How do we get supply chains back on track after years of constant disruption and setbacks? The supply chain backlogs came largely from the shock at the start of the pandemic, but even before then, there have been many supply chain vulnerabilities.

Supply Chain Resiliency: Alleviating Backlogs and Strengthening Long-Term Security

Recently, Congress met to discuss our national and global supply chains, current supply chain issues that we need to focus on now, and how to build supply chain resiliency for the long term. Congress invited individuals and organizations to come to testify, to present their views for inclusion on the topic. U.S. Senator for Delaware, Tom Carper, asked Doug Potvin, Chief Financial Officer (CFO) of Trinity Logistics to testify.

With 16 years of service at Trinity and over 30 years of industry experience, Doug sees first-hand the problems plaguing supply chains. Doug’s testimony gave the Members of this panel valuable insight into the continued problems in supply chains and how members of the Transportation Intermediary Association (TIA), like Trinity Logistics, continue to serve the nation amidst these difficult times.

Doug’s Testimony Before Congress

“ I want to introduce myself as the CFO, Chief Fun Officer at Trinity Logistics because we like to have fun when we’re working hard. Thank you for the opportunity to speak with you today regarding how policymakers and business leaders are addressing the existing backlogs in the supply chain in the short term and building more resilient supply chains in the long term. My name is Doug Potvin. I’m the CFO of Trinity, a third-party logistics company (3PL) headquartered in Seaford. I’m privileged, honored, and humbled here today representing Trinity, our association, Transportation Intermediary Association, and the entire third-party logistics industry that we serve.

We serve as an intermediary in solving the logistical needs of our shipper customers by sourcing capacity from motor carriers and vendor partners. We are proud to report today that this past year we’ve generated over 1 billion dollars in revenue, arranged over half a million shipments, and offered 350 individuals full and part-time jobs. We truly are a proud Delaware company.

From Charles Dickens, the novel, The Tale of Two Cities; It was the best of times, it was the worst of times. Season of light is the season of darkness, a spring of hope is a winter of despair. Over the last two years, the same could be said of the international supply chain and from our perspective, closer to home, the domestic transportation industry.

In March of 2020 as both domestic and international countries shut our businesses including the shutting of the port cities and operations in China and the fact most consumers were at home facing an uncertain future, freight volumes plummeted. Motor carrier capacity increased dramatically due to the steep drop in goods moving and the transportation market saw prices for motor carriers fall. In fact, Trinity Logistics was mentioned on a Facebook post that we were earning an average gross margin of 60 percent, which was simply wrong.

In addition, a small number of motor carriers came to Washington D.C. and demanded rate transparency. Interesting after the businesses, ports, and countries opened up freight volumes began to skyrocket, available motor carrier capacity tightened up, and rates paid to motor carriers increased due to reflecting the change in market conditions. Demand for rate transparency went silent.

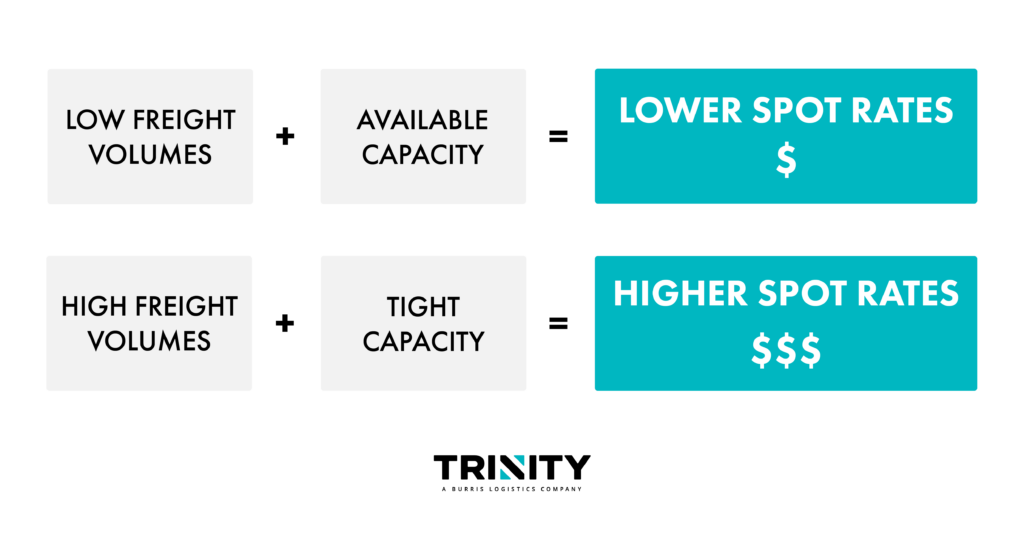

The pricing in our industry is driven by market conditions, supply and demand. Large scale, no entity on either side of the equation has enough market share to drive rates. In addition, each shipment has its own variable considerations to take into account including everything from available to capacity in various regional markets, lead time for products, dwell time at shippers and consignees, commodities needing move, and type of equipment needed. All this happens in real-time to ensure goods get to market, keeping our economy moving forward.

Now more than ever, the role of third-party logistics professionals has become more valuable. Companies like Trinity and the other 28,000 licensed property brokers are working overtime to ensure that essential goods continue to be delivered in an efficient manner to meet our customer and consumer needs. Our industry along with motor carriers are the main component as the why during the crisis and disruption, the supply chain bent but never broke.

Trinity Logistics applauds the U.S. Senate and House of Representatives’ Bipartisan passage of the Infrastructure Investment and Job Act, a historic investment into transportation and infrastructure. We’re very pleased to see how quickly the Federal Motor Carrier Safety Administration (FMSCA) established the Safe Driver Apprenticeship Pilot Program. Trinity hopes this three-year pilot program will be successful and made permanent so individuals ages 18 to 20 will explore interstate transport careers. Trinity also believes that as the spending on the Investment Act ramps up in the near future it will provide enough support to the economy to keep the motor carriers employed as we are starting to see freight volumes pull back over the last 30 to 60 days.

Trinity would also like to thank Chairman Carper, John Cornyn, Senator Menendez, and Senator Tim Scott for the support in offering legislation and getting the Senate to act unanimously in passing the Custom Trade Partnership Against Terrorism Act (CTPAT).

Currently, the vaccine mandate for truck drivers coming to the country to deliver freight from Canada and Mexico continues, these professional drivers spend most of their professional time alone in the truck cab, presenting a zero percent risk of spreading Covid-19. This should be lifted immediately to open up capacity and shorten the amount of time it takes to move goods across borders.

Another issue that greatly impacts not only the efficient movement of goods, but highway safety, is the lack of a federal motor carrier safety selection standard. Currently, because of broken safety rating systems from the FMCSA, almost 90 percent of trucking companies are considered unrated. There are no requirements in place before selecting a trucking company, that drastically impacts the overall safety of our nation’s highways. The latest report from the national highway traffic safety administration noted that the number of accidents involving commercial motor vehicles increased 13 percent in 2021. The status quo is not working, and highway safety needs to be improved. Trinity Logistics and our trade association, TIA, fully support legislation to create a motor carrier safety selection and mend the safety rating process.

The U.S. trucking spot market conditions have reflected towards weaker and more normal conditions, though we still will see what the future holds and how that trend continues. Hopefully as a result of this meeting and coordinated actions taken by the United States, our trading partners, manufacturers, supply chain vendors, our nations become resilient when facing similar conditions and uncertainty.”

Trinity Logistics would like to thank Chairman Tom Carper and the TIA for inviting Doug to testify before the Committee. He is a very valuable leader in the industry and Trinity Logistics appreciates all he does for our company, our industry, and our nation.

If you would like to watch the full hearing:

Stay in the know. Join our mailing list.When one hears “supply chain,” typically they first think of the physical components; the raw materials needed by a specific time for manufacturers or finished products to retail stores. The digital parts of supply chains work in a similar fashion. Cyber supply chains focus on keeping the physical aspects of business moving using applications, information systems, or digital vendors. And so, cyber supply chain risk management is crucial for business continuity.

Without addressing cyber supply chain risk management in an intentional and thoughtful manner, the industry will continue to remain susceptible to further disruption. Publicized breaches are the tip of the cyber-impact iceberg. Attacks occur with such frequency, and via many attack vectors, that a breach is occurring or imminent in any network or system.

