07/25/2025 by Nicole Peterson

6 Manufacturing Trends You Don’t Want To Miss

Big shifts are reshaping manufacturing, and staying ahead is crucial.

Many of today’s manufacturing trends are in line with the industry’s goals to improve processes, create efficiencies, and meet customer demand. Manufacturers must do more than simply keep operations running. It’s pivotal for them to adapt, evolve, and embrace change to thrive in the industry.

Here are the six trends you need to know so your manufacturing company can stay relevant and resilient.

WHAT ARE THE SIX MAJOR MANUFACTURING TRENDS?

SUSTAINABILITY & CLIMATE PREPAREDNESS for Manufacturing

Improving sustainability is no longer optional. It is a business necessity.

Combatting climate change is a priority on everyone’s mind, and the manufacturing industry is no exception. Manufacturers are under growing pressure to adopt carbon-neutral practices and meet Environment, Social and Governance (ESG) demands.

Here’s how manufacturing companies are reducing their environmental impact:

- Using intermodal shipping to cut emissions

- Purchasing carbon offsets, such as sponsoring restoration projects

- Adapting platforms like EcoVadis to track and report sustainability efforts

Additionally, as the climate becomes more unstable, severe weather is the new normal. And with that brings disruption. In fact, the U.S. National Climate Assessment reports that in the 1980’s, a billion-dollar extreme weather event occurred once every four months. Today, they occur every three weeks.

High winds, flooding, wildfires, and droughts are disrupting deliveries, damaging infrastructure, and increasing costs. With these severe weather events becoming more frequent, there is less downtime for affected supply chains to regroup.

When severe weather and disasters strike, the last thing you want is to be left guessing where your freight is or whether it’s still on track. That’s why many companies are implementing a Transportation Management System (TMS). With real-time tracking, smarter routing, and proactive updates, a TMS helps you stay ahead of disruptions and keep shipments moving even when the weather isn’t cooperating.

Speak with an expert in Managed Transportation TodayEXPANDING ROLE OF TECHNOLOGY in Manufacturing

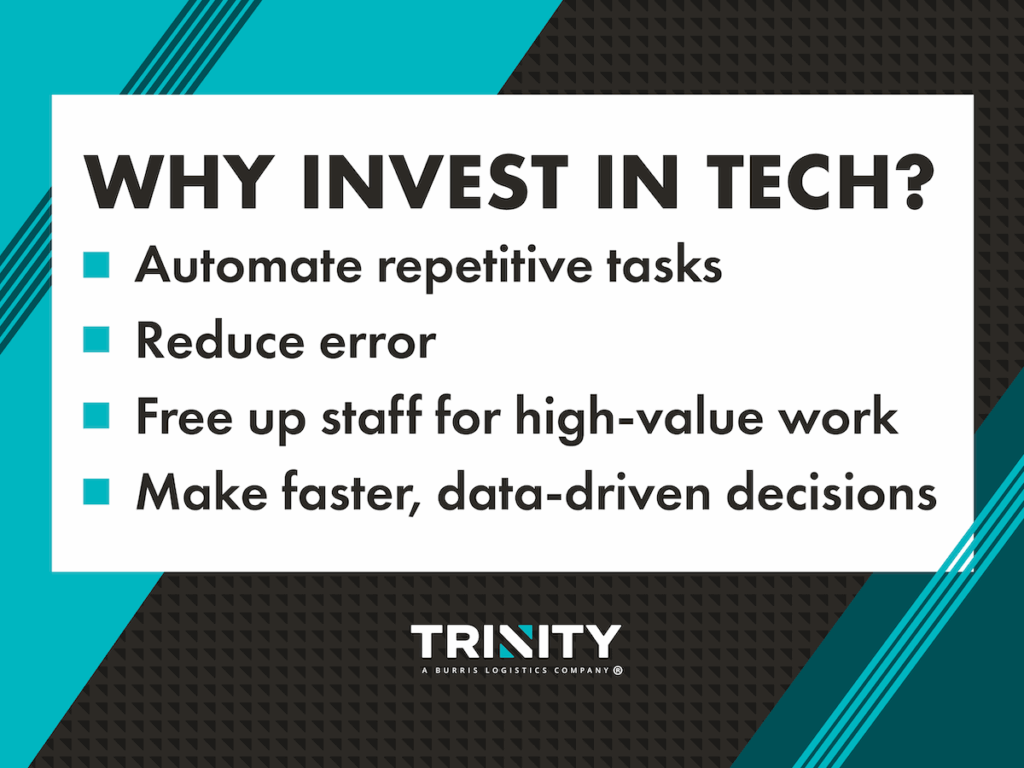

The manufacturing industry continues to embrace advanced technology to meet rising demand and overcome labor shortages. Industry 4.0 is what many refer to as this current manufacturing trend. It’s a shortened term for what is called the fourth industrial revolution.

With tech like Machine Learning, the Internet of Things (IoT), and real-time analytics, manufacturers are:

- Freeing up staff for higher-value work

- Reducing errors and boosting product quality

- Making faster, data-driven decisions

As the adoption of Industry 4.0 tech continues to grow, it’s important for businesses to focus on empowering their people with better tools, not letting them take over.

ARTIFICIAL INTELLIGENCE in Manufacturing

There’s no doubt that Artificial intelligence (AI) is the hot topic of most industries today, manufacturing included. According to Deloitte’s 2024 Future of the Digital Customer Experience survey, 55 percent of industrial product manufacturers already use AI and over 40 percent plan to increase their AI over the next three years.

AI is helping manufacturers to:

- Predict demand more accurately

- Streamline operations

- Reduce costs

- Improve quality control and maintenance

- Make smarter decisions faster

AI is quickly gaining more and more momentum year after year. It’s certain to continue to revolutionize the manufacturing industry.

