These common mistakes when shipping hazardous materials can end up costing your business a lot of money.

Shipping hazardous materials have very little room for mistakes but very large consequences if done incorrectly. Mistakes when shipping hazmat materials can cause injury, damage to property, or endanger lives, so hazmat shipping should always be handled with tremendous caution.

Safe hazmat shipping is possible but requires diligence, communication, and attention to detail.

These are the most common mistakes companies make when shipping hazardous materials.

- FAILING TO LABEL AND DECLARE GOODS PROPERLY

- NOT ACCOUNTING FOR DIFFERENCES IN MODES OF TRANSPORTATION

- LACK OF FAMILIARITY WITH SPECIFIC REGULATIONS FOR EACH SUBSTANCE

- ASSUMING GOODS AREN’T HAZARDOUS

- LETTING UNTRAINED EMPLOYEES HANDLE HAZARDOUS MATERIALS

- NOT FOLLOWING EXACT INSTRUCTIONS FOR PACKAGING BY THE MANUFACTURER

- THINKING ANY MISTAKES WILL BE OVERLOOKED

DEFINITION OF HAZARDOUS MATERIALS/DANGEROUS GOODS

First, let’s clarify what hazardous materials or dangerous goods are.

Many think of hazardous materials as things like explosives, gasoline, or acids. Yet, many common goods are hazardous when shipped, such as aerosol sprays, nail polish, alcohol, paint, dry ice, or cosmetics. Any substance or material that can pose a risk to health, safety, or property is a hazardous material or dangerous good.

SHIPPING HAZARDOUS MATERIALS VIOLATIONS

Hazmat safety regulations exist to keep people, property, and the environment safe. The Pipeline and Hazardous Materials Safety Administration (PHMSA) handle these regulations.

One reason you don’t want to make any hazardous shipping mistakes? Violations. Currently, hazmat regulation penalties are:

- Maximum civil penalty violation is $84,424 per day, per violation,

- Maximum civil penalty violation that results in death, serious illness, severe injury, or large destruction of property is $196,992 per day, per violation,

- Civil penalty for a violation of hazardous training is $508 per employee, per day.

HAZARDOUS SHIPPING MISTAKE EXAMPLES

Many companies have made hazardous shipping mistakes. Here are some true scenarios.

Example 1: Online Retailer

Fined $91,000

An online retailer shipped a package by air containing flammable liquid adhesive. The motor carrier discovered the product leaking from its container. The online retailer offered the shipment, not including the required shipping papers or emergency response information. The freight’s packaging was incorrect and not marked or labeled as required. Nor were the company’s employees trained in handling hazmat packages for shipment by air.

Example 2: Chemical Company

Fined $325,000

On two separate occasions, a chemical company shipped undeclared hazardous material that is illegal to transport by air. The chemical company allegedly shipped pints of acrolein, which can become explosive when combined with air. Neither shipment had the required shipping papers or emergency response information. Additionally, one of the shipments was not marked, labeled, or packaged as required. Employee training was also found to be non-compliant.

Example 3: Flooring Company

Fined $63,000

A flooring company shipped a package of hazardous freight. The motor carrier found a package leaking. The flooring company did not provide the required shipping papers or emergency response information, nor did they mark, label, or package the shipment as required. Additionally, employees were not trained to handle hazardous materials.

COMMON HAZMAT SHIPPING MISTAKES

Failing to Label and Declare Goods Properly

Failing to label and declare hazardous goods is one of the most common shipping mistakes. Transparency is critical at every level to ship hazardous materials without mistakes.

All hazardous freight must have the proper UN hazmat labels or hazmat placards to identify their contents. Shippers must also disclose the information on the shipper’s declaration form.

Failing to properly mark, label, and declare your hazardous materials keeps employees from knowing what kind of materials they are handling, which hazard class they belong to, and what kind of precautionary measures they need to take. In the end, improper labeling and declaration can be an endangerment.

Not Accounting for Differences in Modes of Transportation

Regulations on certain hazardous goods and packaging methods can vary based on which mode they’re shipped with.

Take dry ice as an example. It has different regulations when shipped by ground than when by air. Another example is magnetized material. It’s only subjected to regulation restrictions when transported by air due to the interference it can cause to aircraft instruments.

That’s why it’s important to confirm the mode of transportation when shipping hazardous materials before packing, marking, labeling, and documenting everything. This way, you and your logistics provider know the exact shipping requirements needed.

Lack of Familiarity with Specific Regulations for Each Substance

The USDOT provides detailed tables of hazardous materials and their specific regulations for each classification. This includes specific information such as what packaging to use or transportation modes to ship. It’s your company’s responsibility to be knowledgeable and familiar with those regulations. Even still, ignorance of these regulations is a common mistake when shipping hazardous materials.

Assuming Goods Aren’t Hazardous

There are many materials that the average person wouldn’t think of as hazardous. Assuming goods aren’t hazardous materials when they are is a common mistake that happens when employees aren’t properly trained on hazmat and dangerous goods. As a result, they lack the required knowledge to differentiate what is and isn’t hazardous. This risks transporting hazardous material without being packaged, labeled, and communicated in the correct manner.

This mistake has the potential to cause catastrophic consequences depending on the product, the transportation mode, and several other factors. Ensure your employees are trained and when in doubt, don’t assume. Take the extra time to research the material if needed and follow hazardous protocol when applicable.

Some common items that are assumed to be non-hazardous are:

- Magnetized materials

- Lithium batteries

- Contaminated medical equipment

- Dry ice

- Aerosols

- Equipment with gas cartridges or compressed air

- Genetically modified organisms

Letting Untrained Employees Handle Hazardous Materials

What’s the easiest and most important way to avoid hazardous material shipping mistakes? Make sure your employees are trained in hazmat shipping.

Many of these mistakes happen due to untrained employees handling hazmat shipments. Therefore, employees need to undergo formal training and show competence under supervision before handling hazardous goods on their own. Additionally, employees should frequently be reeducated to stay keen on hazmat shipping requirements.

Not Following Exact Instructions for Packaging by the Manufacturer

Hazardous material packaging is designed to meet regulatory requirements. Many hazmat packaging manufacturers will include detailed instructions on how to use their packaging for safe and compliant shipping. It’s important that employees have access to these instructions and understand them completely.

Thinking Any Mistakes Will be Overlooked

It can be easy to think your business won’t get caught with a hazmat shipping violation. Yet, as noted by the examples above, it can and does happen. As the U.S. government remains vigilant in cracking down on hazmat shipping violations, fines continue to increase, making it even more financially smart to stay compliant. Not to mention that those violations can cause harm to the environment or people. No matter what, risking a hazmat shipping violation is never worth it.

AVOID HAZARDOUS SHIPPING MISTAKES WITH AN EXPERT

Everyone makes mistakes sometimes, but when it comes to shipping hazardous materials, it’s crucial to do all you can to reduce them. Now that you know the most common mistakes when shipping hazmat, you can be more aware of avoiding them.

An easy way to help stay compliant when shipping hazardous materials is partnering with an expert knowledgeable in its regulations, like Trinity Logistics. We’ve been in the business of arranging hazardous shipments in several modes for over 40 years. We’ve also been Responsible Care certified since 2009.

If you’re looking for a reliable partner to help you with shipping your hazardous materials, consider Trinity Logistics. We can help take the guesswork out of keeping your hazmat shipments compliant.

Get help with my hazmat shipmentsStay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

SOMEWHAT HO-HUM

The current landscape for over-the-road freight looks like what it was a month ago. Freight volumes are lower year-over-year (YoY) but seem to have found a floor.

