Whether it’s lumber, piping, hay, palletized goods, or construction supplies, flatbed trailers, also known as open-deck trailers, can handle it all. Flatbed trailers are extremely versatile in their use, but that’s because, unlike enclosed trailers, there are many variations of flatbeds to choose from. If you’re considering a flatbed or open-deck trailer for your shipment, how do you know which one is best for your freight? This article will help you answer just that. Read on to better understand the different kinds of flatbed trailers that are available so you can make an informed decision on which one your freight needs.

Types of Flatbed Trailers

Flatbed trailers come in all shapes, sizes, and load capacities; each designed to carry different types of cargo. The one tricky part of flatbed shipping is choosing and finding the flatbed trailer that is capable of hauling your freight’s weight and size. It’s also important to note that anything exceeding legal dimensions and weight can be considered oversized and may require more to ship, such as state permits, police, escorts, or more.

Shipping oversized? Download our FREE Over-Dimensional Shipping Guide.*Important Note – Trailer capacity, weight, and dimensions mentioned in this article are general specifications and should be used as an estimated guideline. These can vary based on the trailer type, brand, or semi-tractor being used with it.

- Standard flatbed

- Extendable flatbed

- Step deck / drop deck

- Stretch single step deck / drop deck

- Double drop

- Stretch / extendable double drop

- Removable gooseneck (RGN)

- Stretch RGN

- Conestoga

- Side kit

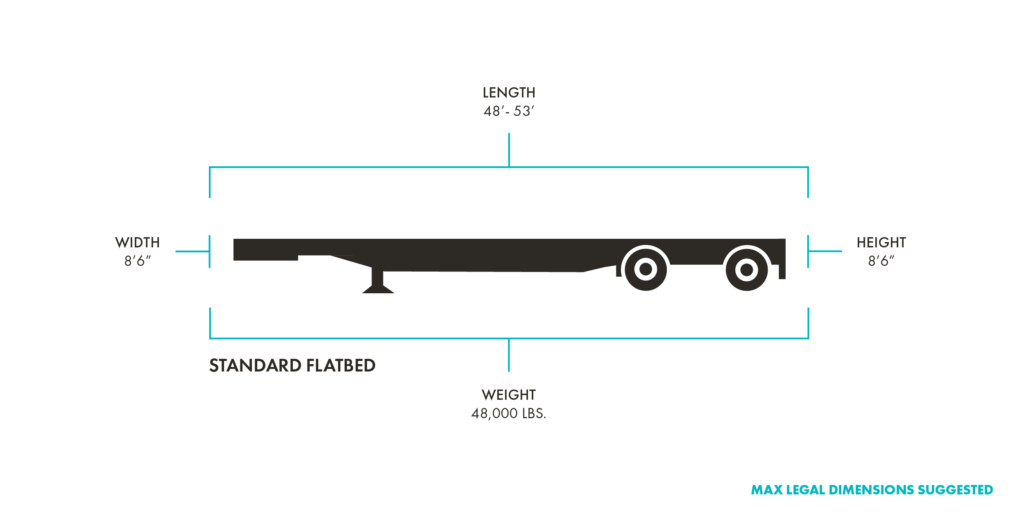

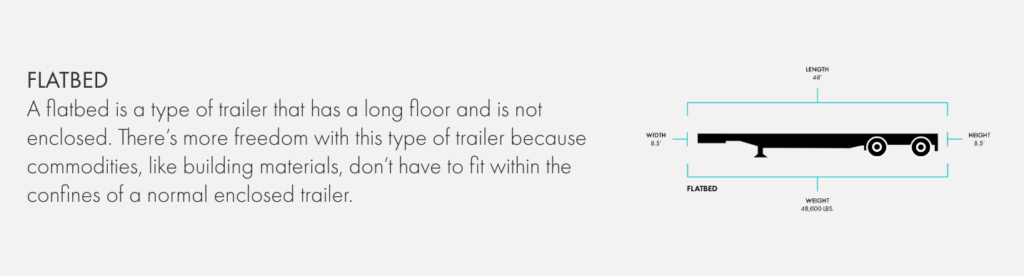

Standard Flatbed Trailers

Maximum Legal Weight: 48,000 lbs.

Maximum Legal Cargo Length: 48 to 53 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 8 ft. 6 in.

Standard flatbed trailers are widely used and versatile, often the most popular of all flatbed trailers. They most commonly haul steel, lumber, and other kinds of building or construction materials.

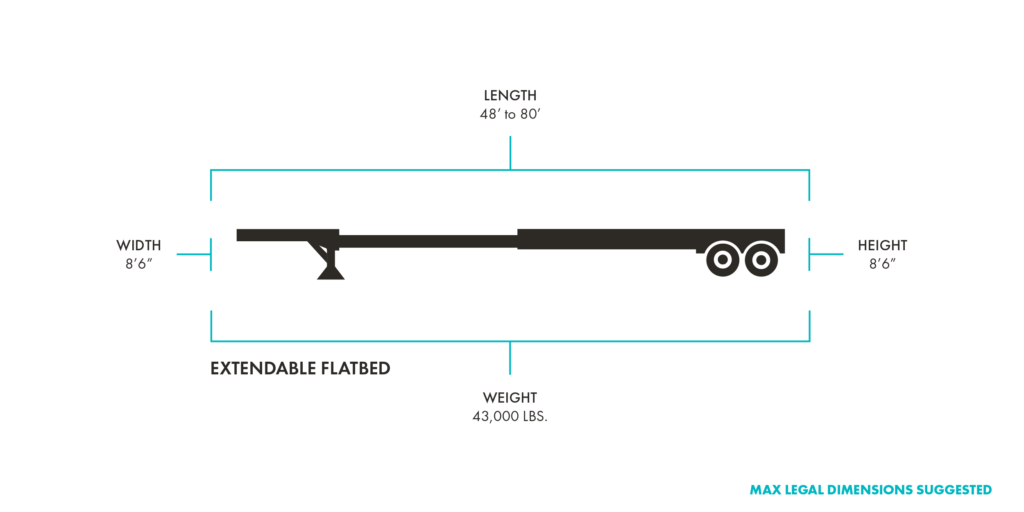

Extendable Flatbed Trailers

Maximum Legal Weight: 43,000 lbs.

