Freight is always on the move, every single day, seven days a week, 24/7. There are different types of ways to move freight, whether it’s shipping international, drayage, truckload, or intermodal, all have different paths to the same destination. But what about those last-minute shipments or freight that has a quick turnaround?

Throughout this article we will discuss:

- The basics

- The difference between this and standard shipping

- The importance and benefits of shipping freight expedited

- The different forms of expedited shipping

- How to partner with the right company

WHAT IS EXPEDITED SHIPPING?

Expedited shipping sounds just like what it is, a means to move freight as quickly as possible from point A to point B. This shipping mode is for those time-sensitive shipments you may have.

It’s also an option when the freight is high-value or fragile, and you would like for it to go in a dedicated truck instead of using truckload or less-than-truckload (LTL) shipping. Or for when you might just need a sprinter van or straight truck for your freight.

Any freight requiring expedited is on a single truck and typically has one driver, but team drivers can be made available upon request. This helps reduce long transit times by having the drivers take turns to keep the truck moving without any stops.

Expedited shipping can be between one and twelve pallets and under 10,000 pounds. This shipping method can be over-the-road (OTR), less-than-truckload (LTL), or air international shipping. While this mode of transportation is often used for perishable goods, many also use it for dedicated or tradeshow freight.

While expedited shipping is not as popular as some other modes of transportation, its use is on the rise, due to the “Amazon Effect”. Amazon, known for its fast delivery of products, has caused people to expect other packages and goods to be delivered at this rapid pace. With, consumer demand growing to expect goods shipped faster, expedited shipping has become more popular.

EXPEDITED VS. STANDARD SHIPPING

How does expedited shipping differ from standard shipping? Let’s look at some of the differences between the two.

Cost

One of the biggest differences between standard and expedited shipping is the cost associated with it. Expedited shipping is higher in price because it has a strict deadline and moves at an above-average pace.

Standard shipping transports at a slower pace, so often it’s less costly due to the less strict delivery deadline. However, it’s important to note that the cost for any shipment varies depending on the nuances of each shipment.

Time Frame

Expedited shipping delivers anywhere from the same day to three days. Standard shipping time frames are going to vary greatly. They can be anywhere from a week to as high as a month, depending on the pick-up and delivery locations.

Types of Shipments

Expedited shipments often include goods like tradeshow materials, perishable goods, new product launches, or just those last-minute shipment needs. Standard shipments transport goods of all kinds.

Unlike expedited shipping, standard shipping can consist of multiple trucks, drivers, pick-up and delivery locations, and stops in between.

IMPORTANCE & BENEFITS OF EXPEDITED SHIPPING

Expedited shipping has many benefits outside of having your freight delivered faster. It allows you to meet tight deadlines, like if you run out of a product in a store and need to restock quickly, then expedited is the solution for you.

While expedited may not be the most popular mode, it’s an important tool to have in case of emergencies with your freight. Also, with e-commerce demand consistently growing, expedited shipments are here to stay and become more commonplace.

YOUR EXPEDITED SHIPPING OPTIONS

Expedited shipping can take many different forms. Below are some examples:

Dedicated LTL Shipments

These are your normal LTL shipments; however, no other freight is on the truck besides yours. Thus, it eliminates the need to drop off other shipments along the way to the destination.

Airport Recoveries

When freight arrives from shipping in the air, airport recoveries mean the freight is being picked up directly from the airport where the freight has landed.

Liftgate assistance

This machinery loads and offloads the freight on a truck, usually when the shipper or receiver doesn’t have a dock, when delivering to a storefront location, or when a truck is broken down and need to transload the freight to another truck.

Next day option

This option is when goods are ordered, and they are available for delivery immediately and will arrive at the destination the following day.

Tradeshow freight

Any items, booths, collateral, promotional items, and televisions for tradeshow events.

STRATEGICALLY PARTNER WITH A 3PL

It can be difficult to navigate supply chains. Every company has unique needs and looks for custom-tailored logistics solutions to meet them. Your solution could be as simple as partnering with a trusted third-party logistics company (3PL) to handle all your shipments for you.

A 3PL can offer you real-time visibility and updates on your shipments and can adapt quickly to delays and disruptions that may occur. 3PLs understand the nuances of each shipment and the urgency for on-time delivery while having the tools, experience, and expertise to provide you with the best logistics solutions.

IS TRINITY LOGISTICS THE RIGHT PARTNER FOR YOU?

At Trinity Logistics, we handle all types of shipments and have years of experience handling expedited shipments. With our network of relationship carriers, we ensure your freight is taken care of from receiving to destination.

Our Team of Experts is here 24/7, day or night to help you. We also provide you with the Customer Portal where you can track and trace your freight any time of day, see its status, and its estimated time of arrival.

If Trinity sounds like the 3PL for you, click below to connect with our Team of Experts by requesting a free, no-obligated freight quote.

CONNECT WITH OUR TEAMOr, if you’d like to learn more about our expedited shipping solutions, click here.

LEARN MORE ABOUT TRINITY'S EXPEDITED SHIPPING SOLUTIONSSEAFORD, DE, June 16, 2023 – Trinity Logistics, a leading 3PL provider of transportation and logistics solutions, is proud to share its selection as a Green Supply Chain Partner of 2023 by Inbound Logistics. This recognition showcases Trinity’s commitment to sustainability and its efforts to reduce its environmental impact.

“We’re honored to be recognized by Inbound Logistics for our commitment to sustainability,” said Sarah Ruffcorn, President of Trinity Logistics. “We believe that improving our sustainability is the right thing to do, so we’re always looking for ways to reduce our environmental impact in all aspects of our business.”

Each year, Inbound Logistics editors select 75 companies that go above and beyond to prioritize green initiatives and help global supply chains become more sustainable. Inbound Logistics recognizes these companies as dedicated to developing and implementing best practices to leave a positive footprint on the world.

Trinity has a long history of sustainability initiatives. In 2008, the company became a member of EPA’s SmartWay Transport Partnership, a voluntary program that helps companies reduce their greenhouse gas emissions and air pollution from freight transportation. Trinity has also been a member of the American Chemistry Council’s Responsible CareⓇ program since 2009. Responsible CareⓇ is a global initiative that promotes the responsible management of chemicals and their safe use. The program also helps companies improve their environmental performance in areas such as pollution prevention, employee health and safety, and security.

