Don’t let your company get caught off guard by CVSA Operation Safe Driver Week, July 7th to July 13th, 2024!

Shippers and carriers, mark your calendars! Operation Safe Driver Week is approaching. While this annual event is designed to make our roadways safer, it’s also a crucial week for those in logistics. This pivotal time can impact operational efficiency for shippers and carriers alike. To be prepared, it’s important for all those involved in shipping freight to understand what Operation Safe Driver Week entails and its effect on the freight market.

- What is the CVSA?

- What is Operation Safe Driver Week?

- Impact on Shippers

- Impact on Carriers

- How Shippers Can Prepare

- How Carriers Can Prepare

- Let’s Work Together

What is the CVSA? What is Operation Safe Driver Week?

The Commercial Vehicle Safety Alliance (CVSA) is a non-profit organization dedicated to improving commercial motor vehicle safety through collaboration between law enforcement, industry stakeholders, and the public sector. In partnership with the Federal Motor Carrier Safety Administration (FMCSA), the CVSA launched the Operation Safe Driver initiative in 2007. The goal of this initiative is to reduce the number of deaths and injuries from crashes involving large trucks, buses, and cars.

This initiative includes an annual event, Operation Safe Driver Week. It aims to improve driver behavior through education and increased enforcement efforts, focusing on unsafe driving behaviors. It takes place across North America, so the U.S., Canada, and Mexico. Unlike the CVSA’s other two initiatives (International Road Check and Brake Safety Week), which solely focus on commercial drivers, this event affects all drivers on the road.

Each year has a primary focus with this year’s being reckless, careless, or dangerous driving. This includes actions like:

- Speeding

- Texting while driving

- Drunk or drugged driving

- Following too closely

- Driving too aggressively

- Improper lane changes

- Failure to obey traffic control devices

- Failing to use a seat belt

Those drivers identified are pulled over by law enforcement and issued warnings or citations.

According to the National Highway Traffic Safety Association (NHTSA), drivers’ actions are the reason behind 94 percent of all traffic crashes. Research from the University of Missouri-Columbia has shown that interactions with law enforcement, not just education, are what brings change. During last year’s event, law enforcement interacted with 66,421 drivers! Drivers were informed and educated on how they can improve their driving behavior and do their part in reducing crashes.

Why Should I Be Concerned About Operation Safe Driver Week?

It’s important to be aware of when Operation Safe Driver Week takes place because of the impact it has on shipping freight. Even though it’s just one week out of the year, no one likes to be unprepared for potential disruption or delays to their business.

Operation Safe Driver Week Impact on Shippers

Shippers may face potential delays, see reduced transportation capacity, and likely higher spot rates.

Potential Delays

Increased enforcement activity can lead to potential delays due to any road stop inspections or pullovers.

Reduced Transportation Capacity

The increased enforcement effort sometimes leads carriers to strategically choose to close their business temporarily for the week to avoid any risk of fines or penalties. You might find it more difficult to secure reliable carriers for any last-minute shipments.

Higher Spot Rates

With the potential for fewer trucks available and delays, spot rates can be heightened during this time.

Operation Safe Driver Week Impact on Carriers

Carriers are similarly affected, and there is the potential for delays, less freight volume, and higher scrutiny from law enforcement.

Transportation Delays

Just like shippers, carriers should expect to see potential delays in the movement of traffic due to the increased enforcement. This could disrupt your operations.

Fewer Shipments Available

Shippers may choose to plan around this week, reroute certain shipments, or even look into alternative modes. Less freight may be available during this week.

Increased Law Enforcement

Expect to see increased law enforcement, so more eyes will be looking for unsafe driver behavior, and drivers may receive fines.

How to Prepare for Operation Safe Driver Week:

Shippers

Ensure Documentation Accuracy

Double-check all shipment documentation. Ensure it is accurate and complete to avoid delays during any unexpected inspections.

Communicate Sensitive Shipment Needs

If you have any special requirements or time sensitivities, communicate this well in advance. This helps your logistics provider plan effectively. Any last-minute communication risks delays.

Find Alternatives

Consider alternative transportation modes or routes if you expect any delays.

Keep Customers Aware

Be proactive and communicate potential delays during this week to your customers to manage expectations.

Share Any Concerns

Discuss any concerns you might have with your logistics provider. They can offer valuable insights and help develop strategies to reduce disruptions.

Pricing Awareness

Be aware of possible higher spot rates during Operation Safe Driver Week. When possible, plan shipments before or after this period to secure better pricing.

Carriers

Double-Check Credentials

Ensure all company credentials, like operating authority, hazmat endorsements, TWIC cards, and any other relevant permits, are current and accessible.

Driver Documents are Up to Date

Have drivers verify that all paperwork is up to date and accessible in case of inspection.

Vehicle Maintenance Check

Double-check that all vehicles have undergone any necessary preventive maintenance and are in top operating condition to avoid delays due to roadside repairs.

Prep Your Drivers

Make sure drivers are aware of this week and the potential for stops or delays. Train drivers on proper procedures for interacting with law enforcement. Make sure they know the channels to communicate any disruptions to their journey.

Book Ahead

Shippers may choose to reroute shipments, choose alternative modes, or plan around this week. Consider booking shipments well in advance for this week.

Remember – Safety First

The importance of this week is not disruptions but road safety. This is a great time to talk with drivers about safe driving behavior. You could also help educate the public on proper driving behavior when interacting with trucks. Remember, this week benefits everyone who shares the road.

Let’s Work Together to Keep Our Roads Safe

We believe road safety is paramount. While Operation Safe Driver Week might cause some temporary disruptions, it serves a vital purpose in promoting safe driving behaviors.

By staying informed and taking proactive steps, you can likely see minimal effects of Operation Safe Driver Week.

For additional opportunities to stay ahead of disruption to your business during Operation Safe Driver Week, consider working with Trinity Logistics. We have over 45 years of experience helping thousands of shipper and carrier companies conquer more complicated shipping situations, like CVSA inspection weeks. We’re confident in our ability to make this week (and all others) a painless one for your business.

After several record setting years, 2023 saw shifts to the freight market. How did the 2023 freight market affect shipper and carrier businesses? Did other businesses have the same struggles as yours? Are they expecting to face similar difficulties in 2024? How are their partner relationships?

Trinity Logistics wanted to get answers to these questions for you, so we asked a random sample of our shipper and carrier relationships to gauge the effect 2023 had on their business and what their expectations for 2024 in our first Freight Market Survey. Here’s what we found out:

2023 SHipper & Carrier Data: Freight Market Survey Results

Past Challenges – Same, But Different

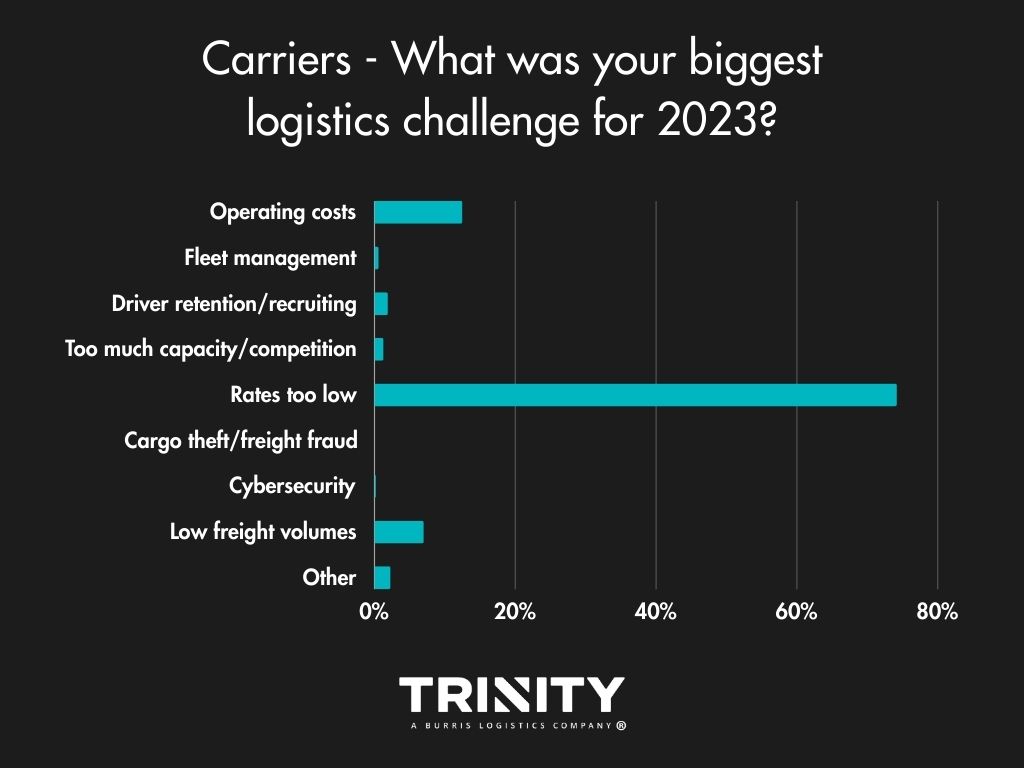

Considering the recent turndown of demand and the freight market, it’s not a big surprise that money was the biggest issue for shippers and carriers alike. Shippers answered that transportation costs were their biggest challenge in 2023, with supply chain delays/disruption and capacity not far behind. Low rates and increasing operating costs were the main challenges facing carriers.

Business Impact – Could Have Been Better

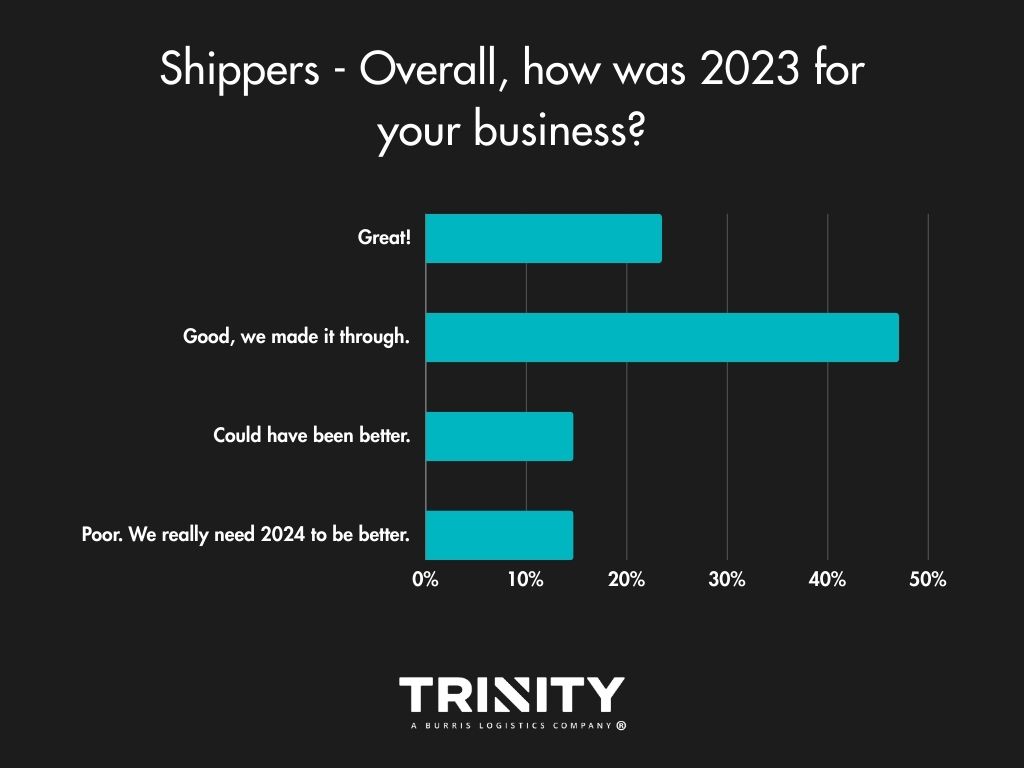

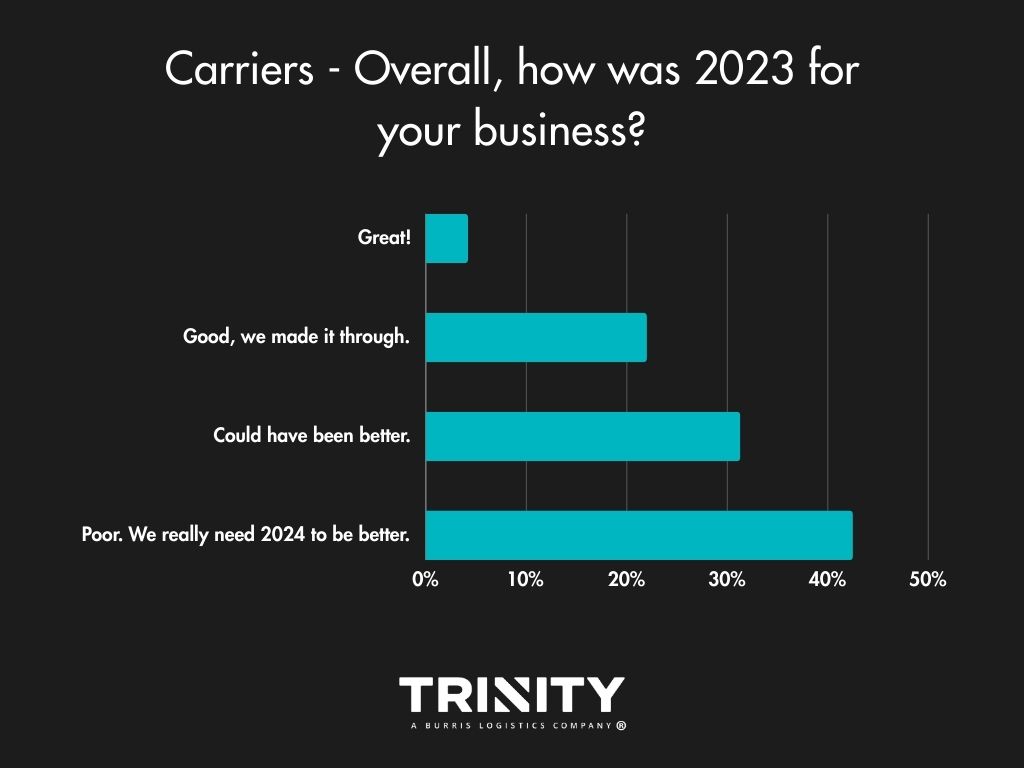

Even with the change in consumer demand trending downwards throughout 2023, most shippers answered that their year was good overall. Carriers on the other hand seemed to face a rougher year in business with over half of them stating their year could have been better or was poor.