Maximum Legal Cargo Length: 48 to 80 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 8 ft. 6 in.

Extendable flatbed trailers can also be known as flatbed stretch trailers. These trailers have an extendable deck to transport cargo that is too long for a standard flatbed, like a piece of large or heavy machinery.

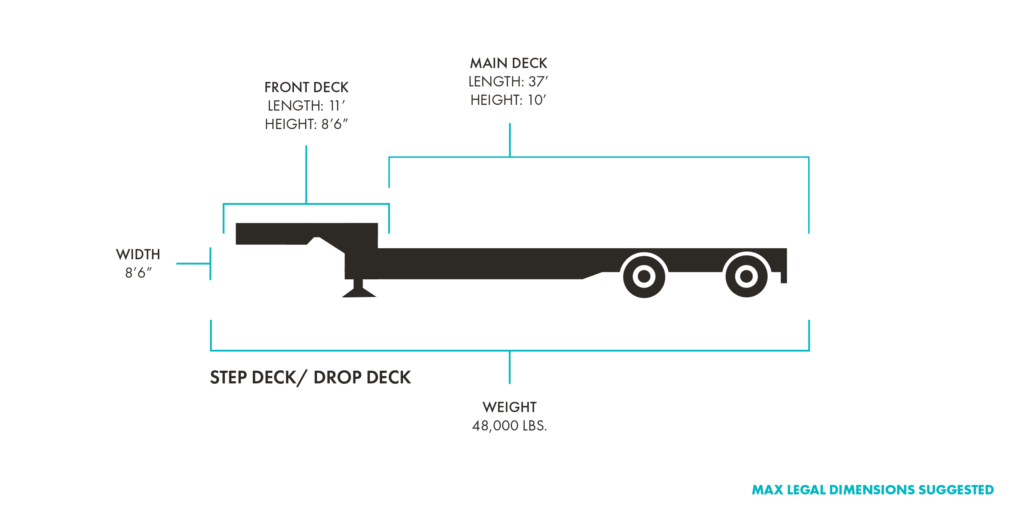

Step Deck/ Drop Deck Flatbed Trailers

Maximum Legal Weight: 48,000 lbs.

Top Deck: Maximum Legal Cargo Length: 11 ft.

Bottom Deck: Maximum Legal Cargo Length: 37 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 10 ft. on the bottom deck, 8 ft 6 in. on the top deck

These trailers are referred to as either a step deck or a drop deck. They consist of a bottom deck and a top deck. These flatbed trailers are great for transporting freight that would exceed the height restriction on a standard flatbed; they are ideal for any tall loads that need to go under low bridges. They also make it easy to use ramps to load and unload freight. A common piece of freight they haul is tractors.

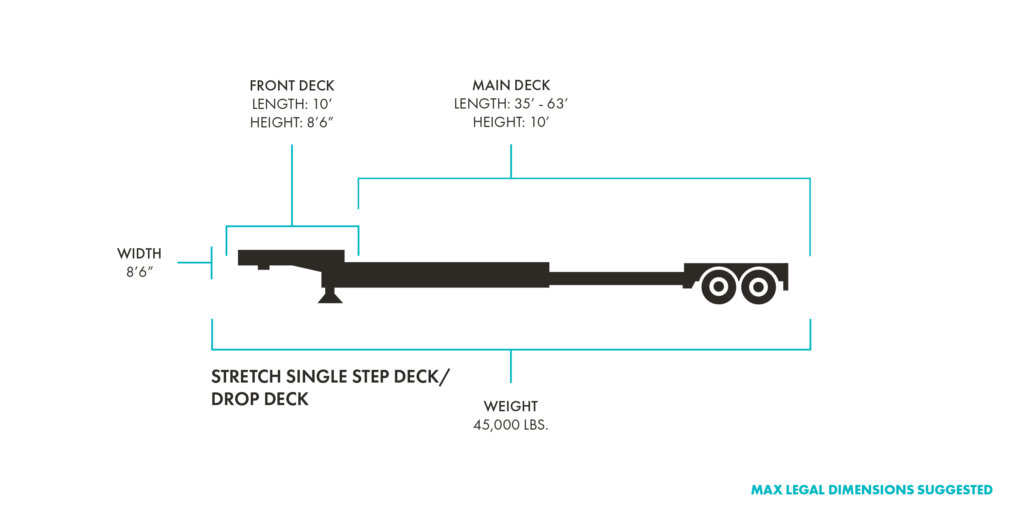

Stretch Single Step Deck/Drop Deck Flatbed Trailers

Maximum Legal Weight: 45,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck: Maximum Legal Cargo Length: 35 to 63 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck: Maximum Legal Height: 10 ft.

These flatbed trailers are like step decks, except they can be extended to transport cargo that can be too long for a standard step deck. This can include goods like scaffolding or drilling and mining equipment.

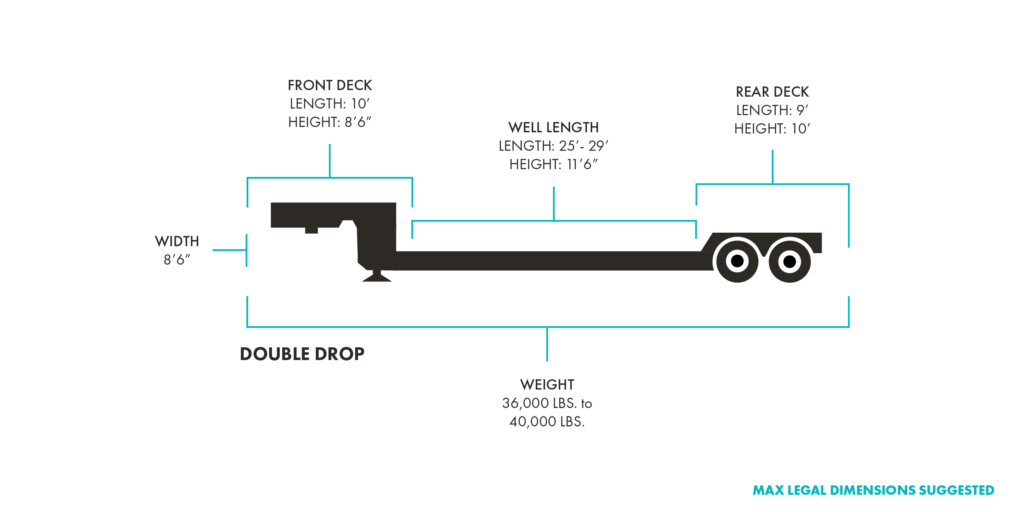

Double Drop Flatbed Trailers

Maximum Legal Weight: 36,000 to 40,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck (well): Maximum Legal Cargo Length: 25 to 29 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

Double drop trailers are also good for cargo that is too tall and generally used to haul oversized freight. Double drop trailers are unique in that they have a longer piece of the trailer called the “well”.