Just last year, Trinity became a CarbonfreeⓇ Partner with CarbonFund, a non-profit that works with its partners to help them become “carbon-neutral” by donating funds to offset their emissions. This year, Trinity expanded its efforts to not only offset the corporate location in Delaware but included the Iowa and Florida offices as well. This year, the company offset 90 tonnes of carbon emissions by donating to the N20 Abatement Project.

Trinity is proud to be named a leader in the green supply chain space and remains committed to making a positive impact on the environment in all ways possible.

Get a free, no-obligation quote

Stay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

Why are Contract Rates Elevated in Comparison to Spot Rates?

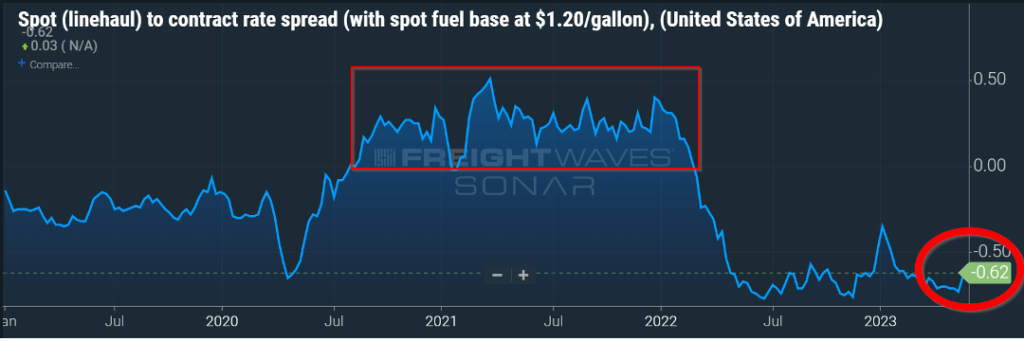

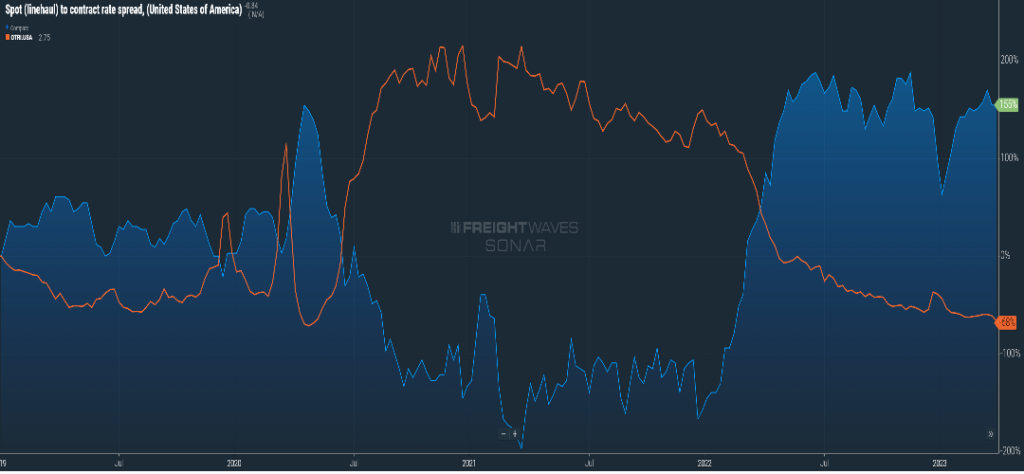

If freight volumes are, by some accounts, 30 percent less than what we experienced in the over-heated freight market of ’21 and most of ’22; and rejection rates are almost nil, why is the gap between contract and spot rates so wide, currently at $0.62 per mile as seen in Figure 1.1?

Typically, the gap between spot and contract in a “normal” freight market hovers around $0.15 per mile. During 2021 and most of 2022, spot rates were higher than contract rates for an extended period. For the majority of 2023, spot rates have fallen short of their contract rate counterparts.

As rates were high, especially on the spot side the last few years, capacity, particularly single-truck or small fleet operations, flooded the market. When challenging consumer conditions presented themselves towards the end of 2022, that meant less freight was traveling on America’s roads. So, you had a situation where less freight was in the contract space, which meant contract carriers were less likely to say “no” to freight tenders. This meant less freight flowed downstream to the spot market. When it did hit the spot market, there was a glut of carriers just waiting to bid for it, oftentimes doing so at break-even or very skinny profit margins just to keep the wheels turning.

We have seen in recent days the gap narrow. Part of that is due to continued pressure on contracted rates and another part of that is due to recent holiday and safety events that have stymied spot capacity. The gap will continue to narrow, mainly due to contract rates continuing to recede as spot rates, while maybe not at their floor, have very little room to move downward before they put carriers in a negative profit situation.

HO, HUM

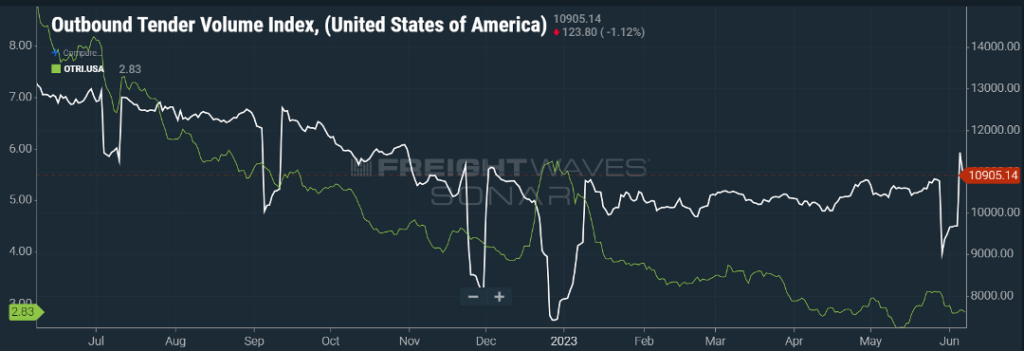

On the topic of volumes and rejection rates, not much has changed since we last visited our trusty SONAR charts (Figure 2.1).

There was a brief blip in volume around the Memorial Day holiday, but that was short-lived, and volumes are returning to the levels we have become accustomed to over the past several months. Additionally, rejection of freight briefly pushed past the three percent mark but has since fallen back into the mid-two percent range.

