You can consider drayage service the unsung hero of shipping. It’s crucial to global supply chains, bridging the gap for both intermodal and international shipments.

Growing businesses often develop a need for drayage services but can easily get overwhelmed by it. Unlike truckload or less-than-truckload (LTL), getting your items picked up and delivered with drayage shipping sometimes isn’t a straightforward process. From port congestion to demurrage, it’s easy to get lost in the tangled process of drayage. Yet, with a few quick tips and the right approach, you can make use of drayage services to your supply chain’s advantage.

What ARE COMMON CHALLENGES WITH DRAYAGE? How Can I avoid Them?

Route Planning

One of the primary challenges faced by shippers handling drayage services is route planning. Ports and rail terminals often operate in congested cities with lots of traffic and frequent road closures. Poor route planning can lead to delays, missed appointments, increased fuel consumption, additional fees, and, most of all, frustrated customers.

Chassis/Equipment Shortages

Just like there can be ebbs and flows with truck trailer capacity, drayage brings the concern of its own equipment shortages. Chassis are what the containers sit on when hauled by the carriers. It’s important to mention that drayage carriers don’t own chassis. Instead, they rent the chassis from the port or terminal, thus adding an additional complexity to drayage services. Chassis shortages most often happen during peak shipping seasons and can create delays or additional costs for shippers.

Port or Terminal Delays

Delays can happen at the ports or terminals for several reasons. Unforeseen events like canal blockages (Suez Canal), the Francis Scott Key Bridge collapse, or possible rail strikes have most recently created delays for shippers. Customs clearance is often the most common cause of delays as the process can be intensive, and any improper documentation or misclassified products can cause a holdup. Container reshuffling can also be an issue from time to time when there are too many containers, whether full or empty, at the ports or terminals.

Additional Charges

Additional charges may be the bane of drayage services, second to delays. Drayage can come with many accessorial fees that can catch shippers off guard if not prepared. The most common fee you’ll hear about in drayage services is demurrage.

Once a container is delivered to the port or terminal, you’re given a set number of “free days” for it to be picked up by a drayage carrier. This is called your Last Free Day (LFD), and that’s the date you want to ensure your container is picked up so you won’t face this additional charge.

There are also drop fees. Drop fees are for when the drayage carrier must drop the container and then come back to pick it up and return it empty to the port or terminal.

Lastly, if the empty container is returned late to the port or terminal, that’s an additional fee.

Lack of Transparency or Communication

With drayage services, you really need to have a clear picture of what’s happening if you want to reduce the chance of accruing any additional charges, not to mention any delivery delays or customer dissatisfaction. Effective communication between shippers, carriers, logistics providers, and port or terminal authorities is essential for smooth drayage shipping.

TIPS TO Avoid DRAYAGE SERVICE CHALLENGES

If you’ve experienced any of the previously mentioned challenges with drayage service, the great news is there are really only two tips you need to make it seamless.

Proper Planning and Time Management

Most of the challenges with drayage are caused by improper planning, unforeseen circumstances, or misinterpretation at the port. Proper time management and planning are essential to avoid those challenges in the first place. Ensuring you have properly evaluated and documented your freight, selecting the right drayage carrier based on your needs, and taking into consideration factors like port or terminal timings or traffic.

Additionally, stay in the know of what’s going on in the market. Are there any anticipated delays or disruptions that could change your plans? Do you have a contingency plan in place should an unforeseen event occur? The more planning you’ve made ahead of your drayage shipment, the better your supply chain will operate.

Work with the Right Drayage Provider

Working with the right provider can significantly impact the success of your drayage service. While that tip is easy to state, how do you determine if a provider is the right one for your needs?

When searching for a drayage service provider, you should ensure they:

- Gain you access to reliable capacity with experienced carriers,

- Offer excellent customer service and clear and timely communication,

- Technology tools to provide you with shipment visibility and tracking,

- Accurate billing practice,

- And has a high on-time delivery percentage.

By prioritizing these characteristics when looking for a drayage service provider to work with, you’ll quickly find that selecting the right one will improve your company’s competitiveness and service by helping you overcome these common challenges.

WORK WITH TRINITY FOR The Best DRAYAGE SERVICES

Speaking of reliable drayage service providers, you’re currently hot in your search already!

Trinity Logistics is a nationwide, top-rated third-party logistics (3PL) provider capable of helping you overcome any challenges you’ve been facing with your drayage service. You should consider us because:

Trustworthy Carrier Relationships

We treat and respect our carrier relationships and aim to build a strong partnership with each one to help their businesses be successful. Because of that, we’ve built trusted partnerships with those in our carrier network, gaining you access to the capacity you need and the service you want.

24/7/365 Support

No matter what happens, we’re ready to support you around the clock. We have a dedicated After-Hours Team to continue the monitoring of your freight and are ready to quickly resolve potential challenges, no matter the time of night, holidays, and every weekend.

Tracking and Tracing

We understand transparency is key to your drayage success, so we offer several ways to view and keep track of your freight, no matter the time of day.

Team of Experts

Our only job is logistics. It’s what we handle day in and day out. We’ve been working in this industry for 45 years and have seen all the ups, downs, delays, and disruptions the freight market has thrown at us, so we know how to handle tough situations. Additionally, we stay knowledgeable about what’s going on and keep you informed of anything that could come your way, with a backup plan at the ready.

Clear Communication About Charges

From the start, we are transparent about costs and help you understand all the different charges that you may see or come across with drayage service.

Your Trinity relationship will provide a list of any potential charges that may arise, such as any overweight, drop, or hazmat fees. Our goal is to ensure you know exactly what to expect so there are never any surprises.

An additional benefit to our trusted carrier relationships is our capability of keeping any fees from the port tied to the clearance of any containers from being billed back to you and being able to be competitive with those drayage rates.

Yes, drayage services can be complex and challenging at times, but it doesn’t have to be if you choose to work with Trinity Logistics.

I WANT TO KNOW MORE ABOUT TRINITY’S DRAYAGE SERVICEAfter several record setting years, 2023 saw shifts to the freight market. How did the 2023 freight market affect shipper and carrier businesses? Did other businesses have the same struggles as yours? Are they expecting to face similar difficulties in 2024? How are their partner relationships?

Trinity Logistics wanted to get answers to these questions for you, so we asked a random sample of our shipper and carrier relationships to gauge the effect 2023 had on their business and what their expectations for 2024 in our first Freight Market Survey. Here’s what we found out:

2023 SHipper & Carrier Data: Freight Market Survey Results

Past Challenges – Same, But Different

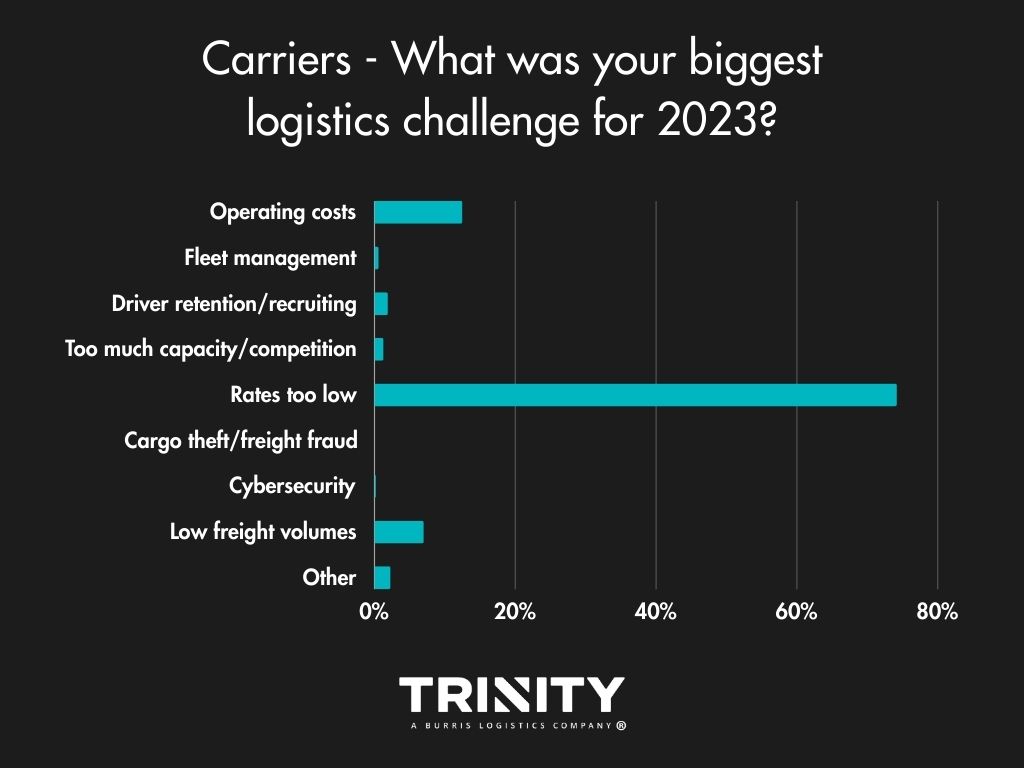

Considering the recent turndown of demand and the freight market, it’s not a big surprise that money was the biggest issue for shippers and carriers alike. Shippers answered that transportation costs were their biggest challenge in 2023, with supply chain delays/disruption and capacity not far behind. Low rates and increasing operating costs were the main challenges facing carriers.

Business Impact – Could Have Been Better

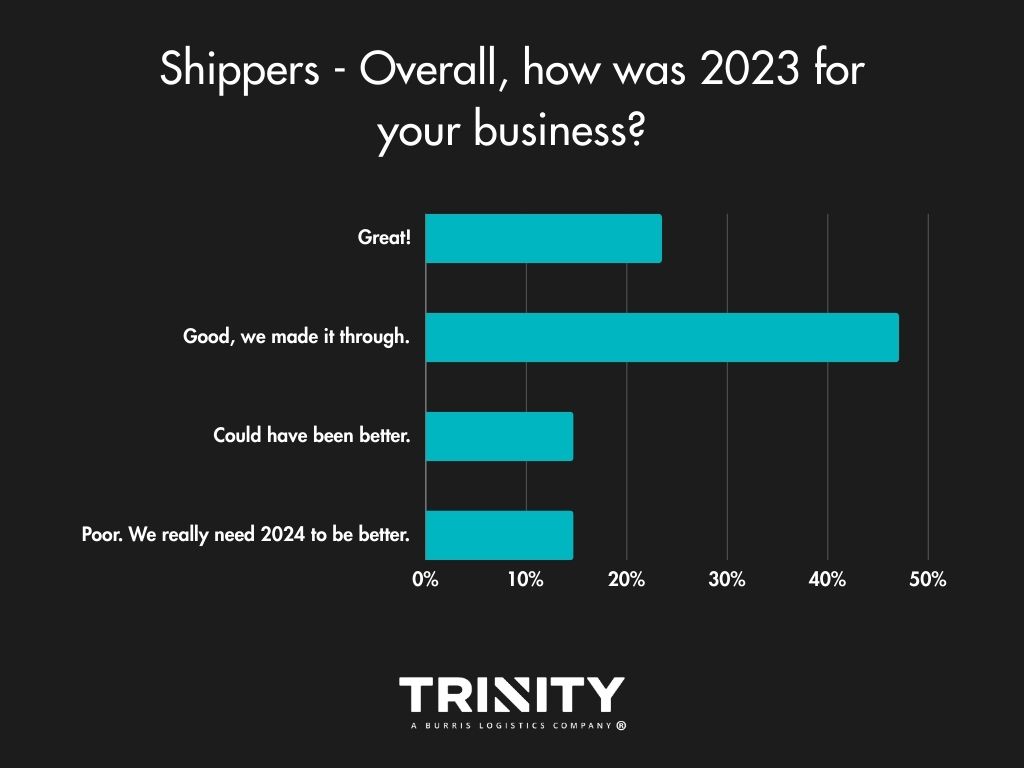

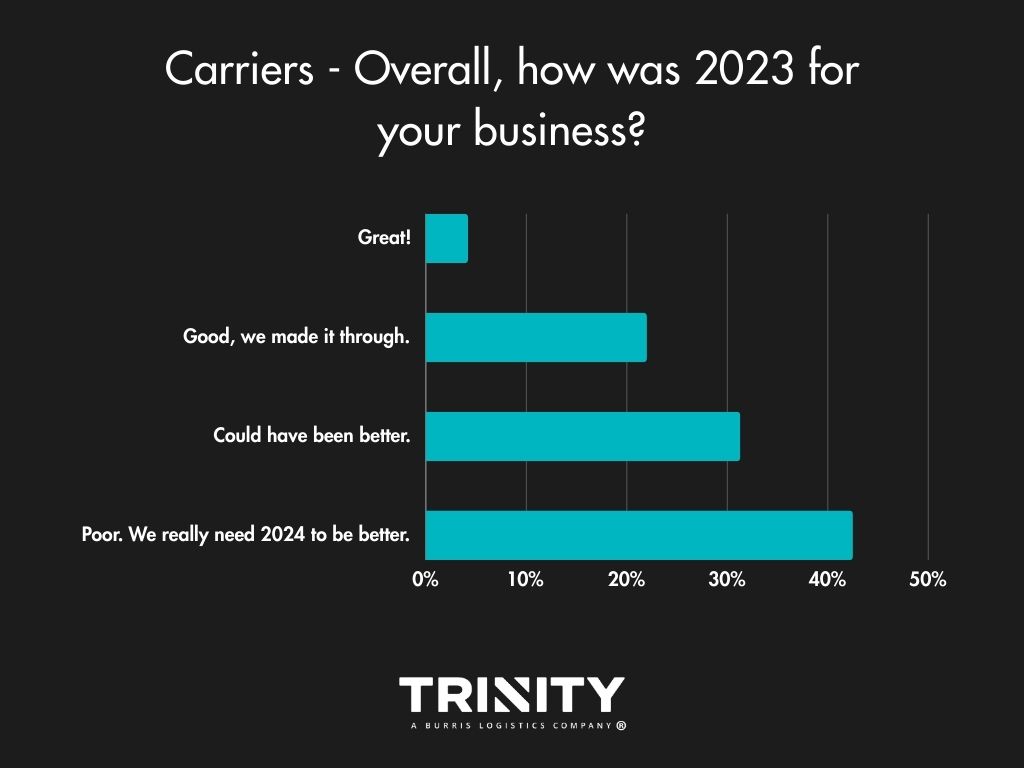

Even with the change in consumer demand trending downwards throughout 2023, most shippers answered that their year was good overall. Carriers on the other hand seemed to face a rougher year in business with over half of them stating their year could have been better or was poor.