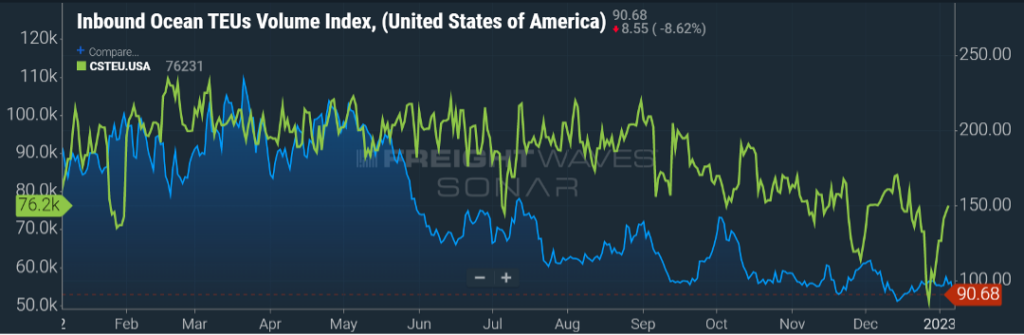

If anything, the flat lining of volume (Figure 1.1) we are seeing is eerily like what we saw in the early part of 2020. And that is not just relative to freight volumes.

Back in ’20, carriers were snatching up tenders as soon as they were offered, with rejection levels hovering in the five percent range. Right now, we are just below that five percent mark. It’s anticipated that freight flows will follow their seasonal patterns, albeit at reduced volumes compared to what we saw in 2021 and most of 2022. Spot rates continue to trend lower than contract rates, although that gap continues to shrink. It’s also anticipated that contract rates will continue to slide while spot rates should be pretty near their floor.

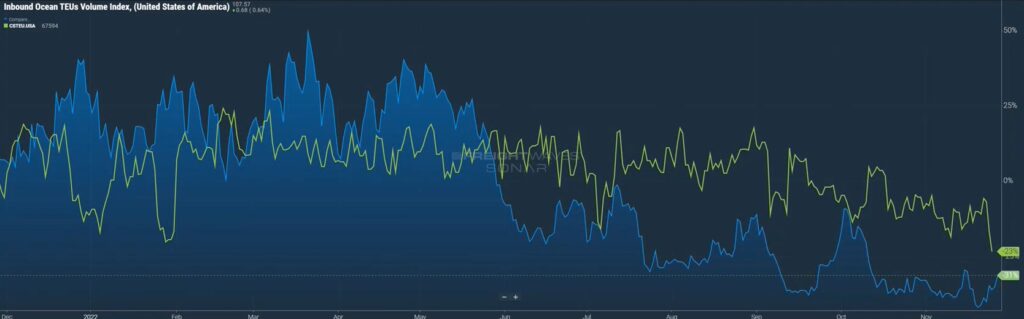

DECLINING PORT ACTIVITY

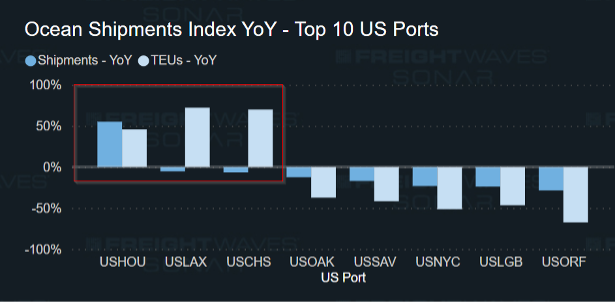

Imports will continue to weaken over the next several months. While some ports have seen slight increases in YoY volume, that increase is not indicative of an overall volume surge. It’s due to the shifting of where the freight is entering the U.S.

So, while ports like Houston (up 5.2 percent) and Baltimore (up four percent) are robust with above-average activity, major entry points like Los Angeles (down 30 percent), Oakland (down 58 percent) and Seattle (down 41 percent) are feeling the lack of volume. An opportunity should be seen with export activity (Figure 1.2). While the U.S. dollar losing value is not good for imports, it has the opposite effect on export activity.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Join Our Mailing List for Frequent News UpdatesWhether owning or renting, heavy equipment is a big investment in your business – and you don’t want to take unnecessary risks that can lead to loss or damage during transportation. Heavy equipment shipping can be challenging, but it’s not as complicated as it appears when you have the right provider. To help you ship your heavy equipment safely, here’s some additional information you may need.

What We Cover in This Article

- What is heavy equipment shipping?

- Common types of heavy equipment

- Rules and regulations for heavy equipment shipping

- Trailers used for heavy equipment shipping

- What should I know about my heavy equipment shipping?

- How much does it cost?

- Preparing for heavy equipment shipping

- Shipping heavy equipment internationally

- Choosing the right provider

What is Heavy Equipment Shipping?

Heavy equipment can be a broad term, but it usually consists of a piece of large machinery or equipment of at least 40,000 pounds or more. Due to its size and weight heavy equipment is often loaded and unloaded by a crane if it cannot be driven on/off the trailer. Often, these kinds of shipments can be oversized and/or overweight, requiring permits, escorts, route surveys, and an experienced motor carrier with specialized trailers to transport your equipment safely and effectively.

Common Types of Heavy Equipment

- Agricultural Equipment and Machinery

- Construction Equipment

- CNC Machinery

- Crawler Cranes

- Gas & Oilfield Equipment

- Industrial Plant Machinery

- Military Equipment

- Mining Equipment Oilfield Equipment

- Renewable Energy Parts and Components

Heavy Equipment Shipping Rules and Regulations

When it comes to heavy equipment shipping, you should have knowledge of U.S. Department of Transportation (DOT) rules, regulations, and restrictions. Overlooking DOT regulations and restrictions surrounding OD/OW transportation can be both costly and time-consuming.

Heavy equipment shipping is regulated by the Federal Motor Carrier Safety Administration (FMCSA), the U.S. DOT, and state governments. Each state varies its rules, regulations, and restrictions for permitting OD/OW travel. Be sure to double-check state regulations before transporting your equipment. Or work with an expert in the field of over-dimensional shipping.

Looking for one place to find all you need to know about oversized shipment regulations?

Download our free over-dimensional shipping guide!

Overweight and oversized shipments can be more comprehensive as, besides the permits, you may need oversized banners, flashing lights, civilian escorts, police escorts, route surveys, bucket trucks, or even a road closure. It’s important that you always take the time to double-check that you’re in compliance with DOT rules and regulations when transporting your heavy equipment.

Need help with your oversized shipping? We have experts ready to help you.

Request a Shipping Quote with Trinity logistics.

Trailers for Heavy Equipment Shipping

Heavy equipment shipping is made possible by the various types of flatbed and specialized trailers available.

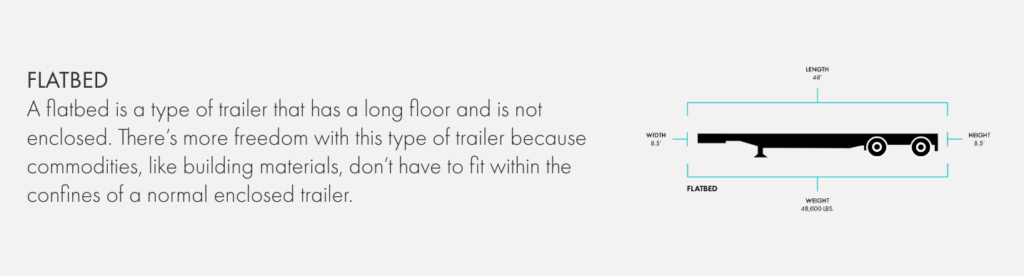

Flatbed Trailers/Open-Deck Trailers

Flatbed trailers allow for easy loading and unloading and can carry up to 48,000 pounds. When choosing your flatbed carrier, make sure to confirm that the trailer will be able to haul the weight of your equipment. Trailer dimensions are approximate: 48’ L x 102’’ W x 58’’ H

There are other open-deck trailers to consider, like step-decks or drop-deck trailers. They can accommodate around 46,500 pounds and can legally haul taller products, up to 10’6’’ tall, and can be fitted with permanent or removable ramps to drive equipment on and off the trailer. Trailer dimensions range approximate: 48’ or 53’ L x 102’’ W x 36’’ to 42’’ H.

Specialized Trailers for Heavy Haul Trucking

Due to the size, some heavy equipment may need a specialized trailer to accommodate its transportation.