According to the annual X-Force Threat Intelligence Index, manufacturing and other suppliers suffered nearly a quarter of the cyber attacks in 2021. Amidst the disruption faced by the pandemic, these attacks only further distressed supply chains. However, with a cyber supply chain risk management plan in place, companies can focus on reducing the frequency and impact of such events.

WHAT IS CYBER SUPPLY CHAIN RISK MANAGEMENT (C-SCRM)?

Cyber Supply Chain Risk Management (C-SCRM) is the process of ensuring the integrity of your supply chain’s supporting systems and data. This includes identifying, assessing, and mitigating the risk associated with the interconnected nature of information technology and service supply chains. Since cyber supply chain risk can be compromised at any point where technology is leveraged, C-SCRM applies to both hardware and software and covers the entire life cycle of those systems.

THINGS TO KEEP IN MIND

C-SCRM is Not Just an IT Problem

Cyber security for businesses isn’t quite that separate from physical security. The digital aspects of supply chains touch all parts of an organization, so C-SCRM should too. Cyber security risks can come from many different places such as physical sabotage or most commonly, human error via social engineering. Don’t make the mistake of thinking C-SCRM is the sole responsibility of the IT department. Whether physical or digital, security is part of everyone’s job.

Know Your Risks and Threats

If you don’t know your cyber security risks, it’s hard to have planned countermeasures for cyber threats. First, make a list of key scenarios that might endanger your cyber supply chain. Some common risks are integration loss, phishing attempts, malware, and hacking. Once you’ve created a complete list of risks, work through the most likely and highest impact scenarios first. Then, create plans to prevent and mitigate risk should a successful breach take place.

Assume a Breach Will Happen

We all like to think a breach will never happen, but these days it’s not if but when. Assuming a breach will happen allows you to better assess the impact of one on your system. Once you understand how affected you could be, you’ll better understand how to mitigate the effect of one.

Track the Links in Your Supply Chain

Working with third parties removes some of the control you have for cyber supply chain risk management. And static monitoring isn’t enough to keep your data and networks in your supply chain safe. Static monitoring gives you a one-time snapshot of their controls, but what about tomorrow or next week? Cyber supply chains aren’t static, so your monitoring shouldn’t be either. Many organizations assume they’re secure once they’ve implemented a cyber supply chain risk management framework, but it doesn’t stop there. Continued tracking is the most efficient way to ensure your data is always protected.

WHAT COMPANIES SHOULD FOCUS ON TO REDUCE CYBER ATTACKS

Network and System Hygiene

Cyber supply chain risk management starts with the management of the components making up the networks and systems of each link in the chain. Much of what supply chains need is straightforward hygiene. This includes updating older components, ensuring patching is consistent and comprehensive, and tighter controls on the use of open-source software to understand and mitigate any potential vulnerabilities.

What is the magical tool needed to affect this, you ask? It’s time. IT departments need enough staff to allow for time spent in this area. Many companies have grown to have some degree of heterogeneous systems and networks in place. Additionally, there’s been a recent move to remote and hybrid work styles. These recent changes have caused IT departments to need more team members to strengthen cyber security.

Monthly manual work is needed to ensure updates are completed and patches are deployed. Making it easier to perform this work involves homogenizing the environment. It’s an investment that can lead to improved cyber security for an organization.

Securely Transform

Digital transformation has been a staple in the changing work environment over the last two years. But those changes are a breeding ground for potential vulnerabilities.

Every digital transformation is a security event. This includes events like moving processes to the cloud or leveraging automation. Understanding the changes introduced in any digital environment is critical to defending your digital borders and reducing the blast radius if a successful breach occurs.

Ensuring the understanding of how new technologies connect to systems, how users interact, and how data flows is key to reducing the impact of the inevitable cyber-attack.

Beyond Logs

Logging security and other events are table stakes these days. But it’s only useful if observation and understanding are applied to those logs.

Based on the number of systems and infrastructure in use today at even a smaller organization, the manual survey of logs can no longer count as observation. This is due to the number of differences between various software and hardware providers.

Having a solution or partner in place to intake and analyze logs is more critical now than it ever has been.

The second need is the ability to understand it all. The trick is that it’s not about understanding one individual log. It’s about understanding them both alone and as they relate to one another. Again, this greater depth of understanding is where a solution or partner comes into play. Understanding allows for the identification of any anomalies so you can act upon them quickly and decisively.

CYBERSECURITY IS A PEOPLE, PROCESS, AND TECHNOLOGY PROBLEM

These cybersecurity steps are critical to keeping your data safe and establishing your business as a reliable supply chain partner. Successful attacks will continue to occur, but if you have the right team, solutions, and partners, your business can be more secure among cyber supply chain risks.

Cybersecurity is a people, process, and technology problem, so make sure to ally yourself with some of the good guys, like Trinity Logistics. We work with all our partners to understand and address potential supply chain risks, providing you with the technology and data you need while maintaining optimal cyber security. Our Technology Team is knowledgeable and experienced in cyber supply chain risk management, consistently working to keep our and your data secure.

Learn more about Trinity Logistics Stay in the know. Join our mailing listInbound Logistics has named Trinity Logistics as a Green Supply Chain Partner of 2022.

Inbound Logistics selected 75 honorees that “walk the walk” when it comes to commitment to supply chain sustainability and given the global environment this year, Trinity Logistics is very honored to have been selected.

Sustainability is something Trinity has always taken very seriously. Since 2008, Trinity Logistics has participated in the Environmental Protection Agency’s (EPA) SmartWay Program to reduce greenhouse gas emissions and air pollution that is caused by freight transportation. Trinity has also been partners with American Chemistry Council’s Responsible Care since 2009, which involves staying committed to improving company performance through community awareness, security, distribution, and pollution prevention.

With one of Trinity’s Guiding Values being Continuous Improvement, the company knows there is always room for improvement, even in sustainability efforts. That’s why Trinity recently become a Carbonfree Partner with Carbon Fund.

The Carbonfund.org Foundation is a non-profit that works with its partners to help them become “carbon-neutral” by donating funds to offset their emissions. Donated funds go toward third-party validated projects that comply with United Nations Sustainable Development Goals. With the help of Carbonfund.org, Trinity was able to calculate electricity usage in its corporate Delaware location and donate funds to the Carbonfund.org Foundation to offset the company’s own emissions by planting trees and funds sent to the Texas Capricorn Ridge Wind Project. Thanks to the Carbonfund.org Foundation, Trinity was able to offset 143 tonnes of carbon emissions.

Additionally, Trinity is working with the EPA and Carbonfund.org Foundation to create a calculated way that our shipper customers can donate to offset their shipment’s emissions and make a difference as well.

“As many companies shift focus to clean energy and reducing carbon footprints, Trinity is excited for our new partnership with the Carbonfund.org Foundation and our continued partnerships with American Chemistry Council’s Responsible Care Management System and EPA’s SmartWay Program to support our customer efforts in going green,” says Kristin Deno, Director of Operational Risk at Trinity.

Trinity is grateful to be recognized for its continued sustainability efforts. Trinity stays determined to find and implement impactful ways to help combat climate change and hopefully soon, can offer more ways for shipper customers to make a direct impact too.

Learn how Trinity Logistics can support your business. Stay in the know. Join our mailing list.About Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 40 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized on Transport Topics’ Top 100 Freight Brokerage List, a Top 3PL and Cold Storage Provider by Food Logistics, and a Top Company for Women to Work for in Transportation by Women in Trucking.

How do truck drivers eat healthy while over the road? Truck drivers can have jam-packed schedules with little time to think about their food choices. While truck stops and fast food joints are often full of food loaded with sugar, sodium, or to-go greasy food. Maintaining a good diet for truck drivers can be hard to do while having fast-paced schedules. It’s easy to get used to these kinds of foods, and with a sedentary work style, it can often add up to an early onset of diseases and poor health. For example, the life expectancy of truck drivers is 16 years less than those of other working professions. And the heavy carbohydrate and sugar load of those convenient favorites can lead to a slower metabolism and insulin spikes – both making you more sluggish behind the wheel and affecting your alertness.