A LOOK INTO 2024

Future Challenges – Money Problems

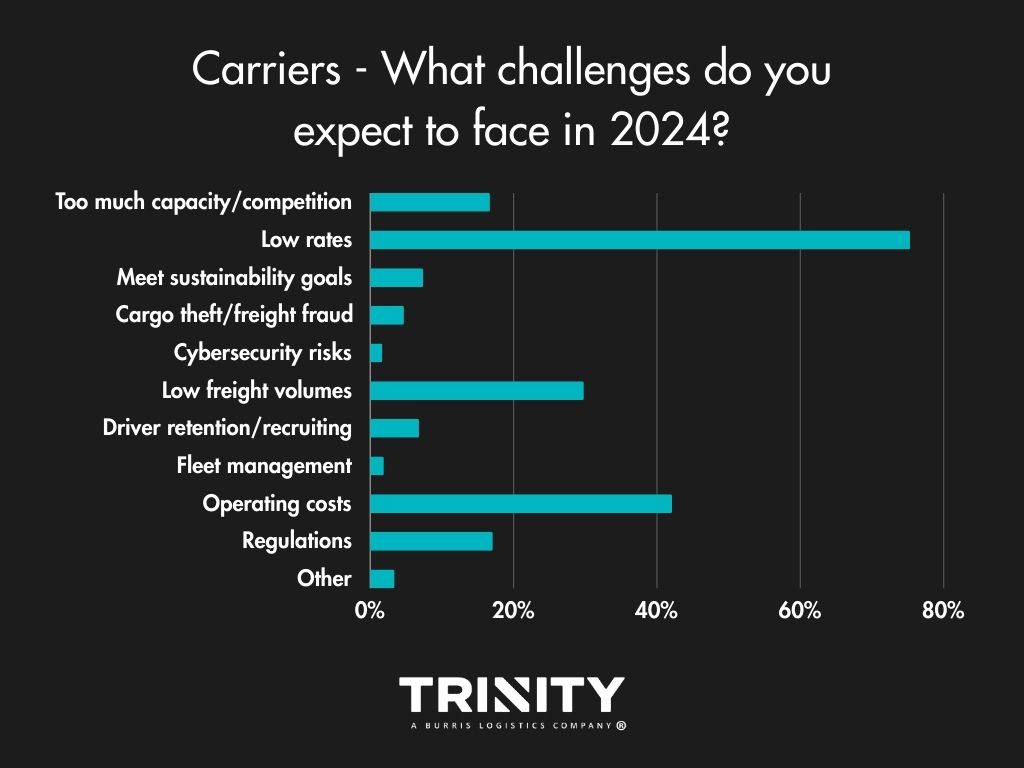

2024 isn’t looking much different in terms of challenges compared to 2023. Shippers look to have the same financial challenges as they did in 2023 with transportation costs, supply chain delays/disruption, and decreased demand being the top concerns selected. Carriers are still concerned about low rates, operating costs, and low freight volumes hurting their businesses.

Hot Trends

Even though transportation costs are shippers’ strongest concerns in their previous answers, it seems the increased amount of supply chain disruptions and delays we’ve all experienced in these recent years have hit a nerve, with the majority answering that supply chain resilience is the trend their business is most interested in. Cybersecurity also looks to be a growing interest.

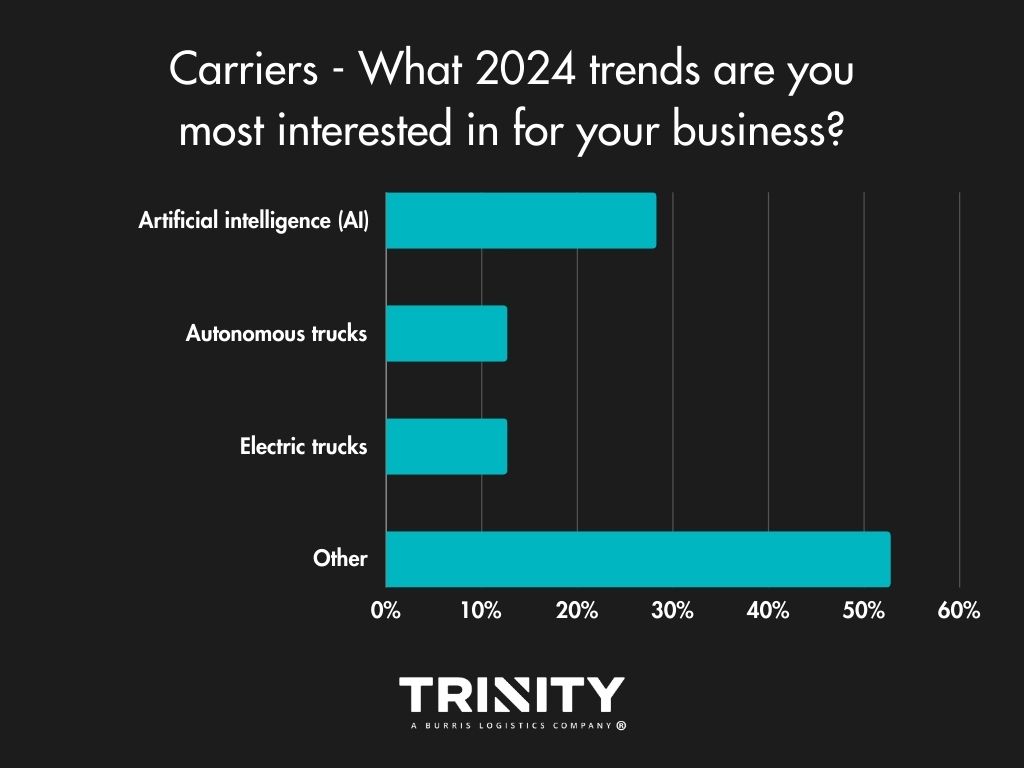

Carriers on the other hand, interestingly enough, look to the recent trend of Artificial Intelligence (AI). Also, as noted in the comment boxes of our “Other” option, increased rates and better fuel prices were trends they’d like to see in 2024.

Load Volumes & Capacity – Slightly Positive Outlook

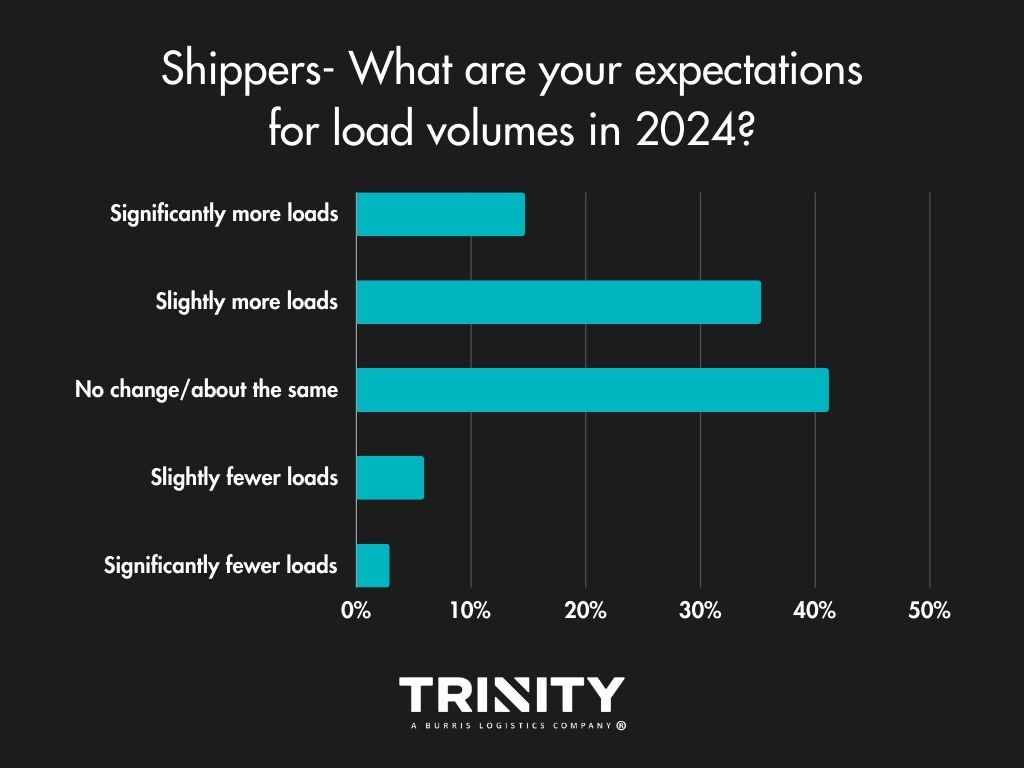

Overall, shippers are slightly more optimistic for 2024, thinking it won’t bring any change or the change it brings will be positive. Most think load volumes will stay the same or there will be a little more in freight volumes this year. As for truck capacity, they think it will be the same as 2023 or slightly tighter.