A LOOK INTO 2024

Future Challenges – Money Problems

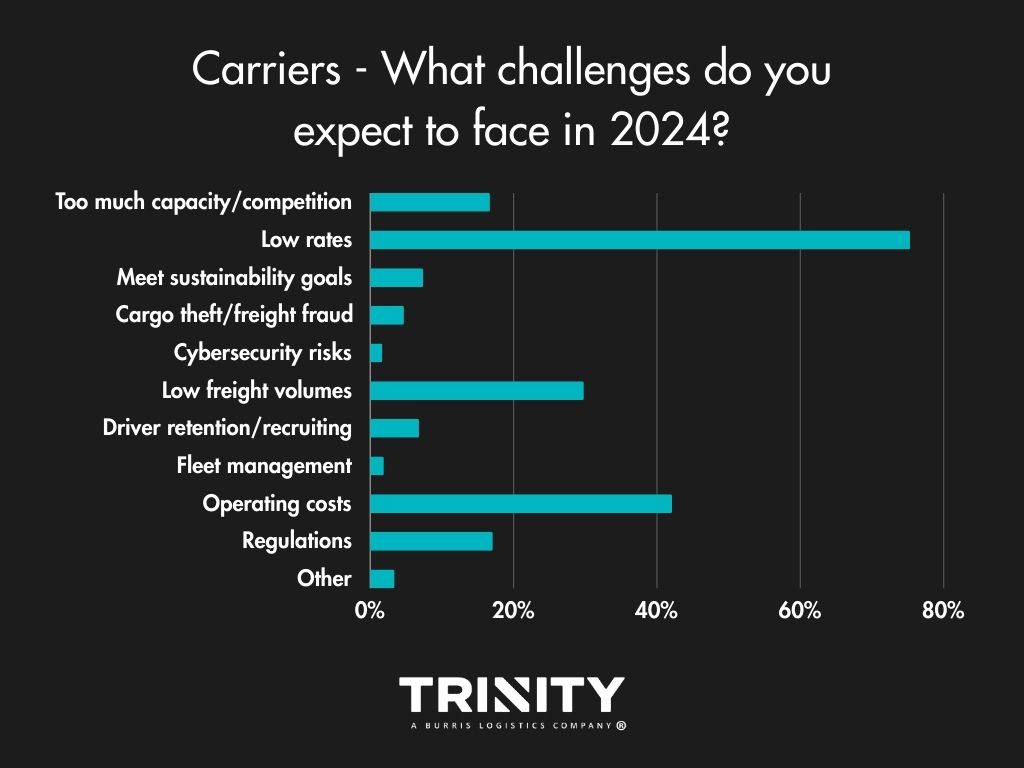

2024 isn’t looking much different in terms of challenges compared to 2023. Shippers look to have the same financial challenges as they did in 2023 with transportation costs, supply chain delays/disruption, and decreased demand being the top concerns selected. Carriers are still concerned about low rates, operating costs, and low freight volumes hurting their businesses.

Hot Trends

Even though transportation costs are shippers’ strongest concerns in their previous answers, it seems the increased amount of supply chain disruptions and delays we’ve all experienced in these recent years have hit a nerve, with the majority answering that supply chain resilience is the trend their business is most interested in. Cybersecurity also looks to be a growing interest.

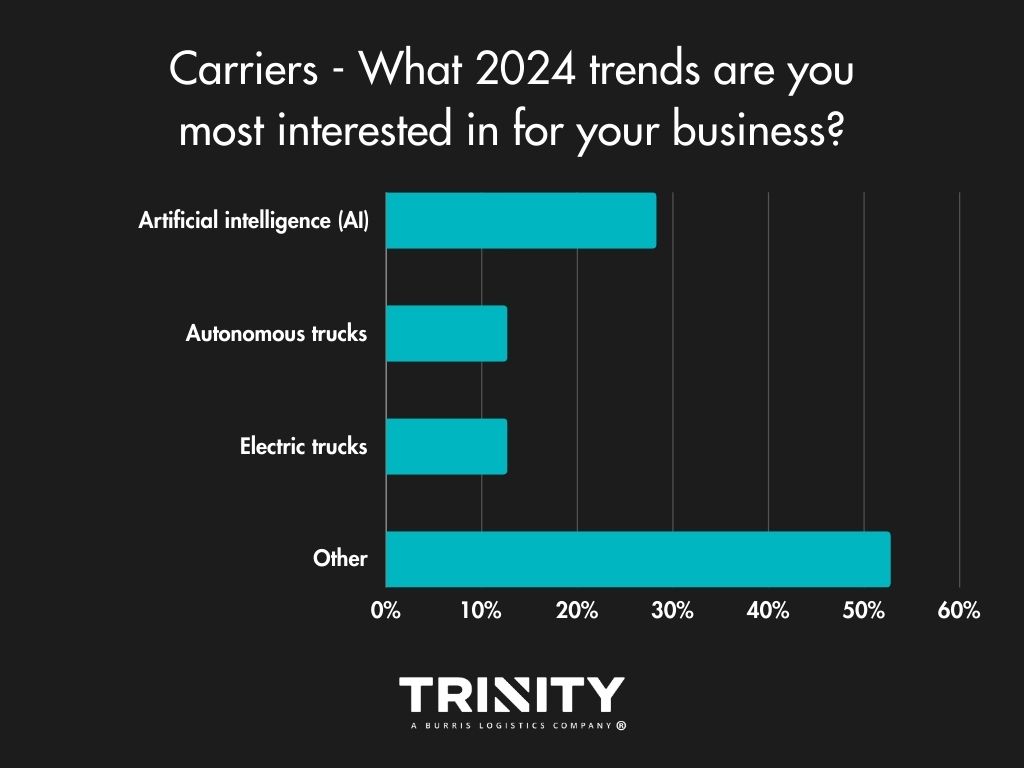

Carriers on the other hand, interestingly enough, look to the recent trend of Artificial Intelligence (AI). Also, as noted in the comment boxes of our “Other” option, increased rates and better fuel prices were trends they’d like to see in 2024.

Load Volumes & Capacity – Slightly Positive Outlook

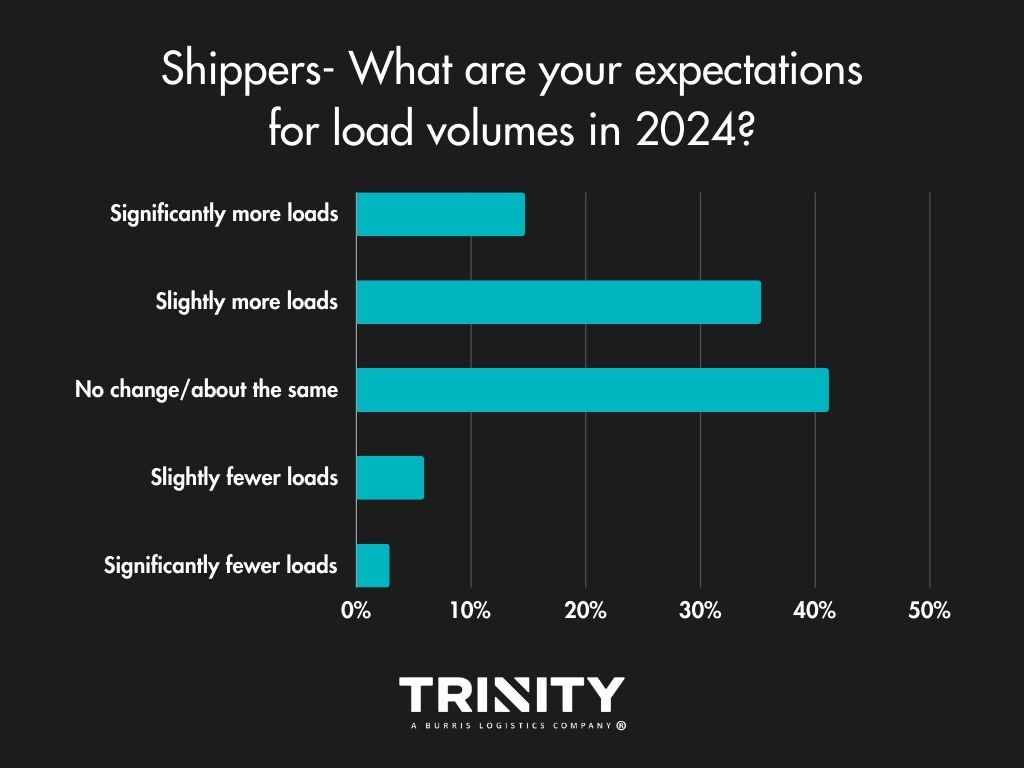

Overall, shippers are slightly more optimistic for 2024, thinking it won’t bring any change or the change it brings will be positive. Most think load volumes will stay the same or there will be a little more in freight volumes this year. As for truck capacity, they think it will be the same as 2023 or slightly tighter.

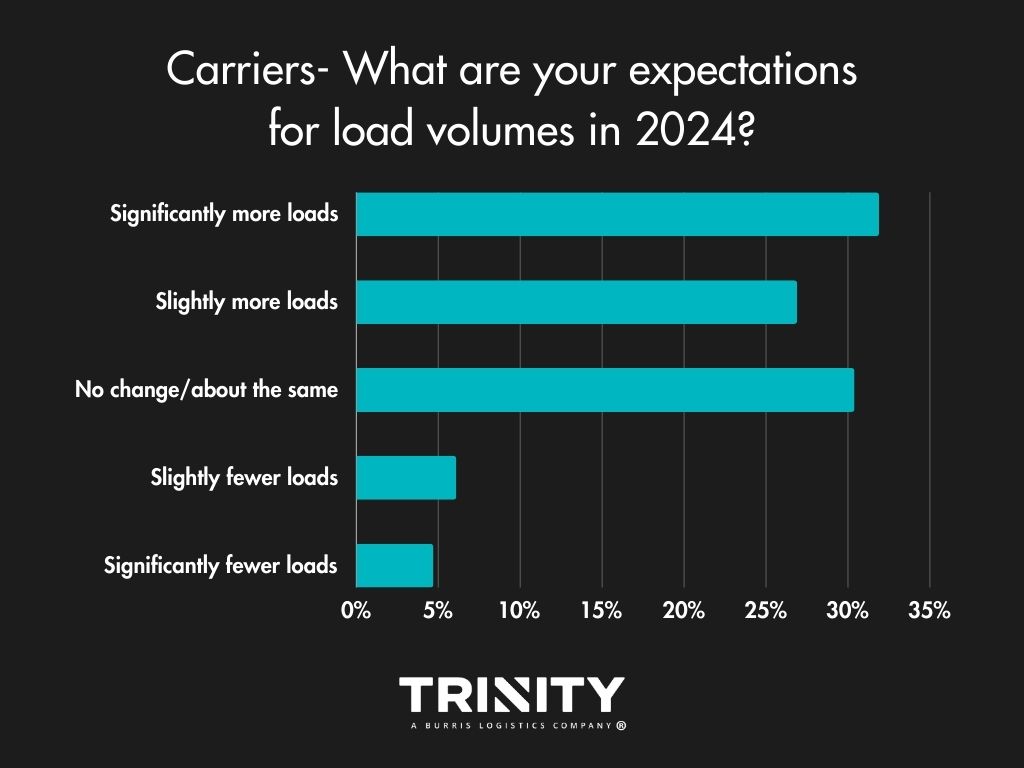

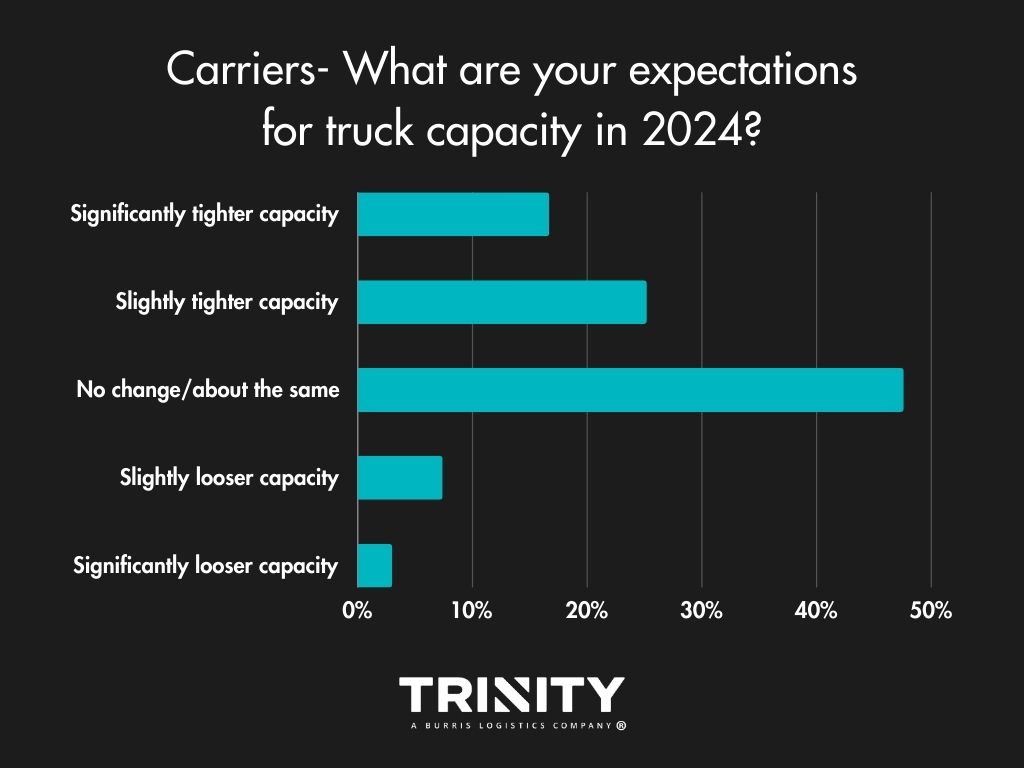

Carriers also think 2024 will bring more freight volumes and that capacity will likely stay the same or get tighten slightly versus 2023.