Thanks to advances in technology and consumer changes, maintaining a good diet while over the road (OTR) is becoming easier. While having a good diet for truck drivers might seem difficult, with a little preparation and planning, it can be doable and keep you hauling freight for years to come. There are many ways to improve your diet, and we’re here to help you find what works best for you. Keep reading for tips, food ideas, benefits to healthy eating, and more so you can find a healthy diet convenient.

Listen to our Heart of the Truck podcast episode on Staying Fit Over The Road!TABLE OF CONTENTS

Skip ahead to the sections you want to read most!

- Storing and Making Food Over-The-Road

- Tips for a Healthy Diet

- Healthy Meal Ideas

- Healthy Eating Benefits

- A Good Diet for Truck Drivers is Possible

- Help Us Help You!

STORING & MAKING FOOD OTR

Making your own meals, whether ahead of time or on the go, allows you to control the content and nutritional value of your food while also saving you some money in the long run. Thanks to today’s technology and appliances, you have options to store any temperature-controlled products or pre-made meals in portable coolers or refrigerators. You can even cook some food right from your truck using a microwave, slow cooker, or a hot plate. Just keep the clean-up in mind

You can also make use of some resources at truck stops, such as a microwave to heat up a packed meal or the hot water at the coffee station to use for things like oatmeal or instant soups. Additionally, many foods don’t need any temperature control, such as many fruits (fresh and dried), PB & J sandwiches, tuna packets, summer sausage, applesauce, and even dried or shelf-stable milk!

And if that’s not enough, you can still eat out. You just have to be mindful of where you’re going and what you choose to eat.

TIPS FOR A HEALTHY DIET

Plan Ahead

Planning your meals and snacks ahead of time is the easiest way to have a good diet for truck drivers. Make sure you’re balancing your diet and steering clear of those foods that make you feel bogged down. Whether you’re meal prepping or eating along the way, plan your meals out, so you know exactly what you’re eating and how it will make you feel.

Know Where You’re Going

This goes hand in hand with planning ahead. Know where you’re going for your meals so you can make the best choice of what you eat. You can still keep the convenience of eating out while choosing the places and meals that fuel your body best.

Eat Every Two to Three Hours to Avoid Hunger Surges

Not only does eating often help keep your metabolism active, but it also helps regulate your blood sugars, keeping your hunger at bay. There’s nothing worse than forgetting to eat for a while and then BOOM, hunger strikes, and somehow, you’ve consumed a whole day’s worth of meals, or worse, a bunch of junk you were craving rather than a well-balanced meal. Additionally, eating every few hours will prevent energy crashes and difficulty concentrating.

Prioritize Protein

Prioritizing protein is the best way to beat energy dips and most importantly, keep hunger and cravings at bay throughout your drive. Try adding some peanut butter or yogurt to your snack, having eggs at breakfast, eating lean meats or beans for lunch or dinner, or even adding a protein bar or shake to your day.

Drink More Water

Your body is made up of 60 percent water and you need to help maintain that balance! Water comes with no extra calories while keeping you hydrated and full of energy. And often, it’s common to confuse thirst with hunger. It’s estimated that on average anywhere from 11 to 15 cups of water is needed to keep signs of dehydration and thirst away, so make sure you’re drinking often. If you’re used to keeping a soda or energy drink on hand, you can always add some fresh fruit to your bottle of water to add some flavor and pizzazz.

Stock Your Cab with Healthier Snack Choices

To keep your hunger at bay by eating every few hours, you’re going to need snacks at the ready. Try to keep away from the bags of chips or candy bars. For a good list of healthy snack ideas, see our list of “Snack Ideas” below.

MAXIMIZE FRUITS AND VEGGIES AT EVERY MEAL

Remember the food pyramid? I think you and I both know we can always eat more fruit and vegetables. According to the Canadian Community Health Survey of Truck Drivers, 70 percent of truck drivers eat less than the suggested five servings of fruit and vegetables per day.

Fruits and veggies are great to fill your plate or snack because they’re full of water, fiber, good carbohydrates, and many other nutrients our bodies need. Fresh fruits are a great treat when you’re craving something sweet, and canned, fresh, or frozen veggies can be good as a crunchy snack or savory side to your meal. Fruits and veggies also contain antioxidant and anti-inflammatory phytochemicals which may help in preventing things like cancer and heart disease.

Limit the “Feel Bad” Foods

Do I sometimes love to eat a cheeseburger from McDonald’s or a Crunchwrap with a Baja Blast from Taco Bell? YES. Does it love me? NOPE.

So that’s why I limit them. As much as I love them, I know they make me feel bloated and sluggish, so I aim to steer clear of them. Of course, you don’t have to give those kinds of foods up completely; just reduce your intake of them. Get a salad with your burger or swap the soda with water to better balance it out when you choose to eat those foods.

HEALTHY IDEAS FOR ALL YOUR MEALS

Breakfast

I’m sure you’ve heard the phrase, “breakfast is the most important meal of the day”. That’s for many good reasons! Breakfast essentially “breaks the fast” that your body had overnight while sleeping. It replenishes your supply of glucose to boost your energy and alertness in the short term while also helping with weight management and reducing your risk of type 2 diabetes and heart disease in the long term. So don’t skip this important meal and make sure your breakfast is rich in protein, complex carbs, and healthy fats. Also, try to keep sugar at a minimum so you don’t crash soon after eating.

- High fiber, low sugar, dry cereal or granola

- Oatmeal

- Whole grain waffles

- Turkey bacon

- Ham and cheese omelet

- Hard-boiled eggs and toast

- Avocado toast

- Yogurt parfait

- Fruit and yogurt smoothie

Healthy Lunch

- Sandwich

- The options are endless! Plus, if you have a refrigerator in your truck, it’s easy to put together within minutes!

- Salad

- Can buy kits from the store or pre-made from truck stops/fast food

- Grilled cheese and soup

- Quick and easy to make, great for those rainy, cold days.

- Frozen vegetables in steamable microwave bags

- Great for a healthy side!

- Stir-fry

- Easy meal to make on the go or ahead of time and reheat. Buy a bag of 60-second cook-in-the-bag rice, a bag of mixed veggies, canned chicken, and some stir-fry sauce. Cook the rice and then add the rest of the items and cook together. Easy and ready in just a few minutes!

- Smoothies

- To start, all you need is some protein powder, milk or water, yogurt, and a blender. Add in any extra ingredients for the flavors you want such as cocoa powder, peanut butter, or fresh fruit – the options are endless and up to you!

Balanced Dinners

Yes, some of these suggestions may have been in the lunch section too!

- Salad

- Can buy kits from the store or pre-made from truck stops/fast food

- Grilled cheese and soup

- Quick and easy to make, great for those rainy, cold days.

- Frozen vegetables in steamable microwave bags

- Great for a healthy side!

- Stir-fry

- Easy meal to make on the go or ahead of time and reheat. Buy a bag of 60-second cook-in-the-bag rice, a bag of mixed veggies, canned chicken, and some stir-fry sauce. Cook the rice and then add the rest of the items and cook together. Easy and ready in just a few minutes!

- Whole grain pasta with tomato sauce, veggies, and lean ground beef

- Homemade chili

- Can even cook in the crockpot while driving!

- Taco bowl

- Can use any sort of protein and is a great well-balanced meal

- Soups

- Can also be made in the crockpot

Snack Ideas

One of our tips above mentioned having healthy snacks on hand so you can keep your hunger satisfied throughout your drive. So here are a few healthy ideas:

- Fresh fruit like apples, bananas, and oranges

- Fresh vegetables like carrots, celery, cucumbers

- Protein or granola bars

- The fewer ingredients, the better

- Unsweetened apple sauce

- Trail mix

- Preferably the ones without the candies

- Pretzels

- Low sodium or unsalted

- Popcorn

- Unsalted and without butter

- Dark chocolate

- A higher cacao percentage means it’s better for you

- Hummus

- Use it as a dip for your fresh veggies

- Guacamole

- Dried fruit

- Roasted chickpeas

- Great source of protein

- Low-fat yogurt

- Low-fat string cheese

- Whole-grain crackers

- Beef jerky

HEALTHY EATING BENEFITS

Adapting to a good diet for truck drivers can seem tough, but once you start, you’re sure to see some of the benefits such as:

Not Feeling as Hungry

Eating often and with foods primed to fuel you properly, you’ll notice your hunger affecting you less, which also helps you make smarter food choices.

