Stay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

GOOD NEWS, BUT…

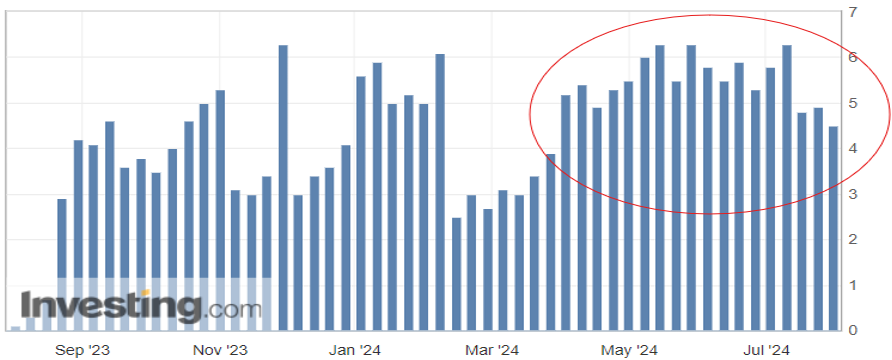

Consumer spending is the biggest driver of the U.S. economy, accounting for roughly two-thirds of the nation’s Gross Domestic Product (GDP). One measurement of that consumer spending is the Redbook index, which compares year-over-year growth for large domestic general retailers (think Walmart, Amazon, Target). The index has averaged just over 3.5 percent for the past 20 years, so the recent year-over-year (YoY) growth in the four-plus percent range speaks to the strength of consumer spending (Figure 1.1). This index alone certainly gives reason for optimism, however there is a cautionary tale with regards to consumer debt.

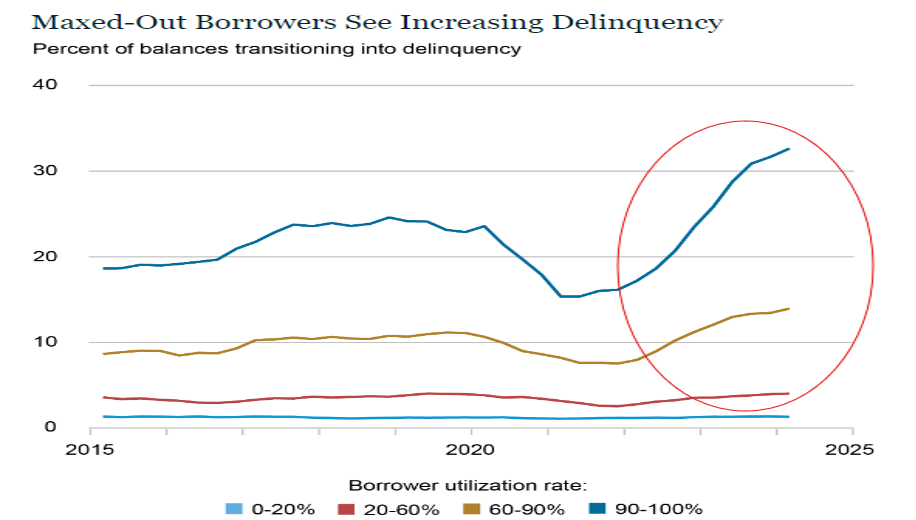

After years of next to zero interest rates to keep the economy on its legs, consumers have seen interest rates on the rise, with the federal funds rate at its highest level since the early 2000’s. With the increase in interest to borrow funds, combined with the increased costs of essentials (food, housing, energy), many households have turned to credit cards to fill the gap for funding of these necessities. Figure 1.2 from the New York Fed Consumer Credit Panel shows the rise in consumer delinquency particularly in those groups that utilize more than half of their available credit line.

While there appears to be relief on the horizon with the impending reduction in interest rates, it appears a portion of active consumers may be pulling back on purchases for those items that are not mission critical. This, in turn, will have an impact on restocking of inventories and trucking activity.

While it is not approaching the levels seen in 2021, the volume index is quickly approaching levels seen in 2022. This has buoyed optimism in the industry.