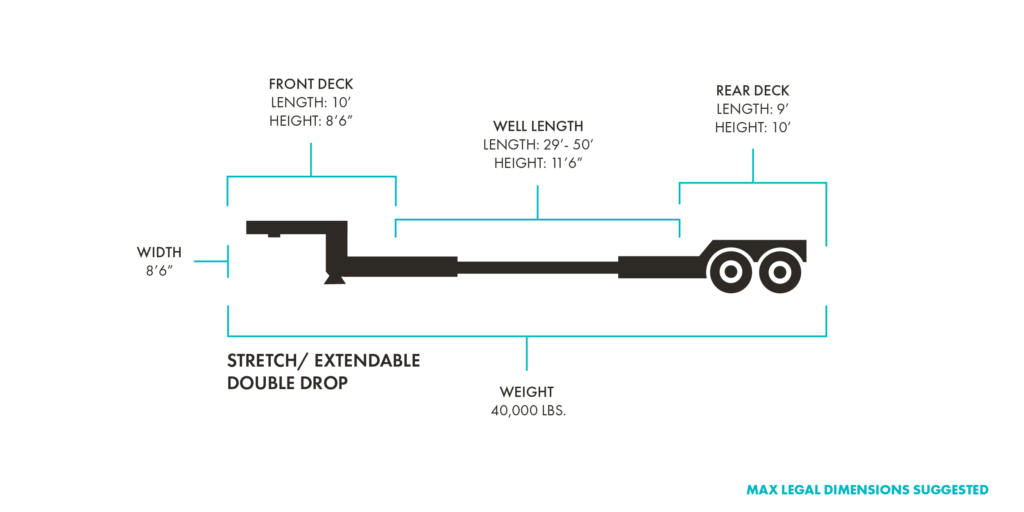

Stretch/Extendable Double Drop Flatbed Trailers

Maximum Legal Weight: 40,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck (well): Maximum Legal Cargo Length: 29 to 50 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

Like the standard double drop trailer, this one is also great for oversized freight. Since this trailer can be lengthened for longer loads, it’s ideal to carrier longer freight since it provides more support and prevents any overhang. It’s also common for this trailer to have two to three axles so it can support more weight. Common freight hauled by stretch double drops are pipes and steel beams.

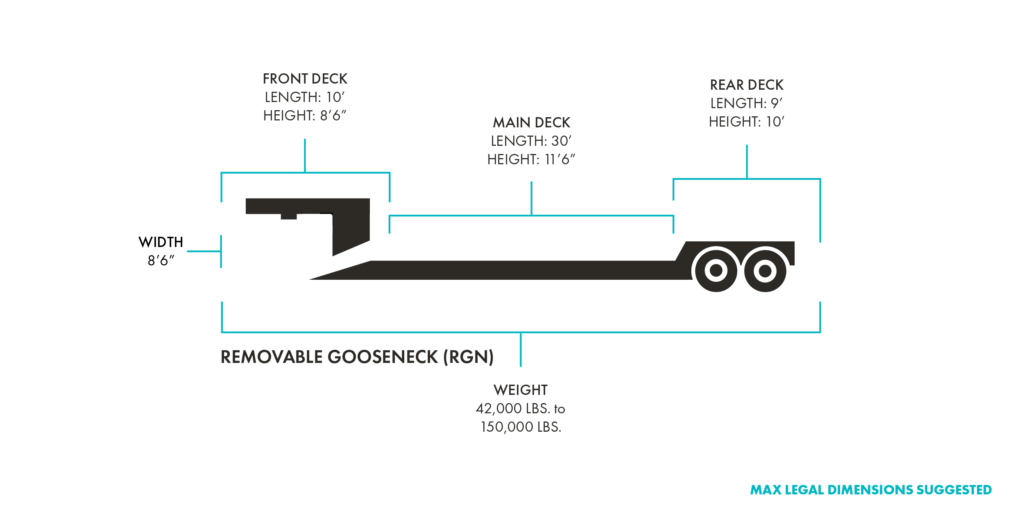

Removable Gooseneck (RGN) Flatbed Trailers

Maximum Legal Weight: 42,000 to 150,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck: Maximum Legal Cargo Length: 30 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

An RGN is one special flatbed trailer. They’re great for long, tall, and heavy freight! They have a detachable front that can be used to create a ramp for loading and unloading and can expand from three axles to over 20, to carry heavy items, like farming combines. However, it’s important to note that since these are more specialized, they can be tougher to find and more expensive to use for your flatbed shipping.