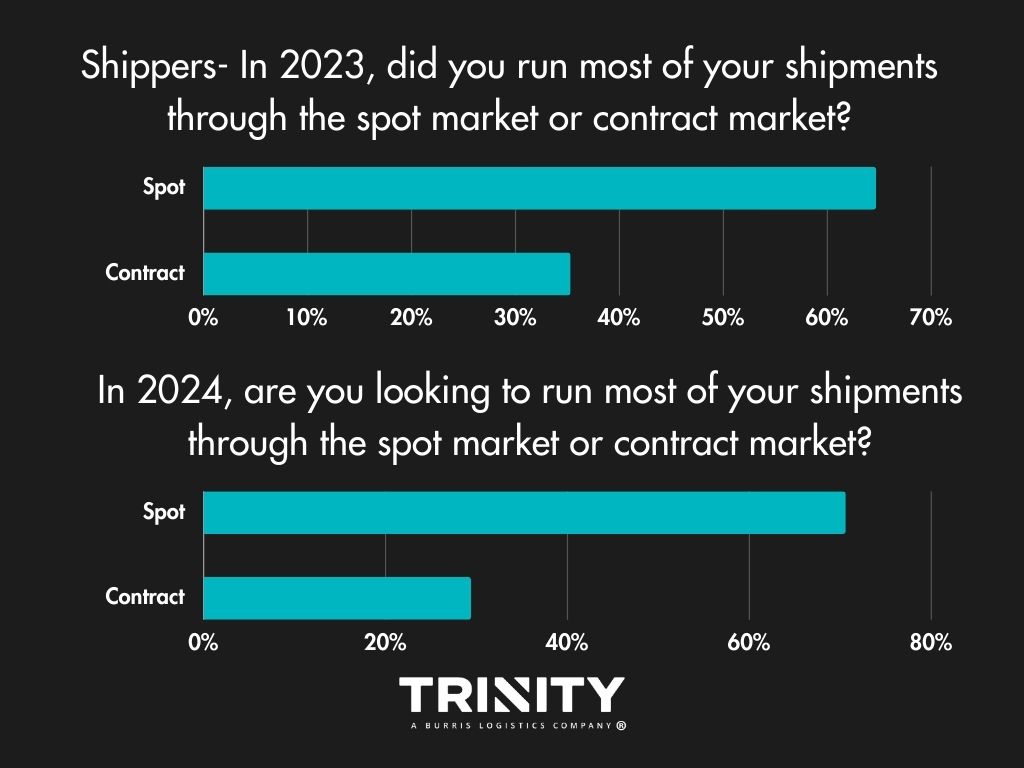

Spot or Contract?

Year-over-year, shippers aren’t looking to change much in terms of which market they turn to. Most look to continue to put most of their freight on the spot market.

For carriers, there looks to be some change anticipated. In 2023, most carriers ran spot market freight but in 2024, over half of them look to haul contracted freight.

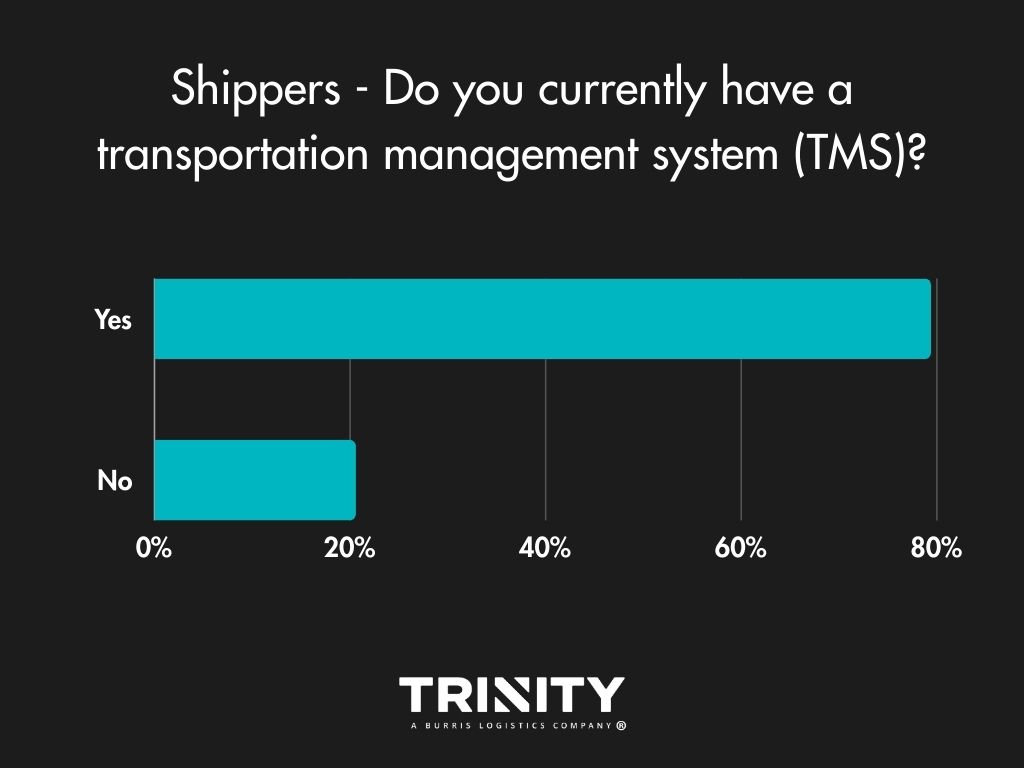

Do Shippers Have a TMS?

It’s 2024, so you’d think most shippers would have a transportation management system (TMS), and no surprise, they do. For those that don’t and answered, it seems they did not have a good experience with one in the past or don’t know enough about them.

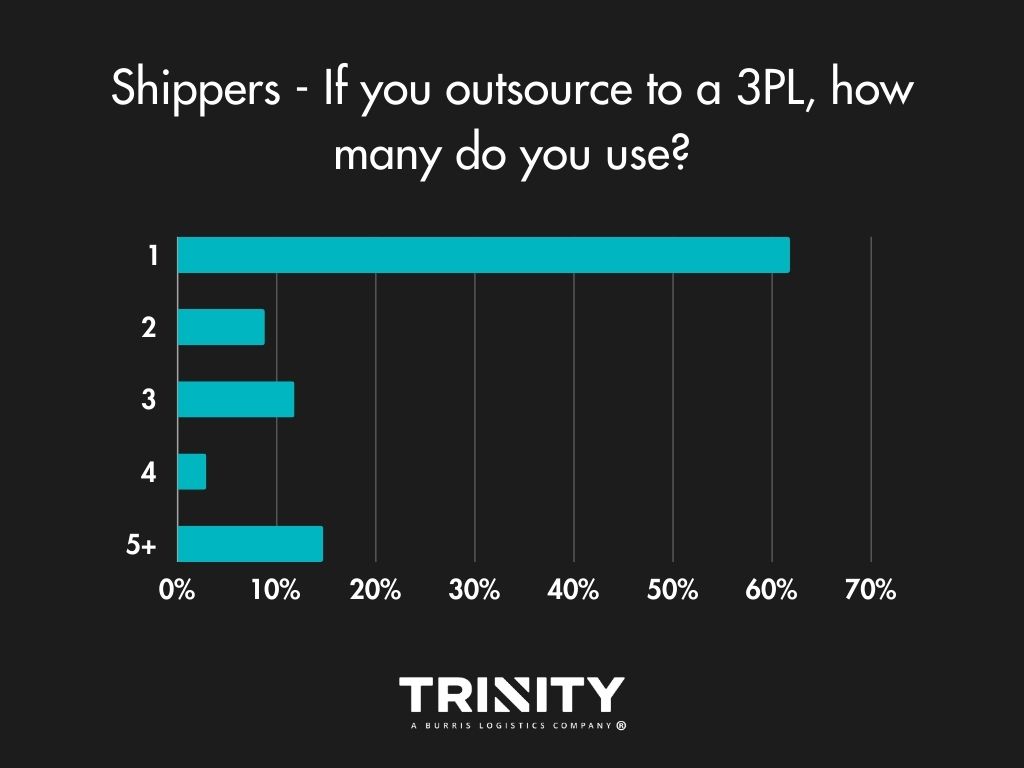

Brokers Are the Way to Go

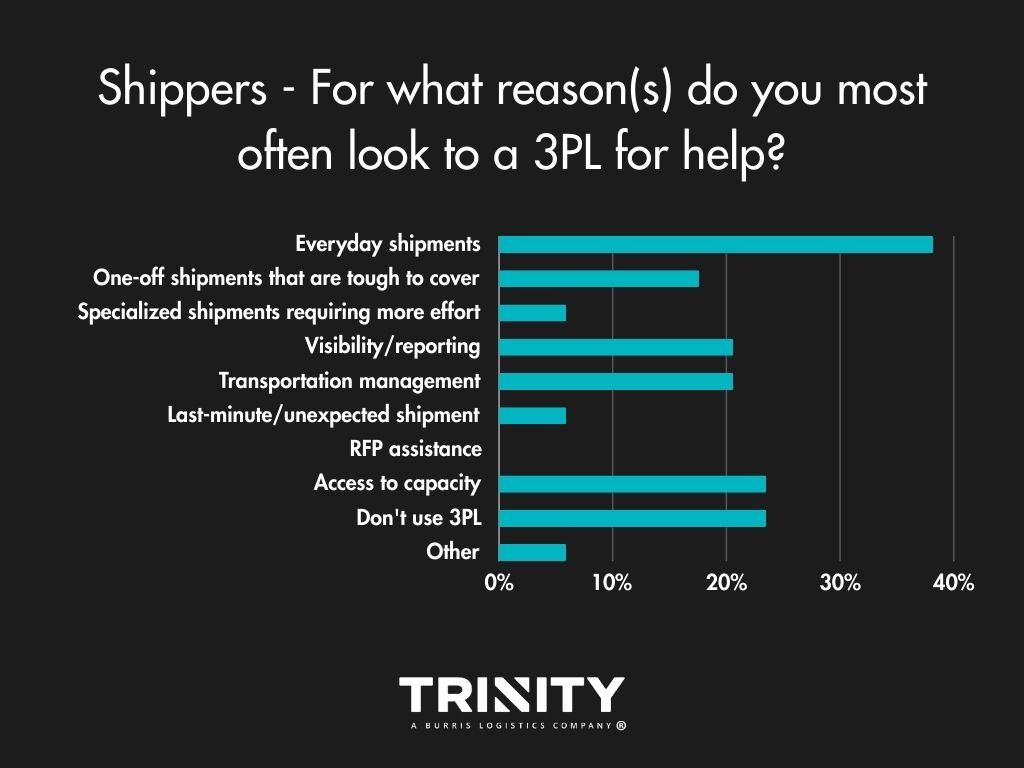

When asked how they like to move their shipments, most shippers use a mix of carriers and third-party logistics providers (3PLs) or just 3PLs. A few do use their own trucks. For those that do outsource to 3PLs, they usually just stick to one provider.