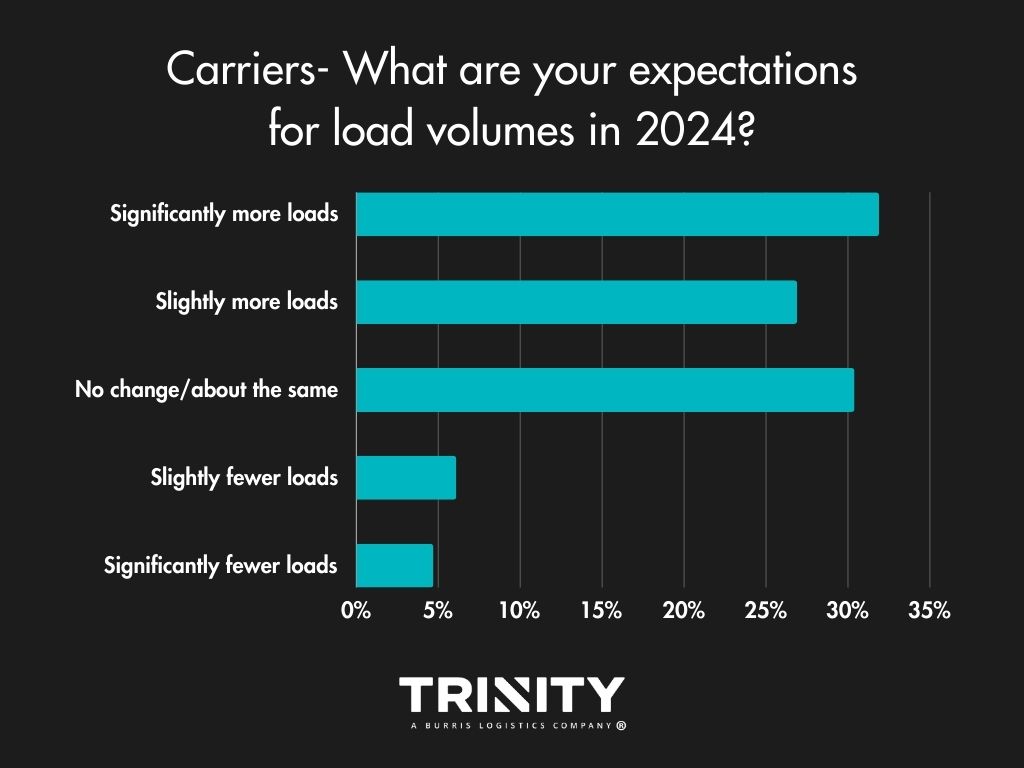

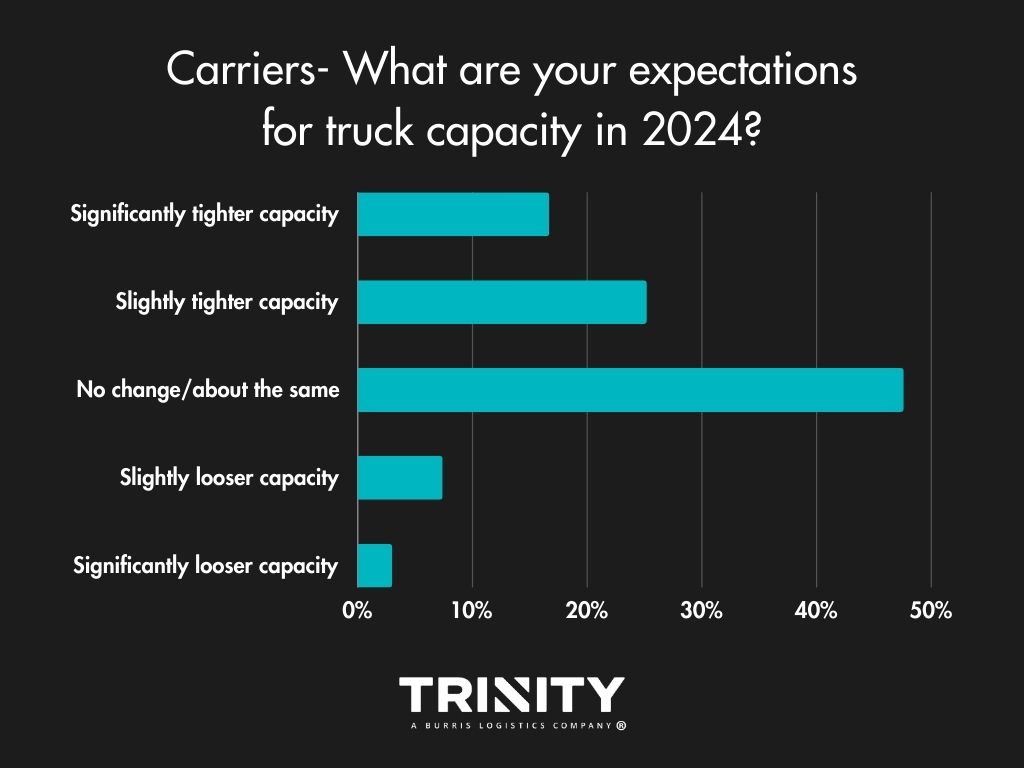

Carriers also think 2024 will bring more freight volumes and that capacity will likely stay the same or get tighten slightly versus 2023.

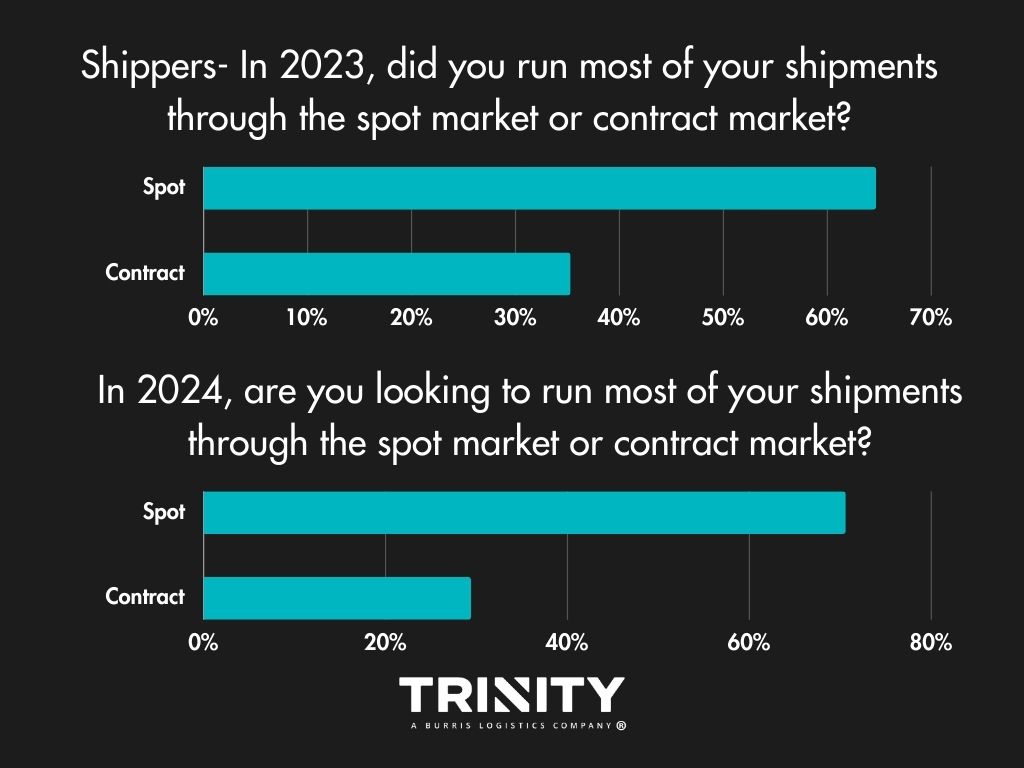

Spot or Contract?

Year-over-year, shippers aren’t looking to change much in terms of which market they turn to. Most look to continue to put most of their freight on the spot market.

For carriers, there looks to be some change anticipated. In 2023, most carriers ran spot market freight but in 2024, over half of them look to haul contracted freight.

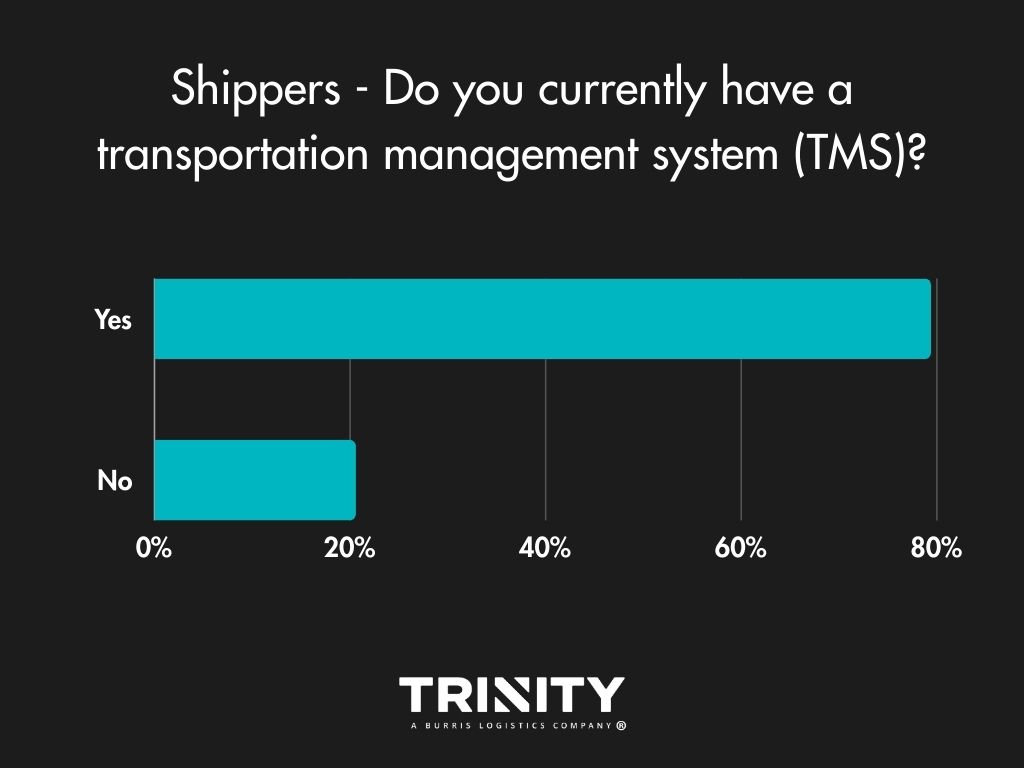

Do Shippers Have a TMS?

It’s 2024, so you’d think most shippers would have a transportation management system (TMS), and no surprise, they do. For those that don’t and answered, it seems they did not have a good experience with one in the past or don’t know enough about them.

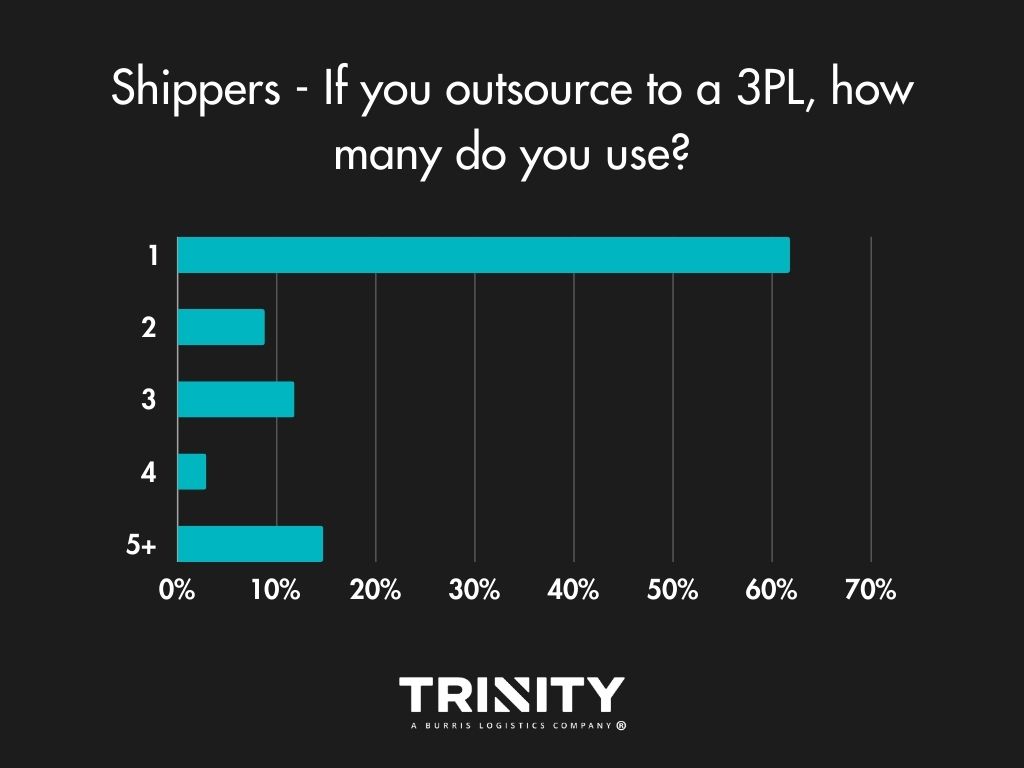

Brokers Are the Way to Go

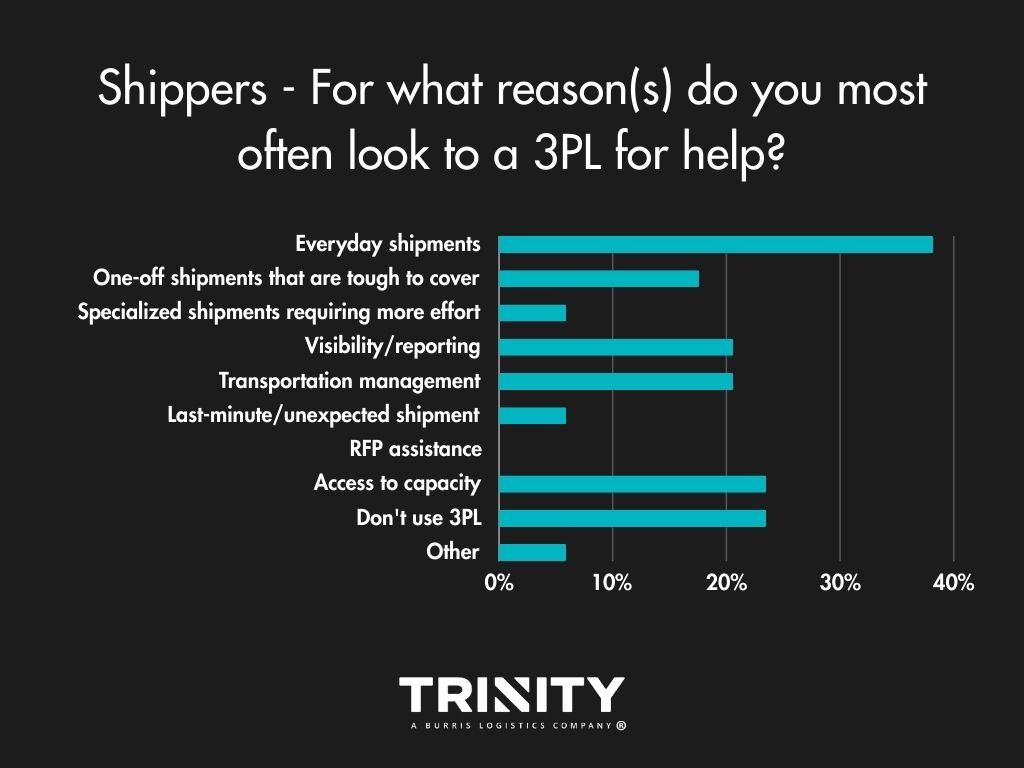

When asked how they like to move their shipments, most shippers use a mix of carriers and third-party logistics providers (3PLs) or just 3PLs. A few do use their own trucks. For those that do outsource to 3PLs, they usually just stick to one provider.