More Energy

When your body is getting all the nutrients it needs and less of what it doesn’t, you’ll quickly realize how much more energy you have in your day-to-day.

Better Focus

Eating healthy increases blood flow to the brain, meaning your cognitive skills stay sharp, something every driver needs. It’s also been shown to help prevent dementia and cognitive decline.

Better Health

One of the reasons you’ll be feeling so much better is that you’ll be in better health. Eating healthy improves your health and prevents common heart disease. It also helps to keep your bones and teeth strong, preventing tooth decay and osteoporosis.

Weight Loss

One of the main reasons people seek a healthier diet is to lose weight. In 2018, researchers found that a diet rich in fiber and lean proteins resulted in weight loss without any need for monitoring calories. As mentioned earlier, focus on filling most of your plate with fruits and veggies and prioritizing protein, and you might notice your clothes fitting a bit looser than before.

Saves You Money

Now, this may not be the case if you continue to buy your food at truck stops or fast-food restaurants, but if you choose to make more of your meals ahead of time or on the go in your truck, this is often the case. On average, analyzed data from Priceonomics found that it is almost five times more expensive to eat out than it is to make your own food. And often, you’ll even find yourself with leftovers when making your own food to save and eat at another meal, saving you time, too.

A GOOD DIET FOR TRUCK DRIVERS IS POSSIBLE

A good diet for truck drivers is one of the most important factors for a healthy lifestyle, as I’m sure you’ve heard of the popular phrase “80 percent diet, 20 percent exercise”. It’s true because food is fuel. Our bodies are meant to thrive by fueling them with the proper nutrients, aka eating, which we do almost all day, every day. You wouldn’t fuel your truck with fuel that would make it run sluggish, slow, or eventually cause problems, so make sure you are doing the same with your body.

When starting to build a habit of healthy eating, the most important thing is to get started, no matter how small. While making healthy food choices on the road can seem impossible if you try whenever you can, you’ll quickly notice how much better you feel and ultimately, find that a good diet for truck drivers is possible.

HELP US HELP YOU

At Trinity, we like to connect with our carriers by building relationships. One of the ways we do that is by creating content on the topics you find most interesting. To find more content you might like, check out our Heart of the Truck podcast, YouTube channel, or sign up to receive our monthly newsletter.

Listen to the Heart of the Truck Check out Trinity's YouTube Get the monthly newsletterIf you’re a large-scale manufacturer, getting liquid freight transported in bulk is a non-negotiable complexity. Bulk transportation, especially liquid freight, has its challenges and may seem daunting. But, with the right information and provider, it doesn’t have to be. So, whether you’re new to bulk transportation for your liquid freight or a seasoned vet, this article breaks it all down so you can safely and efficiently have your liquid bulk product transported.

What Kinds Of Bulk Liquid Products Are There?

What Is Bulk Transportation For Liquid Freight?

Complexities Of Bulk Transportation For Liquid Freight

What Can Go Wrong With Shipping Bulk Liquid Freight?

What Kind Of Equipment Is Needed For Bulk Liquid Transportation?

How Do You Transport Bulk Liquids?

Bulk Transportation: Liquid Freight Regulations

WHAT IS A BULK PRODUCT?

Before we dive into bulk liquid freight, let’s go over what bulk products are. The term “bulk” is used in transportation to describe goods that are not in containers and loose, transported in mass quantities or volumes. Bulk products are usually packed in one large container to be moved, such as a tanker trailer. Bulk products are often not intended for general consumers but are useful to manufacturers. Examples of bulk products are raw materials, ingredients for food manufacturing, materials for landscaping, gravel, dried beans, oil, or grains.

Another term to be aware of when working with bulk products is “break bulk”. Breakbulk is when a bulk shipment is broken down into smaller containers. This is important to know because bulk shipments are handled as loose goods whereas breakbulk shipments are loaded individually in some sort of container. Therefore, when you have a product to ship, it’s very important to properly communicate whether your shipment is bulk or breakbulk.

WHAT KINDS OF BULK LIQUID PRODUCTS ARE THERE?

There are many sorts of liquid products that ship via bulk transportation. These types of liquids are often used in manufacturing, food processing, agriculture, and more. Some examples of bulk liquid freight are:

- Vegetable oil

- Alcohol

- Milk

- Juice

- Syrup

- Sugar alcohols

- Vinegar

- Essential oils

- Mineral oils

- Artificial colors or dyes

- Chemicals

- Hydrogen peroxide

- Sulphuric acid

- Nitric acid

- Mining chemicals

- Solvents

- resins

- All types of water

WHAT IS BULK TRANSPORTATION FOR LIQUID FREIGHT?

Bulk transportation for liquid freight involves using a tanker trailer instead of smaller drums or tanks. Bulk liquid transportation usually refers to the act of moving liquid freight by truck over long distances.

COMPLEXITIES OF BULK TRANSPORTATION FOR LIQUID FREIGHT

Bulk liquid freight, especially when it’s hazardous, can carry more risk than other types of freight. For example, an accident involving a tanker truck can cause the shutdown of roadways, manufacturing production lines, and ultimately, the loss of raw material needed for many products.

The first complexity of bulk liquid freight is the way it’s packaged and stored. Unlike other freight, it’s not packaged in totes or smaller containers. Instead, bulk liquid freight is stored and transported in large containers and tankers, and because of their liquid state, they can slosh around and spill.

Since bulk liquid freight shipments transport differently than dry van shipments, you’ll find complexity in its logistics like:

Longer Lead Times

Tanker transportation is considered more of a specialty compared to dry vans, so you’ll notice fewer tankers available. This can make finding an available tanker longer to find.

Higher Rates

Being a specialty type of transportation, it’s easy to see why rates will be higher for this type of shipping. First, carriers pay more for this kind of special equipment. On average a tanker trailer can cost $100,000 to $125,000 compared to the cost of a dry van around $35,000 to $40,000.

Also, your shipping costs will include deadhead miles every time as each delivery requires a trip to wash the tanker. And unlike other types of transportation, you’ll have the same rate regardless of how full the tanker trailer is since different liquid freight cannot be combined for motor carriers to create a “full tank load” shipment.

Different Driver Requirments

No matter the product, tanker drivers are required to have a tanker endorsement, and if the liquid freight is hazardous, they’ll also be required to have a hazmat certification as well.

More Insurance

Carriers hauling hazardous liquid freight in bulk must carry a minimum of $5 million in liability insurance.

WHAT CAN GO WRONG WITH SHIPPING BULK LIQUID FREIGHT?

A lot can go wrong when shipping bulk liquids, so working with an experienced provider is very important. Drivers must be extra careful when pulling a bulk tanker trailer of liquid freight. Just as you must be careful when carrying a glass of water, liquid freight in a bulk tanker sloshes around with movement. If a driver brakes too hard or turns too fast, the weight of the liquid freight can surge to one side and topple the trailer. And if the freight is hazardous, then massive environmental damage can also happen.

Outside of concerns about a toppled trailer, drivers must be mindful of other issues. For example, what happens when you shake or stir liquid? It agitates and causes foam. This also happens with liquid freight during bulk transport. While foam can be annoying when later unloading the trailer, at worst, too much aeration can ruin a shipment depending on the kind of liquid.

Another thing that can go wrong when transporting liquid freight is contamination. Therefore, tank washing is a requirement for every shipment. If a tank isn’t properly cleaned before the next shipment is loaded, residue from the previous shipment can contaminate it.

Lastly, leaky tanks are another serious issue with bulk liquid shipping. If a leak goes unnoticed, even a small one, a significant amount of product can be lost during transport.

WHAT KIND OF EQUIPMENT IS NEEDED FOR BULK LIQUID TRANSPORTATION?

Bulk liquid freight cannot be transported without the proper equipment. Most often, a bulk tanker trailer is needed to haul liquid freight. A bulk tanker is a large, cylindrical metal tank pulled by a standard freight truck.

But there are several different kinds of tankers that can be used for the bulk transportation of liquid freight. For example, there are tankers designed to keep a product’s temperature regulated or tankers with hoppers on the bottom to make unloading easier. In addition, some tankers include pressurized tanks or acid-resistant tanks. Which type of tanker you’ll need is determined by the liquid freight you need to transport.