Double-drops and Removable gooseneck (RGN) trailers are ideal for heavier machinery and equipment that needs easy loading and unloading or drive-on drive-off capabilities, and they are great for freight exceeding the legal height and weight maximums.

What Should I Know About My Heavy Equipment Shipping?

You’re ready to get started with heavy equipment shipping. What should you be prepared to answer when looking for a provider?

Know the Dimensions of Your Heavy Equipment

Size matters. The equipment’s dimensions and weight will help determine what kind of trailer the carrier will need to transport your freight and if any permits, escorts, or other accessorial charges are required that will ultimately determine the total shipping costs.

Breaking Down or Shipping in One Piece?

Does your equipment need to be taken apart to ship and then reconstructed upon delivery? Can your equipment be crated or boxed? Is it more effective to break down your equipment into smaller components for shipping? If shipping in one piece, what are the things that need to be done before shipping, such as having any fluids discharged or batteries removed? These are all important questions you should know so all parties involved know what is to be expected throughout the entire shipping process.

What Equipment is Needed to Load and Unload Your Freight?

This is very important information that is needed for your shipment. Do you need a ramp, forklift, or crane to load and unload your equipment? Do you have the required equipment ready to unload and load your freight? Or can the equipment be driven on and off of the trailer?

Know What is Covered by Your Provider’s Insurance

It’s important you know what is covered by your provider’s insurance, so you know whether you will need to buy any supplementary insurance to make sure your heavy equipment is fully protected in case of any issues.

How Much Does Heavy Equipment Shipping Cost?

While we’d love to give you exact numbers, there can be quite a few factors involved that make each quote unique, such as:

Size of Your Heavy Equipment

The larger or more oddly shaped your piece of equipment means it may need specialized trailers, permits, or routing requirements, likely raising your shipping price.

Time of Delivery

If you need your equipment delivered at a specific time, this will likely raise the shipping price as well.

Pick-up and Delivery Location

The further distance your equipment must travel, the higher it will cost you. Additionally, more congestion (think cities) in or around your pick-up or delivery location can increase your shipping costs.

Time of the Year

Adverse weather conditions, such as during the snowy and icy winter months or hurricane season, can affect your pricing if certain routes are shut off, making your equipment’s journey longer. There’s also flatbed peak shipping season, which ranges from April to October, which increases flatbed demand – and rates.

Current Fuel Rates

The more fuel costs motor carriers, the higher your shipping cost will be.

Permit or Licenses Required

When transporting heavy equipment, oversize or overweight permits may be required. Costs can vary by state and province, and some states may take longer to issue permits due to each state’s unique regulations and infrastructure.

Escorts Required

Escorts will increase your shipping costs as they need to be paid too! When freight is over 12ft wide or tall, it’s a good idea to check routing to see if escort cars are required.

Preparing Heavy Equipment for Shipping

You’ve got your quote and provider selected. What’s next? Here are the steps you should take to ensure your equipment remains safe and secure during shipping.

Have Documentation Ready

You’ll want to ensure all required documentation and permits are sorted and ready before pick up. Make sure to confirm with your shipping provider what permits are required and that they are in place to limit the chance of any shipping delays or fines.

Planning Transportation Routes, If Needed

Planning your route is necessary if your shipment is considered Oversized. Depending on the dimensions of your equipment, you may need to have your provider avoid bridges with low clearances, sharp turns, or even roads of a particular width.

Check the Condition of Your Heavy Equipment

Just as car rental services do before lending their vehicles, inspect your equipment, and take photos before shipping, so, should anything happen during the transportation process, you have it documented.

Make Sure Any Loose Parts or Tools are secured

You don’t want to lose anything important during the transportation of your equipment!

Cover Any Important Parts

Your equipment will likely be hauled through open air, facing the wind and other elements. Covering any vulnerable or important parts is a great way to ensure that your equipment stays safe and functional.

Check Your Equipment’s Manual

The manufacturer’s manual is a great resource for getting your equipment ready for shipping. It will help you determine exactly what steps you need to take before pick-up.

Ask Your Provider How You Can Help

If you’re unsure, ask your provider how you can help make your equipment’s transportation a smooth process. Based on their experience and expertise, they can give you tips and advice and will appreciate you taking this extra step to work together as a team so your equipment can be delivered safely.

Shipping Heavy Equipment Internationally

What if you need to ship your heavy equipment internationally? There can be many challenges to overcome, which you may find incredibly difficult to do alone. In this case, it makes the most sense to hire an expert to help you. While it can be costly, it’s the most stress-free way to safely transport your heavy equipment internationally.

Here are some tips to ensure your international heavy equipment shipping is successful.

- Make sure the provider you select to help you with your international shipping is experienced, has relevant credentials, and has a good reputation.

- Just like shipping inland, know the dimensions and weight of your heavy equipment to inform your provider.

- Determine the best shipping method for you. Your expert provider can help you figure this out. Your options are

- Roll on/Roll off (RoRo) is popular and involves driving the machinery onto a flatbed style truck at the pick-up location and rolling it off after it arrives at its destination. RoRo is speedy, efficient, and often less costly than your other shipping methods.

- Flat rack containers have walls or support posts on the ends, allowing loading from the top or sides. Flat racks mean your equipment is exposed to open air and so this method can be less costly, but then your equipment is exposed to the elements throughout its transport.

- Lift on/lift off (LoLo) is a method of loading and unloading containerized cargo over the top of a shipping vessel using cranes or derricks. LoLo ships usually have onboard cranes and can often carry a larger container capacity.

- Be prepared for the costs. With international shipping, you have extra costs such as taxes, tariffs, and customs checks.

Choosing the Right Heavy Equipment Shipping Provider is Important

You have many options for selecting a provider to help you with your heavy equipment shipping needs. Though too many options can feel overwhelming. How do you know you’re making the best choice for your company and freight?

Here are some qualities you should consider when looking for a provider.

Extensive Experience in Heavy Equipment Shipping

You’ll want to look for a company that has been in business for a long time, has the experience transporting the heavy equipment you’re shipping, and has a good reputation. This is a great opportunity to ask for references and contact them for their feedback.

Offers Flexible Shipping Solutions for Your Unique Needs

Do you need help with prepping your equipment for shipping, obtaining any necessary permits, or any other specialized services? Make sure the provider you’re considering has all the solutions you may need.

Carries the Proper Insurance

You want to make sure your heavy equipment is protected should anything happen during the shipping process. Verify that the provider you’re considering has the appropriate insurance to cover your equipment and enough liability insurance should anything else occur.

Trinity can help with Your Heavy Equipment Shipping

It’s easy to see that heavy equipment shipping has the potential to be a complicated process. If you’re looking for a provider that can help simplify your shipping, saving you time and stress, please consider working with Trinity Logistics.

Trinity Logistics is an industry-leading third-party logistics company with expert knowledge, ready to help you with your oversized, heavy haul, or any other flatbed shipments. We do this by providing our best-in-class People-Centric service and building strong relationships with skilled and experienced motor carriers.

We have the experience you’re looking for and the reliable carrier relationships you need to move your heavy equipment safely, securely, and on time.

Learn how Trinity can help you with your shippingIt’s no secret that capacity gets tighter and freight rates higher for all shippers during produce season. While the increased freight demand during produce season affects all markets, produce shippers and those with other temperature-controlled products are hit the hardest. Yet, produce shippers that make use of these suggested tips have a better chance of finding capacity and keeping their costs manageable.

TABLE OF CONTENTS

- When is produce season?

- Tips for produce shippers during produce season

- Make your produce easy to work with

- Have your produce truck ready

- Make sure your carriers are vetted

- Find providers that run temp-controlled year-round

- Make use of technology

- Be the produce shipper all the carriers want to work with

- Look into multimodal solutions

- Measure carrier performance

- Consider a 3PL

- It’s not too late!

When is Produce Season?