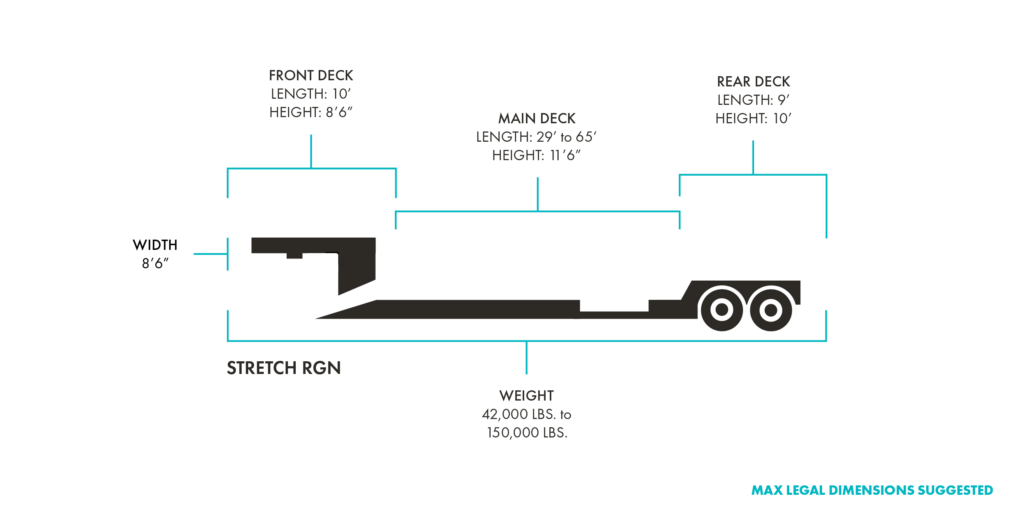

Stretch RGN Flatbed Trailers

Maximum Legal Weight: 42,000 to 150,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck: Maximum Legal Cargo Length: 29 to 65 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

When you need an RGN that can haul longer freight, a stretch or extendable RGN can help. Just like the standard RGN, axles can vary, from three and up, depending on the freight weight. The only real difference with this RGN trailer is the main deck is extendable up to 65 feet long.

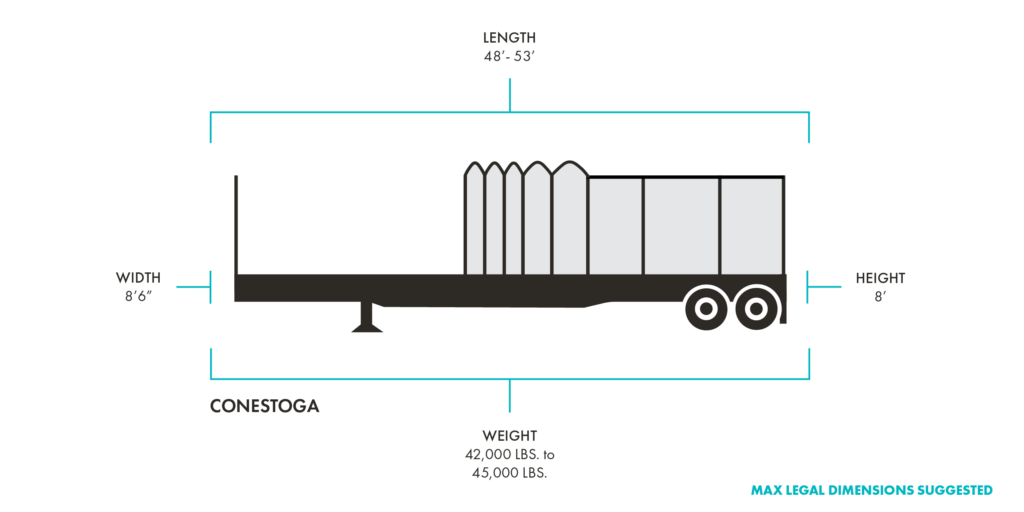

Conestoga Flatbed Trailers

Maximum Legal Weight: 42,000 to 45,000 lbs.

Maximum Legal Cargo Length: 48 to 53 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 8 ft.

One interesting fact about Conestoga trailers is that Conestoga is also a brand name for them. Conestogas are specialized, flatbed trailers that have a hard shell and rolling tarp system, which is great for freight that needs better protection from outside elements. These can be one of the most requested flatbed trailers due to their versatility. They can often be seen transporting freight like CNC machinery or helicopters.

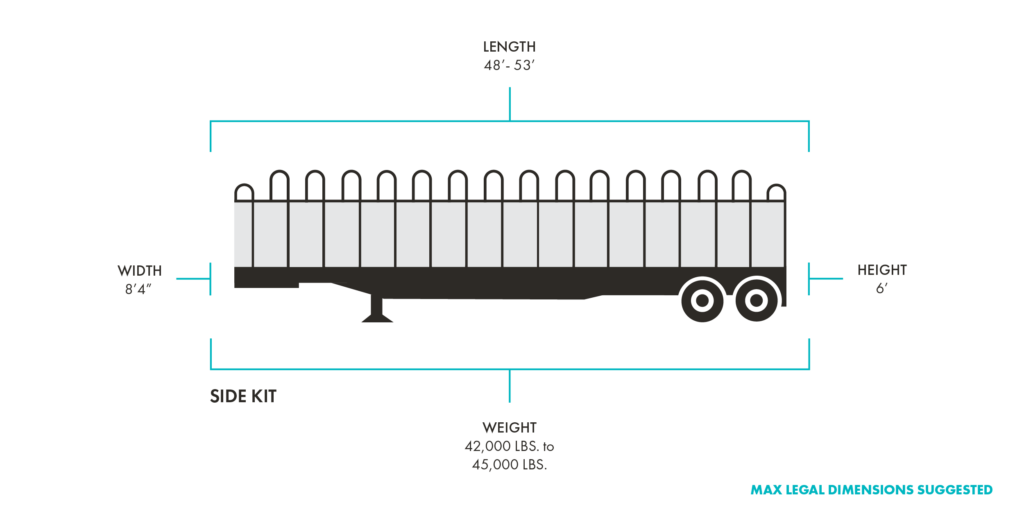

Side Kit Flatbed Trailers

Maximum Legal Weight: 42,000 to 45,000 lbs.

Maximum Legal Cargo Length: 48 to 53 ft.

Maximum Legal Width: 8 ft. 4 in.

Maximum Legal Height: “technically” it’s 8 ft. 6 in. but because of sides, 6 ft. is more easily accomplished

Side kit trailers are like Conestogas in that they are flatbed trailers that offer more protection. These trailers have panels surrounding often made from plywood or fiberglass, allowing for tarping over the top. Side kits are great for freight that is not packaged or crated, like corn or watermelons.

Flatbed Trailer Tips

Match Your Cargo to the Correct Flatbed Trailer

It’s important to know your cargo and that you have the right flatbed trailer to transport it. If the wrong trailer pulls in and it can’t carry your freight, you’ve lost out on precious travel time. Additionally, having the correct trailer ensures safe transport.