Produce season will certainly give a boost to volumes, and drive rejections a tad higher. As well, depending on the situation with labor disputes at the west coast ports, that could potentially cause a brief halt to movement out of the west coast ports. When the labor disputes are resolved, it will give a burst to freight coming out of the ports of Los Angeles and Long Beach especially. But for now, things are a bit ho-hum.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Get Weekly News Updates in Your InboxStay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

READY FOR A REBOUND?

Given the sluggish flow of freight in 2023, seeing any signs of life is encouraging. The industry muddled through the first four months of the year with the volume index registering very little movement as seen in Figure 1.1.

Heading into late April, and the early part of May, seeing upward movement was a welcome sight to carriers and intermediaries. Mid-spring typically brings a bounce from produce and seasonal freight, and this year we are seeing that lift, albeit not at an aggressive pace. Still, even with the slight upturn, freight opportunities continue to be gobbled up by carriers, particularly on the contract side. Historic low rejection rates of under three percent not only mean less freight heading to the spot market, but shippers continue to have the pendulum in their favor with regard to rates.

FLATBED SEES BALANCE

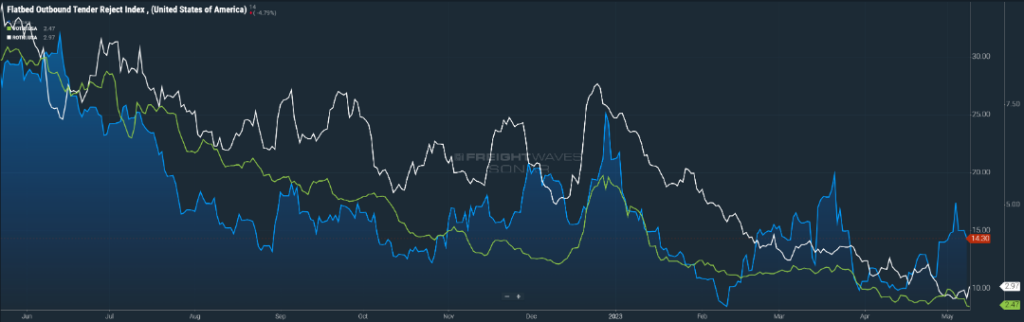

Speaking of tender rejection rates, the low rejection rate is not being felt across all types of equipment as we see in Figure 2.1.

Vans and reefers are pretty much accepting anything that comes their way. These are two equipment types that saw increases in their number from mid-2020 through 2022, primarily in response to the overwhelming consumer goods demand which typically travels in these types of trailers. Now that demand for these items has cooled, vans and reefers find themselves in a situation where demand is still there, just nowhere near what it was the past few years.

Flatbeds, on the other hand, did not experience the same demand. In the over-heated freight market, we experienced in the last few years, flatbeds felt the most normal with regard to freight patterns and demand. While they did not get the direct benefit of shippers clamoring for their services, flatbed carriers have also not experienced the same falling out. As a result, they enjoy a balanced market with rejection rates hovering in the mid-teens. This could be short-lived as downward trends in manufacturing and industrial production, combined with a cooling housing market, will lessen the demand for flatbed services.

the gap remains

Carrier rates continue to normalize.

As seen in Figure 3.1, the spot rate on the van side seems to have found a bottom. Contract rates have contracted slightly, but the spread between carrier-published rates and those available with spot rate pricing continues to push past $0.70 per mile. An uptick in spot rates may relieve some of the pressure from shippers on the contracted side for carriers. Ideally, a spread of $0.15-$0.20 would be more balanced.

Could this modest uptick in volume shrink the rate gap even more? Stay tuned to June’s update to find out.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Join Our Mailing List for Frequent News UpdatesOptimized load planning is fundamental to improving your service and revenue.

Could your company be wasting money on a logistics strategy that doesn’t work? Efficient load planning is more critical than ever and a key performance area for any supply chain. Ideally, you want to be able to move your product to your customers while maintaining desired service levels in the most efficient way. Logistics optimization strategies such as improving your load planning processes can be an effective way to reduce freight costs by as much as 10 to 40 percent.

While this sounds great, load planning can be a very manual and time-consuming process. A transportation management system (TMS), specifically one that includes a freight optimization tool, is one way to analyze and take your load planning process from hours of manual work to minutes through automation and technology.

Start saving time and get your free supply chain analysis with Trinity Logistics.COMMON LOAD PLANNING TMS MISCONCEPTIONS

Before we dive into how a TMS can help you with your load planning, perhaps you’ve thought of one of these common misconceptions.

A TMS Optimizes on Its Own

First off, not all TMS platforms are the same. Some may not even offer load planning tools. It’s also important to see what kind of support is offered, as having an expert available can help provide you with more insight than the software alone.

The Optimized Load Plan Will Be Perfect Every Time

Technology is a great tool to make your logistics processes more efficient. The word to remember here is “tool”. Even a TMS with a freight optimization tool can overlook certain opportunities for freight consolidation, so it’s important to always treat your transportation technology as an aid to your load planning process and not as a full replacement for it.

BENEFITS OF OPTIMIZED LOAD PLANNING

- Cost Savings

- Higher profitability

- Improved logistics performance

- Improved logistics collaboration

- Improved customer service

HOW A TMS HELPS OPTIMIZE YOUR LOAD PLANNING

A TMS is a powerful tool for optimizing your load planning. A TMS provides you visibility into your entire logistics process. This allows you to monitor performance and create efficient plans. It helps you with your forecasting and planning so you can find cost-saving options. A TMS can help give you a clearer picture of your entire freight network by housing all your transportation information in one system.

Now, there is a lot of transportation management software out there. To gain the most benefit for your load planning process, you’ll want to make sure you select one with a freight optimization tool.

New to transportation management software? Download our FREE Guide to Transportation Management Software.WHY WOULD I NEED A FREIGHT OPTIMIZATION TOOL?

Anyone who has gone through the process of figuring out how to reduce shipping costs for each of their loads knows how much of a pain it can truly be. The process starts with tracking down all your open shipments, deciding what loads should be moved together, and then building, rating, and tendering those loads manually. For those who have not implemented a TMS, this is usually done with paper and pencil or an Excel spreadsheet.

Many factors go into optimizing shipments, including the number of pallets and weight of each shipment (taking trailer size into consideration), delivery availability for locations, and special services needed.

Perhaps one of the most important dynamics of building a shipment is delivery deadlines. It’s imperative to take note of whether a truck can deliver to single or multiple locations and arrive on time, factoring in the drivers’ hours of service (HOS) and loading and unloading times.