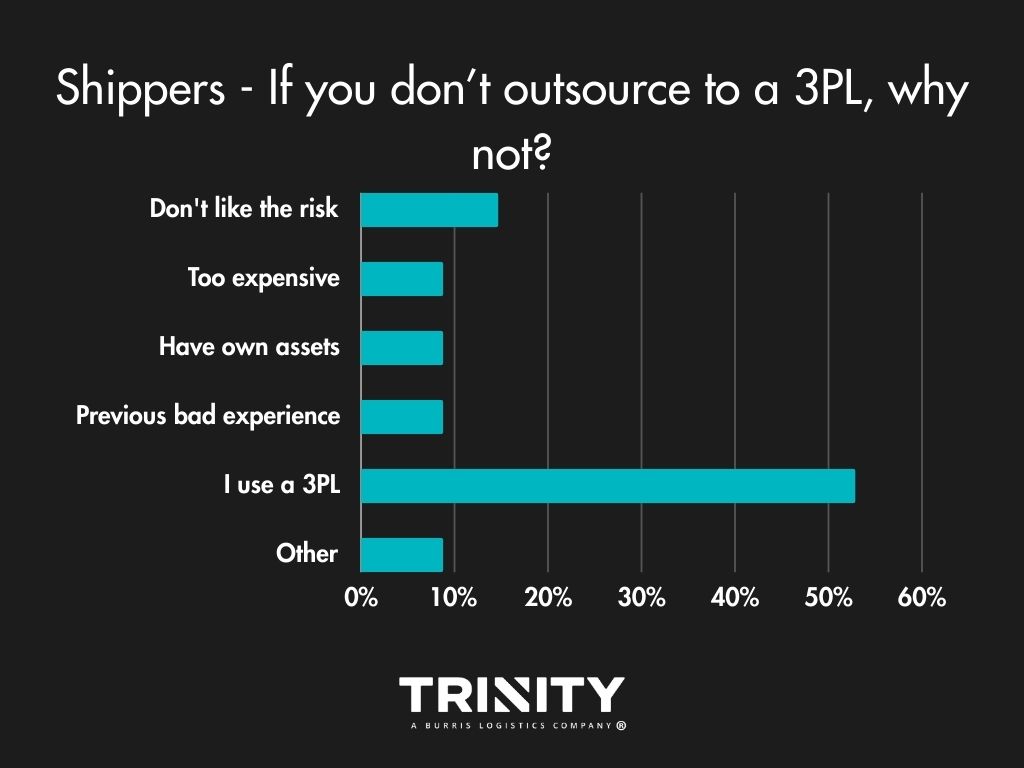

Shippers most often look to a 3PL for help with their everyday shipments, for transportation management, visibility, and access to their capacity. The main reason shippers choose not to work a 3PL for their logistics? They don’t like the risk.

Transportation Modes – Staying Consistent

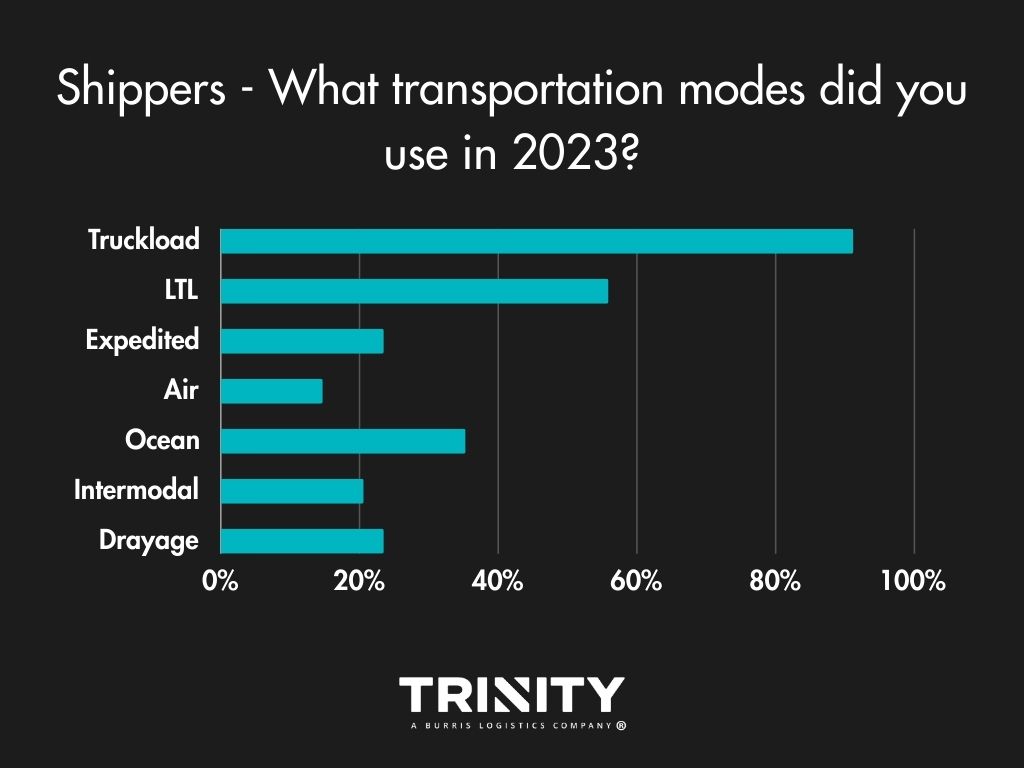

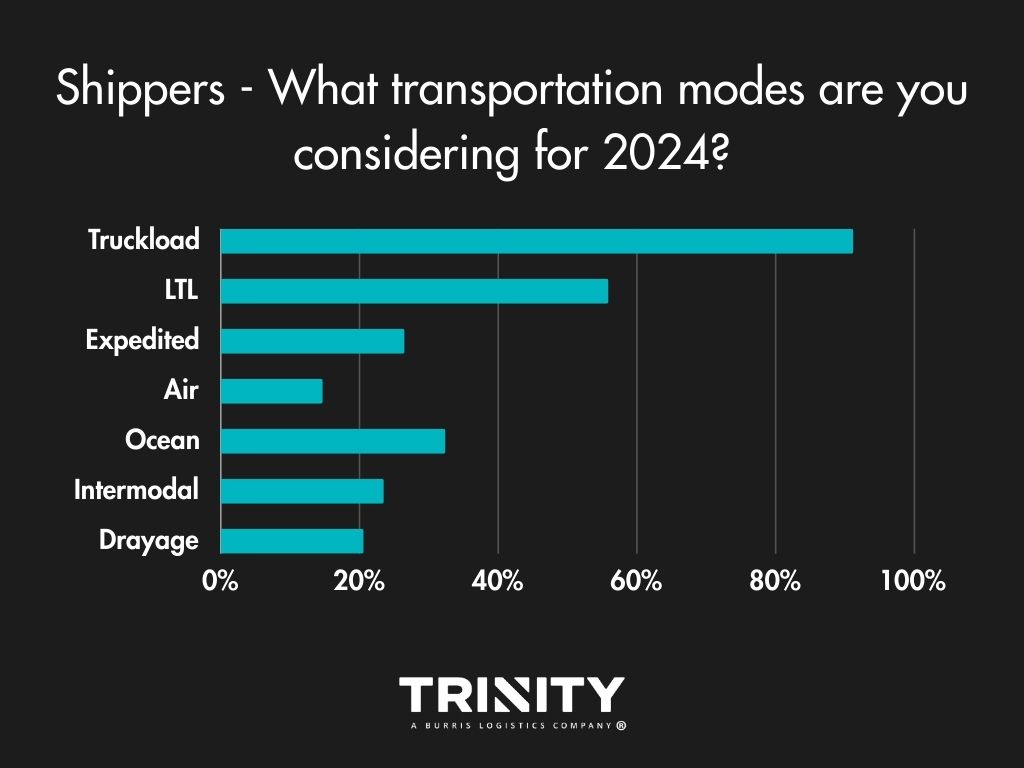

Overall, shippers aren’t looking to change what transportation modes they use for their shipments. Truckload and less-than-truckload (LTL) are the primary modes they like to use, with a little diversification sprinkled in.

Exceptional Service Stands the Test of Time

When it comes to their logistics partners, shippers find the most value in receiving exceptional service, with costs coming in as a close second.

Most Wanted: Long Mileage, Flatbed Shipments

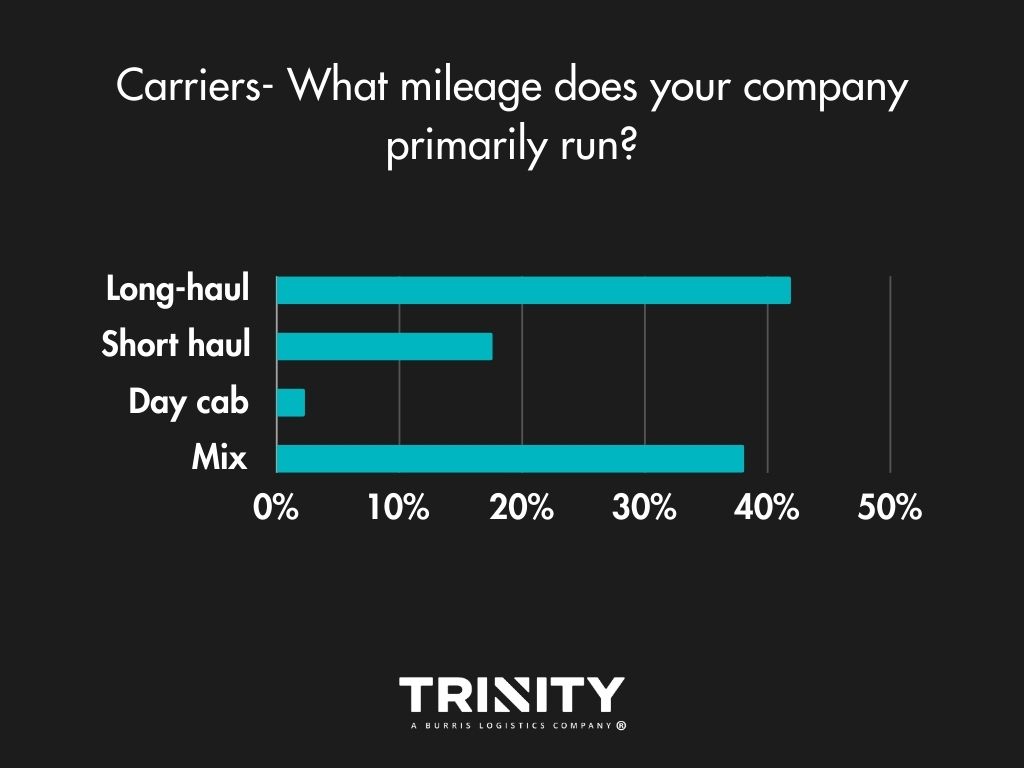

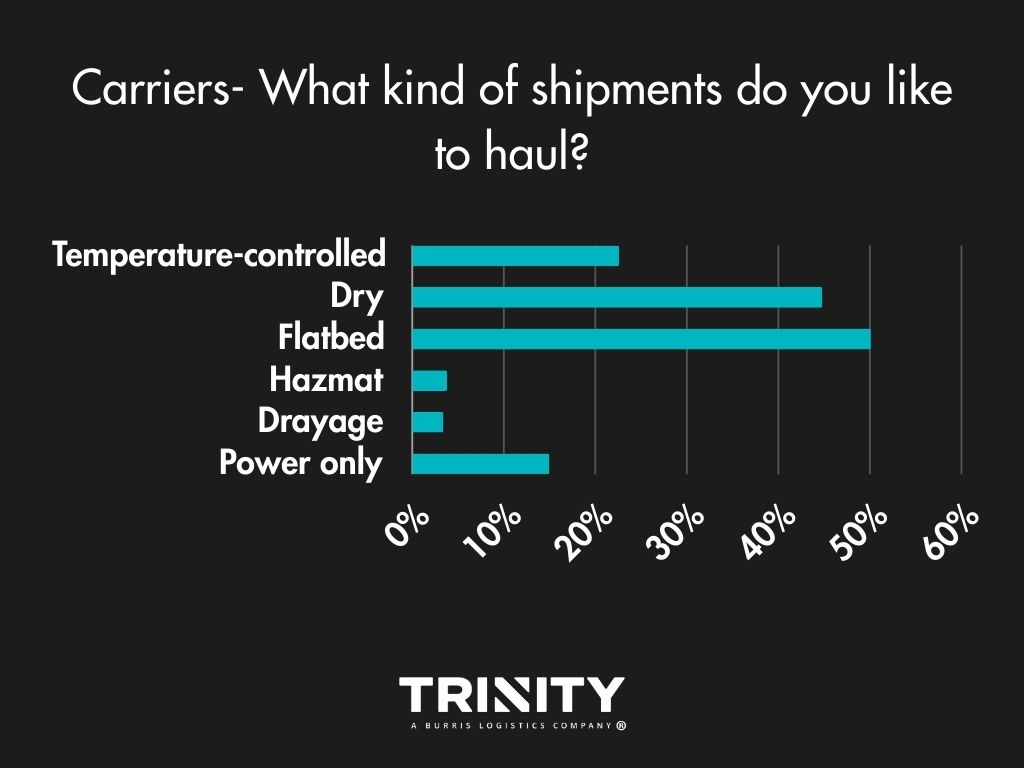

When it comes to mileage, most carrier companies tend to run long-hauls or a mix of short and long shipments. Flatbed hauls are the type of shipments most carriers like to haul with dry van coming in as a close second.