Communicate the Details

Regardless of what kind of product you need to transport, a lack of detailed communication with your logistics provider is important to avoid confusion and setbacks. For a logistics provider to effectively support you with your flatbed shipping needs, you’ll need to share specific details such as:

- Dimensions of cargo (length, width, height)

- Cargo weight

- Type of commodity

- Does your freight have any sharp edges?

- Does it need tarped/element protection?

- Is your cargo multiple pieces or singular?

- Is your cargo loose or palletized?

Understanding Your Flatbed Trailer Needs

Understanding the different kinds of flatbed trailers there are helps you make more informed and cost-effective decisions. You’ll better know their limitations and whether they may be more costly and time-consuming to acquire. For example, by knowing that more specialized flatbed trailers like RGNs or Conestogas are tougher to obtain, you’ll know to give your logistics provider advanced notice for those shipments, giving you the benefit of a more successful relationship and potentially cheaper rates.

Access the Flatbed Trailers You Need with Trinity

Now that you know more about the different kinds of flatbed trailers, you’d think you would be set to manage flatbed shipping on your own. However, flatbed shipments aren’t always easy to facilitate. Depending on the type of freight, the flatbed trailer needed, and whether it’s an oversized shipment can all hinder and complicate things.

Flatbed shipping requires proper planning, effective communication, and access to carrier relationships with a variety of flatbed trailers to ensure supply chain success. Luckily for you, Trinity Logistics has over 45 years of experience and trusted relationships with expert flatbed carriers. Working with Trinity is like adding an extra person to your logistics team – one who’s able to take on the workload that comes with arranging flatbed shipments, finding the right flatbed trailer for the right cost, reducing your risk, ensuring the freight you need gets delivered right where it needs to on time and intact.

DISCOVER ALL THE BENEFITS OF SHIPPING FLATBED WITH TRINITY LOGISTICSMost of us over the age of 25 can remember when the World Wide Web made its debut. We remember the “beep-boop” sound of dial-up and the big chunky computers that were as wide as a television set in the 1990’s. It’s been almost 30 years since the dawn of the Internet. It’s mystifying to look at the impact it still has on our everyday lives. Because of the Internet, e-commerce was born, and the need for flatbed shipping has increased.

The Beginning of ECommerce

Over time, ecommerce has taken the baton from traditional brick-and-mortar stores, leaving many big-box store retailers high and dry. Since Amazon Prime’s arrival in 2005, online shopping has exploded in the marketplace. The ease and convenience of it have forced many retailers to develop a strong online presence or risk closing their doors for good.

COVID-19 Creates Rapid Growth

Due to health concerns and social distancing practices, COVID-19 rapidly escalated the use of ecommerce. Total online spending in May 2020 was up 77 percent year-over-year (YOY), according to a report on online spending released in June by Adobe. In that report, Vivek Pandya, Adobe’s Digital Insights Manager, states that it would have typically taken 4-6 years to see the level of growth in online shopping that was seen then. Contactless online ordering helped individuals attempt to limit their exposure to the virus by shopping from home, so it’s easy to see why those reported numbers were so high.

Since the pandemic, the changes in the ways consumers shop have remained. While in-person shopping has increased compared to then, it still lacks in the amount of foot traffic that was received previously. Consumers continue to like the ease of online shopping, and with fewer in-person shoppers, companies are investing less in their brick-and-mortar locations, which has only made people less likely to want to shop in person. In fact, it’s estimated that 40,000 to 50,000 retail stores will close in the next five years, according to the UBS investment bank.

Ecommerce continues to experience growth, with 22 percent of retail sales being online in 2023, the largest U.S. ecommerce sales percentage to date, according to the U.S. Department of Commerce. As e-commerce growth carries on, it’s created a growing need for companies to expand their inventory and improve their ability to distribute their products. What used to be a problem of “too much” storage space for companies before the pandemic has quickly turned into a necessity in today’s time.

The Need for Storage Space

As online distributors continue to see growth, their need for storage space has grown as well. Prior to Covid-19, one or two warehouses could keep a medium-sized company running efficiently. Now, more space is needed to keep up with the increasing demand of companies. Having more than one distribution center can be a huge benefit to a company’s ability to stay successful these days.

This all trickles down to the construction industry. As demand grows for new or renovated warehousing, the need for building materials to meet that demand has also increased.

How ECommerce Growth Affects Flatbed Shipping

Flatbed shipping has always been a leading mode of transportation for industrial freight. Lumber, stone, racking, and other building materials travel best on an open trailer due to their odd dimensions and additional weight requirements.

Looking for an extensive guide to keep on hand for your over-dimensional shipping?

Download our FREE guide!Usually, flatbed shipping sees an increase in volume in the summer months. Construction companies take advantage of the warmer weather, which is most suitable for outdoor construction work. During this peak shipping flatbed season, it’s not unusual to see tightened capacity and higher freight rates, but any added demand for warehousing can add to that, making securing a flatbed carrier more difficult.

Strong Relationships Help

Having a relationship with a third-party logistics company (3PL can be a benefit to those who coordinate freight to be delivered to a job site. Typically, job site freight is very hands-on and has a perpetual knack for being time-sensitive. Installation crews are on-site to receive and install the material scheduled to be delivered. Even the slightest delay can cause significant ramifications to the completion of the construction project. Having a strong relationship with a 3PL can help companies mitigate risk, reduce costs, and provide peace of mind to those who are coordinating the freight.

Be Ready for Anything

It appears online shopping is here for the long-haul and whether it’s causing you to expand your warehousing or not a 3PL like Trinity Logistics can help you be prepared for any changes that may come your way. With Trinity, you’ll gain a Team of experts that can help you optimize your supply chain and arrange shipping for various of transportation modes, including flatbed, while offering end-to-end visibility of your shipments. No matter what changes the future brings, you can stay one step ahead when you choose to have Trinity Logistics by your side.

Stay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

READY FOR A REBOUND?