JUST SOME GOOD LUCK? TIME WILL TELL

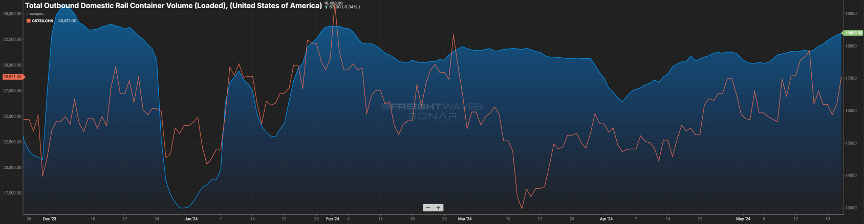

The uptick in consumer spending, restocking of inventories and the threat of labor strife in the fourth quarter of this year has been to the benefit of those involved with the rail and import business.

In Figure 2.1 below, the blue line represents loaded container rail volume in the U.S. and the past three months have seen the volume grow. Similarly, container volumes to the U.S. have been on the rise.

The orange line represents container volume from China over the past six months. While some of that traditional volume is now flowing through other countries, like Mexico, there is still a great deal of activity with U.S.-China trade. Will this continue or is it fool’s gold? That is something we will continue to keep an eye on as a pullback in consumer spending will dictate how the needle moves.

STAYING RIGHT WHERE WE ARE

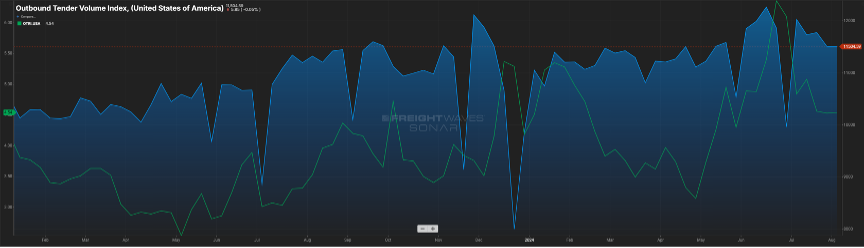

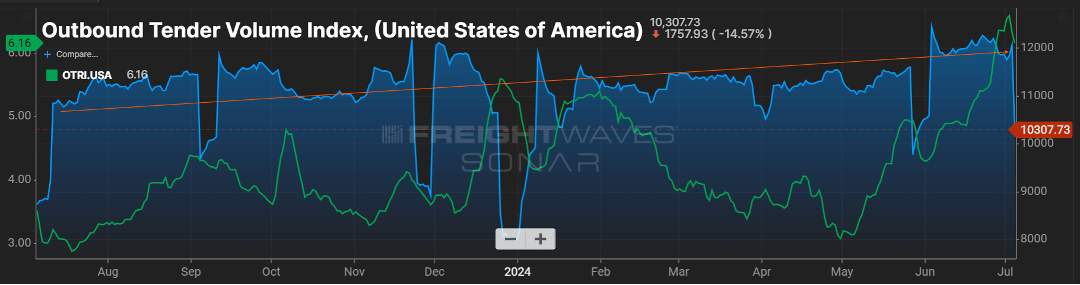

Finally, looking at domestic over-the-road volume (blue line) compared with carrier rejection rates (green line). The slight upward trend continues with volumes and rejection rates (Figure 3.1). Rejection rates continue to inch towards 2022 levels, but a five-to-six rejection rate is about half of what one would see in a balanced freight market.

This has yet to manifest itself in the way of increased freight rates, as capacity still exists in the market.Shippers and carriers should anticipate little change in conditions (although hurricane season is looming) until early 2025.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive the top five logistics articles of the week every Friday morning by selecting “Weekly News Update” when you select your preferences.

Get Weekly News Updates in Your InboxTrinity Logistics, a leading third-party logistics (3PL) provider, proudly welcomes Jimmy Bryant as its new Director of Agent Support.

Hosting a wealth of experience in the logistics industry, Bryant previously held a Senior Director position at Rockfarm Supply Chain Solutions, where he successfully managed and developed their Agency Program for the past six years. Previously, he served as a Sales Director for a large brokerage in Indianapolis.