Some questions to ask yourself, or that your provider may ask of you, to determine what kind of equipment is needed are:

- What bulk liquid do you intend to transport?

- Is the freight hazmat?

- Is the freight temperature sensitive?

- What volume are you transporting?

- From what kind of container(s) will you be loading it?

- Can the loading facility accept a center or rear unload trailer?

- Does the tanker truck need special connectors?

- Is a pump or compressor required for unloading?

- Can the customer accept air compressor offload?

- At what pressure can the tanker unload?

- Does the product need a rubber-lined trailer?

- Are there any prior content restrictions we need to be aware of?

- Will you need a dropped trailer?

- Do you need any extra hoses for loading or unloading?

- What are the pre and post-wash requirements?

Types of Tanker Trailers for Liquid Freight

Tanker trailers can be categorized into two categories, depending on the content they transport or their structures.

Tankers by Structure

General Purpose Tanker

These tankers are used to transport bulk liquid freight that doesn’t require special care or procedures. They are usually made of steel.

General Purpose w/ Heat Coils

These tankers are the same except for the addition of heat coils to help raise or maintain the temperature of the product.

Pneumatic Tanker

These tankers have a series of hoppers on their underbellies to help with unloading. Although pneumatic tank trailers are mostly used to transport dry bulk freight. They are also effective for liquid bulk.

Vacuum Tanker

This is simply a tanker with a pump to help load bulk liquid from underground or any other location into the tank. These tankers are most used to transport septage, industrial liquids, sewage, or animal waste.

Rubber Lined Tanker

These tankers are commonly used to transport corrosive chemicals.

Aluminum Tanker

These lightweight tankers can carry more volumes before reaching their weight limit and have lower operating costs. They are typically used to transport petroleum and petrochemicals.

Compartmentalized Tanker

These tankers have compartments built into them that allow tanker carriers to ship different chemicals.

Fiberglass Reinforced Plastic Tanker

These tankers are most used for food-grade bulk liquids, corrosive chemicals, and other hazardous liquid freight.

ISO Tankers

These tankers are built according to the standards of the International Standard Organization (ISO) for the shipping of most bulk liquid freight.

Tankers by Liquid Content

Fuel/Petroleum

These carry gasoline, fuel, oil, or propane. Most often these tankers are required to carry a hazmat certification, also making this a more dangerous job.

Food Grade

These tankers carry liquid freight like water, milk, or juice. These tankers can be equipped with heating or cooling systems for temperature control.

Chemical/Acid

These are used to transport many types of industrial chemicals. Some are designed to carry corrosive chemicals.

But Wait, There’s More…

Before we move on to the next section, two things you might want to know about are baffles and tanker weight limits.

Baffles

What are baffles? Remember when we spoke on liquid agitation earlier? That’s where baffles come in. Most tankers have baffles on the inside to help reduce the movement of the liquid. They act as different chambers to help divide the liquid up into smaller compartments, so the entire weight of the liquid is prevented from surging up against the side of the tank.

Tanker Weight Limits

Tankers are not limited by the amount of liquid they can contain, but by their weight. The U.S. Department of Transportation mandates that the maximum weight limit for trucks on public roads cannot exceed 80,000 pounds. So, if the liquid you need to transport is dense, like syrup or paint, you might not be able to fill an entire tanker truck. This is essential to keep in mind when arranging your bulk liquid shipments.

HOW DO YOU TRANSPORT BULK LIQUIDS?

Now that we know what kinds of equipment are used in transporting bulk liquid freight, let’s talk loading and unloading. These proper handling procedures ensure your liquid freight is transported safely.

Loading and Unloading

Before loading, the carrier must have the tanker cleaned so that it is without any residue or odor. The only time a tank washing may not be required is if the tanker is transporting the exact type of chemical it most recently unloaded.

They must also thoroughly inspect that nothing is out of place and there are no leaks. If there is any concern, the entire tank can be filled with water to test for leaks. Not only is a leaking tank inconvenient and expensive, but it’s also illegal.

There are two major methods for loading and unloading liquid freight from a bulk tanker: compressors and pumps. Pumps suck the liquid out of the tank while air compressors rely on pressure to force liquid out. It’s important to know that you cannot use air compressors for any flammable liquids as static electricity could build up and cause a spark.

Fun fact: When you unload a tanker of liquid freight using a pump, you must vent it by opening the hatch on top. The trailer can implode if this step is missed, just like your pressurized cooker at home. However, if you’re unloading with a compressor, make sure the hatch is closed.

When a bulk liquid shipment arrives for unloading, the receiver should always first take a sample to confirm the right product was delivered and in good condition.

Hazardous Labeling

Regulations mandate that any trailer transporting hazardous materials must be labeled. This helps anyone recognize the kind of content the trailer is carrying so they know what precautions are required.

WHO IS RESPONSIBLE FOR WHAT?

It’s important to know your and other parties’ responsibilities to ensure a safely transported bulk liquid shipment.

Shipper Responsibilities

- Have knowledge of the properties of the liquid product you’re shipping

- Communication that information with the provider, along with any needed equipment or certifications

- Know which regulations apply

- Give the driver any placards, seals, or other items required

- Give the drive all paperwork for the shipment

- Provide personnel to load the tanker

Receiver Responsibilities

- Before unloading, verify that you’re receiving the correct commodity and in good condition

- Make sure there’s enough room for the delivered product

- Provide a clean and safe environment for unloading

- Assign someone to check unloading

Carrier Responsibilities

- Provide a clean tanker

- Have appropriate insurance

- Provide a driver who is well-trained and has all necessary licenses, certifications, or permits

- Provide any safety equipment required by the shipper to ensure safe loading

- Provide proper driver safety equipment, such as personal protection equipment (PPE), if the shipment is hazardous

BULK TRANSPORTATION: LIQUID FREIGHT REGULATIONS

Depending on what kind of liquid freight you’re transporting in bulk, regulations can vary. For instance, if you’re shipping liquid intended for human consumption, you’ll need to abide by any regulations set by the U.S. Food and Drug Administration (FDA), like the Food and Safety Modernization Act (FSMA).

If you’re shipping hazardous liquid freight, you’ll need to abide by any hazmat regulations.

Regardless of the kind of liquid freight you’re transporting, you’ll need to make sure the provider you work with has a tanker endorsement.

Managing transportation costs is a top challenge for shippers, while another challenge that goes in hand is sourcing consistent and reliable capacity. Here enters the contract and spot markets. Which one is best? Which has better shipping freight rates?

Some believe the spot market is the way for shippers to save money and stay on top of capacity, while others think it’s contract. Choosing to use spot rates versus contract rates can be one of the biggest decisions for a logistics manager. Understanding their differences and when is best to use them will help give your business success. So, let’s dive into each of these markets so you can better determine your business’s strategy.

WHAT ARE SPOT RATES? WHAT IS THE SPOT MARKET?

Spot freight rates are short-term transactional quotes for moving freight. These shipping freight rates are the price a transportation provider offers a shipper for a one-time quote to move their product from origin to destination. They reflect the real-time balance of supply and demand in logistics and the truckload market.

The quote is based on the value of the equipment needed at the moment of settlement. What determines the value of that equipment? Well, whether there is an excess or shortage of that exact equipment in the market and the lane at that time. Because market conditions directly affect spot rates, they are dynamic and can change day to day, even hour to hour. This is because the freight market can be more complex than simple supply and demand.

Thus, an increase in supply will lower spot rate prices if not accompanied by increased demand. And an increase in demand will raise spot rate prices unless accompanied by increased supply.

How to Track Rates in the Spot Market

You can keep track of the spot market through several industry websites and freight load boards to give you an inclination of what’s happening in the spot market. Some resources we like to follow are DAT and FREIGHTWAVES.

We even push out a monthly update to keep you in the loop of rates and other happenings in logistics. You can find our latest Freight Market Update on our YouTube channel.

It’s crucial to stay on top of the spot market should you find the need to use it. Even if you decide to use contract freight, it’s good to keep a pulse on it as contract rates are affected by the spot market. The higher spot rates are, the higher contract rates are too.

Who is the Spot Market Best for?