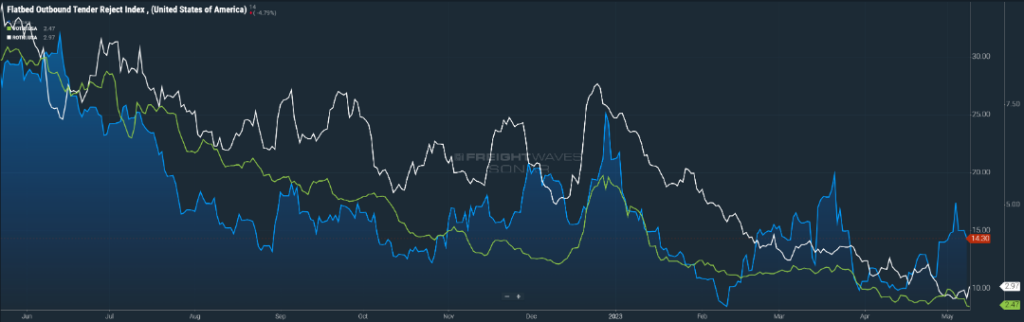

Given the sluggish flow of freight in 2023, seeing any signs of life is encouraging. The industry muddled through the first four months of the year with the volume index registering very little movement as seen in Figure 1.1.

Heading into late April, and the early part of May, seeing upward movement was a welcome sight to carriers and intermediaries. Mid-spring typically brings a bounce from produce and seasonal freight, and this year we are seeing that lift, albeit not at an aggressive pace. Still, even with the slight upturn, freight opportunities continue to be gobbled up by carriers, particularly on the contract side. Historic low rejection rates of under three percent not only mean less freight heading to the spot market, but shippers continue to have the pendulum in their favor with regard to rates.

FLATBED SEES BALANCE

Speaking of tender rejection rates, the low rejection rate is not being felt across all types of equipment as we see in Figure 2.1.

Vans and reefers are pretty much accepting anything that comes their way. These are two equipment types that saw increases in their number from mid-2020 through 2022, primarily in response to the overwhelming consumer goods demand which typically travels in these types of trailers. Now that demand for these items has cooled, vans and reefers find themselves in a situation where demand is still there, just nowhere near what it was the past few years.

Flatbeds, on the other hand, did not experience the same demand. In the over-heated freight market, we experienced in the last few years, flatbeds felt the most normal with regard to freight patterns and demand. While they did not get the direct benefit of shippers clamoring for their services, flatbed carriers have also not experienced the same falling out. As a result, they enjoy a balanced market with rejection rates hovering in the mid-teens. This could be short-lived as downward trends in manufacturing and industrial production, combined with a cooling housing market, will lessen the demand for flatbed services.

the gap remains

Carrier rates continue to normalize.

As seen in Figure 3.1, the spot rate on the van side seems to have found a bottom. Contract rates have contracted slightly, but the spread between carrier-published rates and those available with spot rate pricing continues to push past $0.70 per mile. An uptick in spot rates may relieve some of the pressure from shippers on the contracted side for carriers. Ideally, a spread of $0.15-$0.20 would be more balanced.

Could this modest uptick in volume shrink the rate gap even more? Stay tuned to June’s update to find out.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive Weekly News Updates every Friday by selecting “Weekly News Update” when you select your preferences.

Join Our Mailing List for Frequent News UpdatesFlatbed shipping is an essential part of the logistics industry.

Flatbed trailers are incredibly versatile and offer many benefits to shippers. Not to mention, flatbed shipping has been on the rise in recent years. In this blog, we’ll divulge to you our comprehensive knowledge of flatbed shipping so you can master this transportation mode.

WHAT IS A FLATBED TRAILER? FLATBED SHIPPING?

Flatbed Shipping

Flatbed shipping is often the transportation choice for cargo that doesn’t need the enclosure of a dry van. It’s ideal for cargo that cannot be loaded or unloaded from a dock as the shipper or receiver can load or unload from a variety of ways. The design of a flatbed trailer allows for cranes and forklifts to unload and load goods from a loading dock, from the side with a forklift or crane, or from above with an overhead, gantry, or crawler crane. This makes a flatbed trailer versatile and critical for numerous loading and unloading scenarios including at job sites, warehouses, and distribution centers.

Flatbed Trailer

A flatbed trailer is the most common type of open-deck trailer used in commercial, over-the-road, long-haul, and specialized trucking such as oversized or over-dimensional shipments. A flatbed trailer is a 48ft or 53ft trailer, that can accommodate loads up to 48,000lbs. They typically have two axles, air-ride suspension, and kingpin for a standard 5th wheel hook up.

Flatbed Freight

Flatbed freight tends to be more industrial than truckload dry van freight. There is a wide variety of flatbed freight in the marketplace. Some higher volume products like lumber or building supplies will generally pay less than more industrial items that support our country’s energy and core infrastructure needs, like construction equipment, generators, fabricated steel, and other project or job site-related freight.

WHAT CAN BE HAULED ON A FLATBED TRAILER?

The most common freight shipping uses for flatbed trailers are:

o Formed concrete items

o Lumber

o Construction materials

o Steel beams

o Scaffolding

o Trusses

o Electrical transformers

o Oil, gas, and petrochemical equipment

o Solar panels or wind turbines

o Commercial heating and air conditioning units

o Landscaping materials

o Large quantities of wrapped and stackable products

WHAT INDUSTRIES USE FLATBED TRAILERS?

Because flatbed trailers have no enclosure, the freight they carry can be versatile and their use extends across several industries, such as;

o Housing

o Construction

o Renewable energy

o Agricultural

o Warehousing

o Manufacturing

o Mining and drilling

o Military

o Automotive

o Landscaping

WHAT ARE THE BENEFITS OF A FLATBED TRAILER?

There are several benefits to using a flatbed trailer for your freight. With a flatbed trailer, there is dimensional flexibility for loading or unloading freight since there are no physical walls or a ceiling to restrict its use. Any cargo that is oddly sized or irregular-shaped can be easily moved with a flatbed trailer.

WHAT ARE THE DISADVANTAGES OF USING A FLATBED TRAILER?

When selecting the type of trailer your freight needs, you should know the disadvantages of each. Compared to traditional hauls, all flatbeds take considerable skill, effort, and time.

Since there are no physical walls to restrain freight, cargo securement and balance are two significant concerns with flatbeds. The FMCSA has a lengthy section in rules specifically for securement, as insecure cargo is a serious safety hazard.