In sum, it’s a like a complex jigsaw puzzle made up of your freight, and trying to figure it out alone can be difficult.

HOW CAN A FREIGHT OPTIMIZATION TOOL HELP ME?

The freight optimization tool in a TMS will take your list of open shipments and consolidate them into loads based on the criteria specified by you. The software’s criteria encompass ship and delivery date flexibility, maximum weight per shipment, the maximum number of pieces, the number of picks and drops, driver hours, and more.

You’re also able to choose which carriers you want to include for consideration. Once these parameters are set and the optimizer has been run, you also have the capability to auto-create loads in the TMS based on the optimizer’s results.

The optimizer tool accomplishes in minutes what usually takes a person hours to calculate and configure, with the likelihood of saving money in the meantime. The top benefits here translate to both time and money saved. Gone are the days of sitting at your desk for hours with a calculator and a headache.

In summary, our TMS (and other similar products) allow you to enter all your shipments, whether it’s 20 or 1000, and will automatically calculate the most efficient way to route your shipments by combining smaller shipments into multi-drop truckloads, keeping other shipments separate, and configuring the way it all gets routed across the country. The results of the freight optimization tool include the reported cost savings and a detailed report of the loads proposed.

START OPTIMIZING YOUR LOAD PLANNING WITH TRINITY’S TMS

Logistics optimization never ends. It is a continuous process only limited by your time, technology, and commitment to improvement. And ensuring your company has access to a best-in-class TMS is the key to starting that process and finding efficiencies.

Discover how Trinity’s TMS, including its freight optimization tool, can improve your logistics processes, like load planning, helping you offer better customer service and reduce costs while increasing revenue.

SIGN UP FOR A FREE SUPPLY CHAIN ANALYSIS AND TMS DEMOStone materials are very versatile and often used in industries like construction, interior decorating, and landscaping. However, transporting stone can be a difficult task for many reasons. Stone materials can be heavy and bulky and yet surprisingly fragile at times and easy to chip or crack. Just as there are various uses of stone, there are just as many challenges to shipping it. If you’re a shipper handling stone material, bookmark this guide for all you need to know about stone transport.

WHAT’S INCLUDED

- Types of Stone Materials

- Uses for Stone Materials

- Packing for Stone Transport

- Equipment Needed for Stone Transport

- Oversized Stone Transport

- How to Ship Common Stone Materials

- Shipping Stone Costs

- Finding the Right Carrier

TYPES OF STONE MATERIALS

When arranging stone transport, you need to consider the type and shape of the stone material you are shipping. Stone materials can be in the shape of slabs, blocks, bricks, tiles, or crushed stone. Each shape and type of stone material requires different handling to be shipped safely and securely.

- Concrete Pavers

- Flagstone

- Limestone

- Granite

- Marble

- Crushed stone

- Slate

- Sandstone

- Landscaping stone

USES FOR STONE MATERIALS

Stone materials are used across many industries. Stone is commonly used as:

- Countertops

- Floor tiles

- Landscaping

- Roadwork

- Fireplaces

- Stairs

- Bridge construction

- Sidewalks

- Statues and decorations

- Interior Design

- Gravestones and cemetery monuments

With such a wide variety of use, it’s no surprise that stone transport often occurs across long distances.

PACKING FOR STONE TRANSPORT

Proper packing and packaging materials are very important for stone transport. Packaging stone materials the wrong way can lead to damaged product upon arrival.

Smaller stone materials, like tile, can be packed in crates with foam material for cushioning to prevent any scraping or breaking. The crate shouldn’t be too large, with minimal extra space to limit the movement of your stone product. Make sure not to stack the stone material too high or load them vertically. Using short stacks or horizontal loading will help with structural integrity.

For larger stone materials, like granite slabs, palletizing is another option, and the stone product should be wrapped around and between with cushioning to prevent scraping or chipping.

EQUIPMENT NEEDED FOR STONE TRANSPORT

Certain pieces of stone materials will need more equipment than others.

For smaller stone material shipments, a 53’ dry van can work for most, especially those shipping less-than-truckload (LTL) and packaged in crates. Stone shipments can be loaded using a loading dock and forklift. If a loading dock isn’t available, a lift gate can be used, but this additional service costs extra and makes it more difficult to find an available truck. Generally, palletized stone shipments are not recommended for LTL unless there are plenty of packing materials wrapping the product.

If you’re shipping large pieces of stone, like granite slabs, you’re going to need to find a flatbed with an A-frame to securely hold it. An A-frame is a piece of wood or metal shaped into the letter “A” and is needed to transport stone slabs to prevent damage. Stone slabs are prone to breaking or cracking when moved horizontally, so the A-frame helps prevent any damage.

Before the granite slab or other stone material can be loaded onto the truck, the A-frame must be placed on the flatbed with a forklift or crane. When it’s ready to move, make sure that the material is secure and strapped in. Moving straps help prevent the stone material from shifting during transportation, preventing damage, and reducing any risk.

Don’t make the straps too tight because doing so could cause damage upon delivery. Everything should be checked thoroughly before transport to make sure a costly incident doesn’t happen when moving over the road.

Intermodal containers can also be an option for stone transport. Not only do these containers reduce the need for any excessive handling and thus, the chance for damage, but many popular bulk stone products used in the U.S. are mined from locations far away from the country, making this an ideal mode for global stone supply chains. When the stone material is ready to head to its destination, drayage carriers can transport the container or freight can be loaded onto a flatbed for its final stretch of travel.

OVERSIZED STONE TRANSPORT

One of the other main challenges with stone transport is it can be heavy, and sometimes oversized, like those granite slabs we mentioned earlier. Often with stone shipments, you’ll find that you need to get an oversize or overweight permit to travel on state highways.

Most often, the state’s Department of Transportation (DOT) issues these permits, but sometimes they can be handled by another department, depending on the state. These permits are only good for a short window and are the only time your shipment can be on the road. Therefore, it’s important to make sure you have all your ducks in a row, so your shipment stays on schedule, and you don’t end up with a costly violation fee.

What Qualifies as Oversize?

Each state has different regulations on its specifics, but most shipments will be considered oversized if it exceeds 80,000 pounds gross weight or if dimensions exceed:

- 14 feet in height

- 8 feet 6 inches in width

- 53 feet in length

Overweight and oversized shipments can be more comprehensive as, besides the permits, you may need oversized banners, flashing lights, civilian escorts, police escorts, route surveys, bucket trucks, or even a road closure. It’s important that you always take the time to double-check that you’re in compliance with DOT rules and regulations for your stone transport.