“Trinity has always stood out for its exceptional agency program,” said Bryant. “What truly sets Trinity apart is its unwavering commitment to staff development and the overall growth of everyone involved. I chose Trinity because of its strong culture and supportive environment. I’m excited about the opportunities to advance our Freight Agent Program.”

“Jimmy’s ability to understand the unique challenges faced by Freight Agents quickly impressed me,” said Greg Massey, Senior Vice President of Agent Development. “His track record of achieving sustained growth while providing top-notch service and support aligns perfectly with Trinity’s mission of being the best, not necessarily the biggest.”

Trinity is enthusiastic for the insight and experience Bryant brings to the company and its Freight Agent program.

LEARN MORE ABOUT TRINITY LOGISTICS'S FREIGHT AGENT PROGRAMAbout Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 45 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized as a Top Freight Brokerage by Transport Topics and as a Top Company for Women to Work for in Transportation by Women in Trucking.

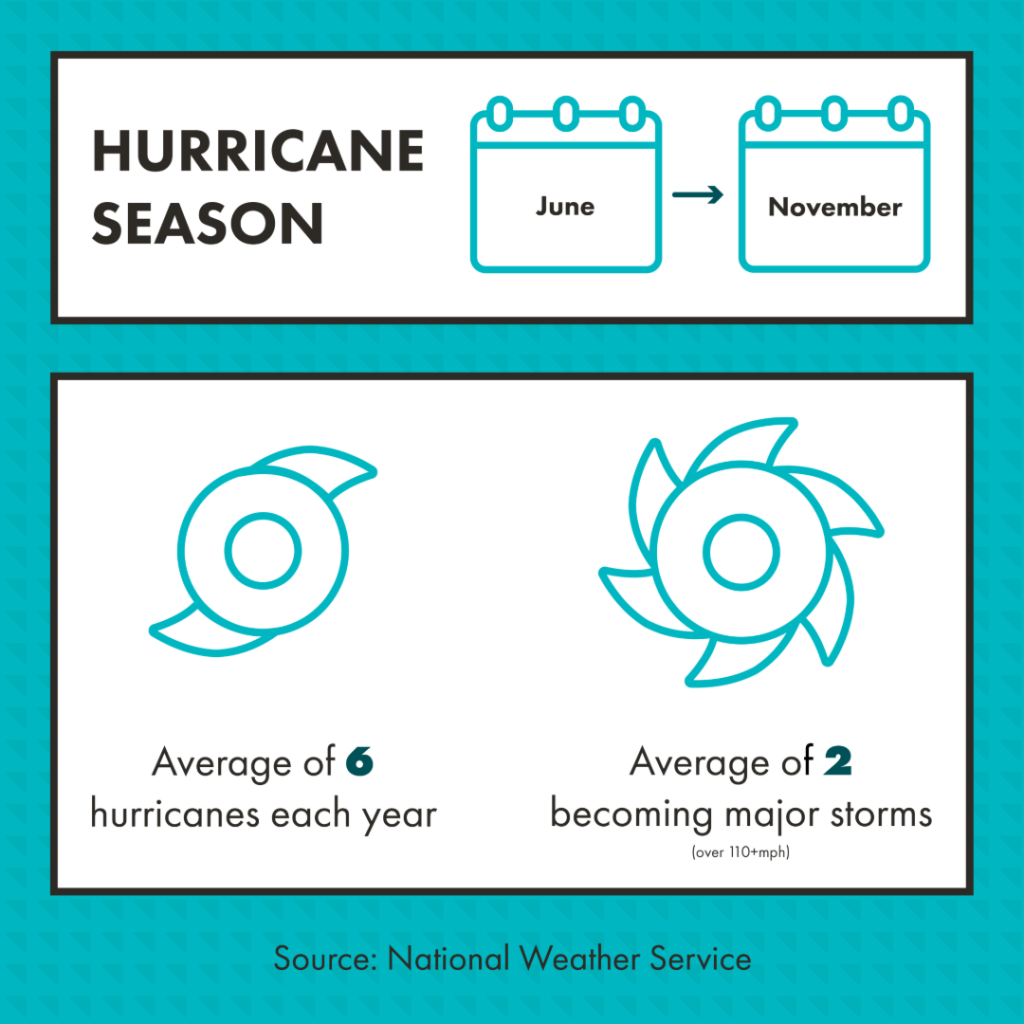

June 1st through the end of November is considered Hurricane Season for the Atlantic and Gulf Coast, with heightened chances of storms occurring from early August to October. According to the National Weather Service, there’s an average of six hurricanes each year, with two typically becoming major storms hosting winds of 110-plus mph.