Proper securement is needed for your freight too because if not done correctly, your freight can get damaged from the securement itself. Also, shipments often shift some during transportation, so even weight distribution and securement are necessary.

Another disadvantage to flatbed trailers is that there are no physical walls. It’s a positive for loading and unloading. Still, it can also be a negative as no enclosure means dealing with the elements (wind, rain, snow, sun, animal or human interference, truck smoke/smog, dust, and road debris). To combat this, there is the option of tarping your freight or using a Conestoga trailer.

There are even more significant risks and responsibilities with any oversized freight as these shipments have even more strict regulations to follow.

Looking for all you need to know about Over-Dimensional Shipping?

FLATBED SHIPPING TIPS

Know your cargo

Be sure to know all the details of your shipment. This includes commodities, value, dimensions, and weight. This information will help logistics providers know how to properly secure your cargo ahead of time.

Understand what trailer you’ll need

Familiarize yourself with the different types of flatbed trailers before booking a shipment so you can make the most cost-effective and safe choice. Each type of flatbed trailer has certain limitations. For example, a specific flatbed trailer like extended trailers and Conestogas can be harder to find so your provider may need advanced notice when they are required.

Be aware of accessorial charges

Flatbed shipping may involve moving specialized loads which can need special equipment or extra services. Make sure you have the proper equipment and services needed for your freight to avoid extra charges, freight damage, or delays.

Choose to work with an expert

Arranging flatbed shipments on your own can be time-consuming and expensive, making sure all regulations are met and your cargo travels safely. Consider working with an expert in flatbed shipping to help secure capacity and locate the right equipment for your freight.

FLATBED RATES AND SEASONALITY

Freight shipping demand, which includes flatbed demand, is something that is often based seasonally. No matter the market, shipping rates fluctuate throughout the year and rise as the demand for freight rises.

Flatbed shipping is very closely connected to construction and industrial production, which can be highly dependent on the weather. These industries often slow down in the winter months, so normally, the demand for flatbed shipping will soften at the end of the year.

Smaller to medium-sized companies often slow down during winter and resume activity when warmer weather returns. However, larger companies are affected less by the seasonality and continue to move their commodities regardless of the time of the year.

Because of the seasonal rise and fall, you’ll find volume and rates lowest in the late fall/early winter, with the peak flatbed season being from April to October. This is when the volume of flatbed loads is highest, as are the rates.

FLATBED SHIPPING WITH TRINITY LOGISTICS

Did you know Trinity Logistics is an industry leader in brokering flatbed freight to small and midsize carriers throughout North America?

Our vast network of Independent Freight Agents, combined with our Regional Service Centers deliver the best-in-class flatbed shipping through our expert carrier relationships. We accomplish this by supporting core energy and infrastructure clients with their project-based, unique, and often specialized freight.

Learn more about Trinity's servicesAll industries are currently facing challenges with their logistics and the supply chain. Challenges that include overwhelming demand, tight capacity, rising freight rates, and shortages in materials, products, labor, and drivers. However, industries facing high flatbed demand, like construction and manufacturing, are seeing more difficulty than others.

These industries have been dealing with capacity challenges throughout the pandemic as they have remained in high-demand. As it continues to rise, the needs for their supplies have increased, creating a surge of flatbed demand that’s weighing on the supply chain. Let’s take a deeper look into these challenges and present some considerations for how those in the industry can overcome them.

FLATBED DEMAND VS. VAN AND REEFER

Finding truck capacity of any type is proving to be difficult. Flatbed capacity seems even more challenging because of the continued demand in construction and manufacturing. As a result, flatbed spot rates are reaching new highs and convincing more shippers to look for solutions.

According to DAT, the flatbed load-to-truck ratio is up 169.3 percent year-over-year (YOY) from June 2020 to June 2021. In comparison, reefer’s load-to-truck ratio is up 111.7 percent YOY. Van load-to-truck ratio is up 57.8 percent YOY.

The monthly national average flatbed spot rates have risen for eight consecutive months, reaching $3.15 per mile in June. There’s not looking to be any fall soon, as the industries pushing the flatbed demand are cranking it into the next gear.

FACING DISRUPTION AFTER DISRUPTION

The return to normal may be farther away than you think. With demand, there are still projects waiting in the wings until materials can be properly sourced and shipped. And demand already has construction projects beyond their pre-pandemic heights. Just look at the Associated Builders and Contractors’ Confidence Index, which is now positive for sales, profit, and staffing level expectations for the next six months.

Covid-19 Hit First..

When the pandemic hit, people had found they had nothing to do while staying home. And so, we saw a rapid uptick in those wanting to buy a new house or remodel. Demand quickly exceeded supply. Supply shortages and delays have put pressure on contractors as the demand rose despite a lack of supply.

..Then There was the Texas Freeze..

In February and March 2021, Texas saw their lowest temperatures in years and were not prepared for the intense weather conditions that they experienced. Many manufacturing plants in the area had to shut down, which created more disruption in the supply chain.

..Then the Suez Canal Blockage..

The ship that blocked the Suez Canal for several days caused severe delays in the imports of many products needed. This created many shipping bottlenecks that we’re still experiencing the aftermath of today.

..Now the Wildfires.

Currently, the raging wildfires on the west coast are causing further disruption and delays to an already stressed supply chain.

Issues such as these are causing supply chain disruption after disruption, resulting in increased costs and delays. Many companies rely on materials that come from delayed or now-unavailable, global manufacturers. This has shifted companies to search for regionally based suppliers, creating higher demand on smaller supply chains. After over a year of continuous supply chain disruptions, there’s been an industry-wide realization that building resilience into supply chains is vital.

RISING FUEL PRICES

One of the areas affecting logistics cost are the continuing rise in the costs of fuel. The latest Energy Information Administration data shows the national average diesel price is at $3.34 per gallon, a $.05 increase from one month ago. Regional diesel prices range from $3.08 in the gulf coast states to $3.48 in the central Atlantic region. California diesel prices are averaging $4.19 per gallon.

