we work with shippers and receivers to monitor load and unload times, checking to ensure trailer doors are not left open, causing temperatures to fluctuate outside of any required ranges.

Now, fear not, because if something does happen, we’re able to help with that too. We have an in-house expert Claims Team to help negotiate any produce claims on your behalf, with an average rate of 60 days in resolving cargo claims.

By working with Trinity Logistics for your produce shipments, you’ll also gain an extra benefit – experiencing our acclaimed People-Centric service. It’s what our customers praise the most about our services and keeps them returning to Trinity Logistics for their logistics needs.

If you’re tired of tackling these produce shipping challenges alone, it may be time to get connected and join the thousands of shippers that choose to make their logistics easy with Trinity Logistics. You won’t be-leaf our exceptional service until you try it!

Get Out of Your Produce Shipping Pickle

Check Out Trinity's Solutions Request a Free Shipping QuoteWhether you’re at a local restaurant, a holiday party, or spending a Friday night on the town, you, or someone you know is having a drink. And no, we’re not talking about a glass of water or soda. We’re talking about alcohol, including beer, wine, spirits, liquors, and liqueurs. What does it take to get alcohol from manufacturing plants to stores and restaurants for consumers? In order to ship alcohol safely, there are many rules and regulations to follow.

Do We Even Drink That Much?

In the United States alone, people who are 21 years and older consumed 7.8 billion gallons of alcohol in 2018, according to a report by the National Institute on Alcohol Abuse and Alcoholism. Breaking this down, means 6.3 billion gallons of beer, 900 million gallons of wine, and 570 million gallons of spirits consumed. So, shipping alcohol is a continued need and one that is only going to grow. Since the pandemic hit in 2020, the volume of consumed alcohol increased at least two percent year-over-year.

The Production

In the United States alone, the alcohol beverage industry handles more than 4 million jobs and generates almost $70 billion in revenue. This number is only going to grow but beers, wine, and spirits are all different for the consumer.

Beer

This sector has been dominated by big brand names ever since the beginning. Big brands like Bud Light, Coors Light, Budweiser, and Corona all make life hard for those small-town local breweries.

While 2021 was a record year for small-town businesses with 710 openings and only 176 of their doors closing across all 50 states, they still face a tall hill to climb. In this situation, it’s David versus Goliath. Big beer companies have the brand reputation, the capital, the marketing, and all the business. Therefore, small breweries must compete not only with them but with other small local breweries to make it in the industry.

However, with everything against them, many consumers prefer a unique-tasting beer compared to the very recognizable Bud Light can.

While small breweries open their doors to everyone, their target audience for their beer is individuals in their twenties, thirties, and early forties. These individuals (especially Millennials) are more likely to try new drinks and prefer ones that have different flavor profiles such as sweet, salty, sour, hoppy, spicy, and more. This shows because, in 2021, the volume growth in small breweries grew by 7.9 percent and produced 24.5 million barrels of beer.

Wine

The wine market is as competitive as the beer field, where big brand names are a household stable with new vineyards and wineries opening across the United States.

Some of the biggest names in this sector are Franzia, Barefoot Cellars, Twin Valley, and more. The wine sector is expected to see significant growth. In 2021, the market was worth $417.85 billion and is expected to grow 6.4 percent year over year. So, while one may face the challenge of competing with big brand names, if a quality product is produced, there is great potential.

Spirits

The spirits industry also referred to as hard liquor, is a sector that made $135.78 billion in 2021. This sector has a lot more variety, including spirits such as vodka, tequila, rum, whiskey, gin, and more. Within each of these categories, they all have well-known competitors, meaning each one presents unique and complex challenges for those within the sector.

But, How Does Shipping Alcohol Work?

Whether you make beer or spirits or are a big brand name or a small business, one thing is for sure, you NEED to ship your product out to the consumers. But what does it take to ship alcohol?

When shipping alcohol you must have certain permits and meet regulations to ship it safely and most importantly, legally in the United States.

What Are the Regulations for Shipping Alcohol?

Here is where things get tricky. When shipping alcohol, you must follow certain rules, but the United States does not have one set of rules for transporting alcohol. This means that all 50 states in the U.S. have different rules and regulations to follow. For example, in Delaware, carriers must abide by the Delaware Office of Alcohol Beverage Control Commissioner rules but carriers traveling through New Mexico must follow the Alcoholic Beverage Control.