Even on its best days, the logistics industry is considered complicated. Throw a hurricane in the mix, and you can have straight-up chaos. Hurricane Season means supply chains should prepare for the worst in weather, like heavy rain, dangerous gusts of wind, limited visibility, and flooding. Shipping setbacks such as impassable roadways, stranded trucks and drivers, loss of cargo, and extended deliveries are just some of what can be experienced. Here’s what your organization needs to know to prepare during peak Hurricane Season so your company can avoid delays and a loss in revenue.

Supply Chain Tips for Peak Hurricane Season

Stay Informed

A hurricane’s path and level of impact can change very quickly. It’s crucial you stay informed of potential storms that could impact your supply chain during Hurricane Season.

Set up alerts to be notified of newly formed storms and hurricanes. When a potential storm is in your path find a trusted weather news source and check it often for updates. Don’t just follow the updates before the storm, but also during and after. You may also adopt and use advanced weather tracking systems to get up-to-date information to make informed, real-time decisions.

Maintain Communication

Natural disasters, like hurricanes, can have a huge impact on your company’s supply chain. An easy way to stay ahead is to be transparent and communicate openly throughout. Transparency builds trust and helps manage expectations during a crisis.

If a potential hurricane threatens your business, acknowledge it immediately. Then, start communicating with your customers and partners about the potential effects. Regular updates on potential disruptions and recovery efforts can go a long way in maintaining strong business relationships.

Have an Emergency Plan Ready

You should have a company-wide plan that outlines its actions during a hurricane. Your emergency plan should include important details like;

- an evacuation route for buildings affected

- a crisis communication plan

- assigned employee emergency roles and responsibilities

- instructions on how to protect inventory and equipment

- where emergency supplies are located and how best to use them

- how capable facilities will support when others are affected

When planning, make safety your company’s top priority during a hurricane. Once established, your plan should be reviewed often and updated as needed to ensure it remains effective. Additionally, running practice drills can help everyone know their roles and responsibilities.

Consider Alternatives

Consider what alternative workspaces and methods of transport you could use in the event of a hurricane. Are there temporary warehouse solutions where inventory could be stored? Could intermodal replace a truckload shipment that’s in the path of the storm? Are there alternative routes? How can facilities outside of the storm’s path support those affected? These alternative options should be included in your emergency plan.

While you may not have all the answers when planning, the more you include, the quicker you can make strategic decisions when needed. Having room for flexibility and adaptability is key to minimizing disruptions.

Have Visibility in Your Supply Chain

Visibility is needed now more than ever for supply chains. Having visibility not only helps you on good days but especially during hurricane season.

A transportation management system (TMS) can provide the necessary visibility during a hurricane. It provides critical data about your shipments and orders in real-time, giving you an advantage should a problem arise. This can help you make quick decisions to reroute shipments, avoid affected areas, and keep your customers informed.

See how a TMS could help youThink About Recovery

According to the Federal Emergency Management Agency (FEMA), almost 40 percent of businesses that have to shut down for 24 hours due to a natural disaster never open again.

Ensure your business won’t be in that 40 percent if it happens. Have a plan ready to roll for the aftermath of a hurricane. Prepare for the worst and then plan how to recover from it quickly. This will help prevent any potentially steep revenue loss.

Recovery Team, assemble! It’s time to identify the key employees and providers to get your business back to normal operations. An initial assessment will need to take place and your team’s sole responsibility should be to restore and resume processes. Having those alternative solutions and backup suppliers or providers will be handy here.

Weather the Storm with a Reliable Logistics Partner

Sometimes, you just need extra help. A relationship with a reliable logistics provider, like Trinity Logistics, can help your supply chain overcome the threats of Hurricane Season.