Looking for one place to find all you need to know about oversized shipment regulations?

HOW TO SHIP COMMON STONE MATERIALS

Shipping Crushed Stone

Crushed stone can easily be transported using a container. A freight truck pulling an empty container can be used and loaded on site, or the crushed stone can be packed into a shipping container and then loaded onto the truck with the help of a crane.

It’s important to note that unless covered, the top of the container will still be exposed during transportation. If uncovered and depending on the kind of crushed stone, sometimes some stone material can fly out of the container during transportation, resulting in damages, injuries, or loss of product. For this reason, it’s often best to have your motor carrier cover and secure the top of the container with a tarp.

Shipping Stone Bricks and Tiles

Unlike crushed stone, shipping bricks or tiles need more careful handling. Palletizing or banding into cubes is the best way to transport these stone materials. However, you can’t pack them the same as other products due to their ease of chipping or cracking during transit.

When packing stone bricks or tiles, it’s best to stack them with layers of cardboard or foam between the layers of the product, cushioning them and preventing any scraping, scratching, or other damage. When banding into cubes, usually the last two cubed loads are placed on rubber mats to further prevent them from shifting.

Additionally, it’s recommended to avoid shipping these products via less-than-truckload (LTL). These stone materials are brittle and susceptible to damage from other products, but also hazardous to other items should they come loose during shipping. To keep your stone products safe, it’s always best to ship full truckload whenever possible.

Shipping Stone Slabs, Like Granite

While nearly indestructible once installed, slabs of granite and similar stone material are quite fragile during transit. Any incorrect handling can result in damage. Like glass, these stone materials will likely crack if laid vertically. Transporting heavy slabs of stone, like granite transportation, requires specialized equipment to keep them vertical during transit.

You’ll need an A-frame to hold up the heavy slabs of stone and make sure they are secured with durable straps. When properly supported, slabs of stone can be sturdy and resistant to cracking.

Shipping Irregularly Shaped Stone Products

Let’s say you need to transport an irregularly shaped stone product, like statues or headstones. Certain products might have sharp corners that can easily chip or have smooth surfaces you don’t want to be scratched, like memorials. It can be tough to figure out how to ship these unusual stone materials.

The best option to transport these stone products safely is to order custom packaging for them, like a sturdy box with Styrofoam pieces sculpted to fit around it so your product is secured from any movement during transit.

As with shipping tile, it’s best to ship full truckload instead of LTL, so your product isn’t handled more than it should be and isn’t at risk from other products.

SHIPPING STONE COSTS

Stone transport can be more expensive to ship due to its heaviness and fragility. Any time you have a shipment that requires more attention to detail or more specialized equipment, it’s going to be more costly.

If you typically ship large volumes of stone materials often, a Request For Proposal (RFP) or contract with a carrier or logistics company can be one way to find savings versus working with the spot market.

FINDING THE RIGHT CARRIER FOR YOUR STONE TRANSPORT

Because of how delicate transporting your stone materials can be, you want to make sure the motor carrier you select is experienced. This is where cutting costs here isn’t always worth it. You also want to make sure your provider has enough insurance and that your commodity is covered should something happen.

TAKE THE GUESSWORK OUT OF YOUR STONE TRANSPORT

Stone transport can be one of the most challenging types of freight to arrange. However, you can choose to simplify your shipments by working with an experienced third-party logistics (3PL) company like Trinity Logistics.

Working with Trinity saves you time from finding and vetting carriers, figuring out what equipment is needed, and gives you full visibility of your product’s transit, from pick up to delivery. Experience our best-in-class customer service and sit back, knowing that we’ll get your product safely delivered.

LEARN MORE ABOUT TRINITY'S SHIPPING SOLUTIONSTrinity Logistics is proud to announce its recognition as a Top Freight Broker by Transport Topics for the 21st consecutive year, ranked 17. This honor serves as a testament to the company’s continued commitment to delivering outstanding People-Centric service in the logistics industry.

Transport Topics is a leading publication in the transportation business and is well-known for its annual comprehensive rankings of freight brokerage firms. Companies are ranked based on gross revenue and services offered.

Trinity Logistics is thrilled to have made spot #17 on the Top Freight Brokers List for 2023 as this accolade reflects Trinity’s commitment to delivering exceptional service to customers and helping them meet their unique logistics needs. With a core focus on exceeding expectations, the company has built a reputation for its integrity, reliability, and customer service.

“This recognition continues to showcase our ability to serve our shippers and carriers with People-Centric Freight Solutions®,” says Sarah Ruffcorn, President of Trinity Logistics. “Team Trinity works hard to continually strengthen our shipper and carrier relationships, providing value to them in simplifying their processes and providing an excellent Trinity experience. Earning this recognition continues to show we are rising to the ongoing supply chain challenges and are serving our customers well. Thank you, Transport Topics, for the recognition. We’re honored to have made it another year in the top 20’s – #17!”

Trinity’s parent company, Burris Logistics, has ranked number 35 on Transport Topics’ Top 100 Logistics Companies List and number 4 on their Top Refrigerated Warehousing List.

To see the complete list, visit Transport Topics.

About Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 40 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized as a Top 3PL and Cold Storage Provider by Food Logistics, a Top Freight Brokerage Firm by Transport Topics, and as an Inbound Logistics Top 100 3PL.

Work with a Top 3PL – Get a Freight QuoteRefrigerated trucking can be a complex, but rewarding job.

You might be transporting anything from fresh produce, frozen food, or important medicines like biologics. But, no matter what it is, the items you’re hauling are vital to many and there’s great pride that comes with that.

Refrigerated trucking is not only more specialized than dry freight hauling but offers more earning potential, and there are certain times of the year during which you can count on higher freight volumes to keep your company profitable.

Whether you’re new to refrigerated trucking or a veteran, it’s important your company knows how to properly transport temperature-controlled products, from pick-up through delivery. At Trinity Logistics, we sometimes see claims on temperature-controlled shipments, and we want to help you avoid any costly mistakes with a few tips specific to refrigerated trucking. So, we’ve crafted this guide to help you prepare for your hauling your next temperature-controlled shipment.