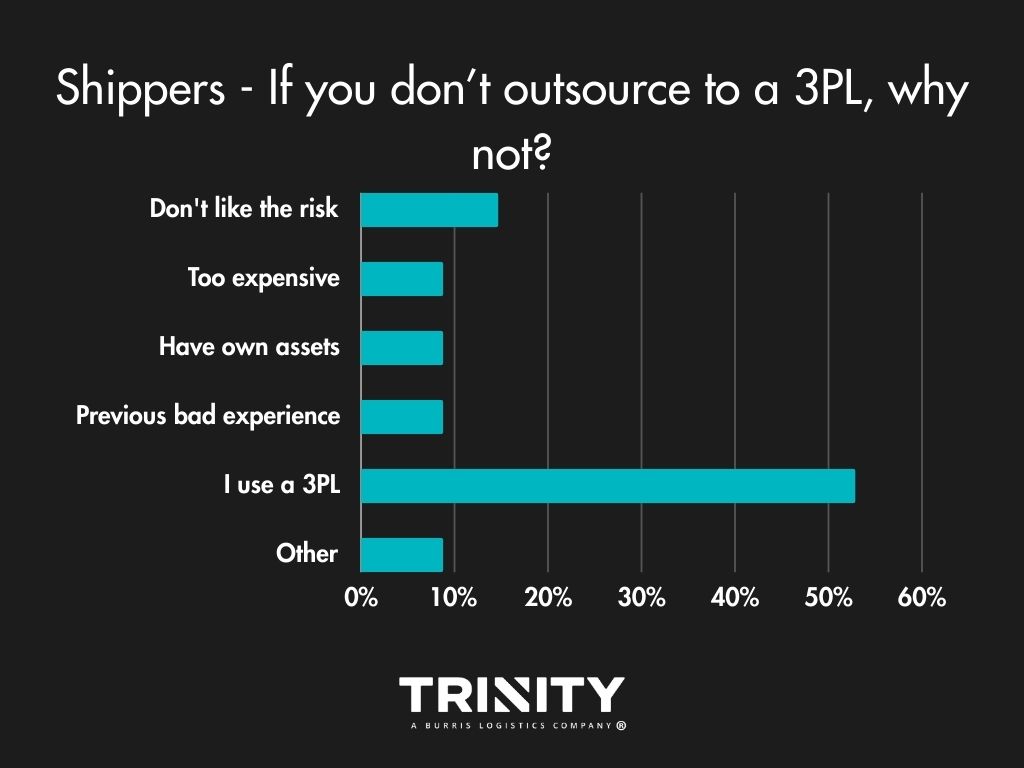

Shippers most often look to a 3PL for help with their everyday shipments, for transportation management, visibility, and access to their capacity. The main reason shippers choose not to work a 3PL for their logistics? They don’t like the risk.

Transportation Modes – Staying Consistent

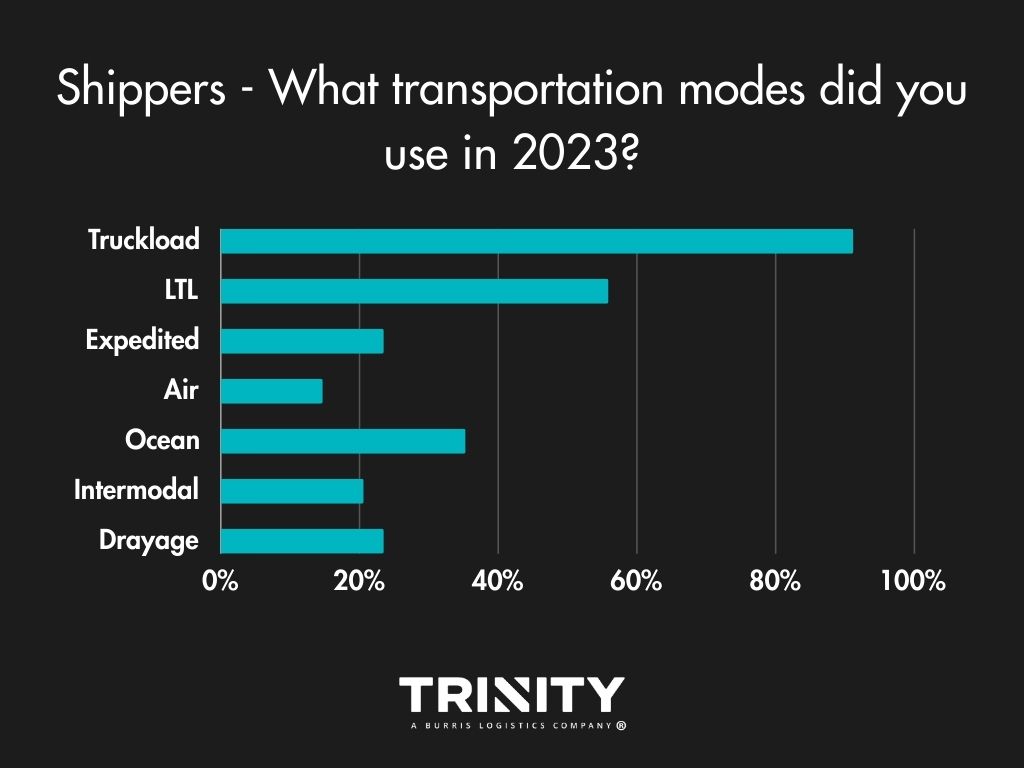

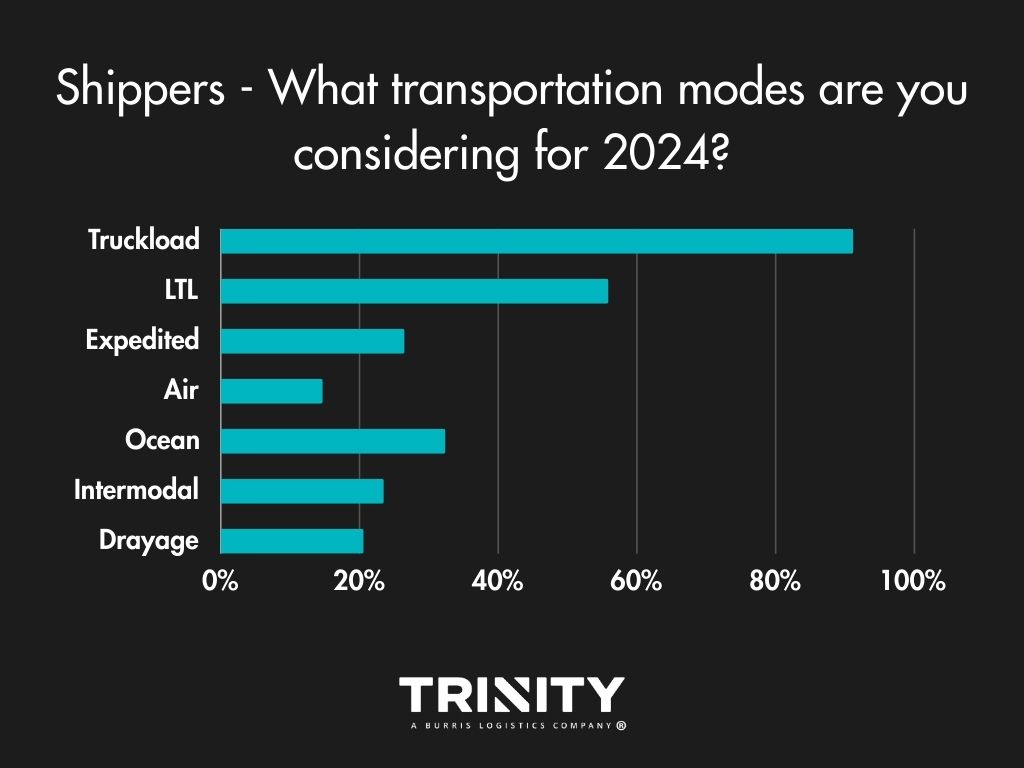

Overall, shippers aren’t looking to change what transportation modes they use for their shipments. Truckload and less-than-truckload (LTL) are the primary modes they like to use, with a little diversification sprinkled in.

Exceptional Service Stands the Test of Time

When it comes to their logistics partners, shippers find the most value in receiving exceptional service, with costs coming in as a close second.

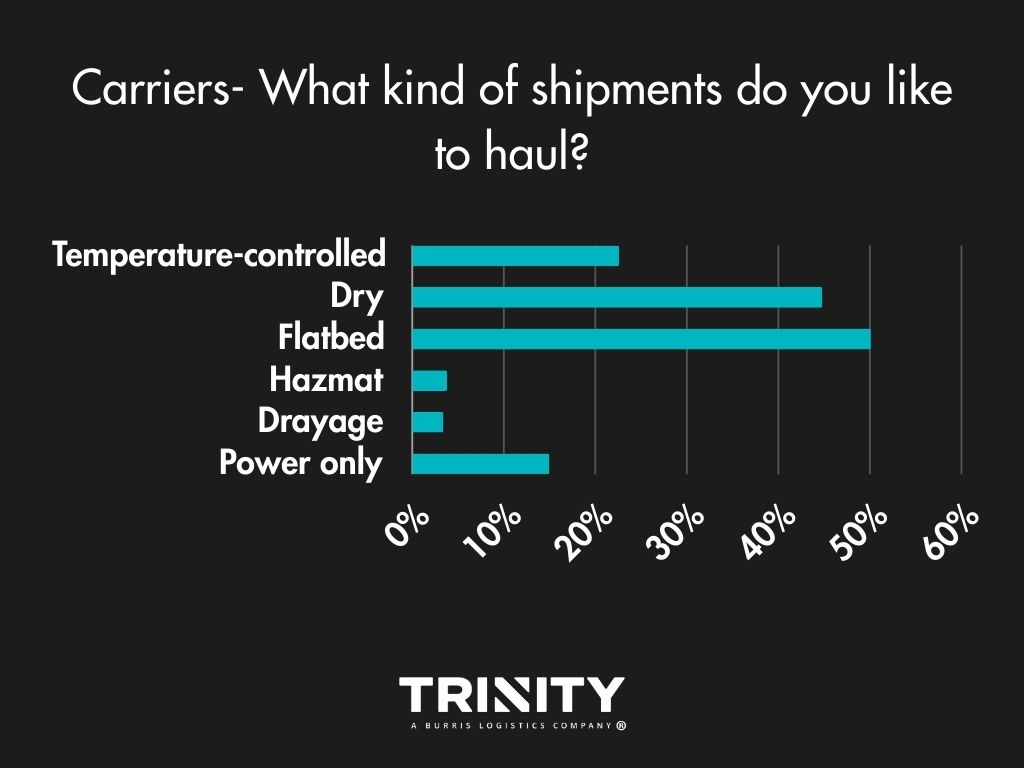

Most Wanted: Long Mileage, Flatbed Shipments

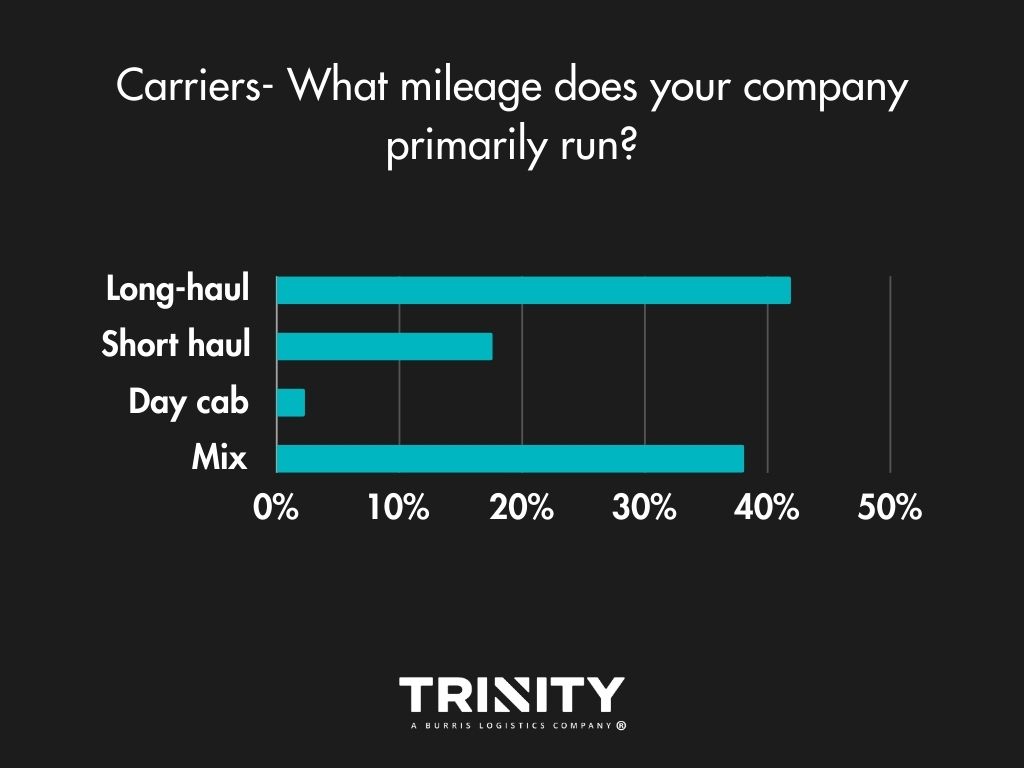

When it comes to mileage, most carrier companies tend to run long-hauls or a mix of short and long shipments. Flatbed hauls are the type of shipments most carriers like to haul with dry van coming in as a close second.