Many carriers, shippers, and third-party logistics (3PL) companies turn to the spot market for competitive rates. No matter how big or small, every shipper will move some of their freight on the spot market at some point. The spot market is great for when you might have a one-off shipment outside your usual shipping lanes. It’s good for shippers who don’t have enough regular volume for contracts or those who need more capacity than they contracted out. Or even those specialty shipments or non-standard load requirements.

Spot Market Pros/Cons

HOW TO GET YOUR BEST SHIPPING FREIGHT RATE ON THE SPOT MARKET

Provide Accurate, Detailed Shipment Information

Though you can get a spot quote with as little as the origin and destination zip codes, pick-up date, and equipment type, it’s best to have ALL shipment information ready. Excluding any critical information may have you unexpectedly paying for it later. The more precise information you have, the more accurate your spot rate quote will be, so you won’t have any surprise added charges.

Information you should have for your best quote:

- Origin city or zip code

- Destination city or zip code

- If your shipment requires EXACT pick-up and delivery appointments, make sure to communicate your appointments times

- Pickup date

- Equipment type (i.e., dry van, refrigerated, flatbed, RGN, etc.)

- Commodity type

- Product weight

- Any special requirements or non-standard requirements

- Examples of special/non-standard requirements are live load or unload, “no-touch” by the driver, drop trailer, hazardous materials, multi-stop, driver assist, floor-loaded, more than two hours of loading/unloading, and equipment age restrictions.

Provide Ample Lead Time

Shippers will request spot quotes anywhere from a week in advance to the day of. Most will request them one to two business days before their shipping date. The more time you can give before your shipping date, the better, as spot rates tend to increase as the pickup date approaches.

Giving yourself a few extra days to secure pricing and capacity will usually work in your favor and lead to less expensive freight rates. This is because there will be more carriers available versus trying to find one on your shipment day.

Don’t Wait Too Long to Confirm a Good Spot Rate Quote

Spot market rates are volatile and quickly change over short periods of time. Therefore, the quote you received yesterday may be different today. So, when you find a rate that works for your shipment, don’t wait to confirm it. Instead, lock it in ASAP for confirmed pricing and capacity. Once agreed on a rate, a reliable provider will rarely change it UNLESS an important piece of information about your shipment changes.

Set Appointments During Regular Business Hours

There is usually more capacity available during regular business hours. As incredibly hard-working as they are, drivers still like to be home on holidays, weekends, or nights when possible.

If your appointments need to be precise, make sure to include that information in your quote request so your quote can be accurate. But, if you can be flexible with your times, setting appointment windows instead of strict appointment times can open you up to more capacity. For example, drivers have to manage their strict Hours of Service so a flexible appointment window can help them better plan their day.

Spot Market Technology

Many providers offer digital freight platforms and give you access to free instant freight quotes. This can be a great way to stay on top of current pricing without sending a lot of emails to different providers. Good freight providers will have logistics experts on call should you have questions or need more help. But having the ability to get quotes on demand can add time back into your day.

Be Mindful of Carrier Selection

While cost is important when choosing your transportation provider, make sure you consider several other factors into consideration. You should consider their experience, efficiency, and service. While a cheap quote is great, it can sometimes result in a missed pick-up, hidden accessorial, or even a damaged product. All this could end up costing your business more.

When shopping the spot market, shop around and get quotes from a few different providers. Once you have a few quotes, evaluate the rates while considering your shipment requirements and ask yourself a few questions about your potential provider:

- Will this provider meet my service requirements?

- Are they easy to do business with?

- Can I use their tech tools to operate more efficiently?

- If something goes wrong, can I trust them to fix it?

WHAT ARE CONTRACT RATES? WHAT IS THE CONTRACT MARKET?

A contract rate is a rate quoted by a transportation provider to a shipper for a set lane and its freight characteristics over a set period of time. Contract rates can also be known as primary rates, bid rates, committed or dedicated rates. In short, they are a long-term, stable pricing agreement between shippers and transportation providers.

The contract market is highly dependent on the spot market. Typically, the three to six months of spot market activity leading up to an RFP will influence contract rates.

Contract agreements are great for both shippers and transportation providers as the shipper gains committed capacity while the transportation provider gains fixed rates and dedicated freight volume. Everybody wins.

How Contract Agreements are Set

Contracted agreements or Requests For Proposals (RFP) can be set as mini bids (monthly), quarterly, bi-annually, or annually. However, since the contract market and its rates are based on the fluctuating spot market, it’s rare to see a contracted agreement set for more than a year to stay in tune with the market.

Contract agreements are set during the bidding process, aka the RFP. The shipper will take the RFP and send it to a network of transportation providers and those providers will reply with their quotes. At the end of the bid process, the shipper will award lanes to specific providers based on their rate, service, capacity, and any other considerations.

CONTRACT RATE PROS/cons

HOW TO GET YOUR BEST SHIPPING FREIGHT RATE ON THE CONTRACT MARKET

Any shipper has the opportunity to host a bid. There’s no set minimum shipment requirement. So, no matter how large or small you are, you can take advantage of an RFP.

Just like getting quotes for the spot market, the contract market requires detailed information to get your best rates. The more information you can tell your potential providers, the more reliable rates and capacity you’ll be able to get offered. Information that should be included in your bid:

- Commodity type(s)

- Weight per load

- Cargo value

- Estimated shipping volume for each lane

- Time frame of RFP contract

- Origin and destination zip for each lane

- Shipment frequency for each lane

- Any performance requirements

- Any special load requirements/accessorials

- Fuel surcharges

- Keep in mind that fuel surcharges account for around 30 percent of a carrier’s operating expenses, and as we all know, fuel costs can fluctuate dramatically.

- It’s important to establish your own fuel surcharge matrix for each potential diesel price and communicate that with your providers before conducting a bid. This will help you get consistent and accurate rates.

What Happens When a Contract is Broken?

Sometimes, contracts will get broken. For both shippers and carriers, breaking a contract may result in fines. Most likely when a carrier breaks a contract, they will end up with a dissatisfied customer and disqualification from future bid opportunities. While shippers will face a damaged carrier relationship, less reliable capacity, and most likely, higher rates on the next bid.

Technology Needed for RFPs

While the practice of RFPs sounds great, what’s the catch? For an RFP to work effectively, shippers need to be organized in their execution and collection of information. No matter your size, every shipper needs a way to track and store their supply chain data and procurement information. It helps to have one central location to keep all your freight volumes, provider names, and awarded lanes.

Some smaller shippers will use tools like Microsoft Excel, Google Docs, or even their providers’ technology platforms to manage their RFP data.

But if you’re a larger shipper, those tools can be overkill. Instead, 90 percent of shippers use digital platforms, often transportation management systems (TMS) to manage their procurement information. A TMS can help take the complexity out of RFPs and take your process from a few hours to a few minutes. It allows you to enter your contract information quickly, select the transportation providers you want quotes from, and click send. It will also help you have one location to easily view bids and communication around your loads, keeping you from overwhelming clutter.

Regardless of which workflow you decide for your business, it’s crucial to have a well-documented record on hand to easily reference.

WHAT’S BEST FOR ME?

Usually, no shipper runs all their freight through the contract market alone. As there are positives to each market and it can be hard to predict all volume, most shippers work to have a strategic blend of both spot and contract rates. What works best for your business will depend on the current state of the freight market, your freight, and your provider relationships.

Some questions to ask yourself when determining what market will work best for you are:

- Are my freight lanes affected by peak capacity demands during the year?

- If you answered yes, the contract market, especially during those times of tight capacity, may be best for you.

- Am I willing to take on the risk of price fluctuations?

- If you answered yes, you might want to look at the spot market first.

- Does the contract price include a capacity guarantee throughout the year, without a general rate increase (GRI)?

- If you answered yes, the contract market may be best for you.

If you have determined that your volume is sporadic and not consistent, the spot market may be best for you, but it doesn’t mean that you can’t work with a carrier contractually. You can still build an approved carrier list with strong relationships even if you have to use the spot market on every shipment.

If you decide contracted freight is best for your company, keep an eye on spot market indexes and position your RFP bidding based on the freight cycle when possible. By moving your RFPs to when the market is at its lowest levels, you’ll gain your best rates.