Hurricanes can roll in a cloudy overcast of unknowns, but Trinity shines a light toward safety and security. We have over 45 years of experience helping thousands of supply chains through ups and downs. We thrive on problem-solving and handling issues like the ones hurricanes can bring. We also have a dedicated After-Hours Team to support and quickly resolve any potential challenges – no matter the time of night, holidays, or weekend.

Our nationwide network of trusted carrier relationships ensures your shipments arrive safely at their delivery locations. Additionally, multiple transportation options offer the flexibility to keep your goods moving. Lastly, we’ll help you find real-time visibility with our customizable Managed Transportation solutions. Our dedicated Team (comprised of six Regional offices across the nation) is ready to help you maintain continuity and resilience in your supply chain.

Partner with Trinity logistics so your supply chain can stay afloat, no matter the weather. (Our exceptional service might just blow you away, though!)

GET A FREE QUOTE ON YOUR NEXT SHIPMENT SUBSCRIBE & STAY IN THE KNOW LEARN MORE ABOUT TRINITY LOGISTICS

Stay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

UP AND TO THE RIGHT

For the past year, the general direction of the Outbound Tender Volume Index (OTVI) has been on an upward trajectory as seen in Figure 1.1.

While it is not approaching the levels seen in 2021, the volume index is quickly approaching levels seen in 2022. This has buoyed optimism in the industry.

Another rise we’re keeping an eye on is the Outbound Tender Rejection Index, the rate at which carriers are saying “no” to freight where they have paper rates with a shipper. A six percent rejection rate may not sound important, but considering the rejection rate has stagnated in the three-to-four percent range for the past year plus, it’s another sign that the freight pendulum may be nearing more of a balanced market.

In 2021, rejection rates hovered in the 20-30 percent range. This was more a product of increased freight volumes and carriers realizing they could get higher rates in the spot market versus the contracted rates they had in place. The uptick in rejection now appears to be more of a limit of capacity in certain markets versus carriers hedging their bets on the open load board.

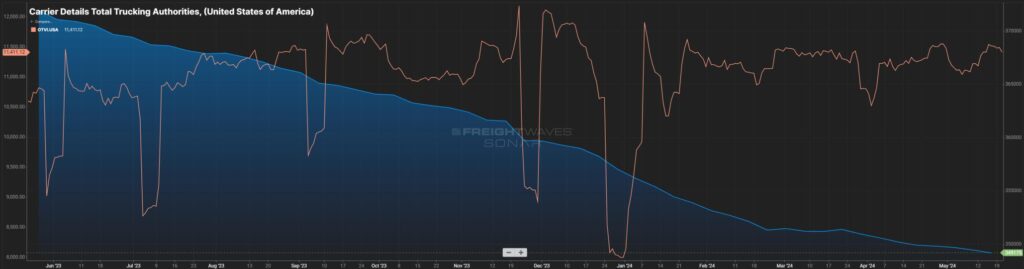

Drip, Drip, Drip

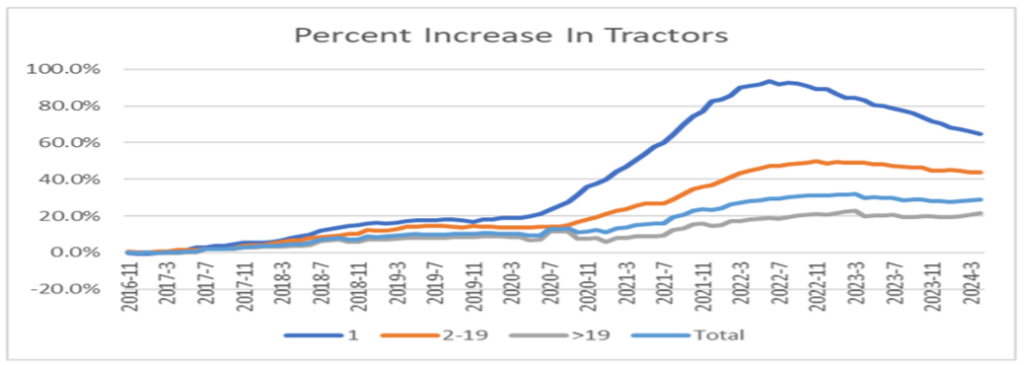

Speaking of that capacity, there is a reduction happening, albeit a slow drip. As shown in Figure 1.2, for the past year and a half, almost two years, the biggest reduction in capacity has been from the owner-operator segment. Most likely, the carriers in this group that have exited the market are those that rushed in when freight and rates were plentiful, and now are finding more normalized rates combined with high overhead to be unsustainable.