Load Boards are the Way

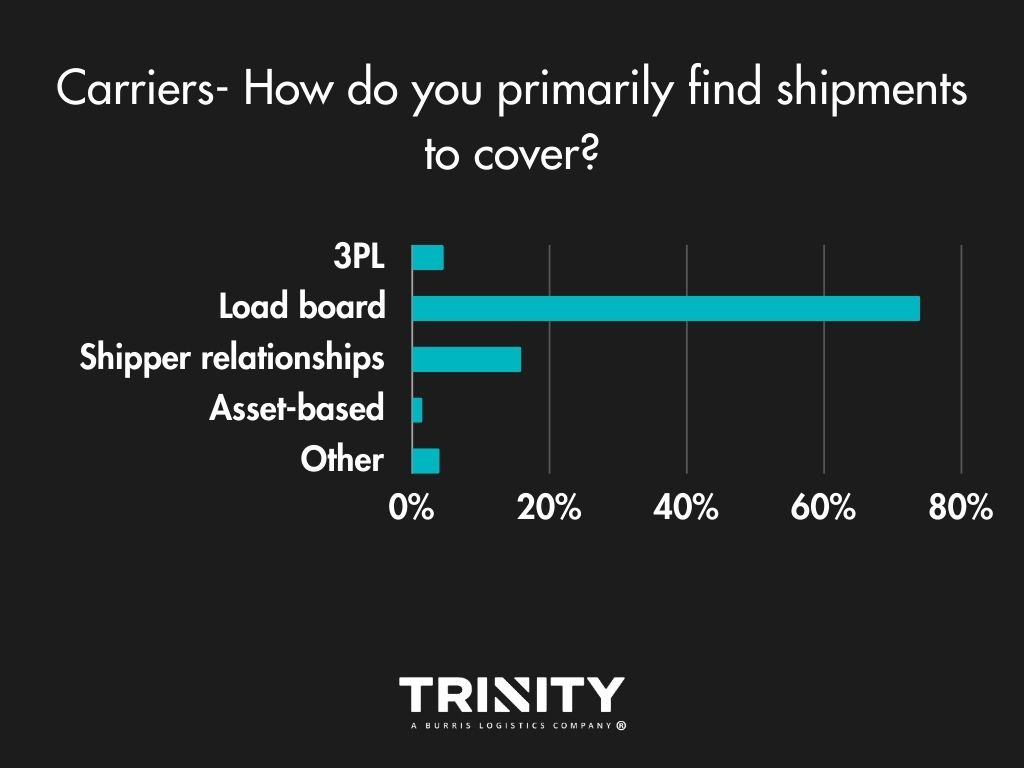

With 74 percent selecting this option, load boards are the norm for carriers to find available shipments. Sometimes they use their shipper relationships, and occasionally they make use of a 3PL.

3PLs – Expanding a Carrier’s Reach

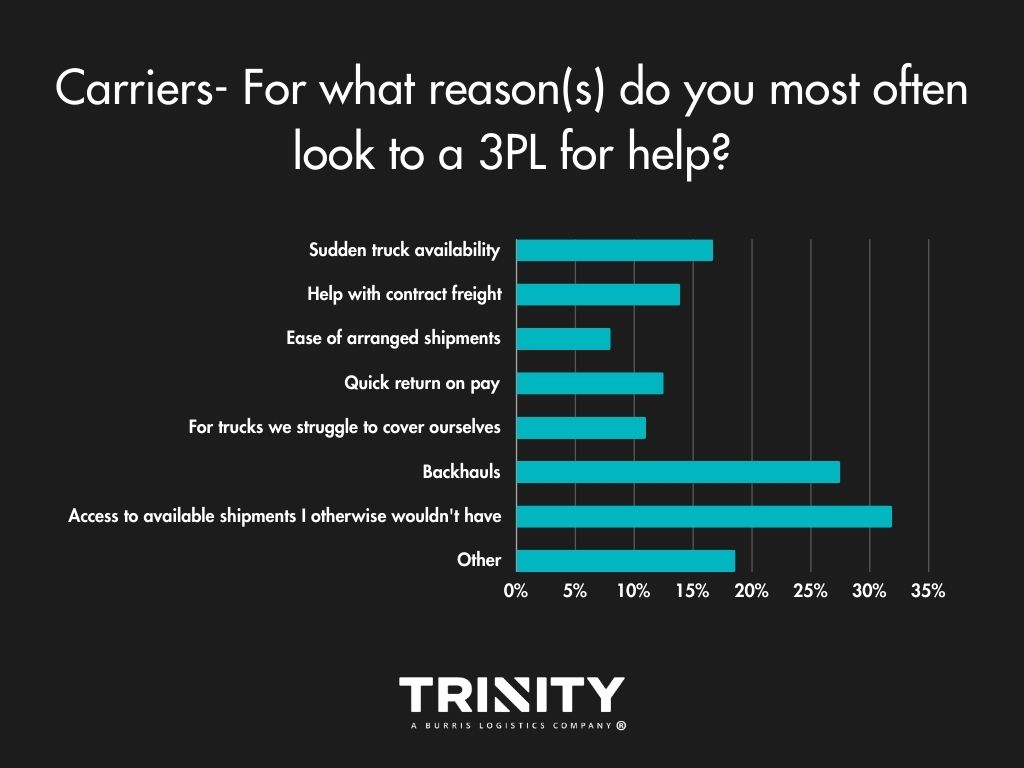

Carriers most often look to a 3PL for help with gaining access to available shipments that they wouldn’t have otherwise. Covering backhauls are another big reason carriers reach out to a 3PL.

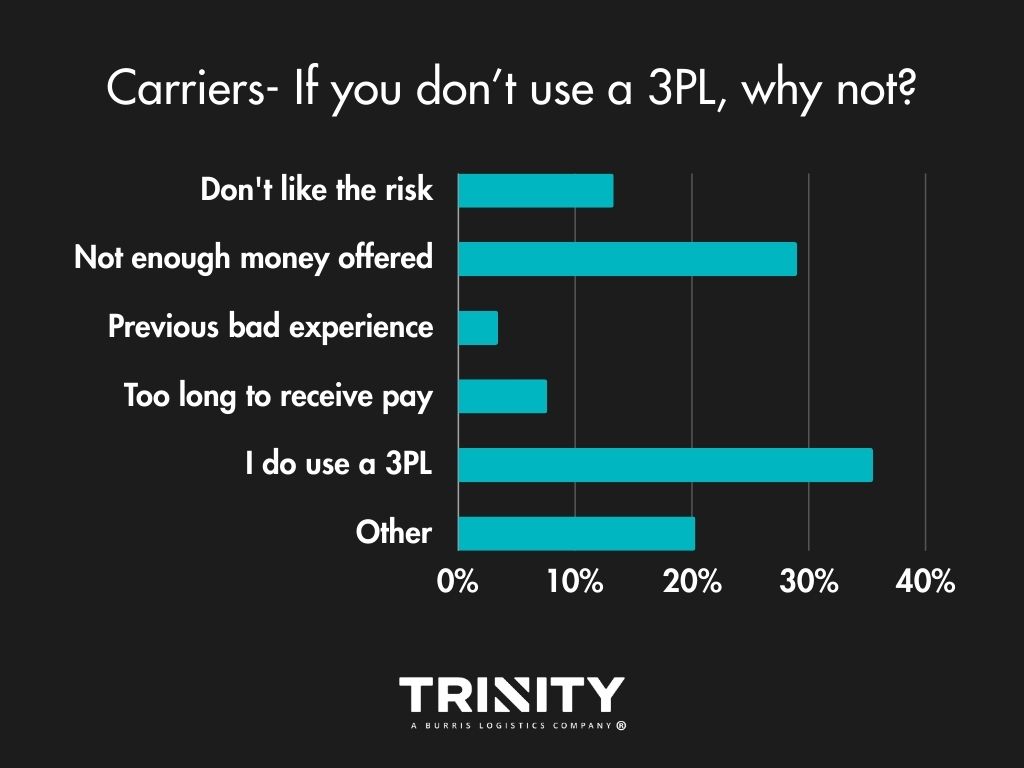

For those that choose to not work with a 3PL, it’s often because of money; rates not being high enough. Surprisingly in the comments, many are not familiar with what a 3PL or freight broker is as well.

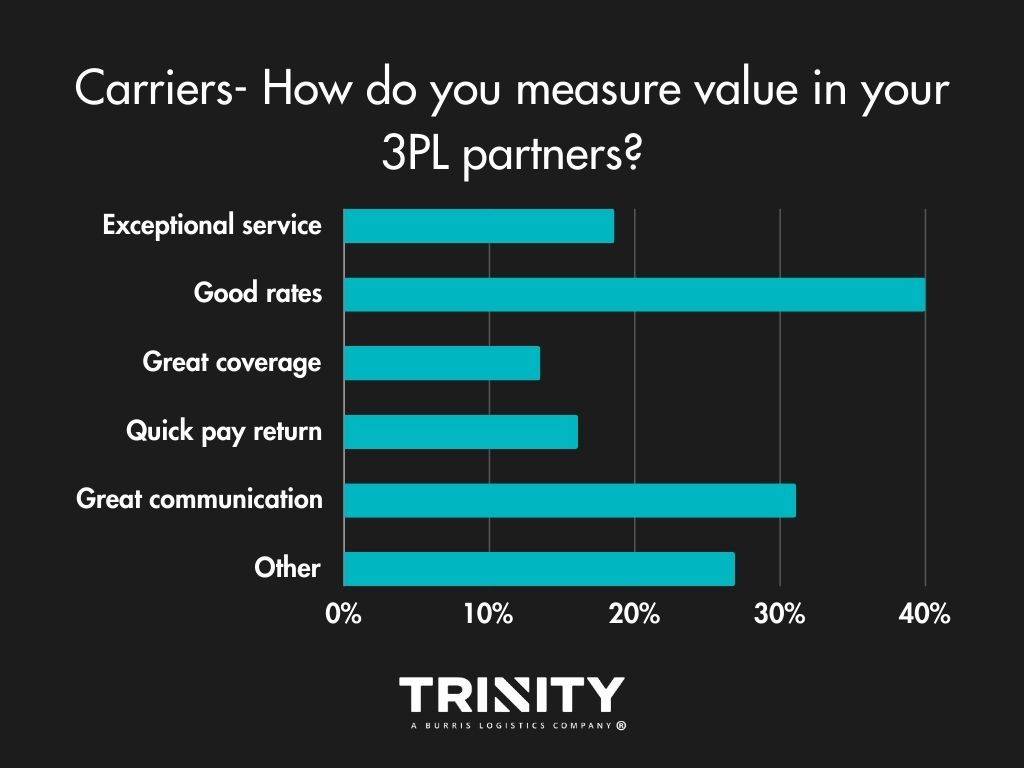

When it comes to measuring value in their 3PL partners, most carriers want good rates and great communication.

Fraud Concerns Growing

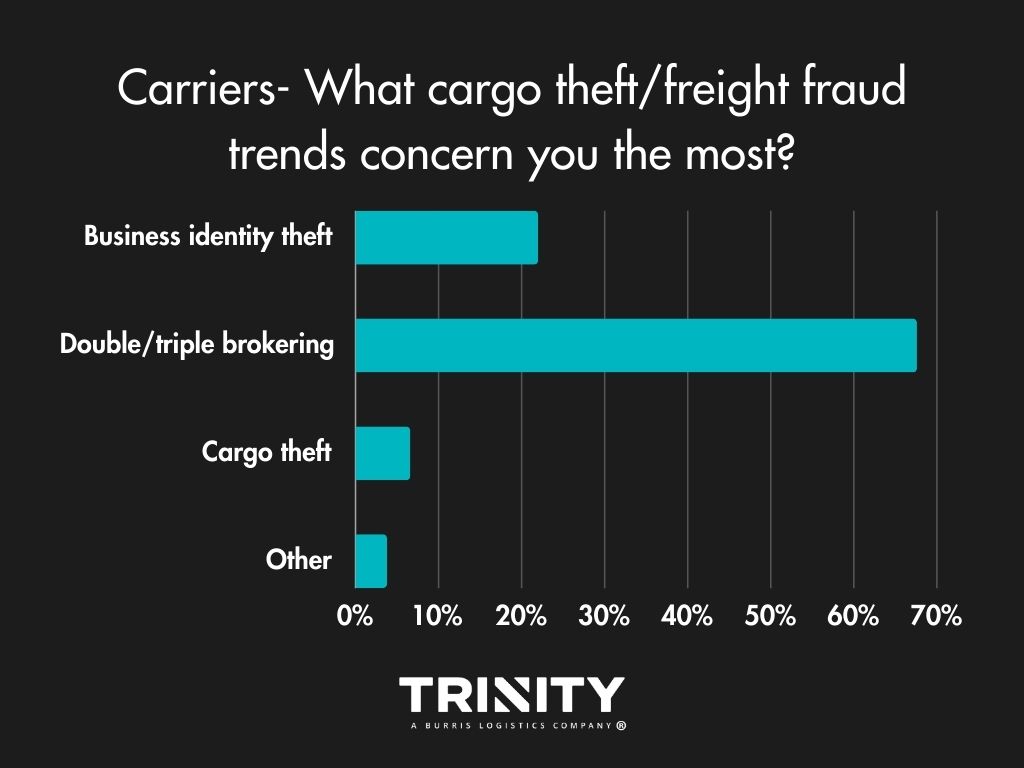

Fraud and scams have been growing in the industry, so we wanted to know what carriers think about it. Carriers are most worried about double and triple brokering affecting their businesses compared to concerns of identity theft or cargo theft.

Have you ever wondered what drayage is? Perhaps you hear the term mentioned by other shippers, motor carriers, or your logistics providers. You’ve likely heard some other terms associated with drayage, like demurrage or drop fees, and are curious what those are. Well, if drayage is piquing your curiosity, we’re here to help you learn what it is and if it’s for your business. Here are the most asked questions we receive about drayage from our shipper relationships.

What is Drayage?

This is a great question. You’re probably wondering, what does drayage even mean? Essentially, drayage is the local movement of a container from point A to point B, usually less than 100 to 200 miles. Point A and point B can be moving it from a terminal or port to a receiver or from a shipper back to the terminal or port location.

How Does Drayage Work?

There are two different forms of drayage – imports and exports.