Some shippers budget for 70 percent contracted and 30 percent spot or 50-50. No matter your balance, the freight market is always changing and so should your strategy. Keep a pulse on the market and your business needs so you can always find what’s best for your company.

NEED HELP WITH YOUR STRATEGY FOR COMPETITIVE SHIPPING FREIGHT RATES?

A shipper’s decision in balancing the use of contract versus spot rates can be difficult. Finding a good strategy for competitive shipping freight rates can be a lot of trial and error.

If you’re having challenges deciding when to use each market, Trinity Logistics can help. We have the technology and expertise you need to simplify your logistics management and offer support. Our Team Member experts are here to help you with your logistics strategy, including offering Quarterly Business Reviews and Freight Market Updates, so you can keep a pulse on industry trends and your company’s growth.

START A CONVERSATION WITH TRINITY TODAYStaying physically fit can be tough for anyone who has a job where most of their day is spent sitting. This rings especially true for truck drivers. Being a truck driver has many benefits; flexibility, freedom, travel, seeing new places, decent pay. But it can bring staggering health problems if you don’t take care of yourself. So we paired up with one of our Trinity Team Members, Sal Ingrassia, who has experience as a personal trainer for over seven years, to help you learn how to stay fit as a truck driver.

| TABLE OF CONTENTS |

| THE STATS ADD UP |

| BENEFITS TO EXERCISE |

| TIPS TO ADD EXERCISE INTO YOUR DAY |

| HOW TO STAY FIT AS A TRUCK DRIVER – BEST EXERCISES FOR YOU |

THE STATS ADD UP

Truck drivers travel a lot of miles each day, but those miles are spent sitting behind a steering wheel. This sedentary workstyle with tight deadlines prevents drivers from getting up and moving around whenever they want. While sitting may be comfortable, it can come with a cost. On average, truck drivers have more health problems and shorter life spans than other careers. These statistics shed light on the hazards that this sedentary workstyle can cause to your health;

- Over-the-road (OTR) truck drivers are twice as likely to develop obesity, which predisposes them to other chronic conditions like hypertension and diabetes.

- The life expectancy of truck drivers is 16 years less than those working in other professions.

- A survey of long-haul truck drivers by the National Institute for Occupational Safety and Health (NIOSH) in 2014 found that 69 percent of truck drivers were obese, with 17 percent being morbidly so.

- According to a study by the Centers for Disease Control (CDC), more than half of the truck drivers had two or more chronic health conditions like high blood pressure, high cholesterol, obesity, and sleep apnea.

Poor health as a truck driver can do more than harming your health; it can also hurt your career.

- In an even bigger picture, a truck driver’s poor physical health can do more than just harm the truck driver. In another survey by NIOSH, 41 percent of crashes caused by trucks occur due to physical factors that affected the driver, like fatigue or illness.

- 87 percent of trucking accidents were due to driver error and 12 percent were due to drivers falling asleep, heart attacks, or other health problems that caused interference.

- 34 percent of truckers have at least one sign of a severe medical condition that has been linked to poor driving performance.

How do you keep from being another statistic? Well, there are two factors in play that you can focus on – diet and activity. Today, we’ll be focusing on exercise. Adding in regular exercise and movement can help you keep your excellent career and health.

Listen to our Heart of the Truck Podcast episode on Staying Fit Over-The-RoadBENEFITS TO EXERCISE

In a survey by Trucker Tools, 76 percent of truck drivers said they wanted to be more active. They want to start moving for a good reason! The health benefits of physical activity are hard to ignore. Exercise can offer you more than just staying fit as a truck driver.

Improved Physical and Mental Health

Want to not only feel better but add years to your life? Exercise.

If you’re looking to prevent common cardiovascular conditions like high blood pressure or heart disease, exercise can help. Being active boosts good cholesterol while decreasing unhealthy cholesterol, keeping your blood flowing, and reducing your risk of cardiovascular diseases.

Regular exercise can help prevent or manage many health concerns such as;

- Stroke

- Metabolic syndrome

- High blood pressure

- Type 2 diabetes

- Many types of cancer

- Arthritis

- Falls

It can help improve cognitive function (much needed for OTR drivers) and helps lower your risk of death.

Additionally, research shows that people who exercise regularly have better mental health, emotional well-being, and lower rates of mental illness. It’s been proven that exercise can reduce the risk of mental illness while also helping manage some like depression and anxiety. For example, Harvard research suggests exercise can be just as effective as antidepressants or psychological treatments like cognitive behavioral therapy.

*Always talk to your doctor about exercise and your mental health. We certainly want to encourage exercise, but don’t encourage quitting any medication without first discussing it with your medical provider.*

Better Sleep

Are you fighting insomnia or restless sleep? Exercise can help with that. Regular activity can help you fall asleep faster and get better and deeper sleep. However, try not to exercise too close to bedtime, or you might struggle to start snoozing due to increased energy.

Less Stress, Improved Mood

Are your tight deadlines increasing your stress levels? Thankfully any form of exercise can help act as a stress reliever. Physical activity, especially any aerobic activity, helps pump up your endorphins or your brain’s feel-good neurotransmitters. So, the more you move, the happier you’ll be.

Regular exercise also helps reduce the negative effects that come with stress. Exercise imitates the effects of stress, but by offering positive effects through your body, it teaches your brain and body to better manage and protect yourself from the harmful effects of stress.

Physical activity also helps you meditate. Going through the movements of your activity and having to focus on that task, help you forget and shed your tension, thus resulting in a calmer, clearer, and more focused mood.

More Energy

Feeling drained? Exercise can help give you a boost. It delivers oxygen and other nutrients to your tissues, which helps your cardiovascular system work better. As a result, when your heart and lung health improve, it gives you more energy. Plus, you’ll also improve your strength and endurance, giving you more energy in the long run too.

MAanage Weight and Feel Better About Your Body

Exercise can help you lose weight or maintain your weight. When you’re moving through physical activity, you’re burning calories. The more intense the activity, the more calories burned. Exercise can help you feel stronger and happy with your body for its strength and all the movements it helps you with.

Less Pain and Improved Posture

Exercise has been proven to reduce pain and even elevate pain thresholds for most people. But most importantly, exercise helps strengthen functional muscles you may use daily. The stronger those muscles are, the better they can endure and support you in daily functions, thus causing you less pain. This also helps improve your posture, which is important to keep back pain at bay.

It Can Be Fun

If you’re new to regular exercise, it may seem intimidating. Most people first picture someone spending hours in the gym or someone out running miles a day. While that may be enjoyable for some, perhaps that isn’t for you. The best part about exercise is it can be enjoyable by picking a form of physical activity you enjoy doing. Run, walk, hike trails, dance, or jump rope. Find a friend to connect with in-person or encourage each other virtually. Regardless, try anything and everything and find what brings you joy and makes you feel good. That will be the easiest way to stay consistent with it in the long run.

TIPS TO ADD EXERCISE INTO YOUR DAY

With so much time spent on the road, it can be difficult and overwhelming for truck drivers to get exercise. In a CDC report, it was found that more than 25 percent of truck drivers had no exercise in the last 30 years. To help change that and make this task less daunting, here are some tips to help you stay fit as a truck driver.

Start Small

While long-term goals are great, don’t jump right into exercise thinking you’ll be running marathons within a few days. Starting small not only is better for your body and prevents injury, but it also helps you better build exercise habitually. Make small goals like dedicating 10 minutes a day, a few times a week, to exercise and slowly increase the longevity of your sessions, the number of sessions a week, or the intensity of your sessions to build strength and endurance.

Break it Up

Finding time to exercise can be the hardest part of getting started. If that’s the case for you, try breaking it up into smaller efforts throughout your day. For example, do lunges, squats, or jumping jacks while fueling up your truck. Or 5 minutes of push-ups on your next visit to the truck stop. Park farther away from the truck stop entrance and get some extra steps in. Exercise is great if you can do it all at once, but any extra movement throughout the day can be just as beneficial to your health and get you closer to reaching your goals.

Do it First Thing

Often after a long day of work, you want to relax and ease into your bedtime routine. Scheduling your exercise first thing in the morning can get it out of the way and offer you several benefits. It can help wake you up, giving you increased energy and boosting your basal metabolic rate which can help you burn more calories throughout your workday.