MOTOR CARRIER REFRIGERATED TRUCKING RESPONSIBILITIES

The purpose of the Food and Drug Administration’s (FDA) Food Safety Modernization Act (FSMA) is to prevent foodborne diseases, and FSMA rules contain essential requirements for shippers, loaders, receivers, and carriers like you to follow with refrigerated trucking. FSMA requires those transporting food to follow best practices for sanitary transportation, such as proper personnel training, maintaining shipment records, and following shipper instructions to keep food properly temperature-controlled during transit.

FSMA Responsibilities for Motor Carriers

Keeping Your Equipment Clean and Operable

You must keep your refrigerated trailer clean between loads and make sure it is running efficiently to maintain any required temperatures to keep food safe while transporting.

Your Equipment Must Meet the Shipper’s Needs

Shippers are responsible for communicating any food safety requirements to providers they work with, such as specifying temperature and pre-cooling requirements in writing. It is your responsibility to adhere to those requirements specified by the shipper.

Keeping Records

When it comes to FSMA, verbal confirmations don’t stand. Shippers and providers you work with require records of previous cargo hauled, equipment cleaning, inspection, and temperature records. This includes recording if your reefer fails or containers are compromised, allowing contaminants in, and showing via documentation that you took action to correct the issue. Keeping thorough documentation will help you, in the long run, should you face any potential claims. It’s recommended to keep all records for 12 months, minimum.

Training Employees

Under FSMA, motor carriers must train all drivers and transportation personnel on their role, FSMA rules, the awareness of potential food safety problems like cross-contamination that can occur during transportation, and sanitary transportation practices. It’s also important to keep records of this training and hold refresher training from time to time.

PREPARING FOR REFRIGERATED TRUCKING AND TEMP-CONTROLLED TRANSIT

*This blog content provides suggestions only and is not meant to take the place of your own company procedures.*

Cleaning Your Refrigerated Trailer

1. If the previous receiver cleaned your trailer, request documentation from them to share with the shipper for your upcoming temperature-controlled shipment. It’s important to keep any trailer washout records and receipts to provide to shippers upon request.

2. Open your refrigerated trailer and remove any items that shouldn’t get wet.

3. Sweep out any debris.

4. Prepare a bucket of food-grade detergent and water.

5. Scrub all interior surfaces with a clean cloth and the detergent mix.

6. Use a hose to spray down the inside, including the ceiling and walls. Pay special attention to any cracks and crevices.

7. Keep doors to the trailer open, allowing the inside of the trailer to air dry.

8. If the outside of the truck and your trailer is dirty, wash down the exterior as well.

Pre-trip

1. Review shipping instructions and confirm the cargo is at the required temperature before it is loaded. Refrigerated trailers are meant to maintain temperature, not change it. For fresh produce, verifying temperature usually involves pulping product with a thermometer or probe dial.

2. Run your refrigerated trailer for at least 20 minutes in “high speed cool” mode to remove any residual heat. Pre-cooling may take more than one hour depending on factors such as equipment and ambient temperatures. Therefore, be aware of the temperature requirements in advance to ensure equipment is at the proper temperature before you arrive at the shipper and the loading process starts.

3. Perform an automatic pre-trip test to confirm that your refrigerated trailer is running properly and confirm that it passes the test. Keep a record of this. If your auto pre-trip test fails, refer to your company’s prescribed procedures or contact your maintenance provider for repair.

4. It’s time to set your refrigerated trailer to the required temperature specified by the shipper. Verify the set temperature after adjusting it to its requirement to confirm it is set correctly. Next, confirm that the unit is set to the correct date and time. If this is not done and the shipper requests a reefer download after delivery, the data will be inaccurate. Some drivers will take a picture of the reefer unit dashboard to document settings before they leave the shipper.

5. Confirm that you have the correct mode of operation selected on the reefer unit prior to loading. Again, refer to your shipment instructions for this. Often, the shipper will require perishables to be hauled in continuous mode as opposed to cycle sentry or stop-start cycle.

6. Allow your refrigerated unit adequate time to pre-cool before loading.

7. Document all pre-trip cleaning, inspecting, and pre-cooling to share with the shipper upon request.

Loading

1. Ensure you witness the loading process, visually confirming product temperature, count, and quality match your shipment tender. If a carrier cannot verify loading conditions or discrepancies exist, the carrier notates the issue on the bill of lading and request the shipper to sign this.

2. Carriers are responsible for the final blocking and bracing of product, so make sure items are not over-stacked or loaded in a way that impedes airflow or circulation. As a carrier, if you are not comfortable with the load condition, you have the right to refuse the shipment.

3. Once loaded and final blocking and bracing are completed, immediately close the doors to maintain temperature. Once again, verify that the correct cycle and temperature are set. If a trailer seal is required, its presence should be documented on the bill of lading by the shipper.

During Transit

1. Make use of the strip curtains as this helps keep temperature-controlled air in and any outside air out.

2. Limit the number of door openings throughout transit to keep temperature-controlled air in and outside air out. Only allow doors to be opened by verified shippers or receivers.

3. Keeping proper airflow is critical. Even with adequate running equipment, poor air distribution can cause spoilage. Verify all sides of the cargo have proper airflow before your trip and any time you make a stop.

PULPING FOR REFRIGERATED PRODUCE SHIPMENTS

Pulping is an essential task when hauling produce with your refrigerated trucking. Pulping is the act of taking the product’s temperature before and upon delivering the shipment.

How to Pulp Produce

For produce that is unbagged, one must insert a pulp thermometer into a piece of produce, inserting for three to four minutes to get the most accurate reading.

If the produce is bagged, like salad mixes, fold the bag in half and place the probe between the two sides, with the produce as close to the thermometer as possible.

Why Pulping is Important

Before loading, it is the shipper’s responsibility to pulp the product, and should be done in the presence of the driver. However, it is the carrier’s responsibility to confirm the proper temperature of the product before allowing it to be loaded on the truck, so there may be the case you need to pulp the product.

Pulping temperatures should be recorded on the shipment’s bill of lading and signed by both the shipper and driver. This can help protect both the shipper and motor carrier from claims if the product arrives at its destination off temperature.

Throughout transit, it is the carrier’s responsibility to monitor the refrigerated trailer temperature, usually with some sort of sensor technology providing real-time information, or with older refrigerated trailers, a temperature download that is available upon delivery.

Upon delivery, it is the receiver’s responsibility to pulp the product for a temperature read and to determine if the shipment will be accepted.