Produce season is impactful because it puts pressure on freight shipping rates, which affects shippers both inside and outside the produce sector. To simplify, it’s the rise in crop volumes and heightened demand for trucks to transport these crops that impact capacity during this season. These factors lead to an increase in rates, not only for the shippers who need trucks with temperature control but for a majority of shippers across other modes and regions as well.

It’s vital for produce shippers and all others impacted by produce season to know exactly when the spike in shipping begins. Generally, produce season begins sometime around February and runs through early fall. The main regional areas shipping increased produce are Florida and the East Coast, Texas and surrounding states, and California.

Texas Produce Season

The most impactful time is from March through June however, produce can be found year-round coming from over the border out of Mexico. In Arizona and New Mexico, there is a push for produce that usually occurs in October or November.

Florida Produce Season

Starting as early as March, southeastern states like Florida begin to see an uptick in produce shipping. As temperatures warm up, produce season creeps its way up the East Coast with northeastern states’ produce shippers slowing down sometime in early fall.

California Produce Season

Like the East Coast, produce season starts in the southern part of the state around March and creeps its way up to the northern region, ending in early fall.

Tips for Produce Shippers During Produce Season

Produce shippers facing challenges with capacity during produce season isn’t new. But there are things produce shippers can do to make shipping during produce season easier. Here are some tips you should consider to make it through this tough season.

Make Your Produce Easy to Work With

When capacity is tight and rates are high, carriers get to pick and choose what load they want. Make your produce shipments more desirable by making the job easy to complete.

One way to do this is through freight consolidation. Regional consolidation makes freight easier for carriers to work with. Simply put, instead of using a long-haul truck to make many pick-ups or deliveries in a regional area, hire a regional short-haul expert to do that part. They make all the pick-ups and deliver to one spot so that your long-haul carrier can make one easy pick-up and drive onward. Vice versa is that the long-haul carrier would drop off at one regional facility, and then you use the regional carrier to make the many deliveries.

We’ve found that consolidating the freight this way increases the percentage of on-time delivery, increasing your product’s shelf life and customer satisfaction.

Make Sure Your Produce is Truck Ready

This goes hand in hand with making your produce easy to work with. Often, produce vendors will work with many packing house facilities. Make sure you confirm with the produce shipper where the truck needs to pick up. It’s never a great start to a shipment when a driver has to search location after location for their pick-up. Not only does the driver get frustrated, but with it being a time-sensitive shipment, you want to make sure there are no hang-ups, so it’s picked up on time, delivered on time, and your product’s shelf life is as long as possible.

Make Sure Your Carriers are Vetted

This may be your most important piece of advice. Make sure your selected carriers are properly vetted.

What exactly do we mean by that? This means making sure they have reefer breakdown coverage. Or making sure they have the right amount of insurance coverage in case something goes wrong.

For example, cherries are hard to come by and based on market conditions, their value can change. Does your carrier have that coverage should there be a problem?

There’s also FSMA compliance to consider now. Does your carrier know how to work with produce shipments? Do they have that experience? Do they carry pulp thermometers in their trucks and understand that process to ensure they are not loading produce that is too hot or too cold, making sure it will be in good shape when it’s delivered? All these factors are something to keep in mind regardless of market conditions.

When selecting and vetting your carriers, remember there is a big difference between the cheapest truck and the RIGHT truck.

Find Providers that Run Temp-Controlled Year-Round

Finding and building a relationship with providers that execute year-round temperature-controlled freight across the country can give produce shippers a competitive advantage. By having that relationship, you’ll know and better trust your provider because they have the proven experience and understanding of working with your perishable freight. Additionally, having that reliable relationship can help you keep your costs down during peak produce season.

Make Use of Technology

Making use of transportation management (TMS) technology can help during this season. A TMS can help you with routing decisions by matching freight with the best carriers, lanes, rates, and transit service. In addition, it will allow you to optimize the in-house processes of your transportation network – which can help in both times of disruption and easier times. By selecting the best carriers and optimizing your routes, you’ll not only increase your service levels but reduce your risk.

Having a best-in-class TMS also provides you with data-driven insight to better manage disruptions, reduce downtime, and effectively plan and budget your logistics spend. By using data analytics, you’ll be able to recognize which carriers are most likely to have the capacity, allowing you to reduce your harvesting to minimal levels.

Having a TMS on hand gives you a full view of your network and transportation management. You’ll be able to see what’s happening across all markets, ensure proper rates for shipments, find freight consolidation options, and track everything from start to finish. You’ll be better prepared for now and any future disruptions. Not to mention, you’ll also gain an extra layer of security to your supply chain, which is something top of mind for everyone in this industry.

Be the Produce Shipper All the Carriers Want to Work With

There is never a time when you shouldn’t strive to be a shipper of choice. Carriers are in the position of choosing which shippers they want to work with. Produce shippers who provide better experiences for carriers can reap long-term benefits in the form of higher service levels, fewer claims, and better rates.

To become a shipper that carriers want to work with, it’s important to run efficient and friendly dock operations, reduce driver wait times, provide comfortable breakroom and restroom accommodations, and pay carriers quickly. Let’s break these down further.

Have a Fair Accessorial Schedule

Make sure it is in line with industry standards. You can also leverage your relationships with other carriers, shippers, and 3pls to see how you compare.

Pay Quickly

In business, cash is king, especially for carriers. Favorable payment terms can make a world of a difference to a smaller carrier company or an owner-operator. Anything under 30 days is often ideal.

Tender with Ample Lead Time

This may not always be possible, but the sooner you get a load tender to your selected carrier, the better they can plan their own workload. Providing as much lead time as possible can help you get the best capacity available at the most cost-effective rates. It can also get you more committed freight and keep you out of the spot market. 48 hours or more is ideal.

Simplify Your Appointment Scheduling Process

Put yourself in your provider’s shoes. What is it like to get an appointment set? Is it a huge effort or is it quick and easy? The easier and more user-friendly the process is, the more carriers will want to work with you.

Have Realistic Transit Times

Whenever possible, schedule pick-ups and deliveries that set carriers up for success. If transit is too tight and a late driver will have to wait hours for the facility to work them in, then the load is less attractive. Whereas if the pick-up and delivery are too far apart and a driver will have to sit around to get unloaded, then the load is also less attractive. Make sure your transit times are reasonable and make sense to keep carriers moving along. They will appreciate it.

Turn Drivers as Quickly as Possible

The industry standard is two hours or less. Anything over that and your facility is at risk of having a negative reputation among drivers. Depending on your freight and operations, this may not be possible, but it is something important to keep in mind.

Provide Basic Amenities for Drivers

Access to bathrooms, vending machines, waiting rooms, Wi-Fi, and most importantly, a friendly smile at the dock will go a LONG way.

Look Into Multimodal Solutions

When truckload capacity is tight, using a variety of modes can help mitigate capacity challenges while reducing your cost. Exploring multimodal options can be a great way to diversify risk, add capacity, and protect your freight budget. It can also give you the opportunity to reduce your company’s carbon footprint.

Measure Carrier Performance

Whether you awarded hundreds of lanes in an RFP event or are a small shipper relying on the spot market, it’s important to have your supply chain driven by data, and tracking carrier performance is a part of that. If you can’t track it, how else can you make improvements?

Be sure to communicate your KPIs to every carrier you work with so they can be crystal clear on your expectations. Regularly evaluate your carrier base. Give them report cards and make sure their performance is not a mystery to you or them. You should also have a process in place for taking action for poor performance when needed. Again, clearly communicate that process to your providers, and be sure to stick with it. Inflationary markets will often show you which providers are serious about being your business partner.

Consider Working With a 3PL

To gain quick access to capacity, produce shippers should work with a quality third-party logistics company (3PL). 3PLs work by having quality carrier relationships often in a network way larger than you can manage alone. Additionally, working with them gets you access to TMS technology and an expert to help you throughout times of disruption. It allows you easy access to multimodal solutions so you can easily compare rates across modes. Quality 3pls will include proper carrier vetting, so you know you’re working with a qualified carrier. Additionally, 3pls keep tabs on the industry and are well known for their skills in navigating disruptions with ease.