For example, let’s say you have an imported container coming into the U.S. from another country into a terminal, like Los Angeles. As your third-party logistics (3PL) provider, we help you arrange the move of that container to be picked up by a drayage carrier at the terminal and transported to its destination or receiver.

Now, for the second example, let’s say you have freight that you need to get transported on a ship from the U.S. to another country. As your trusted 3PL, we’ll help arrange a drayage carrier to assist you in getting your freight to the port. That drayage carrier will pick up an empty container from the terminal and bring it to your pickup location to get loaded. Then the drayage carrier will take the container with your freight to the port to be loaded onto the ship.

Why is it Called Drayage?

The term dray refers to the movement of freight in a local setting, so a very local move. The word dray stems from moving freight or something heavy in a cart or wagon with no sides. This used to be done using horses, so you’d have dray horses moving dray carts. However, now the containers have replaced the carts, and trucks have replaced the horses, but the movement of freight still refers to a short, local move.

What’s the Difference Between Drayage and Freight?

Drayage itself is the movement of the freight. But what is the freight? The freight is the actual product being moved via drayage.

What is Demurrage?

First off, it’s pronounced like “duh-mur-uhj”. As a customer, you may see or hear the term demurrage from time to time. Essentially, it’s a storage fee.

Once your container arrives at its terminal or port, they are going to give you a certain number of days in which your container can sit there for free.

For example, let’s say you have three free days. Your container arrives on June 5th, so you have June 5th, 6th, and 7th, in which your container can sit there, free of charge. Once June 7th approaches, that is called your Last Free Day (LFD). LFD is a term you will hear very often. Once it’s June 8th, that is going to be the first day of demurrage, or the terminal or port charging you for storing your container and taking space in their yard.

Why is Drayage Important?

You may be wondering, what’s the big deal with drayage? Why do I hear this term so often? What do I need to know about drayage?

Drayage is important because it’s another mode, another way to move your freight. Instead of a standard truckload or less-than-truckload (LTL), it’s another way to get your freight overseas to its destination in the U.S. or from the U.S. to overseas. Really, it’s another way to reach your market or suppliers that may not be located here in the U.S.

What is a Drop Fee in Drayage?

This is important, as you want to know all the fees you may incur. You may be told that there’s a drop fee on your shipment. In a traditional shipment when picking up or delivering, they are being loaded or unloaded right then and there. This is what we call a live load.

In drayage, if a receiver says, “I need you to drop this container today, but we likely won’t be able to unload it until tomorrow. I’ll let you know once we can unload it and then you can come back.” This is where a drop fee comes in. Since the drayage carrier will have to drop the container and then come back to pick it up, the drop fee is a charge by the carrier for having to come back and pick up the empty container to return it to the terminal or port.

You want to make sure you’re having conversations with your logistics provider to get a full understanding of what’s needed for that container. Are they loading and unloading live or is it loading and unloading as a drop? That way you know whether to expect any drop fees.

What is a Chassis? Who Owns Them?

A chassis is the underbody of the truck and container. It’s what the container sits on. Pickup trucks have chassis, as do your 53-foot dry vans.

Drayage carriers do not own chassis. Instead, the drayage carriers must rent the chassis from the terminal or port. Once the drayage carrier has the chassis hooked on, a crane will load a full or empty container onto the chassis for them to transport.

What is Overweight for Drayage?

Every drayage carrier has slightly different weight limits, but universally there are some general limits.

First off, you have different types of containers and sizes. The standard sizes are 20-foot and 40-foot containers, and you have refrigerated (also referred to as a reefer) or dry containers.

Refrigerated containers will be able to hold a little less than your dry containers because reefer containers hold heavier freight, like frozen goods. They also sometimes have generators connected to them as well, taking away from the amount they can carry.

A 20-foot refrigerated container can hold up to around 36,000 to 38,000 pounds.

A 40-foot refrigerated container can hold up to around 38,000 to 40,000 pounds.

A 20-foot dry container can hold up to 38,000 to 40,000 pounds.

A 40-foot dry container can hold up to 42,000 to 44,000 pounds.

Make sure you’re having a conversation with your logistics provider to get a full scope of the weights that can be handled so your freight can be loaded correctly on those containers.

Who Needs Drayage?

Well, if you’re reading this article, you might be considering drayage because there may be some point at which your business will need it. It’s a great mode and tool to have when you may be talking to other suppliers overseas. Drayage is one way to service them. For example, with drayage, you can say, “Not only can we get your freight from Germany to California, but we can do that final mile delivery for you as well.” It gives you more to offer your partners and another way to move your freight.

How is Drayage Cost Calculated?

As a customer of Trinity Logistics, we want to make sure we’re transparent with you and that you understand all the different charges that you may see or come across.

Typically, you’re going to have three charges that you’ll see on most of your drayage quotes.

First, there’s your line haul. That’s moving the freight from point A to point B.

Then, there’s your fuel surcharge, which is a percentage of your line haul for fuel expenses.

Lastly, there’s the chassis charge.

As far as any additional charges, your Trinity relationship will provide you with a list of any potential charges that may arise, such as that overweight fee, drop fee, hazmat, or refrigerated fee. We want to make sure you know exactly what you’re being charged so there are never any surprises.

LEARN MORE ABOUT TRINITY'S DRAYAGE SERVICE.As more shippers look to reduce freight costs and their carbon footprint, intermodal logistics continues to see rapid growth. The Intermodal Freight Transportation Market has predicted a Compound Annual Growth Rate (CAGR) of 8.27 percent from 2021 to 2026 for intermodal logistics. And with intermodal peak season on the way, shippers using this mode must have the right shipping strategies in place.

Intermodal can be a very effective mode when it matches up with the right customers, but with the rapid growth of customers choosing intermodal logistics, we often hear a similar question from our shipping customers: “What should I expect during intermodal peak season?” So, let’s learn more about what peak season for intermodal is, how it may affect you, and what you can do to stay ahead.

WHEN IS INTERMODAL PEAK SHIPPING SEASON?

Peak shipping season refers to the time of year when freight volumes see an influx. For most modes, this falls in line with the time of year when retailers begin pushing inventory for back-to-school and the holiday season. During this time, shippers try to keep up with demand and manage inventories while fulfilling a high volume of orders, and motor carriers are busier than usual trying to deliver freight on time.

Historically, the peak shipping season for intermodal logistics is around June to December. While June may seem a bit early, many shippers are rushing to get their goods through West Coast ports before June 30th, and rail is a popular way for shippers to transport their West Coast imports. According to the Alameda Corridor Transportation Authority, since 2006, the number of goods imported and then loaded into intermodal equipment through Los Angeles and Long Beach ports has grown 25 percent.

With roughly two-thirds of intermodal containers coming off the West Coast from import traffic during peak season, this limits the supply of 53’ containers heading East.

Even though June is the typical start of peak season for intermodal, it can fluctuate. Some years it can be later or earlier. But since the start of the pandemic, intermodal logistics have been greatly affected by capacity, making peak season more year-round than in former years. This is because of the rapid increase in online shopping year-round for consumers, which the pandemic only heightened.

“The past two years since the beginning of covid-19 has greatly impacted intermodal capacity,” says Jennifer Fritz, Trinity intermodal expert. “Historically peak season for intermodal logistics usually starts June through December, but with capacity affected by the change in supply chains from covid-19, it’s been tight year-round, making peak season pressure felt year-round instead of a few months of the year.”

CHALLENGES OF INTERMODAL PEAK SEASON

Expected or unexpected, any time there is a major shift in supply chains, it can throw off your operation. So, how does peak season affect intermodal logistics? Well, it’s not much different than peak season shipping for any other mode.

You’ll see tightened capacity because of the increased freight volumes and demand. And anytime we see tightened capacity, we see increased prices as well. So, the more in demand something is with less supply, it equals higher rates.

You’re also bound to see some shipping delays and need to give longer lead times. Your usual service levels may also drop because of the overwhelming volumes of freight needing to be moved during peak season shipping. Especially lately with the continued covid-19 pandemic still affecting the market, West Coast ports, and ultimately, intermodal logistics.

Take Control of Your Intermodal Logistics During Peak Season

Make sure you’re not unprepared for intermodal peak season. Each peak season is variable, rarely unlike another, and planning is more critical than ever with it being more frequent and extreme. Here are some tips to help you take control of intermodal peak season.

Give Even More Lead Time

Book your intermodal shipments as far in advance as possible. Prices are volatile during intermodal peak season, and the rate to move a shipment through intermodal logistics can increase by hundreds of dollars over a single day. In addition, available equipment can often be an issue. This is not the season to wait until the last minute.

Stay Updated on the Industry

Ever since the start of the pandemic, it’s more important than ever to know what’s going on in intermodal logistics. As we’ve seen over the past few years, supply chain disruption can happen at any time, so make sure you check the news daily or have a good resource to give you all the information you need.

Try Shipping Later

Perhaps all your items don’t need to arrive during peak season. Great. If possible, schedule those shipments to ship after intermodal peak season, when there is more capacity and you’ll likely get a better shipping rate, or at least stagger them. So, if part of your shipment needs to arrive right away, have that delivered faster. And for any freight that doesn’t need to deliver quickly, schedule that shipment for a later date.

Plan for Extra Time

As noted, with the influx of freight needing to be moved, there are bound to be delays. Many intermodal carriers have fully planned days and if they get delayed, it affects the rest of their movements. So, make sure you allow plenty of time for your products to get to their destination. This will help keep a delay from happening and possibly get you a better freight rate.

Shop Around

Prices can fluctuate between providers and from day to day. If you have the time, try getting prices from a few different providers or being more flexible with your dates to see if you can find a better value. For example, the difference between a 15-day delivery time and a 20-day delivery time could be significant. Check out all avenues and find what works best for your budget and freight.

Have Modal Flexibility

Sometimes a mode will max out on capacity. If capacity is reached for intermodal logistics, ensure you have relationships with over-the-road carriers or a third-party logistics company as a backup. This ensures no matter what, you’ll be able to get your freight from point A to point B.

Leverage Partnerships

Partnering with an experienced 3PL can make navigating peak season for intermodal logistics, or any logistics mode, more accessible. Companies, like Trinity Logistics, often have longstanding relationships with carriers for all modes, plus logistics technology and well-trained teams ready to help you. A reputable 3PL will have seen it all during peak shipping seasons and be able to help you manage your logistics without batting an eyelash.

GET HELP WITH YOUR INTERMODAL LOGISTICS, NO MATTER THE SEASON

While we can’t look into a crystal ball and predict how long this never-ending peak season for intermodal logistics will last, we can tell you that many logistics providers and shippers are adapting. Intermodal peak season shipping can be stressful, but these tips can help you better navigate your intermodal logistics during the peak shipping season.

If you’re looking for help, Trinity Logistics is here to support you. We have a full Team of Intermodal Experts, experienced and ready to assist you with your intermodal logistics. Simply click the button below and let’s get connected.

Learn about our Intermodal serviceWith cold chain logistics, every product that you deal with has very specific temperature requirements that you need to adhere to. These products are ending up on tables across the entire country, so you want to make your product arrives precisely the way it needs to be so it’s safe for human consumption. Because of this, cold chain logistics can be challenging to manage, and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. It would undoubtedly be helpful to find one provider that could offer you end-to-end cold chain management, from production to delivery. And that’s what we’re here to talk about today. Burris Logistics and Trinity Logistics working together could be the solutions you’ve been looking for to simplify your cold chain management. Keep reading to find out how we work better together to serve your complete cold chain.

BURRIS LOGISTICS CAPABILITIES

Let’s start with Burris Logistics. What do they offer that can enable cold chain shippers and their businesses to thrive in the face of its complexities?

Quick Background

Burris Logistics has been around for 96 years. The company started as a produce hauler from southern Delmarva to Philadelphia. They quickly grew and expanded into the frozen food business and found their purpose as a driven food logistics provider. Today, they own 14 cold storage sites up and down the east coast and out into Midwest. Burris Logistics currently has a family of brands including Burris PRW Plus, Honor Foods, and Trinity Logistics.

Burris Logistics offers you logistics technology solutions that never sleep. With a Technology Team of over 100 Team Members, they work around the clock to provide you with technology resources designed to meet your specific needs.

From a Burris asset standpoint, they’re able to track all their trailers with ELD and reefer tracking, with the ability to ping the tractor and trailers to see where each of their assets are in real time. In addition, they have access to technology that can start and stop the units, reset them, or check temps on them, no matter the distance. With the complexities of cold chain transit and the current driver shortage, Burris works hard to put in place any technology that can make a driver’s job easier. They want to cut any obstacles drivers may face on the road while having any data be transparent to help both them and ultimately, any customers.

Burris also has technology for their cold storage warehouses. They focus on providing their customers with freshness, clarity, and visibility. They offer real-time monitoring and any differentiation from setpoints gets recorded. They make sure to get real-time data to those who need it should meaningful decisions need action, and have secondary and tertiary backups available.

Some of their other logistics technology offered are:

· Warehouse management system software

· Enterprise resource management

· Produce inspection tool

· External integrations

· Supply chain portal

· Demand planning

· Order status

· Delivery status

Burris Logistics works with you to create the best possible warehousing and distribution solutions. They’ll support you with a network of strategically located warehouses, 96 years of expertise, and a solution customized for your unique needs.

In a reflection of national trends, the newest and fastest-growing business line within Burris Logistics is their direct-to-consumer to support those in the cold chain e-commerce space. Through current resources and expertise in temperature-controlled logistics, Burris can deliver a premier frozen fulfillment network with cutting-edge technology, thought leadership, and warehouses across the country. Burris’s knowledge of shipping supplies, coolant technology, and two-day parcel shipping capability ensures quality is delivered with every package.