Before arranging your shipment of alcohol, you must be aware of each state’s regulations for the transportation of it. Find out what you need to know about a certain state’s requirements by clicking on the link below:

Making Shipping Alcohol Easy with a 3PL

No matter if your company is big or small, selling beer or wine, everyone must follow these rules when shipping alcohol. However, ensuring the carrier has the proper permits can be a pain-stacking task. By using a 3PL, like Trinity Logistics, you’ll gain access to a network of strong carrier relationships and Team Member experts with experience in the regulations for shipping alcohol.

Working with a 3PL means you’ll have someone on your side to help all the backend logistics work so you can focus on making and selling the best product. Plus, we offer a variety of shipping solutions for you, from less-than-truckload shipments to temperature-controlled intermodal, we have the shipping solution you need.

Learn how Trinity can support your businessIf you haven’t already noticed, cold chain logistics is currently a hot topic. The demand for fresh products and quality supply chain processes are at an all-time high. Recognizing these trends in cold chain and taking action will help you fulfill your customer’s needs. Let’s look at five trends going on in the cold chain industry.

1. An Increased Demand on Quality Products

Big trends in cold chain, specifically the food industry, has been the demand for fresher and higher-quality products. Consumers want their peaches to be juicier and their avocados to be riper. To satisfy the customers’ wants, you need to make sure the carrier that is shipping your product is well versed in cold chain management. They need to know how to avoid changes in the texture and taste of the produce when a shipment fluctuates beyond the required temperature. The focus on quality products means that refrigerated warehouses will need to maintain temperature zones.

Quality products don’t stop at fresh food. With the COVID-19 vaccine being administered, people want to make sure that what they’re getting injected into their bodies is safe. In addition, the amount of biological drugs and gene therapies is growing. Because of this, logistics companies are also widening their capacity for temperature-controlled transportation to meet the demand.

As we’ve stated in our Shipping Pharmaceuticals blog, cold chain logistics play significant role in the pharmaceutical supply chain. Manufacturers of these vaccines and medications need the cold chain to run smoothly to prevent any damage to the expensive drugs. Pharmaceuticals also need to arrive as good as new because medicine that has sat in incorrect temperatures for an extended period can be ineffective or detrimental to a patient’s health.

2. The Global Cold Chain Market is Booming

A recent report by Grand View Research shows that the global cold chain market size is expected to grow 14.8 percent from 2021 to 2028. Many nations have recognized a rising need to avoid food waste and loss of healthcare products due to spoilage. Moreover, the demand for fresher products is on the rise. Nations such as China and India are boosting their global cold chain efforts to meet the demand for their exports. International trade liberalization has also boosted the use of cold chain, globally. Because it is the global cold chain is rising, manufacturers need to become more specialized in their products so they can ship their goods to a wider variety of customers across the globe.

3. Stronger Regulations

Another trend in the cold chain has been stricter regulations on shipped products. Both globalization and the recent rise of food and pharma counterfeit incidences have caused production and cold chain rules to be reevaluated. The beginning of these rules started with the Food and Drug Administration’s Food Safety Modernization Act. This act requires anyone in the food supply chain to document every step of the process. Certain products like fruit must be traced all the way back to the point of origin.

Being proactive with these firm rules and regulations has also been a common trend across cold chain logistics. Manufacturers are strengthening their processes in-house to help mitigate any issues with their cold chain. Safety should be a top priority for the manufacturer when shipping through cold chain.

4. Innovative Packaging

Specialized packaging has been a trending topic in the cold chain industry. Whether it be for pharmaceuticals or food and beverages, manufacturers have been more specific on how they want their products packaged.

For pharmaceutical companies, there has been a conflict between packaging and transportation costs. For smaller shipments moving through the supply chain, a company can choose either a 24, 48, or 72-hour packaging that will protect the products from becoming ineffective. The more insulated the packaging is, the higher the cost. Globalization is also a major factor in this dilemma. If the U.S. ships cold chain products like pharmaceuticals overseas, it is imperative that the carrier knows to re-ice the shipment if any delays occur.