SHORTAGES AND DELAYS

Lumber shortages continue to be a significant problem nationwide. Both steel and electrical supplies have faced steep price increases in the past year. According to the U.S. Census Bureau’s Small Business Pulse Survey, 59.7 percent of respondents reported domestic supplier delays which is a huge jump over the national average of 36.3 percent. These aren’t domestic only issues as 19.1 percent of respondents are also dealing with foreign supplier delays.

MATERIALS THAT HAVE BEEN EXPERIENCING SHORTAGES

- Timber

- Steel

- Roof tiles

- Cement

- Electrical components

- Paints and sealants

- Plaster and plasterboard

- Concrete

- PIR insulation

- Bricks and blocks

- Aggregates

- PE and PP plastics

- Screws

- Plumbing items

THE RAW MATERIAL SHORTAGE

There is currently a global shortage of raw materials. This comes from factory slowdowns and, in some instances, factory closures due to many reasons. The shortage of raw materials continues to put a strain on the production of products, like insulation, paints and adhesives, and packaging.

THE LABOR & DRIVER SHORTAGE

Another cause of rising costs and delays is the shortage of labor and drivers. Labor rates have skyrocketed in recent months. This is due to the high labor demand and trades raising their rates because of the overwhelming amount of work. The big challenge these industries face is finding qualified labor to perform work, whether that be driving a truck to deliver materials and products, painting a house, or installing plumbing. In logistics, driving a flatbed truck, especially one hauling an oversized load, requires a different skill set than your typical van trailer trucking.

HIGH PRICES KEEP HEADING HIGHER

The Associated General Contractors of America (AGC) released a survey recently showing 93 percent of more than 1,400 respondents reported higher costs for materials, parts, and supplies. Construction material prices have increased so much in 2021 that the AGC issued a rare Construction Inflation Alert. This hasn’t taken since place 2008, citing a 12.8 percent jump of input costs for projects since the pandemic began. While that number is notable, some materials have risen even more. Lumber and plywood jumped 62 percent and steel recorded a 20 percent rise since April 2020. Diesel fuel, the lifeblood of the heavy equipment and transportation haulers needed to build major projects, has surged 114 percent. Even when materials are ready to be shipped, the transportation market is trying to play catch up. As mentioned earlier, there is currently more demand than there are trucks available.

Rising costs and supply chain disruptions have pushed more hardships on the construction and manufacturing industries, slowing down their projects and business progress. Data found that more than three-fourths of construction firms have indicated projects are being postponed or canceled due to unavailable materials or cost overruns.

POSSIBLE SOLUTIONS

Experts are estimating that the high demand in these industries and flatbed demand may continue through 2022. Not to mention, who knows what other possible disruptions we may see soon. Hurricane season is upon us and could cause some more delays.

It’s never too late to find ways to improve your supply chain and keep costs budgeted. Here are some suggested solutions to facing this difficult time we’re in.

LOOK FOR ALTERNATIVE ITEMS

It might be worth checking into other materials to offer your customers. Many other companies are doing what they can to keep their projects moving forward and communicating this with their customers. For example, with rising lumber costs, you may find redwood or cedar to be more affordable alternatives. They may also be much easier to get your hands on.

INTEGRATE TECHNOLOGY

Integrating technology has become a necessity for all stakeholders to maintain real-time communication and visibility. Gain total visibility and trust from your stakeholders with logistics technology like a transportation management system (TMS). A TMS can help you with routing decisions by matching your freight with the best carriers, lanes, rates, and transit service.

Having a best-in-class TMS also provides you with data-driven insight to better manage disruptions and budget your logistics spend. By using data analytics, you’ll be able to recognize which carriers are most likely to have capacity and have a full view of your transportation management and what’s happening across all markets.

CONSIDER NEW OPTIONS

When possible, see if you can use van options for your transportation, considering the load-to-truck ratio shows less demand and lower freight rates. You may also be able to consider other modes, if possible, but any oversized freight must be hauledwith a flatbed trailer.

PLAN IN ADVANCE

Many other companies are stocking up on available supplies or finding other ways to look far ahead. Consider doing the same. Stock up on what materials you use most often for your projects. Do keep in mind that the more you stock up on, reduces the overall supply, increases demand, and thus pushes prices higher. Don’t go overboard and hoard ALL of it but do try to keep some stock in supply. Try planning your projects far enough out, correlating with the longer lead times we’re experiencing. If the material you need says it will take nine to ten months, then plan your project around that time frame.

BUILD A STRONG NETWORK OF CARRIER RELATIONSHIPS

Due to the over-demand of freight, load boards don’t move shipments the way they once did. Strong relationships will get you the coverage you need, better pricing options, and often better service. If building a large enough network for you seems daunting, you can always partner with a third-party logistics company (3PL), whose main role is their relationships among shippers and carriers. Here at Trinity Logistics, we have over 70,000 qualified carrier relationships to help haul your freight.

BUILD A RESILIENT SUPPLY CHAIN

At a time when your costs are a critical issue, reimagining your supply chain could be a way to build resilience and reduce costly disruptions before they happen. Now is the perfect time for companies to build resilience into their operations to be better prepared for future disruption we may see.

Opportunities to do so range from reevaluating your business models and building efficient industrial supply chains, to building new and more regional manufacturing and distribution facilities to help with the vulnerabilities the pandemic brought to light. You could put in place more flexible sourcing and distribution strategies, including shifting your suppliers closer to home.

WORK WITH A QUALITY 3PL, LIKE TRINITY

We do more than arrange your freight. Consider us your logistics consultants. As logistics experts, we keep a close eye on the market, keeping you educated so we can help you plan and forecast.

No matter the market, you can use your Trinity relationship and discuss your current and upcoming projects, even if they are in the planning stages. This helps us give you things to look out for to keep your transportation aspect of business more stable and reliable. When markets fluctuate, having a solid relationship with experts such as Trinity will prove to be your largest asset.

Should issues arise, we at Trinity, work until they are resolved through and communicated. In the logistics industry, things will happen, and bad news doesn’t get better with time. We stay upfront with any challenges, and we bring solutions. When given the chance to prove our communication and service, we make sure to set the bar high.

If you’re ready for a reliable provider to help you with your shipping needs and logistics management through People-Centric Freight Solutions®, then request your first quote to get started.

Author: Paul Nelson