IT’S NOT TOO LATE!

If you found some tips that could better help you, it’s not too late to act. Any improvements that you make now will help you ship better. The faster you act, the more likely you will beat your competition to the punch. Now all this might seem like an overwhelming amount to do, which is why we’d like to offer you our help.

Trinity has over 40 years of experience working through produce season and years of supply chain disruptions. We can help you with capacity through our network of strong carrier relationships available. We can also help you in your journey of being a shipper of choice as we offer carriers Quick Pay options through TriumphPay, available within two days.

Interested in freight consolidation or multimodal options? Our Team of Experts are here to help. We also have best-in-class TMS technology available with customized solutions to fit your needs, not the other way around, and experts to support you in those applications. Most importantly, we offer you a People-Centric approach throughout every step of the process.

No matter what you need to get through produce season, Trinity Logistics is capable and ready to support your business.

Discover how we help produce shippers succeed Get a Free Freight QuoteStay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

Not Interested in Reading? Check Out Our Video Instead!

2023 Crystal Ball

It’s usually this time of year when predictions for the upcoming year start to make headlines. It’s safe to say that most folks could make some predictions based on what has transpired recently, so I wanted to highlight a few of those as we kick off the new year.

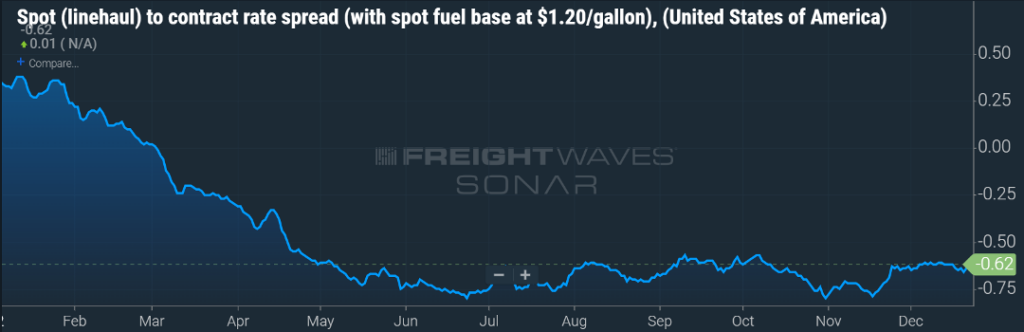

The gap between spot and contract rates will stabilize.

Now, this does not mean that they will be equal – that rarely happens. Just about a month ago, the spread was quickly approaching $1.00 per mile between contract and spot rates (with contract being higher). That gap is slowly starting to shrink (Figure 1.1). Some of that is due to spot rates seeing a holiday bump, and part of that is related to new contract rates taking hold. With many carriers taking an extended break from the road since mid-December, less capacity has pushed spot rates higher. This upward trend will be short-lived and expect rates below $2.00 per mile to become the norm as we chug through winter and into early spring. Contract rates will also trend downward, finding a floor most likely in the middle part of the year.

Few sectors will see bright spots in 2023.

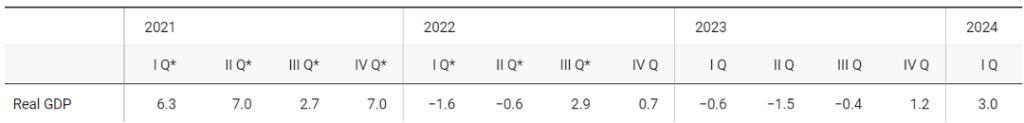

I don’t think anyone thought the economy could continue to chug along at its rapid pace seen in the latter half of 2020 and through most of 2021. Even though 2022’s growth was not as robust as the prior year, the U.S. Gross Domestic Product (GDP) should seek out a modest two percent growth rate. However, where that growth occurred sets the stage for this year.

2022 saw a return of spending on services versus goods. So, while things like healthcare are important to the overall economy, from a freight standpoint, service spending has much less impact on transportation. Expect auto sales, both new and used, to continue their strong run. As parts and inventory issues continue to be resolved, vehicles with temporary tags will be more commonplace as Americans continue to purchase cars and trucks.

On the opposite end, most notably, the housing market will have a rough 2023. With Americans seeing inflation compete for more of their take-home dollars, and the cost of borrowing increasing, many will choose to remain in their current situation. And it’s not just the building materials that will see less of a demand. With fewer new homes comes less demand for things that go in those homes – like appliances, carpets, and furniture.

Following the building industry, manufacturing will be the next downstream effect, and banking will also see less demand for consumer and business loans. Overall, expect 2023 to see, at best, no year-over-year (YoY) growth in GDP, with 2024 being a rebound year (Figure 2.1)

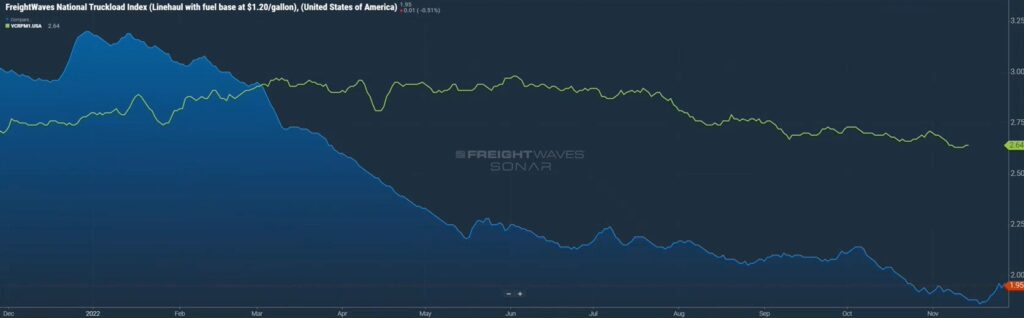

Import activity will continue to slow.

As we saw in last month’s update, Figure 3.1 shows the impact of the ship backlog being resolved and container movement starting to slow. That will be a common theme this year. While 2022 saw year-over-year import activity down almost 20 percent, that downward YoY story will continue in 2023. This will have an immediate impact on intermodal activity, but also over-the-road and less-than-truckload volumes will feel the impact.

One thing to keep in mind as we see recent actual and forecasted numbers showing negative, that is against a backdrop of a very successful 2021 and modest growth year in 2022. So while 2023 will not continue that positive trend, by comparison to a recent down year like 2019, 2023 will be up from an overall volume standpoint versus just a few years ago.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Join Our Mailing List for Frequent News UpdatesEvery day, all day, your life as a Freight Agent is a steady stream of fires that need to be extinguished. From negotiations to late deliveries, and the phone ringing off the hook, keeping your head above water is the only thing that you dream about at the end of each day.

Remember those dreams of growing your Freight Agent business into a large income-producing machine? You knew that one day you wanted to take your business to the next level, but now the idea of taking time away just to pick up lunch is a pipedream – let alone planning a full-scale growth strategy.

So, how do you do it? How does a Freight Agent know when it’s time to take the leap into growing his or her business? How do you know what to do next? Keep reading to find out the first steps in recognizing the time for growth and moving your numbers in the right direction….Up!

How TO RECOGNIZE WHEN IT’S TIME TO GROW YOUR FREIGHT AGENT BUSINESS

Know Where You Are

The first step to reaching your growth goals, or even deciding what those goals are, is first knowing where you are now. This step always seems like a no-brainer. Sure, you know how much the deposit into your bank account is every week, but do you really know how it got there and how much you possibly left on the table at the end of the week?

This is where you have to take some time and learn your numbers inside and out. How many shipments do you move in a week? What is your average margin per shipment? What is your net revenue? How many customers do you arrange shipping for every week? Then, how do these numbers compare to this time last month? Last quarter? Last year? Have you grown since last year? Are you moving more shipments, but your deposits are the same? These questions will help you decide what your next step is in planning your growth strategy as a Freight Agent.

Know How Much it Costs You to Run Your Freight Agent Business

Don’t forget that time equals money! Do you have fees associated with the company you broker through? How much goes into your pocket compared to how much goes to the company? What does it cost to use their operating system, load boards, or ancillary services?