Companies that specialize in temperature-controlled packaging are making single-use or reusable packaging for all your cold chain needs. There are new refrigerated shipping systems that don’t require gel coolants, and they weigh much less than typical cold chain packages. These systems use evaporative, reactive cooling technology that responds and adjusts to fluctuating temperatures.

Whether it be significant innovations such as evaporative cooling technology or something as simple as adding handles and straps to your packaging, traditional packaging is starting to become a thing of the past. Companies are trying to gain that competitive advantage of being the most innovative packaging company for your cold chain needs.

5. Outsourcing to a Third-Party Logistics Company

Another demand in the cold chain has been for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the transportation of their products. That is why a 3PL provides a wide range of technology services to promote transparency within the supply chain.

Consumers today are becoming more conscientious about their needs. No one wants to settle for spoiled milk or ineffective pharmaceuticals. It is imperative that manufacturers stay up to date on these current trends in the cold chain in order to satisfy their customers. Doing research and staying in the know are both imperative ways for your business to be successful. Being proactive and listening to what customers want is the best way to stay on top in the cold chain industry.

Interested in learning more about Trinity’s experience in cold chain?

Speak With an expertFrozen food is considered one of the safest forms of food preservation because the freezing temperatures prevent harmful bacteria. This doesn’t necessarily mean that frozen food is foolproof. Several situations that could cause your frozen food to go bad and ways to prevent them from happening. If you’re new to shipping frozen food, or you’re a seasoned veteran staying up to date with the ever-changing world of cold chain logistics, here are a few things to keep in mind that can impact your company’s bottom line.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

Improper Packaging

Improper packaging is the most common mistake in frozen food shipping. It may also be the most involved part of your process. Multiple layers of packaging and ensuring an airtight seal to eliminate any heat or humidity penetration is critical. Your packaging’s inner layer should be waterproof to prevent any leakage from melting refrigerant causing damage to your outer packaging.

The person responsible for packaging your frozen food should have a strong understanding of dry ice and how to store it in proper containers. Although it a great source for cold chain packaging, it could be detrimental to your shipment if misused. If dry ice is packaged in an airtight container, there could be a pressure build up and cause that entire container to burst.

Package your frozen food with the proper amount of dry ice or frozen gel packs to prevent temperature fluctuations from happening. You should also ensure that you have the proper sized box to store your products. Too large with extra space means your goods could become damaged in the process of moving.

To prevent improper packaging, ensure that you have full knowledge of the temperatures required for that shipment and what type of insulation you want to use. Partnering with a 3PL that works with vetted carriers that have a strong understanding of how to transport frozen food will also save your shipment from spoiling or getting damaged.

Underestimating Shipping Times

When you underestimate shipment times, the result could impact your bottom line. If your product arrives to its destination melted or spoiled, you’ll end up with rejected products. This means money lost.

Plan your frozen food shipments ahead and research estimated transit times so you can pack enough coolant material. This will also provide insight on which refrigerant choice would work better for that shipment. One to two blocks of dry ice will last between 18-36 hours in a small Styrofoam shipping container. In a larger shipping container, dry ice can last between two to three days. It’s never a bad idea to make sure you have enough refrigerant packed so that it could last an extra day or two should your shipment have some unforeseen delay. Communicate the estimated transit time with your third-party logistics provider to ensure that the carrier shipping your frozen food has all the necessary information.

Not Properly Recording Information

Keep record of every detail about your shipment. This is paramount to staying compliant with the Food Safety Modernization Act (FSMA) and proving that your business has done everything possible to prevent the spread of foodborne illness. This includes the proper labeling of packaging, any providers used, and temperature records from before, during, and after transit.

The FDA Food Safety Modernization Act (FSMA) is transforming the nation’s food safety system into one that is based on the prevention of foodborne illnesses. Our team stays updated on these regulations and have processes in place to stay compliant.

Not Using a Qualified Provider

Maintaining the correct temperatures when shipping frozen food means maintaining its quality. You should make sure you choose a provider who is experienced with your frozen food product. Don’t make the mistake in trying to lower shipping costs by shipping mixed temperature goods together, which if not done properly, can compromise their quality and result in rejection of your product. Shipping mixed loads can be done, but you need to make sure it’s with a provider that has trucks with separate compartments capable of holding different temperatures, and the experience to handle it.