Facility Design is the process of considering new construction via greenfield facility sites or the re-purposing of an existing operation. Many companies are facing changing business needs, including the need for multi-channel execution. This makes the ability to scale up and scale down with various capabilities an essential part of planning. With partners who increase their dependency on Burris Logistics, they’ve been able to scale their operations to accommodate their programs with new locations, modifications to existing assets, and technology to keep the supply chain efficient.

Your customers desire the right products, in place, at the right time. Honor Foods, a Burris Logistics company understands how important it is to have on-menu and on-shelf products available while also minimizing food waste. They can help you plan inbound and outbound freight, using logistics technology and their warehouses to maintain food quality and safety.

With one of their other brands, Honor Foods, Burris offers Private Label In-house brands that have developed into trusted names amongst food service operators. These products undergo scrutinous selection and quality assurance knowing that our restaurant partners only accept the best. Your customers want what is trending, and Burris can help you meet this demand. Their brands come sourced from trusted shippers and can be a noticeable cost saving for you.

Burris Logistics understands that products need different environments, which is why their facilities can provide different temperatures and humidity, depending on your product. Newer warehouses are purposefully being built with ambient/dry storage space to accommodate increased partner needs. Additionally, their warehouses and distribution centers are in strategic locations near major transportation hubs and ports, making it easy to get your freight on the move quickly.

TRINITY LOGISTICS CAPABILITIES

Quick Background

Trinity Logistics has been around for over 40 years. The company was started by the Banning family in Cambridge, Maryland. Throughout the years, the company grew and expanded as a non-asset-based third-party logistics company (3PL) and was acquired by Burris in 2019. The two companies saw similarities in company culture and future goals, deciding to unite for greater opportunities and offer more supply chain solutions for our customers.

Burris + Trinity = Better TogetherURRIS

What’s great for Trinity being part of the Burris Logistics family of brands is being able to offer more help to Burris customers. Trinity’s support helps Burris better assist some of the existing freight business they have for customers either coming back into their buildings or going to other places.

The addition of Trinity also offers Burris customers a wider variety of options in modes and technology, or even help outside of the cold chain. Trinity is very experienced in heavy haul moves or more complicated hazardous moves for the chemical industry. So, no matter the size of your company or freight, we have a solution for you. But, we’re here to talk about the cold chain, so let’s focus on refrigerated and frozen freight.

While it’s not always hard to find a refrigerated carrier, you do want to be selective. There are a lot of carriers out there, but Trinity has a robust vetting process in place. We make sure carriers hauling your freight have the right amount of insurance, requirements, and experience. In addition, we make sure these drivers are representing Burris and Trinity the way we need to and that our customers are getting their products delivered safely.

You might ask, how do we guarantee safety with our carrier network? Well, these carriers mean as much to us as our shipper customers do, so we build just as strong carrier relationships. We offer our carriers many different kinds of technologies for location tracking, temperature tracking, and so on. We make sure to continue to evolve our technology solutions to keep the shipping process easy and safe for both carriers and customers. Additionally, we have our communication. Our communication is one of our strongest assets to ensure both parties have their needs and solutions met. Our bottom line is bringing value and if we can do that, we’ll be successful.

We offer and use several different technologies like Macropoint or Fourkites, so we can ping shipments and know exactly where they are and what the temperature of the product is, giving our customers instant access to look at their freight. That’s just one piece of the technology puzzle.

Even with the technology available, we never lose contact with our customers. We strive to stay very People-Centric. Our technology only helps make it easier for our customers to view information, especially with our Customer Portal, giving them the ability to trace loads without having to reach out. It gives them access to see updates at any time of day and offers backend access to their invoices to answer billing questions, make payments online, or provide them with a breakdown of what each load costs, lumper fees, accessorials, or pallet exchanges. Our Customer Portal allows you to manage that piece of business on your own time and at your own speed. We’ll always be available, but the Portal and any of our technologies are there to bring you even more value and efficiency.

Current logistics technology available:

· Carrier Portal

· My Carrier Packet

· TriumphPay

· FourKites

· Trucker Tools

· MacroPoint

· Customer Portal

· Customized Transportation Management Solutions

· Banyan LTL

· DAT Book Now

· Trucker Tools Book It Now

WAREHOUSING

We know that one size does not fit all when it comes to warehousing. That’s why we have warehouse providers with locations across the nation to allow you to scale your business at your own pace, plus our cold storage solutions with Burris Logistics. Our growing network supports reliable service and premier dry, refrigerated, or frozen solutions so you can focus on what you do best.

TRUCKLOAD

Our truckload service provides you with the means to get your freight moving quickly. Truckload is faster than traditional LTL or intermodal shipments which means your shipments can arrive on time and on schedule.

LESS-THAN-TRUCKLOAD (LTL)

Our LTL service provides you with the means to get your freight hauled through a range of options. By leveraging our volume and extensive network of LTL carriers, we can provide you with lower rates for LTL shipments consisting of 1-10 pallets of either dry or temperature-controlled products.

INTERMODAL

You can add value to your supply chain by using this cost and environmentally-friendly shipping option. By shipping intermodal, you’ll reduce your carbon footprint and have reliable and consistent capacity when over-the-road capacity can be tight.

EXPEDITED

Sometimes your freight is time-sensitive or needs less handling. When this happens, we can arrange over-the-road or air-expedited shipping. We’ll make sure your freight arrives on time and without stopping at terminals in between.

DRAYAGE

Your freight can be delivered from the port or rail right to your door, or from your door to the port or rail. Either way, we’ll save you money in the process. From servicing imports and exports, returning empty or full containers, helping you avoid unnecessary fees, long drayage options, or more, our Team is ready to help.

INTERNATIONAL

Arranging international shipments can be tricky and requires a lot of communication. If you are looking for help with arranging your Full Container Load, Less Than Container Load, door-to-door, or port-to-port services, we can help. We’ll be your intermediary with freight forwarders to arrange your air and ocean freight international shipments.

MANAGED SERVICES

In this service, we combine our experienced account management and best-in-class transportation management technology to deliver you a customized solution that helps your company achieve its unique supply chain goals.

HOW WE CAN SERVE YOUR COLD CHAIN BETTER TOGETHER

Experience in Cold Chain

For many reasons, Burris Logistics and Trinity work well together for cold chain shippers. First off is our combined years of experience. There are certain things in cold chain you can only learn from the experience of working with temperature-controlled shipments. For example, things like picking and loading fresh produce, understanding what those temperatures are and what they need to be for storage and transit, and keeping track of those temperatures. Or understanding how to move ice cream from the West Coast and knowing that you can’t go over the mountains; that you must travel around them so as not to cause shrinkage. By having years of experience and understanding of those complex situations and small details that make or break a cold chain shipment, you can trust your temperature-controlled freight is handled safely and correctly with Burris and Trinity.

Technology

Between both Burris and Trinity, we have incredible logistics technology available, but what differentiates us from others is that we keep in mind that logistics is still a “people” business. Technology will always be a tool for our Teams to use and bring logistics solutions to other people who need them. Therefore, we try to stay away from technology just for technology’s sake and make sure what we use and offer is always a valuable solution.

Communication

Because of our years of experience, we are well-versed and experienced in many different situations. We know when and how to pivot quickly and keep business moving forward. When issues arise, we work until they are resolved and keep open communication every step of the way. Having a solid relationship with experts like Burris and Trinity will prove to be your largest asset no matter what supply chain bottlenecks you may face

Flexible, Customized Solutions

Because our two businesses offer many options while keeping business People-Centric, it means you can find a solution that’s customized for your growing business and needs and your solution can be flexible. We know the cold chain and solutions aren’t static, they are ever-changing, so you need a provider that can keep up. By working with Burris and Trinity, you’ll never have to worry about changing up your logistics plan as we’re readily equipped to accommodate any changes you may need. In addition, we can help you stay flexible as one sole provider instead of working with several.

Visibility and End-to-End Cold Chain Management

As the cold chain sector continues to grow, there’s been a growing demand for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the logistics of their temperature-controlled freight. Working with Burris and Trinity can not only give you a wide range of technology to gain visibility and provide you with all the logistics services you may need, thus making your cold chain efficient and transparent. We’ll provide you with dedicated, knowledgeable experts, increased productivity and workflows, and reduced complexity by working with Burris Logistics and their family of brands instead of several different providers.

HAVE YOUR COLD CHAIN LOGISTICS TAKEN CARE OF, END-TO-END

Between Trinity and Burris, we have a substantial Team with a lot of experience in cold chain and knowledge about its potential pitfalls. As a result, we’ve created processes and different services so that we get it right the first time, every time we handle a cold chain shipment.

You can find value in our combined companies’ sizes and services offered. Cold chain logistics can be complicated and trying to do it all alone can be frustrating. That’s why we’re here to help you simplify it. You can count on Burris Logistics and Trinity to serve and support your cold chain all the way from production to delivery, and every step between.

FIND YOUR END-TO-END SOLUTION WITH BURRIS LOGISTICS GET A SHIPPING QUOTE FROM TRINITY LOGISTICSMany companies and consumers are waiting and wondering, where are my goods? If you work in logistics, then you know exactly where they are. A significant number of ships are waiting outside of U.S. ports, carrying millions of dollars worth of goods ordered by Americans. What started as a binge in online ordering during the pandemic has had lasting effects on supply chains. There’s continued to be overwhelming demand, creating port delays which then caused higher shipping rates, newly created fees, and so many more issues brought to light among global supply chains. We’ve seen record-breaking highs of imports throughout the year and currently, there’s no end in sight. Many are trying to find solutions and put them into place to get out of this hole we’ve dug, but is it working?

PORT PROBLEMS

Before the surge of imports faced by the ports, containers would wait at terminals for up to four days on average before unloading and delivering to warehouses. For those delivering by rail, it would take less than two days. Now, the average for ships waiting is nine days, if not more. Some have waited weeks. According to reported data by the Port of Los Angeles on November 12th, the average time ships had to wait at anchor was up to 16.9 days.

Besides the growing wait times are the increasing number of ships that are stuck waiting. According to Marine Exchange,before the pandemic, ports would see no more than 17 ships waiting to dock. However, recently it’s been common to find upwards of a hundred or more ships lingering in the ocean near ports, waiting.

It doesn’t seem there is one particular problem that is causing these backlogs and port delays. Rather, many port problems are being highlighted.

Returning Empty Containers is a Struggle

One of the loudest heard complaints adding to the port delays is the struggle truck drivers and companies are facing in returning empty containers. In a survey by the Harbor Truck Association, 15 companies responded that they had a combined 4,251 empty containers sitting. Additionally, 86 percent of them were on wheeled equipment and the rest were in stacks. One motor carrier stated that they had been stuck with empty containers since August 31st because the terminal would not accept them.

Many motor carriers and importers say there are port delays and cargo not getting picked up because the port terminals don’t allow drivers to return their empty containers and make a swap. Meanwhile, the port officials are saying they first need to make room to be able to accept them. Additionally, these sitting empty containers are further adding to these port problems by creating a chassis shortage.

Where are the Chassis?

First off, if the term chassis is new to you, let me briefly explain what it means. The chassis is a special trailer used to carry and transport the ocean container over the road. They are needed for truck drivers to be able to haul and deliver these containers.

A short supply of these chassis is another problem causing the growth in port delays. Typically, a truck driver will go to the port to swap the empty container they have and retrieve a full one to deliver. However, when truck drivers are turned away from the port with their empty containers, they will often park them and the chassis, at truck lots. But, without the chassis and ability to make a swap, they then can’t go pick up a full container from the port. So, currently, most chassis in Southern California are sitting under empty containers, strewn across truck lots.

Simply No Space

Another reason for the port delays is simply a lack of space. Warehousing and truck yards have been so full lately that they have little room to receive a new container of goods. Local officials have indicated some shippers eager at avoiding extended delays, ordered their goods earlier for next year, essentially using the ports as a makeshift warehouse for the time being. And even with the recent implementation of 24/7 operations at the Southern California ports, the ports may be running 24/7, but the warehouses are not. There’s just not a lot of space to put all the containers.

Lack of Labor

The labor shortage has affected every industry, but the ports are having a tough time clearing out all the freight due to a lack of labor. A shortage of dockworkers and truck drivers is one reason for port delays. Being that two-thirds of the cargo at the two ports in Southern California is hauled by trucks, these terminals are saying that the driver shortage may be to blame.

Inefficient Appointment Booking

Others are blaming the ports’ outdated booking system for the growing port delays. Usually, truck drivers must make an appointment to return an empty container and pick up a full one. But with the surge of freight and no space, port terminals have placed new restrictions. Every terminal has its own set of rules on when and where containers can be returned and picked up. This even pertains to the color of the container. With no centralized database, truck drivers are making bets by placing multiple appointments at different terminals in hopes they’ll meet requirements somewhere and get to return an empty container. Yet lately, the marine terminal could decide last minute that the terminal is full or that they aren’t accepting a certain color container that day and turn the truck driver away, usually after they have already waited a while. Terminals are saying that there are more no-shows lately with the truck drivers, stating that they just don’t show up 50 percent of the time.

Too Much to Handle

What may be the biggest problem with the port delays is that there is too much freight to be handled. Gene Seroka, the executive director at the Los Angeles port recently told 60 Minutes that the entire system is overwhelmed with the tsunami of orders that are flooding in from Asia to the U.S.