So, now that you know where you stand, are you ready to take the leap? Growth can be a scary thing, so here are two areas to help determine how to jumpstart your growth:

JUMPSTARTING YOUR FREIGHT AGENT BUSINESS GROWTH

Determine the Need for Additional Help

Are you a one-person operation moving 100 shipments per month? Think about the time it takes you to cover one shipment, track it, handle any issues that arise, and keep your customer informed throughout the entire process. Now multiply that by the number of shipments you have waiting to be booked, or in transit, each day. Maybe, it’s time to bring in some help!

You will never be able to bring on new business and keep the service level you need to maintain with your current customers when you are managing 15-20 loads per day all on your own. This seems to be a “sweet spot” for many freight agents. You know, that “magic number” to let you know that it’s time to bring in the help!

Start looking for someone who shares the same values and work ethic that helped your business get where it is today. Then, have them slowly start taking on some of the day-to-day duties that keep your head submerged underwater so that you can do what you do best – build those customer relationships!

Analyze Your House

No, not your real house…your work house. What is the company you broker with costing you at the end of the day? What do they offer to help you grow? Here are some questions to start asking yourself to make sure that you are partnered with the right company:

Devoted Freight Agent Support Team

Are you just a number when you call and have to leave a message? Do you talk with an actual person who knows your business and cares about your success?

Reputable Corporate Presence

Does the corporate headquarters have executives that know the value of Independent Freight Agents? Do you have teams at the corporate level who are billing your customers and paying your carriers that understand the value of your customer? Does the corporate office consistently communicate its vision and company goals with its Independent Freight Agents?

Fees

Is it costing you to broker with your current company? Are you charged fees? Upfront costs? Do you understand any adjustments to your commission payments and are they justified?

Continuing Education

Does your current company offer consistent education opportunities to help you stay on top of the market? How about classes to help refresh your sales skills? Does your Agent Support team continually offer coaching opportunities to find areas of your business that have growth potential?

Taking a step back to analyze all of this information will help you realize when it’s time to take your business to the next level. Make sure that you know your numbers, that you are looking for the right person to help you, and that the company you are working with is dedicated to helping you grow. Taking the leap into growth can be scary, but the rewards are abundant. Go ahead, take that first step!

TAKE YOUR FREIGHT AGENT BUSINESS TO THE NEXT LEVEL

Trinity Logistics has over 30 years of experience aiding in the success of our freight agent businesses, with many of our newer businesses seeing a 50 percent increase over a two-year period from joining. Consider joining our Authorized Agent Network today so you can gain more time to focus on your customers, and generate more revenue. We’ll focus on everything else.

To learn more about our Authorized Agent program and all the ways we can save you time and help you build a successful Freight Agent business, feel free to contact our Agent Team by phone at 800-846-3400 x 1908 or click the button below!

Join our Agent NetworkThe chemical industry faces challenges such as volatile raw material prices, shortages, supply chain disruption, and more.

The chemicals industry is one of the most important sectors, with 96 percent of all manufactured goods depending on them. With many moving parts and various stakeholders involved in the chemical supply chain, there are several challenges this industry faces. Here are some of the biggest challenges affecting the chemical industry.

CHEMICAL INDUSTRY CHALLENGES

- Managing Raw Materials

- Transportation Disruptions

- Regulations

- Large Amounts of Data

- Complex Supply Chains

- Lack of Visibility

- Climate Change Pressure

MANAGING RAW MATERIALS

The chemical industry, specifically chemical manufacturing, relies heavily on raw materials. Raw material prices, such as those for crude oil, are volatile and can fluctuate at any given time. This can make it difficult to forecast costs and budget and, keep prices competitive.

Keeping an adequate supply of these materials can be an additional challenge. Having too much inventory can potentially lead to chemical waste or spoilage while too little can make it difficult to meet customer demand.

TRANSPORTATION DISRUPTIONS

Chemical industry supply chains can be long and complex. They have many moving parts, making the transportation of chemical products a challenge. If you add in transportation disruptions, it makes it even more problematic.

While transportation disruptions usually occur at some point, in recent years, there’s been a lot of supply chain disruption caused by the onset of Covid-19.

According to a survey by the American Chemistry Council, 97 percent of companies reported having to change to their operations due to supply chain issues in recent years. Because of this, the chemical industry must stay on the tip of its toes and be able to adapt quickly whenever disruption may happen.

Also, global supply chains see the most impact from transportation disruptions. The chemical industry has more global supply chains than other industries, making this challenge more difficult.

REGULATIONS

Chemical products are often specialized and need specific storage and handling. In addition, they face strict regulations on the transport of their products, especially hazardous materials. These regulations are necessary to have in place to protect the environment and people.

In recent years, several high-profile incidents have involved the release of hazardous chemicals into the environment. This has caused governments to introduce more strict regulations. As a result, this has increased the costs for chemical companies to operate. It’s been estimated that chemical companies will have to spend more than $300 billion over the next few years to meet regulations.

The chemical industry must be more vigilant than ever to remain compliant. These increased regulations put more pressure on chemical companies already trying to meet global standards.

The chemical industry has to work with many different regulations and agencies, such as;

- Environmental Protection Agency (EPA),

- Food and Drug Administration (FDA),

- Good Manufacturing Practices (GMP),

- Occupational Safety and Health Administration (OSHA),

- and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH).

LARGE AMOUNTS OF DATA

The chemical industry handles a lot of data. All manufacturing and operational data must be recorded, categorized, and processed. It’s estimated that chemical companies handle up to;

- 50,000 data points per raw material,

- 100 samples per test,

- 10,000 pieces of equipment per plant,

- 150 data points per customer!

This massive amount of data can be a challenge, especially with supply chain management.

COMPLEX SUPPLY CHAINS

The chemical industry is a complex one. It can include various kinds of chemical processes with products in all forms, from raw to intermediate, to finished goods. There are also many stakeholders involved, from chemical manufacturers to distributors.

Additionally, chemical products are often required to have very specific characteristics with little to no room for variations. Chemical companies also handle more complex items, like hazmat or temperature-controlled. Chemical supply chains are often worldwide, making them much more complex than other industries.

LACK OF VISIBILITY

Due to its complexity, lack of visibility can be a challenge for chemical supply chains. It can be difficult for chemical suppliers to know their inventory levels or how products are being used. Therefore, it’s important for chemical companies to have an accurate picture of their inventory and supply chain. Improved visibility can provide insight into opportunities to reduce costs without sacrificing quality.

CLIMATE CHANGE

The chemical industry is one of the top contributors to global carbon emissions. As the world becomes more concerned about climate change and sustainability, there’s more pressure added onto chemical companies that already face strict regulations.

There’s also a growing demand from consumers for more green and ethical products. For example, many companies are having to find alternative solutions for plastic or use recycled materials.

To keep up with the ever-changing market and demand, chemical companies need to change their processes. They must find ways to create less waste and more products that help reduce their environmental impact.

Also, as the planet warms, more severe weather is taking place. This is causing more disruptions to chemical industry processes. Whether causing a halt in transportation or a shortage of oil, climate change presents several challenges for the chemical industry.

OVERCOMING CHEMICAL INDUSTRY CHALLENGES

The chemical industry can be a tough market to compete in. To overcome these challenges, chemical companies need to remain resilient and competitive. As the world and market continue to change, they need to be able to adapt.

Finding like-minded, expert partners with applicable technology is ideal to overcome these challenges. A third-party logistics (3PL) company, like Trinity Logistics, is one such resource.

Trinity Logistics has been in business for over 40 years and has worked with chemical companies of all sizes. Trinity is a trusted partner to help chemical companies better navigate their complex supply chains. We’re well-versed in the chemical industry and can help find a quality carrier for your shipment or offer improved visibility through our customized technology solutions.

When choosing to work with Trinity, our Team Member experts keep you up to date on industry news, upcoming regulation changes, or any other relevant information your business needs to stay successful.