Finding and building a relationship with a qualified, experienced carrier to haul your frozen food products can be a long and time-consuming process. At Trinity, we have a network of over 70,000 qualified carrier relationships to help you.

Why not choose to save some time?

Request a QuoteIf you find it difficult to juggle multiple providers for your cold chain logistics, there’s a better, even seamless, way of doing business. Cold chain logistics can be difficult to manage and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. Often you may find yourself with many providers and contacts to sort through. What if you could reduce all your cold chain logistics companies down to one? What if you could replace the rest by finding one with a range of modes for your cold chain freight, including warehousing, transportation management, and more? Sound too good to be true? Keep reading.

RISKS OF MULTIPLE PROVIDERS

When you ship and manage temperature-controlled freight, you often find yourself working with more than one logistics provider. This means there can be more handling, which can become a cause for safety concerns.

Manual processes in the transportation of cold chain freight can cause decreased visibility along your freight’s journey. The majority exists within the food industry due to the Food Safety Modernization Act (FSMA). Because of this, shippers need to practice diligence when selecting and vetting the carriers they choose move their freight. They must make sure to communicate responsibilities such as required temperature requirements, having access to temperature readings, and making sure equipment is inspected before moving.

When you work with more than one carrier the process becomes more complicated. Each one adds complexity to your cold chain and every handling adds risk. Take time to map out your supply chain end-to-end, identify gaps, simplify your processes, and reduce the number of providers that move your freight. This can reduce your cold chain safety risks.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

HOW WORKING WITH TRINITY CAN BENEFIT YOUR COLD CHAIN

This is where partnering with Trinity Logistics can help. As a Burris Logistics Company, we’re uniquely qualified to arrange solutions across your entire cold chain. Working with us means you can feel at ease knowing your cold chain products are well taken care of during transportation. Stop searching for and working with multiple cold chain logistics companies. We vet every carrier in our network, reducing your risk and time spent finding providers. Some of the benefits of working with one 3PL include:

…INCREASED FLEXIBILITY

The ability to be flexible and quickly adapt to change is important for your cold chain business to stay competitive. When you partner with Trinity it gives you that flexibility of having a whole network of vetted, qualified carriers at the ready. And because we’re under the Burris Logistics umbrella, should you need other logistics solutions outside of our range, we can still support you by working with Burris to arrange those cold chain solutions that fit. We can help you stay flexible as one sole provider, instead of working with several.

…REDUCED WASTE

When you work with only one cold chain logistics provider, you can reduce your waste. At Trinity, you’ll build a relationship with a logistics expert. We can help you reduce supply chain inefficiencies through transportation management or reduce emissions by finding better routes. We can help you use trucks efficiently, such as reducing deadhead miles or suggesting intermodal when it makes sense.

…SAVE MONEY

When you work with a cold chain logistics company, such as Trinity Logistics, you can save money. With more flexibility, increased efficiencies, and reduced waste, you’ll be able to use your money better and reduce your logistics costs. By working with one provider instead of several, you’ll save time in billing and invoices. We provide a Team of dedicated, knowledgeable, and flexible experts, bringing you increased productivity and workflows within your logistics. Working with a provider such as Trinity, is a great way to cut costs without losing quality, time, or deadline requirements when it comes to your freight management and transportation.

WORKING WITH A COMPANY LIKE TRINITY, A BURRIS LOGISTICS COMPANY

When choosing to work with Trinity Logistics, you’re choosing to cut complexity. Cold chain logistics is complicated in itself and trying to do it alone can be frustrating. Choose to reduce your frustration with cold chain logistics companies by choosing the right one.

With Trinity, you’ll gain end-to-end supply chain management. Trinity is one part of the Burris Logistics umbrella, so working with us offers you access to other Burris options such as cold storage or direct-to-consumer fulfillment should you need it.

With Trinity and Burris combined, you’ll gain a greater level of flexibility in your cold chain with customized solutions. You’ll have a greater level of agility in your logistics execution while reducing cost. Since we focus on how you operate as a shipper, we make sure we fit your mold and help to solve your problems, not the other way around. You can count on Trinity Logistics to be able to serve and support your cold chain all the way from production to delivery.

Simplify your cold chain logistics today.

REQUEST A QUOTENeed more info?

WATCH OUR COLD CHAIN WEBINAR