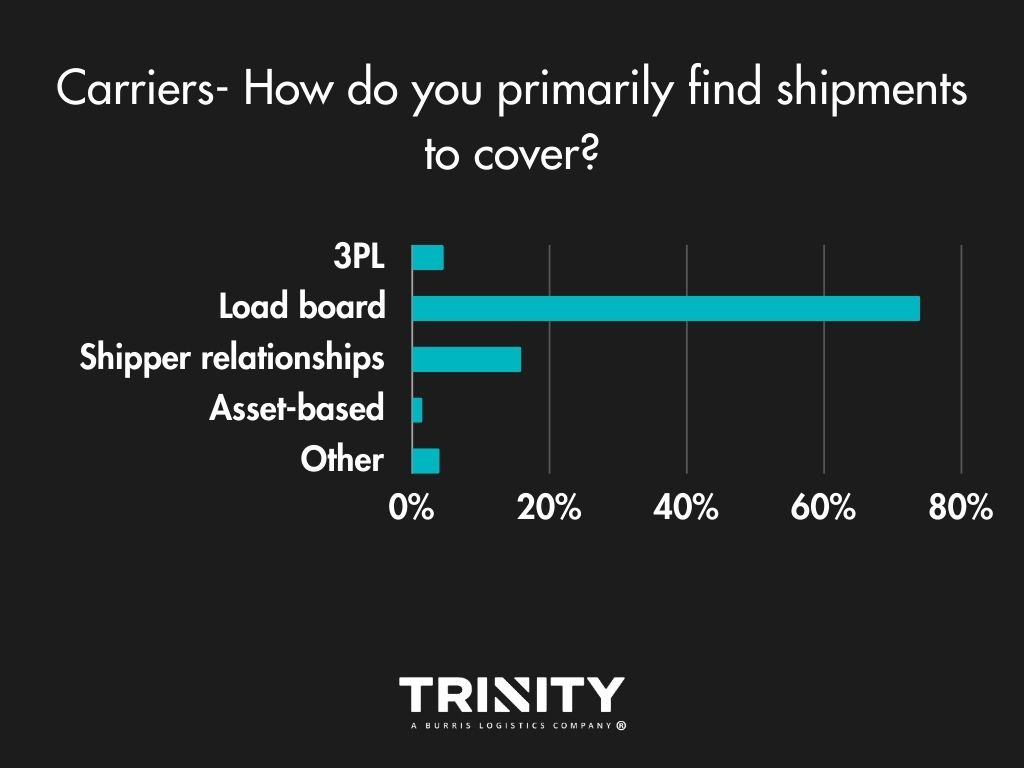

Load Boards are the Way

With 74 percent selecting this option, load boards are the norm for carriers to find available shipments. Sometimes they use their shipper relationships, and occasionally they make use of a 3PL.

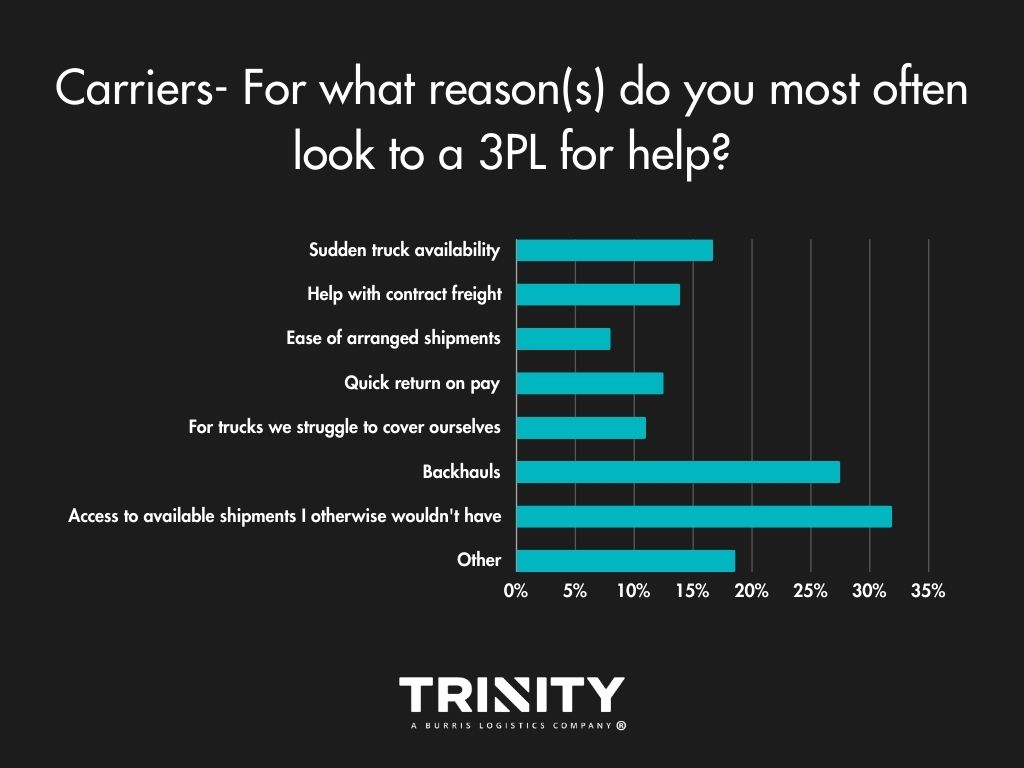

3PLs – Expanding a Carrier’s Reach

Carriers most often look to a 3PL for help with gaining access to available shipments that they wouldn’t have otherwise. Covering backhauls are another big reason carriers reach out to a 3PL.

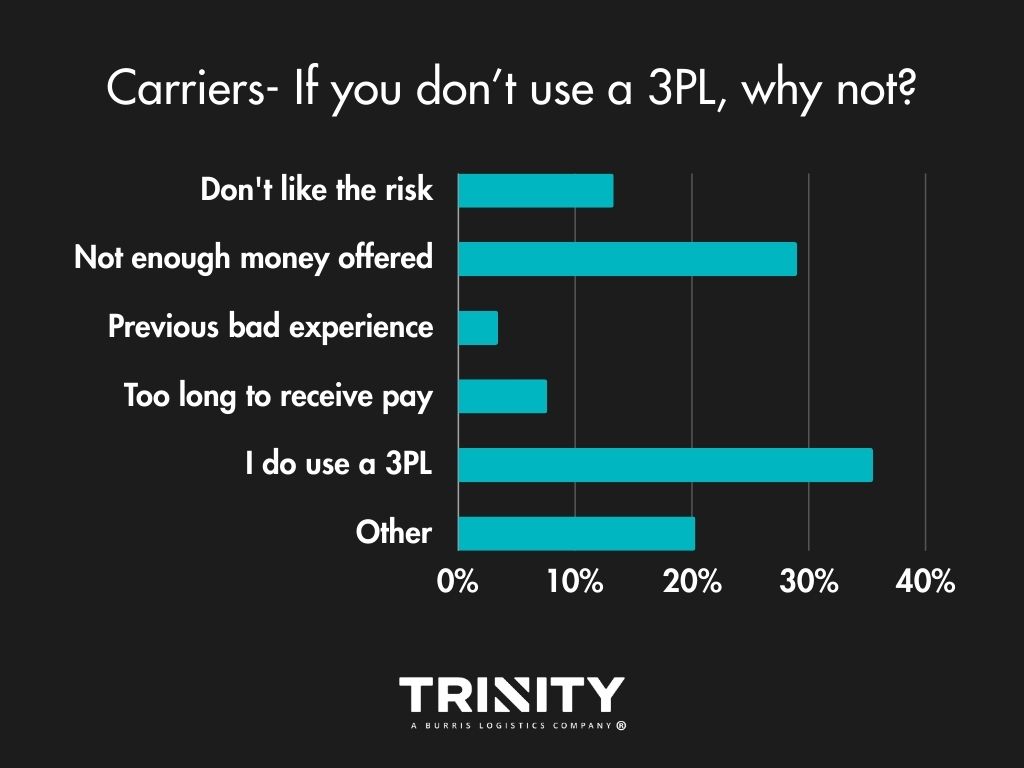

For those that choose to not work with a 3PL, it’s often because of money; rates not being high enough. Surprisingly in the comments, many are not familiar with what a 3PL or freight broker is as well.

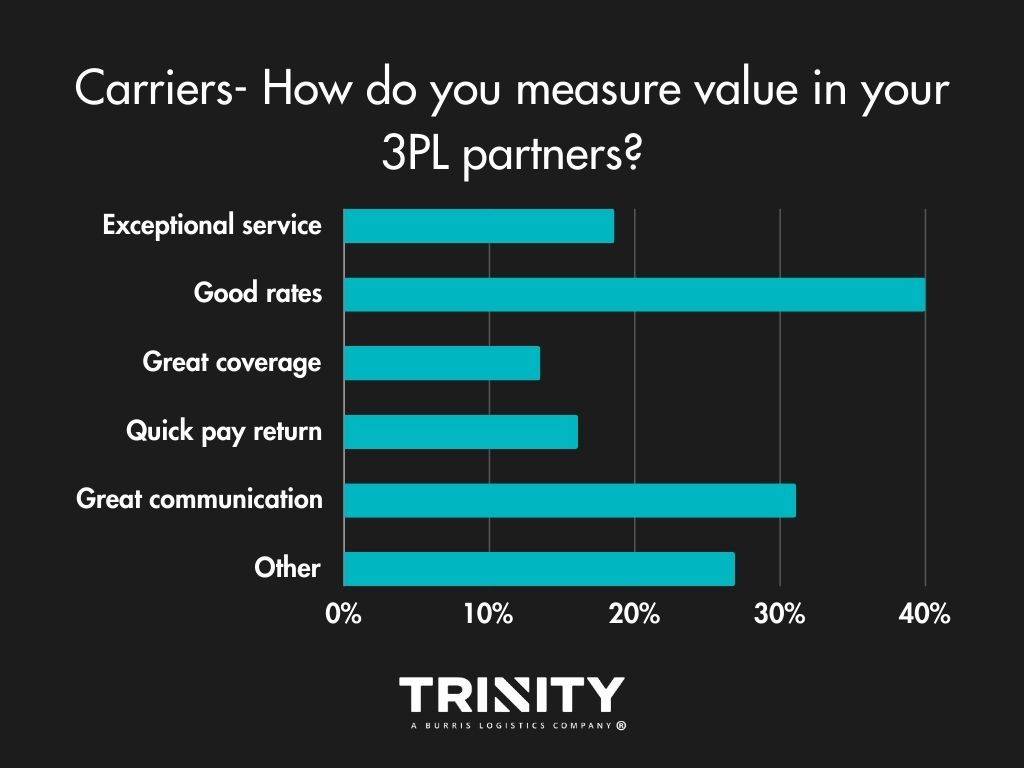

When it comes to measuring value in their 3PL partners, most carriers want good rates and great communication.