There can be many reasons to attribute to the growth in port delays. With everyone pointing fingers, one of the questions is, how do we get everyone to take some time off from playing the blame game and instead talk through a plan to clear out the backlogs at the ports? Because until then, the number of ships waiting off the coast of the ports is repeatedly breaking record highs.

PORTS HITTING RECORD HIGHS

Los Angeles and Long Beach

The number of ships waiting in the San Pedro Bay to dock at the port of LA and the port of Long Beach broke the previous record of 87 ships on November 15th, according to cFlow. To put that into perspective, the number of containers on those waiting ships is roughly 24 percent more than the port of Los Angeles imported during the entire month of September.

Back around October 14th, the cargo waiting off the two Southern California ports was worth around an estimated $25.5 billion, which is more than the annual revenues of McDonald’s.

At the start of November, there were nearly 60,000 containers at these ports that had been there for more than nine days, according to reported data by American Shipper.

Both Southern California ports are moving 19 percent more containers than in 2018, which held the previous record. Currently, the ports look to outpace 2018’s record of 17.5 million containers processed in 2018. This year alone, the two ports are looking to handle a combined 20 million twenty-foot equivalent units (TEUs).

Virginia

In October 2021, both the ports of Charleston and Virginia achieved container volume records. The Port of Charleston reported 234,923 TEUs handled, while the Port of Virginia’s new record was 318,000. That’s about a 16 percent increase year-over-year (YOY).

Combined, the Virginia Port Authority said that since August 2021, 444,600 imported TEUs had been processed, which is a 19 percent increase YOY. Additionally, there was a nine percent increase in exported TEUs, with a volume of 254,600.

South Carolina

Since the start of the fiscal year, South Carolina ports have faced a 15 percent increase in processed containers YOY, having handled 919,440 TEUs. In October, South Carolina ports handled 107,773 imported TEUs, a 12 percent increase, with furniture imports rising 55 percent YOY and vehicles up 5 percent.

Georgia

In October, the Georgia Port Authority announced that, for the first time ever, the Port of Savannah had processed more than 500,000 TEUs in a single month. The previous record was 498,000 TEUs in March 2021, with the new record being 504,350 TEUs, an increase of 8.7 percent YOY.

TRYING TO SOLVE THE PORT CRISIS

24/7 Southern California Operations

In October, the Biden administration unveiled its plan to help the port delays in Southern California. Since the ports of Los Angeles and Long Beach account for 40 percent of the sea freight in the U.S., they wanted those two ports to be running 24/7. Having round-the-clock operations and pushing truck drivers to make appointments outside of peak times should help address some of the backlogs there.

Southern California Implements Fees

Also in October, the two ports announced that they would begin fining shipping companies $100 a day for every container left on the docks, past an allotted time. In their guidelines for the fees, shipping companies have six days to move containers if their next step is rail or nine days if the next step is by truck. Every day over, the fee would be increased by $100; so $100 the first day, $200 the second day, and so on.

The fees were initially supposed to go into effect November 1st, but it was then delayed to November 15th to give shippers and carriers more time to avoid the new fees. Even with the delay, the ports started keeping track of containers waiting on the docks on November 1st. As of publishing this article, the charges are delayed to November 22nd.

These emergency port fees were aimed at getting containers moved out of the ports faster. The charges will go to the carriers who would then pass it along to the shippers. These charges, if they go into effect, could become millions of dollars in fines. According to port data. as of Friday, November 12th, the Port of Long Beach had 17,314 containers for trucks over nine days and 575 containers by rail over six days. If the fees had gone into effect that day, ocean carriers would owe at least $1.8 million in combined fees.

Port of Long Beach Ups Container Stacking

The City of Long Beach also recently loosened zoning restrictions on container stacking temporarily. It used to be that only two containers could be stacked together at container yards and warehouses, but now they are allowing up to five to be stacked. The higher stacking could help free up some space.

The State of California Makes Efforts

The state of California has been working on its own efforts to improve the backlogs and port delays. Governor Gavin Newsom recently directed agencies to find any state-owned properties that could store containers near the ports by December 15th.

Additionally, starting November 17th, Newsom announced that California will increase weight limits for trucks carrying goods in and out of ports. The weight restriction has increased from 80,000 pounds to 88,000 pounds in hopes it will help speed up the processing of containers. This will be applicable through June 30th.

By the end of this year, the California Labor and Workforce Development Agency also have a plan to help the labor shortage affecting the ports. They plan to name an industry panel to explore how to increase training and education programs for port workers and others in the supply chain who could lose jobs with automation and the transition to clean-fuel vehicles.

Washington Also Implements Fees

In early November, the Port of Tacoma and Washington United announced one-off long-term dwell fees of $315 and $310 for loaded containers that sit at the terminals for more than 15 days. This is in addition to their current late fees of $230 every day for any that are waiting more than four days.

Pop-Up Container Yard Projects

Georgia‘s Port Authority is reallocating $8 million o open five pop-up container yards in Georgia and North Carolina. This will free up dock space for the Port of Savannah, which leads the U.S. in agricultural exports.

Cargo congestion has been so bad at the Port of Savannah, those officials are planning to use a small airport in Georgia as their temporary overflow yard. Containers will move to these pop-up yards by truck or rail to create more space for cargo coming off ships.

Infrastructure Bill

Lastly, there’s also the $1.2 trillion infrastructure package to help aid U.S. ports. This package contains funding for port equipment and upgrades, dredging and channel maintenance, marine highways, rail needs, safety improvements, and emissions lower projects. This includes $5.2 billion in direct funding for any ports that handle 90 percent of internationally bound cargo, according to the American Association of Port Authorities.

GOOD NEWS

Even though the port delays seem like there is no end in sight, there has been much good news on the situation recently. For one, the recent shift to 24/7 operations at the Southern California ports has already improved service times for container ships. The LA and Long Beach ports have seen a 20 percent reduction in the number of container ships spending more than nine days as more shippers have agreed to move cargo during off-peak hours.

Additionally, the recent fees announced by the Ports of LA and Long Beach have been delayed to November 22nd. This is because the port of Los Angeles has seen a 32 percent decline in the number of containers qualifying for the fee compared to October 28th. Both ports reported a combined 26 percent decline in aging cargo. Because of the significant improvement in clearing containers, the ports decided to push back the fee another week to give shippers and carriers an extended grace period. They will continue to track the data to see what steps to take next.

Since September 1st, the Port of Savannah has seen a decrease of 60 percent in waiting containers, as retailers have been picking up cargo more quickly. Because of the extra space for dockworkers, Savannah reduced the number of ships waiting by 40 percent. As a result, their turnaround times have been much quicker, around 41 minutes for a single move and an hour when dropping an empty container to pick up an import load.

ADVICE FOR SHIPPERS

Even still, experts don’t foresee a large slowdown anytime soon. Instead, port problems and delays will continue into 2022 because of all the challenges supply chains have faced and some of the solutions are longer-term.

What we’re seeing is more cargo owners working with their ocean carriers to try to diversify their supply chains. Some of this includes rerouting to less busy and backlogged ports or ordering only what is needed to give the ports more time to move containers instead of creating more backlogs by ordering too early.

The best advice we can give you when working with your logistics provider is to make sure you are communicating your shipments early on. Giving AT LEAST two weeks or more notice (more is better here!) will help you secure any type of capacity.

You should also prepare for any extra costs. This includes demurrage, port wait time, per diem, or other fees and charges.

Lastly, make sure you work with a provider who helps you with more than just arranging your shipments. Find a provider who also works as your logistics consultant. You want someone who has eyes and ears on the market and can communicate and help you navigate any current or future disruptions so you can get ahead.

LOOKING FOR A LOGISTICS CONSULTANT?

Trinity Logistics is here and ready to help you. We stay updated on the freight market and help you pick up on any early warning signs of disruptions or delays, finding ways to help you prepare for potential constraints to your shipping.

We treat your shipments as our own and work with you to find the best alternative solutions when needed. We stay dedicated and do not stop working until we can help resolve any challenges you may face with your logistics.

Our Team Members are true experts in the logistics industry. We’ve been in business for more than 40 years and have been through many cycles of the logistics market. Because of that, we do more than just arrange your freight. When you choose to work with Trinity, you’ll find you have a whole Team of logistics partners invested in your business. Our only goals are to simplify your logistics so you can succeed and see growth.

Request a Trinity QuoteAuthor: Christine Morris

All aboard! Intermodal (rail) shipping is a popular mode of transportation as it’s a cost-effective and greener alternative to truckload. Typically, rates for intermodal shipments will be lower than those for truckload shipments. With modern supply chain challenges, like tightening capacity on America’s highways and driver shortage, many shippers find intermodal to be a good transportation solution to have available. However, 2020 threw a curveball for many industries and modes of transportation, intermodal included. Here’s a breakdown of recent intermodal market trends and what you can expect currently.

PORT CONGESTION

Recent high levels of congestion at ports are causing service disruptions for intermodal providers. Port congestion is causing havoc on drayage and door-to-door intermodal. With the surplus of imports coming in from the backlog caused by Covid-19 and increased volume, chassis shortages and terminal congestion it’s having a negative effect on capacity – especially on the West Coast.

Delays in shipments and restrictions are being put in place by several intermodal providers. The congestion is being caused by the rapid increase in online sales and e-commerce, as well as other reasons such as labor disruptions, equipment shortages, and more. Retailers are also having to continuously restock because of the increase in sales. Typically, during the holiday season, there is a slowdown, but that didn’t happen in 2020.

Intermodal has consistently been moving since September 2020, with intermodal traffic being up 11 percent year-over-year in the past month. This is resulting in delays. Truck drivers are experiencing up to nine hours of wait time to pick up a container while shippers are seeing shipments delivered weeks late.

A DECLINING WORKFORCE

According to the Surface Transportation Board, November of 2020 had the lowest employee numbers of U.S. operations of Class I railroads since 2012. Year-over-year, employee headcount is down 13.7 percent since 2019 and down 1.58 percent since just October. With intermodal volume increasing and employees decreasing, capacity continues to be strained and rates remain high.

STRONG FREIGHT VOLUMES WILL CONTINUE

As consumers have continued to increase their online spending, companies are consistently needing to replenish their inventories. This looks to continue throughout the first half of 2021. Due to the recent stimulus and the vaccine coming into play, manufacturers are looking to put products back on shelves as consumers hopefully look to spending more in person again versus online. Regardless, freight volumes are expected to continue to remain elevated.

INCHING THE WAY BACK TO NORMAL

The intermodal sector closed 2020 with the closest numbers to pre-pandemic levels that they have been due to the heightened freight volumes. Capacity is looking to begin to loosen a bit for door-to-door intermodal across many markets. Rates are also looking to fall, currently down 4.2 percent the week prior as of January 5th. However, they still remain 6.7 percent higher from 90 days ago and up 79.3percent from a year ago. 2021 will hopefully bring us closer to the pre-pandemic volumes, capacity, and rates we used to know, but we certainly have quite a ways to go before that. Buckle in because it looks to continue to be a wild ride.

Luckily for you, we have a Team of experts here to help you no matter the current intermodal market conditions. For more information about our intermodal services or to get a quote,

CLICK HEREAuthor: Christine Morris

When Trinity Logistics first opened its doors in 1979 as Trinity Transport, the small family-owned company specialized in the arrangement of truckload freight. In the last decade, Trinity has expanded its focus into the arrangement of more specialty services, designing solutions that don’t necessarily fit within the cookie cutter of ordinary freight arrangement. One of those services is dray service, or drayage, which is typically needed with shipments where freight is coming into a port or being transported via intermodal, or rail.

What is Drayage?

Drayage is most commonly known as the act of pulling containers out of a rail yard or ocean port and either loading them or unloading them before returning the container to the port or rail yard, typically over short distances. With dray service, an empty or full container can be mounted on chassis, or a flatbed, to be delivered either from your door to the port or rail yard or from the port or rail yard to your front door. Drayage is an important part of the shipment and transportation of products to and from different modes of transportation.

The term “drayage” comes from “dray,” meaning a horse-drawn cart with low sides, used to transport goods a short distance. Eventually, the horse-drawn carts were replaced by trucks, but even today drayage refers to short distances between multiple modes. Drayage moves continue to prove highly valuable in keeping freight moving without interruptions. The upward trend in globalized trade has increased imports and exports that are shipped via ocean, drawing attention to the need for dray services.

Why is Dray Service Needed?

Most people in Logistics think of drayage as it relates to intermodal or containers on a ship, but here are two other dray services you may not have considered: shipment to shopping malls and trade shows. For many shopping malls, there may be a centralized loading dock or drayage area where receivers pick up from in order to limit congestion at the mall itself. If you exhibit at trade shows, you are probably familiar with paying bills for trade show drayage. Whether you ship directly to the show site or to a show warehouse, every company’s exhibit needs to get from the loading dock to its respective spot on the show floor. Imagine the traffic jam if that were left entirely up to the individual companies to retrieve their crates from the loading docks! Many trade shows employ outside services who provide drayage, delivering crates to each company’s designated exhibit space, and back to the loading dock after the show is complete.

We can arrange pickup and/or delivery in advance, on a tight turnaround for port cut, or to get your freight out before the Last Free Day. Our Logistics Team is trained in drayage and can help you avoid any necessary fees to keep your freight moving.

Think you could benefit from the arrangement of drayage services? Give us a call today!

Need a freight quote?

Fill out our simple form and a logistics expert will contact you with a quote within 24 hours.