Keep Exercise Equipment on Hand

Driving over the road shouldn’t stop you from exercising. You can do many kinds of exercises with a few basic pieces of equipment to get started. Ideas for what you can bring with you on your travels are:

- A small set of dumbbells

- Resistance bands

- Ankle weights

- Good pair of sneakers for running/walking

- Yoga mat for planks, pushups, etc.

- Smartwatch to track physical activity

- Mini trampoline

- Jump rope

- Medicine ball

- Kettlebell

Keep it Consistent

On average, it takes around two months for a new behavior to become an automatic habit. While that seems like a rather long time to build a new habit of exercising regularly, it doesn’t need to be perfect and every day to happen. Set a goal with a set amount of time you want to exercise each week or how many times you want to exercise within a week and try keeping to that small goal for the first two months. Even if you miss your goal one week, researchers found if you aim to stay consistent, it’s okay to mess up now and then. But set that goal for regular exercise, aim for it, and in two months’ time, not only will you be feeling better, but exercise will also feel automatic and easy to do. And at the end of the day, to start a new habit, all you’ve got to do is start with Day 1.

Log it

Need another way to keep on top of your new exercise goals? Log it. By keeping a daily journal of your movement, you’ll be able to feel accomplished the weeks you hit your goal and spot any patterns that cause you to skip a workout. Looking for an even easier way to keep that information logged? Invest in a smartwatch, like a Fitbit, to keep track of your goals and activity levels for you.

Take Advantage of What’s Around

Are there trails you can walk or run close to one of the truck stops you consider for parking? Or often, parks have a designated fitness area in addition to their trails. What about parking at a gym? Find one with a nationwide presence so you can go to any location, and even better, they have showers you can use after your workout. Some truck stops, like TA or Pilot, offer health and wellness programs, including walking trails and gyms to help you stay healthy over the road.

Maximize Your Time

You might imagine exercise routines needing to be an hour or longer, but that’s not true. While they can be if that’s what you enjoy, there are many ways to maximize your time and keep your workouts short. Keeping your workouts vigorous and maintaining a 75 to 85 percent max heart rate will maximize your time and fat burning. High-intensity workouts are great for this. You can also look at compound exercises to work out multiple muscle groups at a time. Some examples of easy compound exercises are squats, lunges, and pushups.

Find What Works for You

While these tips are all great advice, they don’t work for everyone. The most important part of building a new habit, like regular exercise, is finding what works best for you. Find the physical activity you enjoy and implement it into your schedule, however that may be.

HOW TO STAY FIT AS A TRUCK DRIVER – BEST EXERCISES FOR YOU

So now you know how to start, but what kind of exercises should you be doing? For this section, I reached out to my coworker Sal Ingrassia. He’s currently a Business Development Representative at Trinity, and has seven years of experience as a personal fitness trainer, in addition to previously managing gyms and fitness centers. Here are some exercises he recommended for you to stay fit as a truck driver. He even included photos to show proper form.

5 Best Bodyweight Exercises for Truck Drivers

Benefits: No equipment necessary. Improves posture and can help you stay focused with a burst of energy.

1. Squats

Start with your feet shoulder-width apart. Lean your torso slightly forward so that your head is over your toes. Squat down as far as possible without losing this posture and then return to the starting position with legs straight. A squat should be led by moving the hips back rather than moving the knees forward. It can help to straighten your arms out in front of your shoulders for balance.

Make sure to have a comfortable range of motion. If needing assistance or modification, use a seat to stop the momentum.

2. Push-Ups

Get on the floor or ground on all fours, positioning your hands slightly wider than your shoulders. Keep your elbows slightly bent and extend your legs back, so you are balanced on your hands and toes, keeping your feet hip-width apart. Lower yourself slowly to the floor until your elbows are at a 90-degree angle, and then return to starting position for one rep.

Make use of a yoga mat and perform on the ground. If needing assistance or modification, use your truck step as an incline to assist.

3. Walking Laps around a Truck Stop

4. Lunges

Start by standing with feet together and then take one step forward, about two lengths of your average step length. Once your front foot is set, keeping your chest up and torso straight, bend both knees in a squatting motion until you approach the ground. Without putting your back knee on the ground, push off your front foot, bringing you back to the starting position. Repeat this motion in the correct direction for reverse lunges and side lunges.

Many variations to this one. Can move forwards, backward, or side to side. All work different muscles.

5. Jumping Jacks

Stand upright with your legs together and arms at your sides. Bend your knees slightly and jump into the air. As you jump, spread your legs to be about shoulder-width apart. Stretch your arms out and over your head. Jump back to starting position. Repeat this continuously for the correct duration of time. Jumping Jacks are good for cardio and are a great exercise to mix in with others. If needing assistance or modification, simply don’t jump, step out instead.

3 Best Weighted Exercises for Truck Drivers

Benefits: Build strength and flexibility, reduce muscle aches while remaining in a seated position for long periods of time, releases endorphins to improve mood, and reduce stress.

Equipment Needed: Medicine Ball, Two Dumbbells, Kettle Bell

All equipment weight is determined by your fitness level. You can increase or decrease as needed based on your current fitness level.

1. Twists

Perform 5 Sets for 1 Minute each

Your feet should be shoulder-width apart. Your arms need to be fully extended in front of your body, holding the medicine ball or dumbbell in front of you. In a controlled motion, rotate your upper body as far as possible to each side without rotating your lower half. You should be feeling a tight crunch in your abdomen on the side you are rotating to. If you don’t feel that crunch/tightness, then you’re not keeping your lower half stationary.

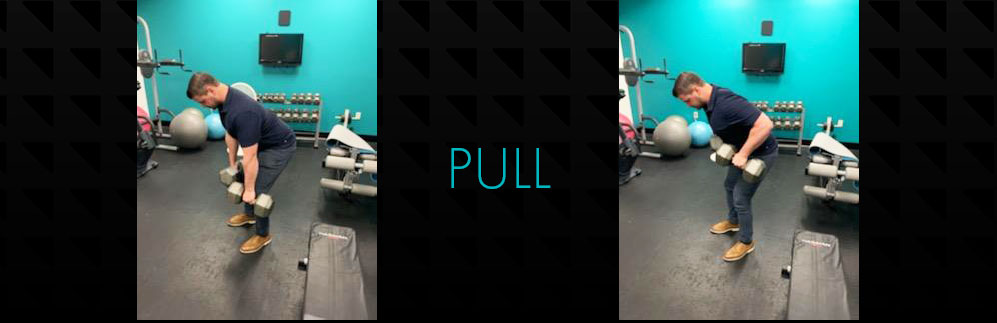

2. Dumbbell Press or Pull

Perform 5 Sets for 30 Seconds each

PRESS – Your feet should be shoulder-width apart, holding each dumbbell in hand at ear level. Keep your elbows tucked in toward your sides, underneath of wrists. Press both hands up to the sky at an equal pace until your arms are fully extended or until your max flexibility is reached. Control the dumbbells as you bring them back down to your ears and press again.

PULL – Your feet should be shoulder-width apart, with your knees bent slightly. Keep your upper body leaned forward to about a 45-degree angle so that your eyes are over your toes. With the dumbbells hanging over your toes, pull your hands upwards, towards your belly button, until the dumbbells reach waist height. Pause and contract the muscles in your back before controllably lowering the dumbbells back down to straight arms, and then repeat.

3. Kettle Bell Swings

Perform 5 Sets for 1 Minute each

Your feet should be slightly wider than shoulder-width, with your knees bent and torso leaning forward at a 45-degrees, holding the top of the kettlebell with both hands between your knees. In one swinging motion, straighten your legs and torso, while at the same time extending the arms in front of your body up to chest height. After extending, bend your knees and lean your torso forward back to starting position, while lowering the arms back down between the knees. Repeat in rhythm for the full set.

STAY FIT AS A TRUCK DRIVER, IMPROVE YOUR HEALTH AND YOUR WORK PERFORMANCE

Even if you aren’t a truck driver, starting to build a habit of exercise is a good one for a healthy lifestyle. But if you are a truck driver, it can make you a better one. How to stay fit as a truck driver may seem difficult, but the most important thing is to start moving, no matter how small it may seem. The benefits of exercise compared to the statistics of a truck driver’s health are hard to ignore. So, what are you waiting for, get moving!

DON’T MISS OUT