Fraud Concerns Growing

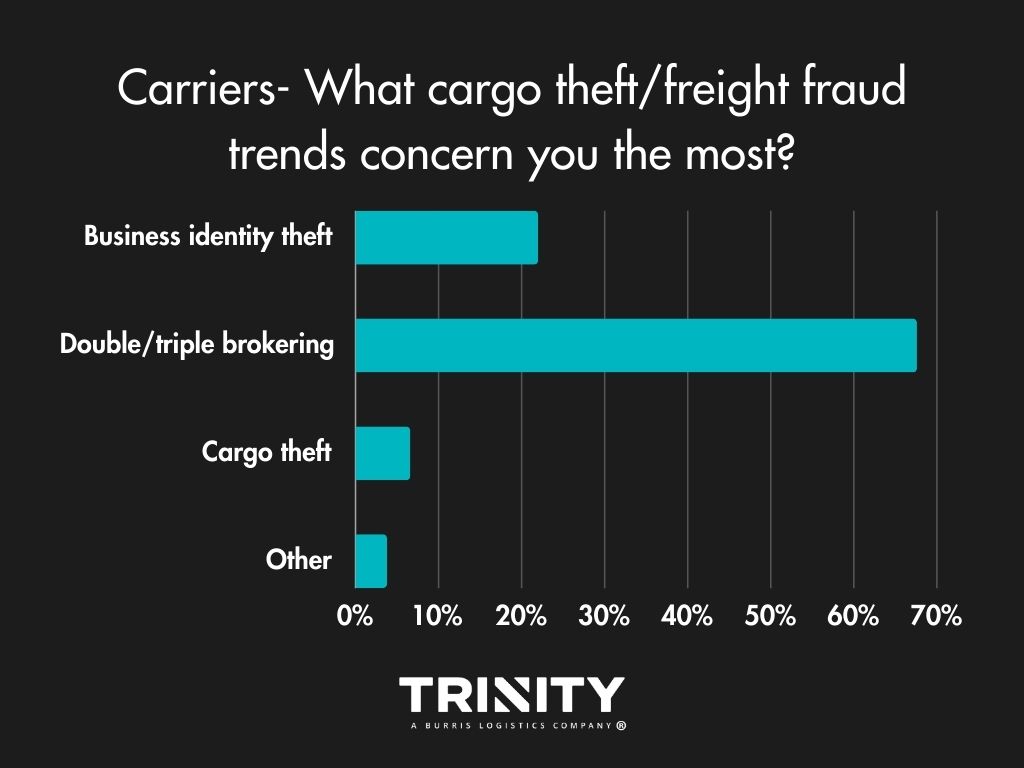

Fraud and scams have been growing in the industry, so we wanted to know what carriers think about it. Carriers are most worried about double and triple brokering affecting their businesses compared to concerns of identity theft or cargo theft.

Have you ever wondered what a freight broker is, what they do, and why they exist?

To put it in simple terms, freight brokers are simply matchmakers. They are the middleman between the shipper (the maker or owner of the product) and the trucking company that moves the freight.

Freight brokers perform a valuable service for both ends of the spectrum, however, they do not function as an actual motor carrier. Instead, they arrange for the transport of goods.

Freight broker activities are under the jurisdiction of the Federal Motor Carrier Safety Administration (FMCSA) which defines a broker as “a person who, for compensation, arranges, or offers to arrange, the transportation of property by an authorized motor carrier”. -49 C.F.R. Part 371

Brokerages

Freight brokerages provide assistance to motor carriers by filling their trucks and providing assistance along the route to help the truck driver deliver the order on time.

Not every motor carrier has a private sales force working to secure loads for their fleet and needs help accessing a network of shippers quickly to keep them rolling. Freight brokers also provide great financial service to truckers, providing fuel advances to help with cash flow and offering quick payment plans. Oftentimes, the carrier is paid before the freight broker collects payment from the shipper! Bottom line, a freight broker exists to help the motor carriers relocate their equipment to a better freight market, or in many cases, back to their home base.

Many companies find the services provided by freight brokers to be an important link in their supply chain. The importance of a freight broker is easy to understand; the freight broker makes sure that the shipments are arranged to deliver on time at a fair price with reputable providers. Without freight brokers, shippers would encounter an enormous investment of time and money trying to find the right motor carrier to transport their products, tracking the shipment, and auditing freight bills.

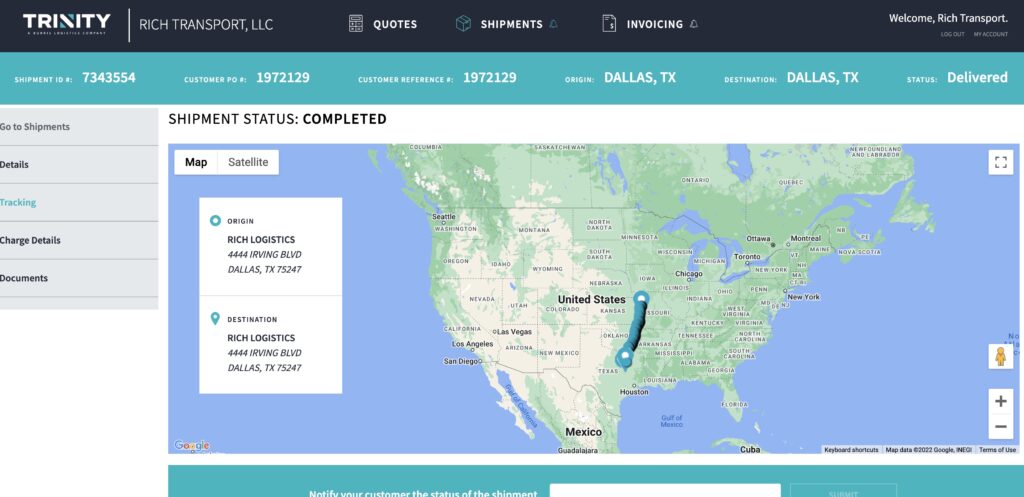

Frustrated with your shipment tracking? Check out Trinity’s Customer Portal and see how easy it is to track your shipments, view and pay your invoices online, and request freight quotes.

Discover Trinity Logistics AS YOUR FREIGHT BROKER PARTNER

Trinity Logistics, ranked by Transport Topics as one of the Top Freight Brokerages for the 20th consecutive year, moves an average of over 40,000 loads per month. With that amount of volume, we carry significant buying power and relationships with our carrier network. That translates into savings on each shipment that many shippers may not be able to obtain based on their volume alone.

Trinity Logistics saves shippers and motor carriers a great deal of time playing matchmaker. Our goal is not only to deliver your product on time but also to deliver time itself so that you can perform at your best without having to become experts in matching loads to trucks or vice versa.

Learn more about our solutions.Using transportation management software (TMS) is a powerful way to gain control and visibility over your supply chain. But trying to decide which transportation management provider to use can be overwhelming. There are so many different software platforms available and providers that offer transportation management software. How can you choose the best software and provider for you?

When starting your search for a transportation management provider, there are several questions you should ask yourself:

- Do I want a cloud-based TMS or otherwise?

- What capabilities do I want from the TMS?

- Do I want a Managed Services option?

- Am I looking for more help than just technology when it comes to my logistics?

- Most importantly, do I want to buy the software outright or outsource it?

BREAKING DOWN THE TWO TYPES OF TRANSPORTATION MANAGEMENT PROVIDERS

On a high level, there are two different types of companies that offer TMS products. There are software companies whose sole purpose is to develop and sell TMS software. Then there are third-party logistics (3PL) companies that offer TMS software as one element of the many other logistics and transportation services they provide.

There are differences and advantages to working with each kind of transportation management provider. Particularly, sourcing your TMS through a 3PL provider can have some major benefits, especially for small- to medium-sized businesses.

In the past, implementing a TMS was usually out of reach if your company was not of a certain size. However, advances in transportation management software have made it an option for more companies than ever.

For this reason, deploying a TMS can be a new experience for small- to mid-sized companies. And working directly with a software provider can be intimidating if that’s the case. Additionally, logistics may not be a core focus for smaller companies, so they might need an extra hand in determining their best solution.

TRANSPORTATION MANAGEMENT SOFTWARE COMPANIES

The transportation management software of today is nothing like it was years ago. However, implementing a TMS will often make it the new backbone of your supply chain. And if you’re looking to purchase software outright versus outsourcing with a 3PL, you’ll soon realize that not all transportation management software companies offer the same thing.

When shopping around for your own transportation management software, you’ll want to look for these capabilities:

- Rating and contract management

- This will help you with managing freight rates, sourcing, contract management, and bid RFP tools.

- Order planning

- This will help you with routing, optimizing your delivery processes, integrating your delivery data, and getting a granular view of all transportation stages.

- Optimization

- This will help you by offering more comprehensive load-building tools so you can identify opportunities to reduce costs, whether through consolidation, multi-stops, zone skipping, pool distribution, or other methods.

- Load Tendering

- This helps you by automating tendering, managing your carriers, and helping turn quotes into loads.

- Tracking

- Simple enough, this helps you by giving you end-to-end, real-time visibility.

- Reporting

- This gives you more insightful data into your processes, so you can review expenses, carrier performance, and more to find what’s working and what’s not.

- Financials

- This helps you by helping automate financial operations.

According to Intek, these are some of the top transportation management software providers:

A TMS ALONE MAY NOT BE WORTH IT

Just like buying QuickBooks doesn’t automatically make you an accountant or purchasing Adobe Creative Suite doesn’t make you a graphic designer, purchasing a TMS outright doesn’t automatically make you an expert in how to use it.

To start seeing the benefits of transportation management software, you’ll need a team of experts to use it. You’re going to need to build out a team of transportation management software specialists who can expertly use, read, and pull reporting from your new TMS. Unfortunately, the amount of expertise and support needed can be difficult to find, establish, and maintain.

This is where you might find a greater benefit to using a transportation management software provider who does more than sell TMS software.

MAKING A CASE FOR A 3PL PROVIDER

You might think 3PL companies only handle arranging freight, but they offer so much more and can be an ideal transportation management provider.

Transportation Management Software

A 3PL can be an excellent option for a transportation management provider. Not only do you gain access to their TMS technology, you know that they will know the software inside and out as most make use of it themselves. You’ll have access to experts who know how to make use of all the tools and reporting. Additionally, many offer Managed Services with their transportation management software, meaning you could have a team of TMS specialists ready to help you from Day 1. No worries over finding, training, and retaining your own in-house team.

Access to Their Relationships

Outside of their transportation management software, you’ll also gain access to a 3PL’s relationships. This includes their carrier, vendor, and technology relationships. So, whether you need them or not, it’s still good to know that should the time come when you need some extra help, you have a 3PL on your side to support you through their built industry connections.

Expertise

Often, 3PLs have seen it all. They’ve most likely worked with many different companies, freight, and complicated situations. They’ve faced supply chain disruption, tight turnaround times, and transportation inefficiencies. Having a logistics expert like a 3PL on your side can be an exponentially significant benefit. It can be near impossible to source the type of knowledge and consultative expertise a 3PL has without directly working with one.

Customizable Solutions

Generally, a 3PL will work with your team to deploy a system that specifically meets your needs, while a software company is more likely to offer an “out of the box” solution. That’s perfectly fine if you know exactly what you are looking for. But for smaller companies with less logistics experience, it can be overwhelming. A 3PL can help fill the knowledge gaps and ensure your investment is valuable and will have ROI.

This difference can also have an impact on the cost of implementation. Software companies tend to consider a customized solution as more work for their implementation team, which translates into person-hours, and into higher implementation fees for your company. On the other hand, an experienced 3PL can guide you through the process and advise the best options for your company, and that’s not considered an additional service. Again, this may not be required for companies with very experienced and knowledgeable logistics departments – especially if they have implemented a TMS before – but it’s extremely valuable for businesses that may be doing this for the first time.

TRINITY LOGISTICS COULD BE THE TRANSPORTATION MANAGEMENT PROVIDER FOR YOU

Trinity Logistics is an excellent example of a 3PL that offers a TMS to its customers while also offering many other services.

At Trinity, we understand everyone’s needs are different, which is why we offer a highly configurable system. To start, we offer you three main options in transportation management software:

- Software-as-a-Service (Saas)

- Looking just for transportation management software? Through this option, you’ll get the tech, support, and account management.

- A managed TMS

- Looking for a TMS and some additional support? Through this option, you’ll get TMS technology and operational support to offload your day-to-day processes.

- An Integrated outsource TMS

- Want to fully outsource your transportation management? This option gives you the TMS plus a fully outsourced logistics team with an integrated partnership.

If none of those three options fit your business’s needs, we can further customize a solution for you, so you get exactly what you’re looking for. No matter your unique needs, you’ll gain access to our best-in-class technology backed by superusers with logistics expertise. And through our People-Centric service, you’ll gain valuable insight, support, and knowledge for your company’s logistics management.

GET A FREE SUPPLY CHAIN ANALYSIS TO SEE WHAT SOLUTIONS WE HAVE FOR YOUNOT LOOKING FOR A FULL TRANSPORTATION MANAGEMENT SOFTWARE EXPERIENCE?

We understand committing to a transportation management provider is a big change. That’s why we also offer you Trinity’s Customer Portal, exclusively for shippers working with Trinity. There’s no commitment or additional charges and you’ll get to experience a sample of our TMS technology. Through the Customer Portal, you can track your Trinity shipments, request quotes, and view and pay your invoices online – all in one place.