Under FSMA, be prepared to provide a record of temperatures in transit via reefer download. Failure of a carrier to provide a record of unit temperatures in transit will prevent a carrier from disputing temperature deviations should there be a claim.

TEMP VARIANCES – HOW MUCH IS TOO MUCH?

One thing you may be asking with your refrigerated trucking is, how much is too much when it comes to temperature variances? Well, that can depend on several factors.

One factor is the type of product. For example, there are some perishable products that are very sensitive to temperature variances, where even a two-degree difference could reduce the shelf life by 50 percent.

Another cause could be the location where the temperature was taken in the trailer or the recording device’s accuracy. Or if a shipment has multiple stops versus one that goes right to the destination.

Temperature variances are usually expected, so it’s important to determine when a variation is tolerable versus when it places the product at risk for spoilage.

It’s also important to note the amount of time the product has been off temperature. For example, frozen goods might be subjected to some temperature variance without much effect on the shipment, whereas refrigerated goods often spoil at a quicker rate.

When it comes to claims due to temperature variances, there simply is no one-size-fits-all for processing these. Shipment claims due to temperature variances are treated on a case-by-case basis depending on the above-mentioned factors. Verifying temperature prior to loading, maintaining proper temperature in transit, and the ability to provide a reefer download documenting transit conditions are ways for carriers to prevent temperature damage.

WHAT IF THERE’S AN ISSUE AT DELIVERY?

First and foremost, be sure to communicate your transportation status and any issues to your point of contact in real time. If there are any overage, shortage, or damage issues at delivery, the receiver should document it on your bill of lading (BOL). If there is a reported issue and you are unclear about the next steps, contact your insurance agent to report the issue and request direction.

If the product is produce, a USDA inspection may be requested to document the condition of the product.

Whenever a temperature problem is reported, get a reefer download for the trailer used for the shipment to document the temperature conditions for the time the cargo was on your truck.

Your cargo policy will not pay for temperature damage if it is caused by an incorrect reefer setpoint or driver negligence. However, if your refrigerated trailer experiences issues during transit, your cargo insurance may step in to pay a cargo claim related to any temperature damage. However, be prepared to provide supporting documentation. To be proactive in the prevention of any issues caused by your equipment, it’s important to perform regular maintenance according to your cargo insurance requirements and company guidelines.

REFRIGERATED TRUCKING – SHIPPER RED FLAGS TO LOOK FOR

There are a few shipper red flags to look out for before accepting a refrigerated trucking shipment or having your trailer loaded.

Mixed temperature shipments can be a red flag. Sometimes shippers will want to try to ship products together that need vastly different temperature requirements to reduce costs, like fresh and frozen products. These types of shipments are “high risk” and not recommended. Whether a shipper is using a bulkhead or not, to keep your company safe, it’s recommended to avoid shipments that combine frozen, fresh, or dry loads on the same truck.

Now, let’s say you’ve accepted a refrigerated trucking shipment but when you arrive at the shipper you notice one of these things:

- There is food labeled improperly (no USDA logo),

- Spoiled or overripe food products or evidence of spillage, such as juices or blood in the cargo area,

- Food products being shipped with chemicals,

- Evidence of product tampering, like a broken seal or cut tape on boxes.

If you notice any of these things, do not get loaded and immediately contact the Food Safety Inspection Service (FSIS).

EASILY FIND THE TEMP-CONTROLLED SHIPMENTS YOU’RE LOOKING FOR

Now that you’re prepared to handle the complexities of refrigerated trucking, it’s time to find available shipments. Here’s where Trinity’s Carrier Portal is beneficial.

Our online load board allows you to search for available shipments, filtering by equipment, lanes, and more. Many of our available shipments even allow digital freight matching, providing you the opportunity to Quote Now or Book Now, saving you time from calling or emailing in. Additionally, new shipments get directed to our Carrier Portal first, meaning you’ll have access to exclusive Trinity loads before they get posted to the public load boards!

Find my next refrigerated trucking shipment*This article provides information only and should not be construed as advice. It is provided without warranty of any kind.*

Stay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

SIMPLE SUPPLY AND DEMAND

We probably all remember at some point in either our high school or college career hearing about supply and demand. A pretty simple concept that applies to goods, commodities, services, and yes, transportation. A great indicator of that is shown in Figure 1.1 which shows the growth in for-hire carriers (blue line) and the outbound tender volume index (green) since mid-2018. While this is not a 1:1 comparison, it clearly shows, especially in the past three years, how supply and demand have been the driver of transportation costs.

From roughly mid-2020 until the early part of 2022, demand was high compared to prior years, and the supply side (carriers) was trying to catch up. As a result, carriers were able to dictate rates in the market. As the supply side began to accelerate, the over-heated freight market began to normalize in late 2021/early 2022, retreating to levels seen prior to the pandemic. The rate pendulum once again swings to the shipper’s side. Some have argued based on this over-capacity situation that it could take years before there is once again equilibrium. Agree, it will take, unfortunately, attrition on the carrier side, combined with a rebound on the freight activity side to find that balance. However, taking years to do so is a bit aggressive. Most likely, mid-2024 will see supply and demand as it relates to transportation reaching a better balance.

THE GAP

We looked at this last month, but the lag between spot and contract rates remains at historic levels. Typically, you will see a gap of maybe 10 cents or 15 cents per mile, but for the last five months, that gap has remained above the $0.50 per mile mark, currently trending at $0.86 per mile higher on the contract versus the spot side.

As you can see in Figure 1.2, that increase in the contract-to-spot gap has been in lockstep with the decreasing outbound tender rejection rate. As carriers with contract pricing are finding fewer freight opportunities versus 2021 and 2022, they are taking almost every shipment tendered their way. On average, for every 100 contracted shipments tendered to carriers, they accept 97 of those shipments. For shippers, it will be a balance between finding cost savings with spot capacity and fulfilling the requirements they have with higher-priced contracted carriers.