ONGOING URGENCY OF CYBERSECURITY In Manufacturing

As manufacturing operations become more digital, they’re becoming bigger targets for cybercriminals. In the 2024 RSM US Middle Market Business Index, 28 percent of executives reported experiencing a data breach in the past year, up 20 percent from 2023.

Slips in cybersecurity and digital threats can compromise:

- Machinery – even shutting down equipment

- Worker safety

- Disrupt your entire supply chain

Cybersecurity isn’t just IT’s problem; it’s a company-wide priority. Investing in things like multi-factor identification, employee training, and recovery plans is paramount to the safety of your company. In fact, KnowBe4 recently shared that consistent cybersecurity training reduced employee phishing attack vulnerability by up to 86 percent!

WORKFORCE SHORTAGES REMAIN A Manufacturing CHALLENGE

Labor shortages remain a hurdle in the industry, limiting production and growth. To overcome these manufacturers are:

- Upskilling and apprenticeship programs

- Focusing on employee retention

- Using AI to forecast labor needs, identifying skill gaps, and personalize training

Deloitte’s 2025 Manufacturing Industry Outlook states that nearly 60 percent of manufacturers cited the inability to attract and retain employees as their top challenge, according to the National Association of Manufacturers.

Focusing on retaining a solid workforce will ensure companies stay equipped to meet future demands.

Schedule a Supply Chain Review

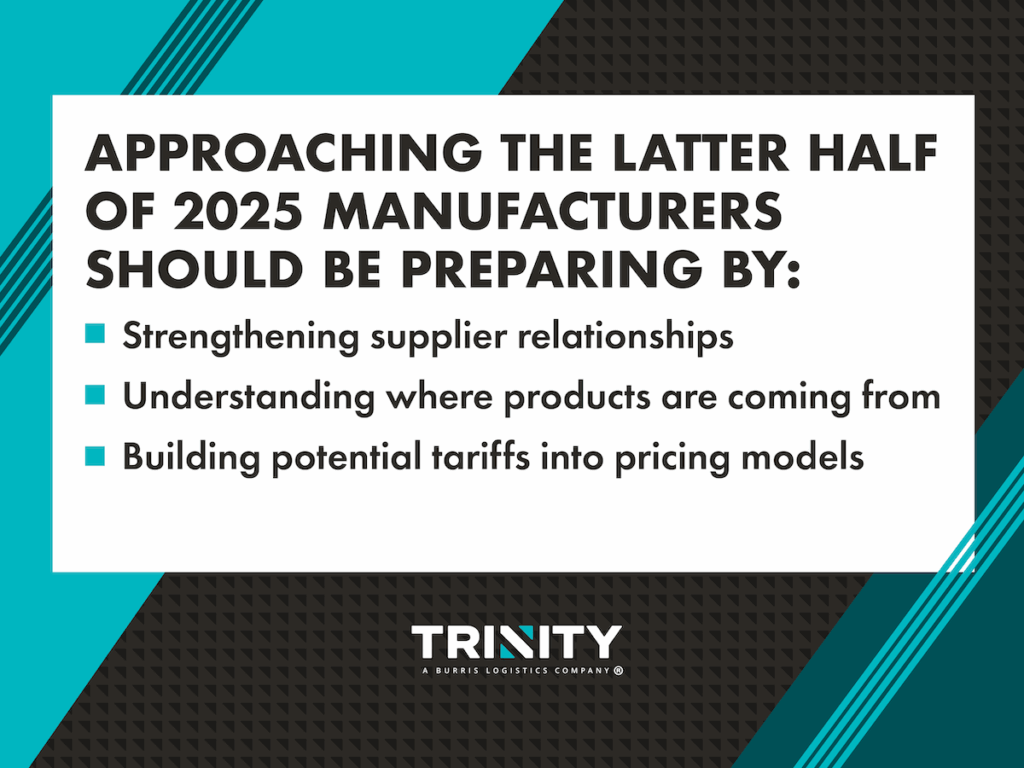

RETHINKING THE Manufacturing SUPPLY CHAIN

It wasn’t that long ago when COVID-19 exposed just how fragile the supply chain is. Since then, manufacturers have worked towards building more resiliency, visibility, flexibility, and stronger digital connections.

In 2025, AI- and tech-driven supply chain keeps an edge on competitors and resilient to future disruptions.

And unfortunately, we must mention what’s top of mind for most manufacturers – tariffs and economic uncertainty. With evolving U.S. trade policies and new tariffs on goods from China, Canada, Mexico, and more, prices for everything are raising. From rising raw material costs to shipping rates and dropping consumer confidence, manufacturers are pulling back on their estimations for growth. Manufacturing revenue is only expected to grow by 0.1 percent in 2025, a staggering drop from last year’s 0.8 percent.

STAY AHEAD OF MANUFACTURING TRENDS

Staying ahead of these manufacturing trends takes more than just some of the internal changes mentioned previously. It takes having the right strategic partners in place, too.

And that’s where a trusted logistics expert like Trinity Logistics comes in. We’re here to help manufacturing companies, like yours:

- Gain visibility into their supply chains

- Tap into smarter, greener, more cost-effective shipping strategies

- Easily adapt to change without added stress

- Be resilient and stay one step ahead of any disruptions

As a People-Centric company, we’re invested in your company’s success. Our experts constantly monitor and stay informed on the latest developments in your industry, so we keep you ahead of the curve, no matter the current trends. Whether you’re looking to explore a new mode of transportation, simplify your operations, or just want to make sure your product gets delivered on time, we’re who you can lean on for logistics support. Allow us to keep things moving while you focus on what matters most – being the leader in your manufacturing space.

Get A Personalized Quote