START SHIPPING WITH TRINITY TO GAIN ACCESSAuthor: Christine Morris

If you’re thinking about expanding your supply chain into shipping to and from Mexico, you’re not alone. Business between the U.S. and Mexico is booming. Currently, Mexico is the U.S.’s second largest trading partner, after China. The U.S. is Mexico’s largest trading partner, with 80 percent of Mexican exports going to the United States. Since the North American Free Trade Agreement Implementation Act (NAFTA) in 1994, U.S. exports to Mexico have risen 517 percent and Mexican exports to the US have grown a huge 797 percent!

Customs Classification

Any goods to enter or leave Mexico is subject to a customs classifications. When shipping to and from Mexico, you’ll have to classify your goods based on the function you’re goods will have either in Mexico or abroad.

If you’re looking to export your finished goods into Mexico for sale or consumption – this is called “definite” importation. Alternatively, maybe you’d like to temporarily ship raw goods into Mexico to be assembled into a final product which will be imported back into the US – this is called “IMMEX” importation, and it allows you to avoid being taxed on the imported goods, since they are not staying in Mexico permanently. On the other hand, perhaps you’re importing materials from Mexico in order to manufacture your products here in the US. No matter the situation, compared to shipping domestically, there are a lot more factors you’ll need to consider when arranging the transportation of your goods.

Shipping to and from Mexico

When you ship a truckload of freight within the United States, it’s a pretty simple process, even though it may not feel like it sometimes! In general, your freight is only loaded and unloaded once with the same truck driver and trailer bringing your goods from door to door and you don’t need to involve any third parties, besides the carrier or freight broker. However, when you’re shipping to and from Mexico, it’s a little different.

In its journey from country to country, a different carrier will be delivering your freight than the original carrier who picked it up. Depending on whether you select “door-to-door” or “door-to-border” service, your freight may be loaded and unloaded multiple times onto different trailers. The services of a customs broker and freight forwarder will be required to assist with customs clearance. If you elect to use a third party-logistics company (3PL) for the arrangement of your shipments, many of these details can be taken care of for you, although you can choose to elect a customs broker or freight forwarder of your choosing if you’d prefer and if the freight is being delivered to you. The provider responsible for making these third-party arrangements depends on which direction you are shipping.

Shipping TO Mexico

To break it down a little more simply, here’s a run-down of the process when you’re shipping TO Mexico (exporting):

- A U.S. carrier will haul your freight to the border and deliver it to the designated freight forwarder that has been selected/hired by the Mexican consignee (the recipient of your goods.)

- The freight forwarder receives your shipment, inspects the cargo, reviews all the documents, and prepares the shipment to make entry into Mexico on behalf of the Mexican customs broker who is servicing your shipment.

- The Mexican customs broker will formally file the Mexican customs entry on behalf of the Mexican consignee.

- Now it’s time for your freight to cross the border! A third party drayage company will haul your shipment over the border, through customs, and then deliver it to the selected Mexican carrier’s facility.

- Finally, the Mexican carrier hauls your freight inland to its final destination in Mexico, the consignee.

Shipping FROM Mexico to the U.S.

Because it’s a little different going the other direction, here’s how it goes down when you’re shipping from Mexico to the U.S. (importing):

- A Mexican carrier hauls your freight to the border city.

- A Mexican customs broker formally files the Mexican customs export entry on behalf of the Mexican shipper so that the goods can legally leave the country.

- Then, a licensed U.S. customs broker clears the shipment and files the U.S. customs entry so that the shipment may enter the U.S. on behalf of the U.S. importer of record (the consignee).

- A third party drayage company will haul your shipment over the border, through U.S. customs, and deliver the shipment to the chosen U.S. carrier’s facility.

- The U.S. carrier hauls the freight inland to the final destination.

INSURANCE LIABILITY

There’s one other important thing to note. The insurance liability for freight moving into Mexico is very different from the insurance liability in the U.S. All U.S. carriers offering door-to-door service have limited or no liability coverage for shipments once they cross the border into Mexico. It’s important to arrange additional cargo insurance for the Mexican portion of the journey, which you can usually arrange either through your logistics service provider or through the customs broker.

SHIPPING TO AND FROM MEXICO WITH TRINITY LOGISTICS

If you’ve never shipped to or from Mexico before, learning the process to do so can be a little confusing or overwhelming at times. However, through having offices in bordering cities, Team Members fluent in Spanish, and years of experience in shipping to and from Mexico , Trinity Logistics is your ideal partner to help you with this process and assist you with any of your Mexico shipping endeavors.

LEARN HOW WE CAN HELP YOU SHIP TO AND FROM MEXICOOnshoring, nearshoring, reshoring – these are terms that we keep hearing in growing popularity lately. Even before Covid-19, many companies have considered onshoring their operations due to concerns about quality and supply chain disruptions. Political tensions and rising tariffs also triggered the growing considerations.

When Covid-19 hit, it led to sky-high air and ocean freight rates. Any companies with operations in China saw their productions come to a halt. Offshoring your operations has never been riskier. You never know what could happen in another region and how that could affect your operations if offshored. So, the question is, should you be onshoring your operations?

A BRIEF LOOK BACK

Before the 1980’s manufacturing had a large presence in the United States. Technology improved communication and global transportation, so companies saw the opportunity to save on costs by offshoring their operations outside the United States. Offshoring grew and became the norm, until recently. Onshoring has become popular again due to politics, rising labor costs, and increased demand for higher quality products.

WHAT DOES IT ALL MEAN?

Onshoring, nearshoring, or reshoring; it all refers to the overall practice of moving manufacturing operations from foreign soil back to the United States. It may also refer to the practice of outsourcing to domestic contract manufacturers rather than overseas. Nearshoring can also refer to the moving manufacturing to outside the United States, but not across ocean waters. An example of nearshoring would be having operations moved to Mexico.

Offshoring involves outsourcing manufacturing assets far outside of the primary country of operations. American companies have traditionally offshored manufacturing to Asian or Southeast Asian regions. Offshoring has been used in situations where production, materials, and labor costs outweigh travel complexities and shipping costs.

ONSHORING VS OFFSHORING WHEN IT COMES TO..

..YOUR CUSTOMERS

Poor customer service can have a huge impact to your company’s success. More than 50% of consumers said they would never do business with a company after just one negative experience. When choosing to onshore your processes, it gives you the benefit of serving and supporting your customers from “home”, which reduces your risk of your customers receiving poor service elsewhere.

Customers nowadays like to support products made in their own country. They feel that it further benefits the local economy and they feel more confident in a products quality when its been made in the same country. Depending on your customer base, this could give you a huge advantage over your competitors.

Due to the recent Amazon Effect, customers now expect their products delivered to them in days. Shorter travel times can make that expectation easier to meet. If suppliers are farther away, delivery times can sometimes be uncertain and take longer. Customers also want full transparency on their freight’s travel, and onshoring can make that more successful on your end.

..YOUR SUPPLY CHAIN

Onshoring can offer you better supply chain management. It allows shorter lead times because companies can operate all within the same time zone (or at least closer to each other than if offshoring). Not to mention other processes that can take time, such as design and approval. All parties in the supply chain can have closer relationships because they won’t have to deal with the challenges of long distances and varying time zones. Nor do you have to worry about the risk of facing language or cultural barriers among locations. Onshoring is becoming very popular for those organizations that need a lot of communication to be successful.

..YOUR COSTS

With rising labor and shipping costs, many find savings are no longer there when it comes to offshoring. Time is money and offshoring can add weeks to delivery times. Shorter distances with onshoring mean reduced (and less complicated) transportation costs. This also means less fuel used, giving you the benefit of being greener (and customers like that).

As time goes on, overseas economies are further developing, taxing is changing, labor, wages, and shipping costs are all on the rise; all making it less profitable to handle business offshore. Tariffs have risen in recent years, with some commodities up to a 25 percent charge. By choosing to even nearshore your operations rather than offshore, you can avoid those increased costs.

There’s also the possibility of defected goods arriving to consider when offshoring. Recalled products have been a rising concern. The defect rates of shipments from other countries can be so high at times that entire batches must be inspected upon arrival. The time and expense to do this and rework or scrap products, can wipe out the savings offshoring promised and even exceed your original budget.

THINGS TO ASK WHEN CONSIDERING ONSHORING

Tariffs, customs, duties

- How many fees will you incur in transporting your finished goods to distributors? Could these fees be avoided if goods are produced elsewhere?

Transportation costs

- Transportation can sometimes be your largest expense. You can reduce costs by shortening travel distances or choosing to work with a logistics company, like Trinity Logistics.

Lead times

- How long will it take to get the finished product in hand? Lead times vary depending on how far away production takes place. Make sure to consider design and approval time. This is one part of the process where differences can slow down your production.

Political environments

- What is the political climate like in the region where your goods are produced? No country is immune to civil unrest. What is the political climate like between your primary company’s country and where the products are made? Consider any chance of future supply chain disruption, and those tariffs.

BEFORE YOU DECIDE..

Before you make your decision on whether to onshore or offshore, make sure to consider all factors. Onshoring may seem like the answer right now, but will it still in the future? If transportation costs and delivery disruptions are your main concern in business, consider looking into outsourcing your logistics with third party-logistics (3PL), like Trinity. Choosing to work with a 3PL can offer you some of the same benefits as onshoring, but with less work on your part.

FIND MY SOLUTIONWhether we’re talking cases of red chili sauce, boxes of brake rotors, or a handcrafted statue of a whale (yes, we’ve moved that!), proper freight packaging can make all the difference when shipping Less-than-Truckload (LTL). Think of the packaging as a line of defense against the transportation elements: forklifts, shifting pallets, unloading a trailer, all the transitions that an LTL shipment goes through from start to finish. Correct and adequate packaging is something that should be a top priority for shippers and manufacturers that work within any freight space (not just LTL) to ensure freight ships and arrives just as it left their facility.

All freight is different; different values, different shapes and sizes, different ways of packaging. There are countless variations of freight packaging, but here are some general guidelines to follow:

Palletized/Crated/Boxed/Toted

- This allows carriers to easily move freight on and off their trailers

- It keeps the freight contained into larger shipping units, reducing the possibility of a misplaced piece

Shrink-wrapped and banded

- Adds rigidity and stability to palletized freight

- Shrink-wrap can prevent any unwanted moisture or dust contact

- Bands keep the freight from shifting or moving off a pallet

Marked with clear and accurate labels and packing slips

- Ensures freight gets to where it needs to go

Minimal freight overhang on the pallet (less than 3 inches on any side)

- Overhang can make it difficult to get forklifts and pallet jacks under the freight

- Excessive overhang can cause freight to tip over and/or raises the risk of damage

Besides providing a great level of physical protection, beefing up freight packaging can have immense benefits for your business.

Don’t let poor freight packaging “claim” you as a victim

Great packaging can protect a shipper’s freight from transportation damages, inherently cutting down on costly freight claims. Think of good robust packaging as a business investment. Putting the time, process, and money into proper freight packaging can really go a long way in preventing any damages caused while in transit. In the unfortunate event that freight damage does occur, claims that contain properly packaged freight have a much better chance of being won and paid. According to the Carmack Amendment, an act or default of a shipper, such as improper freight packaging, is one reason why freight damage claims get denied by carriers.

Packed like peas in a pod.

Having all the product densely packaged and contained onto shrink-wrapped pallets or enclosed crates can reduce the risk of having misplaced or missing freight. Think of a shipment of boxes as a Jenga puzzle: nice, neat, and well-stacked but without anything to support it, it can easily fall over, or a piece can be misplaced. Take that same Jenga puzzle and wrap it in shrink-wrap, throw some shipping bands around it, and slap it on top of a pallet. Now it’s nice, neat, well-stacked, and contained into one dense and stable shipping unit that can easily be transported.

Build better relationSHIPs.

Effective and excellent freight packaging can also produce positive business reception from consumers and consignees. Something as simple as how freight is packaged to ship can create a lasting impression on consumers and receivers. It conveys a sense of quality and care in the goods that a shipper manufactures and sells.

Packaging is often a shipper’s first line of defense against transportation mishaps. If you’re ready to learn more about how to effectively package LTL freight, contact us. Need a quote? Click here.

There was over two feet of rain and an estimated $18 billion in damages as Tropical Storm Florence pummeled the Carolinas and other parts of the Atlantic. There were 691,000 customers without power and water had closed parts of Interstate 95. As Florence pushed on in the United States, Typhoon Mangkhut hit the Philippines that Saturday and then China on Sunday, causing an estimated cost impact on Hong Kong’s gross domestic products of $627 million per day. Although devastating, these side-by-side catastrophic events are seemingly becoming a norm.

The last two decades have brought about increasingly destructive natural disasters. From Hurricanes Katrina and Sandy to the eruption of Eyjafjallajokull volcano in Iceland to the earthquake and tsunami in Japan. Along with widespread devastation to their physical surroundings, each of these natural disasters has impacted business operations in many cases on a global scale.