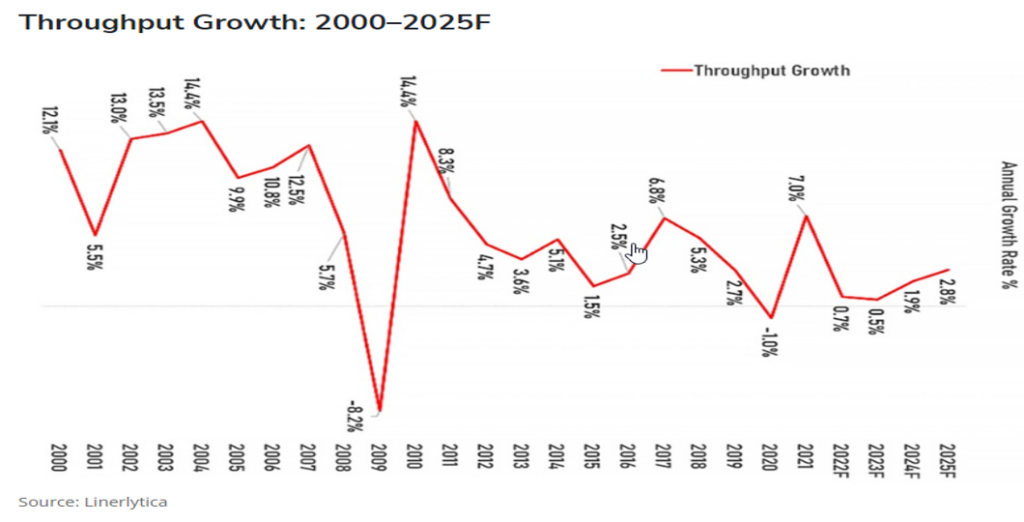

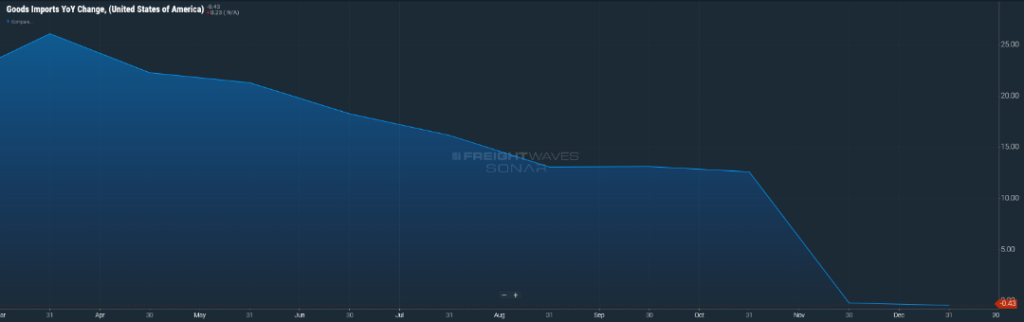

BLAH IMPORT CONDITIONS

On the international side, particularly imports, we continue to see declining volumes and blank sailings. While the ports were inundated in late 2020 through the first half of 2022, that volume has stalled. Stalled to the point where the largest U.S. port of LA/LB encountered almost 100 ships at one point waiting to offload to now having “plenty of good parking spots available.”

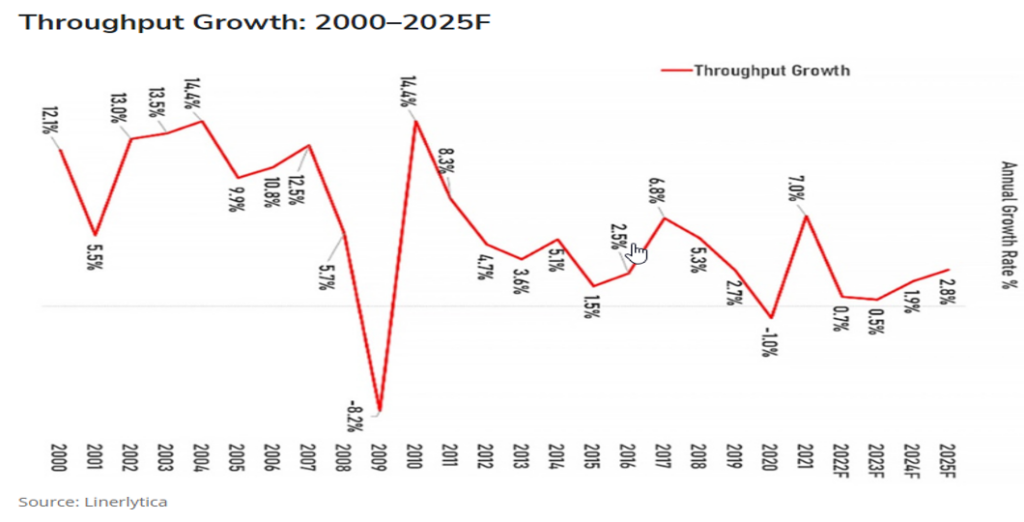

Figure 1.3 clearly demonstrates the decline in consumer demand, along with near-shoring efforts, and the year-over-year impact. Expect, for lack of a better word, blah import conditions throughout 2023 with a rebound on the horizon for ’24 and ’25.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Join Our Mailing List for Frequent News UpdatesStay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

WHEN WILL FREIGHT VOLUMES START TO IMPROVE?

That is the $64,000 question. Since the start of the year, freight volumes have been stable but certainly suppressed as compared to the last few years (Figure 1.1). In addition, the rate at which carriers reject shipment tenders is almost nil, with almost 97 percent of the freight tenders being nabbed by carriers with contract pricing.

We will certainly see the seasonal freight patterns in 2023, with produce and outdoor products providing a boost in the coming weeks. And the end-of-year push for back-to-school and Christmas should also lend a boost, although that end-of-year buying seems to be more spread throughout the year. Many in the industry got accustomed to an over-heated, reactionary market over the past few years. With that as the backdrop, the one word I can think of to describe how the market will feel is “blah” in 2023.

Contract rates continue to outpace the spot market. While carriers with submitted contract rates are right-sizing rates in response to the market, expenses that have been exaggerated over the past few years, such as driver pay and benefits, maintenance costs, and insurance premiums, are keeping contract rates well above spot.

As one can see in Figure 1.2, as rejection rates have declined, meaning less freight being pushed to the spot market, it has a mirror effect on the spread between contract and spot rates, currently sitting at $0.84 less per mile on the spot side. Shippers will continue to fulfill their contractual obligations with regards to tendered volume, but being able to utilize the spot market does bring cost savings to shippers.

Finally, activity at the ports continues to decline, especially on the import side. As seen in Figure 1.3, just a year ago, ports were handling 10-20 percent more inbound volume, that change today is a decrease from a year ago. Inventories have been replenished over the past year and a half, and consumer demand for goods is less. This trend is most likely to continue through the year, driving the spot container cost down and subduing activity around U.S. ports.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Join Our Mailing List for Frequent News Updates