Additionally, we’re a Responsible Care certified partner, meaning we’re committed to providing you with the best service for your logistics and transportation management while staying committed to sustainability practices.

At Trinity Logistics, we’re not your typical 3PL. We’re invested in your business and are here to help your business succeed. If you’re looking for a like-minded logistics partner to help you overcome some of your industry’s challenges, we’re here and ready to help.

SEE HOW TRINITY CAN HELP YOUR CHEMICAL BUSINESSStay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

As we near the end of 2022 and the start of 2023, let’s look at three things in relation to the freight market: freight volumes, the rates, and what’s happening in the maritime segment.

SLOWING FREIGHT VOLUMES

In Figure 1.1, you can see the contracted outbound tender volume index over the past four years. The yellow line on the top represents 2021, the blue line represents 2022.

Since about the end of the first quarter of this year, we started seeing those volumes pacing around the same way as last year, but then all of the sudden they started to take a nosedive. Contract volumes are down around 15 percent below 2021 levels. What that means is we’re seeing less volume trickling to the spot market and this trend will certainly continue as we go into 2023.

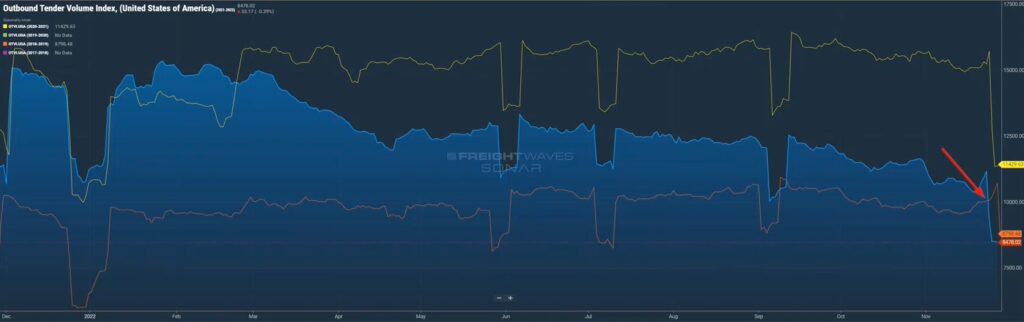

FALLING RATES

Speaking of rates, in figure 2.1, you’ll see the top green line represents the average van rate for contracted freight. The blue line is vans for the spot market.

As you can see, just like with freight volumes, they were running neck and neck until about March, and then there was a discrepancy. We’re seeing this on the rates side as well. Typically, the difference between contracted and spot rates is maybe 10 or 15 cents per mile. The fact that right now it’s about 70 to 80 cents a mile, we’ve never seen it at that high of a discrepancy. We do feel that as we get into the bidding season, new contracted rates will start to kick in, so we do anticipate that the green line will trend down. I’m not sure how much the blue line, the spot line, can continue to go, as it’s currently sitting at just below $2.00/mile. We may soon reach a point where carriers are not profitable on spot rates.

FINDING MARITIME BALANCE

On the maritime side of things, in figure 3.1, the green line shows the number of actual containers that are clearing customs. They are coming off the ships, being unloaded, and clearing customs to be distributed via warehouses, intermodal, truckload, and what have you. The blue line shows the number of actual import bookings that have happened.

You may say to yourself, that doesn’t make sense. If somebody is booking freight and that number is going down, how come we are still clearing these containers? Remember, throughout much of 2021 and even 2020, there was a backlog of ships, particularly on the West Coast, waiting to get unloaded. So, while the flow of ships is not coming into the ports as greatly as it was, it just kind of shows you how big of a backlog there was, that it’s taken six months and we’re still not through this backlog of ships, both on the West and East Coast.

Overall import volume is down 20 percent year over year. Yet, East Coast and Gulf ports are up as shippers moved their freight to the East Coast when the West Coast was originally facing backlog delays.

KEY TAKEAWAYS

Low, single-digit rejection rates on contracted freight mean less is hitting the spot market, by some accounts 30 percent less than last year.

Carriers need, and we need carriers, to remain solvent. Be diligent in negotiations with carriers but understand that we are very close to the floor for when a carrier becomes unprofitable.

Less freight is coming through the ports. Short-term will trigger an over-supply situation, particularly on ports with declining YoY volumes like Los Angeles and Long Beach. Other ports like Savannah, Houston, New York, and New Jersey will see more capacity balance.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Join Our Mailing List for Frequent News UpdatesThe following is an opinion article on AI in supply chains, written by Russ Felker, Chief of Technology (CTO) of Trinity Logistics.

Artificial intelligence (AI) continues to grow its presence in our everyday lives, businesses, and now, supply chains. In a recent MHI Annual Industry Report, 17 percent of respondents said they use AI, with another 45 percent stating they will begin using it in the next five years. And of more than 1,000 supply chain professionals surveyed, 25 percent stated they plan to invest in AI within the next three years. While AI in supply chains has its benefits, it continues to be overhyped as a replacement for human cognitive abilities.

AI in Supply Chains: We Need to Change Our Focus

The technologies leveraged by today’s AI offerings fall flat when applied to the complex day-to-day of supply chain interactions. We need to stop chasing the inflated promises of artificial intelligence and start focusing on the very powerful pattern recognition and pattern-application technologies marketed today as AI to support our teams more effectively. Instead of focusing on AI, we need to reorient on CAI (computer-aided intelligence).

Now, this might seem like a semantic argument, and to a certain extent it is, but the difference between artificial intelligence (AI) and computer-aided intelligence (CAI) is distinct. You might ask, “What does it matter if the technologies are being put in place and create efficiencies?” “So what if it’s called AI?” I would say it makes all the difference in the world.

What AI in Supply Chains Currently Does Well

First off, let’s talk about the technologies backing the products that include AI. As with many technology implementations, they are, by and large, applying rulesets to data. Being able to quickly process a defined pattern against a large data set is both no mean feat and hugely beneficial in a supply-chain setting. In the end, however, these implementations are no different than a rules engine – albeit one with a high degree of complication. For example, take an area of the supply chain that has had this form of technology applied to it, quite successfully, for many years – route optimization.

Optimizing a single route is relatively simple but optimizing the routes of multiple vehicles in conjunction with related schedules of item delivery commitments and layering in things like round-trip requirements and least amount of non-productive miles (miles driven without a load) and the level of complexity moves well beyond what an individual could do in a reasonable period of time. What can take on this type of task is a processing engine designed to apply complex patterns within a given boundary set – and that’s what current implementations of AI can do. And they do it well.

Why AI Can’t Replace Humans

The first problem comes in when we examine the stated goal of AI – the ability for a machine to work intelligently. The difference between hype and reality is in how we interpret a keyword – intelligence. Even the most recent and hyped AI systems continue to fail at the same core intelligence functions such as understanding nuanced context and broader application of existing patterns.

Take Gato from DeepMind, a division of Alphabet, as an example. While it can examine an image and draw basic conclusions, the context and understanding are both entirely missing from its analysis. Tesla provides another example where a driver had to intervene as autopilot couldn’t recognize a worker holding a stop sign as something it should avoid. These limitations minimize the tasks for which AI technologies can, and should, be leveraged.

The second problem is related to the first. The acceptance of “AI” from teams has been wrought with, at a minimum, intense change management and, in the worst case, rebellion. If you are bringing in AI to a team, why wouldn’t they draw the conclusion that your goal is to replace them? To start down the path of both realistic expectations from senior management and more widespread adoption of technology, we must change the approach we take with stakeholders impacted by implementations of AI. We need to talk about CAI.

It’s Time to Set the Stage for CAI

Just the acronym alone talks to a much more practical and achievable marriage between a person and a computer. It’s not the computer that’s intelligent; it’s the person using the computer. What a computer can be taught to do, is to effectively deliver relevant information to a person at the time they need it based on their job function and recognized point in the process. So instead of using a technology such as a recommendation engine to pick a product you might like or a movie you’re likely to want to watch, let’s turn our focus to delivering salient business information to our people. We can effectively use analytics and machine learning to create data recommendations and deliver those recommendations directly to users in their primary applications at the right time in their process, so they don’t have to go find data in multiple reports or sites. Once a pattern is recognized, by people, and the data is organized correctly, again, by people, we can use things like machine learning and analytics to deliver that result set effectively and consistently.