Over the years, climate changes are happening at a faster pace than originally anticipated. This has resulted in rising sea levels, which coincides with more severe storms, temperature swings, and volatile precipitation. Because of this, we have seen and will likely continue to see more intense weather that will have greater destructive potential, according to the National Oceanic and Atmospheric Administration (NOAA).

In this blog, we’ll go over the economic and supply chain impacts that result from these events and how you can best prepare your supply chain.

Impacts on the economy and supply chains

Severe weather has exponential impacts on our global economy. According to Aon Benfield’s 2016 Global Climate Catastrophe Report, the world saw $210 billion (USD) in economic losses because of 315 separate natural disasters. That’s 21 percent above the 16-year average of $174 billion (USD).

In 2017, Hurricane Harvey victims saw over 178,000 homes lost, $669 million in damages of public property, around a quarter million vehicle losses, $200 million in Texas crop in livestock losses…and the list goes on.

Additionally, businesses saw significant and expensive losses due to flooding, electrical outage, and employees’ inability to get to work, all causing temporary disruption of the flow of goods and services.

But the impacts of natural disasters reach far beyond the local damages of affected areas. When these natural events happen, numerous businesses find their supply chains shook.

The Tohoku Earthquake and Tsunami in Japan and the Thailand Floods in 2011 are both examples of natural disasters that had a much wider indirect economic effect. Both disasters caused severe disruption to global technology supply chains.

After the Thai floods, there was a global shortage of computer hard drives that sent consumer prices skyrocketing until factories were able to get back up and running. When the 2011 tsunami struck, several major car manufacturers were forced to shut down production at factories throughout Europe and the U.S. due to a lack of available parts from factories in Japan, setting off a supply chain reaction that impacted multiple suppliers of parts throughout the wider global economy.

Snowstorms are also a culprit of transportation delays and supply chain worries. If weather conditions drop below a certain temperature truck engines will not start, quickly accumulating snow may mean railroads might not be able to clear the tracks fast enough and snow and ice can make it impossible for planes to travel safely. All causing disrupted supply chains across the country.

Preparing your supply chain

With the increase of natural disasters, ensuring that your business is prepared for the potential disruption is very important. Disaster planning needs to consider not just the direct impact to your infrastructure, but how the after-effects of events far away from your base of operations could affect your supply chain and markets.

Create a disaster preparedness plan

Have a plan ready that outlines what to do in case of emergencies and natural disasters. This plan should take into consideration all types of weather and natural disaster your area is most susceptible to, and perhaps some that would particularly be considered unlikely. Snow in Florida? Probably not, but hey, with climate change you never know. Also, be sure to ask companies you partner with for their disaster plans to ensure alignment with risk management.

Monitor for threat

Supply chain risk management works best when companies have the earliest possible notice of potential disruptive impacts. Keeping up with potential weather, running a data analysis, and running simulations across your supply chain to identify pressure points where natural disasters would most likely impact your operations are all ways to keep up with your disaster preparedness plan.

Be transparent and flexible

Many natural disasters may be impossible to predict (earthquakes, wild fires, etc.) so disruption may be inevitable. Be open with members of your team and companies you partner with about how weather or natural disaster may affect capacity and your company’s supply chain. Additionally, think about substitute work spaces and methods of transport for your goods.

It’s never too early to revisit your risk management and disaster preparedness plans. As we all know, disaster can strike at any moment. At Trinity, we work with a network of over 70,000+ carriers and we’re always looking at the state of the industry and communicating with our customers.

If you’re looking to partner with a 3PL to help manage your supply chain or help your business, fill out our quick form.

A day in the life of logistics has a loose framework and cycle, with each shipment navigating its way from creation, shipment, billing, and payment. Each day is different and exciting for shippers, carriers, and third-party logistics companies alike.

As a 3PL, we spend our days receiving shipments and working with carriers to arrange transportation via truck, rail, air, and sea.

So, want to know what a day in the life of a third-party logistics company is like? We’ll give you a front row, 3D tour (okay, not 3D…we don’t have a Virtual Reality tour just yet).

Shipments

Every day, our Logistics Specialists, Logistics Assistants, and Account Managers for each Team come in, get their morning coffee, tea, etc., say hello to their colleagues and sit down to their computers.

On average, there are about 90-100 shipments waiting to be covered when the day begins. Some have already been handled by our 24/7 Team (the night crew, if you will) and some will be easier to find a carrier for than others.

Our Operations Department at each Regional Service Center (five offices around the United States) is made up of individual teams that each handle certain customer accounts. These teams will be responsible for checking what shipments have been sent in by our customers, what is already loaded into the system, and calling to check up on other customers to see if they have any shipments that need to be taken care of.

As soon as the day begins, these teams spend the next 8 or so hours making the magic happen. Talk about hard workers with dynamic personalities!

Cycle of a shipment: finding a carrier

When a customer has a shipment that needs to be covered that day, it is listed as pending in our freight management software. It can make its way to us through a phone call, fax, email, or our Transportation Management System (TMS). At this point, our job is to find a carrier who can pick up and deliver that shipment in the necessary time frame. This is where the fun and unique form of matchmaking begins.

We have a network of more than 32,000 carriers who are currently vetted in our system and checked for operating authority, insurance information, and safety ratings. These carriers are checked on a daily basis for compliance and before every shipment.

When choosing a carrier for a particular shipment, we either work with what we call “relationship carriers”- carriers that we’ve developed a relationship with over time, or a carrier that is newer to us, in terms of tenure with us or number of shipments handled. The idea is to develop relationships with all of our carriers to not only build rapport but to help our customers receive the best rates and service possible.

Once we’ve found a carrier for that shipment, we call the carrier or driver directly to dispatch them on this particular shipment.

Logistics and Relationship Carriers

It seems impossible– a network of 32,000 carriers, you can’t possibly get to know them, right? Walking through the operations floor, you’ll hear the conversations and know that building relationships with our carriers is a part of what we do.

Two of our Logistics Specialists, Nicole Hastings and Carrie Harman, booked more than 300 shipments each in April 2017. Carrie says working with relationship carriers is a huge part of hitting that number, but so is coming in early to cover hot shipments, putting in extra effort to find carriers to haul harder to move or less desirable freight, and staying on the phones day in and day out.

Cycle of a shipment: Carrier Relations

Before a carrier is dispatched for a shipment, our busy bees in Carrier Relations get to work. This team makes sure that everything needed for compliance is on file. If anything needs to be updated, someone from the Carrier Relations team will contact the Carrier and make sure it happens so the driver can get on the road. This team stays in contact with the Logistics Specialists to make sure everything runs smoothly.

Driver is on the move

After we dispatch one of the drivers in our network, they begin heading to pick up the shipment and get it to its destination. Whether it’s a truckload of tomatoes, a few pallets of paint, a container of radios to go over the rail, or an expedited shipment of emergency response equipment that has to ship fast, our logistics team is contacting carriers and getting tracking updates on all shipments for our customers.

If there’s any factor that could create a delay in a shipment, our team is working around the clock to troubleshoot and problem solve.

If a truck were to break down “after hours,” which has happened before, our 24/7 Team is able to find another driver who could get there, load the shipment onto his/her truck and be back on the road, without a single hiccup in the delivery window. The customer knows there was a change in trucks, but there was no interruption in service.

Driver arrives at destination

Once the driver arrives at the freight’s destination, he or she either backs up to a loading dock or uses a forklift or liftgate, etc., to unload the shipment. The receiver (the location/person receiving the shipment) verifies that everything came off the truck as it should, and our team confirms.

At this point, the driver can then be released to head out to the destination, and the “behind the scenes” work on that particular shipment can begin.

Billing Cycle

Once the shipment is delivered, the billing and payment cycle begins. The drivers can either email or fax their paperwork to our billing team. Then, the carrier gets paid and the customer is billed for the shipment.

In April 2017 alone, our billing team processed tens of thousands of bills – and our Customer Service team fields any questions that may come through about payments.

This entire process cycles again for every shipment that is booked through Trinity Logistics. This process happens hundreds of times a day on our operations floor – a converted bowling alley with Teams of Logistics experts in a “bull pen” –solving issues, covering freight, and finding solutions for the most challenging shipments.

Why work with a 3PL?

In the cycle of arranging shipments, there are only three real pieces of the puzzle that involve our customers. First, our customers contact us with their shipment details. Later in the cycle, we provide them with tracking updates. Then, they receive a bill for the shipments, and only have to pay Trinity for the shipments, instead of each individual carrier.

We work with customers who are looking to cut down on the amount of time spent finding trucks to cover their shipments and are looking to expand their capacity. Some of our customers take advantage of our Transportation Management Systems to completely outsource their logistics operations with Trinity’s account management and carrier base.

We take the time to update our customers on industry news that could affect their core business and find solutions together. Our main goal is to help save our customers time, money, and headaches.

We also offer:

– Single source for all shipment arrangement

– Innovative solutions

– Integrity and personal relationships

– A full team ready to make your shipments flow quickly and smooothly

Get a Quote Today!

Give us a call or fill out our form.

Our Logistics Experts are always a phone call or click of a button away. Fill out our simple form and we will reach out to you with a quote on your shipment. It’s that easy!

If you’re unfamiliar with third-party logistics companies, or 3PLs, you may be left with a lot of questions about what exactly they are, what to expect from 3PLs, or the benefits of working with one.

Whether you’re currently working with an asset-based company, you’re starting to shop around for the best rates for the lanes you need, or you’re working out of your basement in the business brainstorming stages, there’s no time like the present to check out why a 3PL could be best for your particular needs.

Here at Trinity, we’re all about teamwork (it’s one of our guiding values). So when you think of a “third-party” in terms of a 3PL like Trinity Logistics, it means we are more of an honorary extension of your team rather than just a silent partner. In this blog we’ll go over what to expect and benefits of working with a 3PL by using a few scenarios.

Scenario One:

Since these are hypothetical scenarios, we’ll make up names for our fictional business owners and associates. Let’s say Bob owns a small packaging company with about $45 million in annual revenue. His business has been family-owned from the start, and he has a good-sized staff that has done their best to manage his supply chain over the years, but their network of carriers is small.

Business is growing and Bob’s staff would either have to devote more time and resources to coordinating the increased freight, or hire additional staff. After meeting with leadership, Bob and his team decided they simply couldn’t afford to tie up any more resources in managing their supply chain.

Bob reached out to a 3PL and learned how he could leverage their experienced staff as an honorary extension of his own team. No longer would valuable time and resources be spent shopping for the best rates and finding carriers to cover their loads.

Working with a 3PL opened up many doors for Bob’s company. He developed a relationship with the manager of his account, who was able to give him a review of areas that could be improved to maximize efficiency. His 3PL was even able to find warehousing for his product, opening up even more opportunities for Bob’s business. Smart thinking, Bob.

Scenario two:

Stacy is an entrepreneur who started her own organic snacks business. She gained her business fame through social media marketing and exhibiting at various trade shows. Now the demand for her product is expanding and she doesn’t know the first thing about coordinating shipping.

Stacy has worked so hard to get her business to this point, so the last thing she wants to do is trust her product in the hand of strangers. In her research, Stacy stumbled across the term 3PL.

After contacting one, she quickly found out that it would be a perfect fit for her company. A 3PL would become an honorary extension of her own team: validating carrier’s insurance, managing her pricing requests, and coordinating the shipment of her products, whether it was less-than-truckload (LTL) or a full truckload, tracking them from start to finish.

Working with a 3PL helps Stacy focus on securing more customers and servicing her current ones better, with peace of mind that her products are arriving where they need to go, right on time.

Scenario three:

Of course, there are many scenarios where 3PLs would be beneficial to a company, but we’ll go through one more. Say Frank is the CEO of a company that makes and distributes private label cleaning supplies that stores purchase to sell as their generic brand.

Frank’s company has an annual revenue of around $140 million dollars. Right now they have inbound and outbound products moving multiple times a day from warehouses across the United States. As part of the company’s vision plan, they wanted to gain better control and visibility over their supply chain.

Frank reached out to a third party logistics company (3PL), and found out a 3PL could help his business save time and money by coordinating their freight. They also offered transportation management software to help Frank and his team see the inner-workings of their business.

Frank’s 3PL was able to offer him business reporting and personnel who would meet with his business to analyze how they could continue to improve their supply chain.

Here’s the moral of these scenarios: don’t go through all of the hassles and headaches of supply chain management alone! There are numerous reasons why partnering with a 3PL would be beneficial. Be like Bob, Stacy, and Frank, and see what a 3PL can do for your business.

Trinity Logistics has more than 35 years experience in the business. Our 3PL team coordinates freight, offers logistics consulting, supply chain technology, and logistics outsourcing services like warehousing, supply chain optimization, on-site freight management, and more. You can also trust that we are on top of the latest trends in shipping and logistics so we can stay ahead of how it would affect your freight.

Have a question? Ask here! If you would like to request a freight quote, click here.