What this approach achieves is reduced interaction by a person and the machine reclaiming time for people to connect with customers outside of transactional conversations. By providing relevant data in-process, you make your team more efficient in their use of the system and create more opportunities for person-to-person interactions and relationships. The goal of any system implementation should be to reduce the time needed for a person to interact with it to achieve the desired result. This is different from having the perspective of the machine doing what a person does – which can be a misguided goal of AI. Instead, the system needs to be built to strategically leverage AI in areas that support the reduction of repetitive, rote work, enabling teams to focus on higher-value work.

A 3PL Focused on People

As a 3PL, a large part of our work tends to gravitate toward the identification and management of exceptions, but many times that is reactionary. We can leverage the technologies present today to enhance exception identification and management. Via AI-enabled supply-chain systems, information can be more present for teams to apply their intelligence, experience, and skill to solving issues optimally. The ability to recognize early in the life of a load the potential of a delayed delivery enables teams to make proactive adjustments with the receiving facility and the recipient. We can gather documents automatically and provide the information in a consumable fashion reducing the amount of manual effort to extract relevance from the documents.

As a 3PL we rely on two primary skills – intelligent use of data and building and maintaining relationships. Neither a computer nor an algorithm can do either of those alone, but a person backed by a Computer-Aided Intelligence system can. Creating systems that focus on CAI is what allows Trinity’s true source of intelligence, our team, to shine and deliver consistently phenomenal results for our customer partners. Now, you might be the exception and prefer to converse with a chatbot, but I’m guessing if you read this far, you’d rather talk to a person – which is what you get when you call Trinity – a person, backed by computer-aided intelligence systems, who is ready to do the work to create a relationship with you and deliver phenomenal results.

Learn how Trinity could benefit your business Stay in the know. Join our mailing listFlatbed shipping is an essential part of the logistics industry.

Flatbed trailers are incredibly versatile and offer many benefits to shippers. Not to mention, flatbed shipping has been on the rise in recent years. In this blog, we’ll divulge to you our comprehensive knowledge of flatbed shipping so you can master this transportation mode.

WHAT IS A FLATBED TRAILER? FLATBED SHIPPING?

Flatbed Shipping

Flatbed shipping is often the transportation choice for cargo that doesn’t need the enclosure of a dry van. It’s ideal for cargo that cannot be loaded or unloaded from a dock as the shipper or receiver can load or unload from a variety of ways. The design of a flatbed trailer allows for cranes and forklifts to unload and load goods from a loading dock, from the side with a forklift or crane, or from above with an overhead, gantry, or crawler crane. This makes a flatbed trailer versatile and critical for numerous loading and unloading scenarios including at job sites, warehouses, and distribution centers.

Flatbed Trailer

A flatbed trailer is the most common type of open-deck trailer used in commercial, over-the-road, long-haul, and specialized trucking such as oversized or over-dimensional shipments. A flatbed trailer is a 48ft or 53ft trailer, that can accommodate loads up to 48,000lbs. They typically have two axles, air-ride suspension, and kingpin for a standard 5th wheel hook up.

Flatbed Freight

Flatbed freight tends to be more industrial than truckload dry van freight. There is a wide variety of flatbed freight in the marketplace. Some higher volume products like lumber or building supplies will generally pay less than more industrial items that support our country’s energy and core infrastructure needs, like construction equipment, generators, fabricated steel, and other project or job site-related freight.

WHAT CAN BE HAULED ON A FLATBED TRAILER?

The most common freight shipping uses for flatbed trailers are:

o Formed concrete items

o Lumber

o Construction materials

o Steel beams

o Scaffolding

o Trusses

o Electrical transformers

o Oil, gas, and petrochemical equipment

o Solar panels or wind turbines

o Commercial heating and air conditioning units

o Landscaping materials

o Large quantities of wrapped and stackable products

WHAT INDUSTRIES USE FLATBED TRAILERS?

Because flatbed trailers have no enclosure, the freight they carry can be versatile and their use extends across several industries, such as;

o Housing

o Construction

o Renewable energy

o Agricultural

o Warehousing

o Manufacturing

o Mining and drilling

o Military

o Automotive

o Landscaping

WHAT ARE THE BENEFITS OF A FLATBED TRAILER?

There are several benefits to using a flatbed trailer for your freight. With a flatbed trailer, there is dimensional flexibility for loading or unloading freight since there are no physical walls or a ceiling to restrict its use. Any cargo that is oddly sized or irregular-shaped can be easily moved with a flatbed trailer.

WHAT ARE THE DISADVANTAGES OF USING A FLATBED TRAILER?

When selecting the type of trailer your freight needs, you should know the disadvantages of each. Compared to traditional hauls, all flatbeds take considerable skill, effort, and time.

Since there are no physical walls to restrain freight, cargo securement and balance are two significant concerns with flatbeds. The FMCSA has a lengthy section in rules specifically for securement, as insecure cargo is a serious safety hazard.

Proper securement is needed for your freight too because if not done correctly, your freight can get damaged from the securement itself. Also, shipments often shift some during transportation, so even weight distribution and securement are necessary.

Another disadvantage to flatbed trailers is that there are no physical walls. It’s a positive for loading and unloading. Still, it can also be a negative as no enclosure means dealing with the elements (wind, rain, snow, sun, animal or human interference, truck smoke/smog, dust, and road debris). To combat this, there is the option of tarping your freight or using a Conestoga trailer.

There are even more significant risks and responsibilities with any oversized freight as these shipments have even more strict regulations to follow.

Looking for all you need to know about Over-Dimensional Shipping?

FLATBED SHIPPING TIPS

Know your cargo

Be sure to know all the details of your shipment. This includes commodities, value, dimensions, and weight. This information will help logistics providers know how to properly secure your cargo ahead of time.

Understand what trailer you’ll need

Familiarize yourself with the different types of flatbed trailers before booking a shipment so you can make the most cost-effective and safe choice. Each type of flatbed trailer has certain limitations. For example, a specific flatbed trailer like extended trailers and Conestogas can be harder to find so your provider may need advanced notice when they are required.

Be aware of accessorial charges

Flatbed shipping may involve moving specialized loads which can need special equipment or extra services. Make sure you have the proper equipment and services needed for your freight to avoid extra charges, freight damage, or delays.

Choose to work with an expert

Arranging flatbed shipments on your own can be time-consuming and expensive, making sure all regulations are met and your cargo travels safely. Consider working with an expert in flatbed shipping to help secure capacity and locate the right equipment for your freight.

FLATBED RATES AND SEASONALITY

Freight shipping demand, which includes flatbed demand, is something that is often based seasonally. No matter the market, shipping rates fluctuate throughout the year and rise as the demand for freight rises.

Flatbed shipping is very closely connected to construction and industrial production, which can be highly dependent on the weather. These industries often slow down in the winter months, so normally, the demand for flatbed shipping will soften at the end of the year.

Smaller to medium-sized companies often slow down during winter and resume activity when warmer weather returns. However, larger companies are affected less by the seasonality and continue to move their commodities regardless of the time of the year.

Because of the seasonal rise and fall, you’ll find volume and rates lowest in the late fall/early winter, with the peak flatbed season being from April to October. This is when the volume of flatbed loads is highest, as are the rates.

FLATBED SHIPPING WITH TRINITY LOGISTICS

Did you know Trinity Logistics is an industry leader in brokering flatbed freight to small and midsize carriers throughout North America?

Our vast network of Independent Freight Agents, combined with our Regional Service Centers deliver the best-in-class flatbed shipping through our expert carrier relationships. We accomplish this by supporting core energy and infrastructure clients with their project-based, unique, and often specialized freight.

Learn more about Trinity's services