As shippers continue to look ahead, not having reliability among this segment of carriers could prove problematic as volumes escalate and more freight flows to the spot market, which is supported heavily by owner-operator drivers. This is a good reason for shippers to ensure they have a good mix of carrier and broker partners.

Baltimore Still Recovering

Finally, it has been just over three months since the bridge collapsed near Baltimore, MD. The waterways in the surrounding area appear to be returning to normal, and the need for traffic that populated the bridge to divert to alternate routes seems to be no worse for the wear on drivers.

Looking at volume in that market in Figure 1.3 since the end of March when the event occurred, after a slight dip when freight had to be re-routed, volumes as measured by the OTVI have increased just over 10 percent. Certainly, there is still work to be done, short- and long-term, but the Baltimore area appears to have powered through an unfortunate event.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive the top five logistics articles of the week every Friday morning by selecting “Weekly News Update” when you select your preferences.

Get Weekly News Updates in Your InboxNearshoring to Mexico is the hottest trend in supply chains.

With Mexico now the top trading partner of the U.S., two-way trade hit a whopping $68.5 billion, according to data from the Census Bureau. In the first quarter of 2024 alone, trade has grown two percent between the U.S. and Mexico year-over-year (YoY).

This growth in shipping to and from Mexico is truly just the tip of the iceberg as companies invest in nearshoring strategies. According to Mexico’s Secretary of the Economy, there have been 378 foreign direct investments within the last year, and private sector businesses from the U.S. account for nearly 40 percent of it.

This surge is driven by companies moving parts or all their supply chains to Mexico, thanks to geopolitical tensions and disruptions like the COVID-19 pandemic. These have shone light on the gaps and difficulties faced by globally distributed supply chains. Companies seek more stability and budget-friendly solutions, finding hope in Mexico. While nearshoring to Mexico offers such benefits, there are common cross border shipping snags you should aim to avoid.

What are the Benefits of Nearshoring to Mexico?

Location, Location, Location!

One of the largest benefits of nearshoring to Mexico is its location. Mexico’s proximity to the U.S. means faster shipping times and lower costs. It also offers more reliability, making supply chains less susceptible to disruptions.

Potential for Savings

Labor costs in Mexico are currently among the lowest in North America, even cheaper than in China. This can be a major draw for companies looking to reduce operational expenses. Shorter lead times also offer the potential for enhanced productivity and further cost savings.

Positive Economic Impact

Cutting costs and sped-up deliveries mean smoother operations, happier customers, and a boost in productivity. This isn’t just good for your business but beneficial for the Mexican economy, too. Businesses established in Mexico create new jobs and economic growth. The U.S. benefits, too, with stronger, more resilient supply chains that are less vulnerable to global disruptions.

But There Can Be Cross Border Shipping Snags

Many business owners don’t realize the complexities that come with shipping across the U.S.- Mexico border. Working with the right provider can make all the difference in whether you’ll face these common challenges.

Here are four major cross border shipping challenges you should be aware of with your nearshoring strategy.

Security Concerns

Cargo theft is a major concern in Mexico, with hijackings being the primary tactic. In April 2024, Mexico averaged about five cargo thefts per day, according to the National Association of Vehicle Tracking and Protection Companies. Unfortunately, that’s trending up compared to the previous year, that’s a 7.7 percent rise in activity. Most hijackings involve some type of violence and often involve food and beverage goods, household items, electronics, and auto parts.

Another security obstacle is Mexico’s poor highway infrastructure. The quality of Mexico’s roadways is significantly lower than in the U.S. According to the 2019 Global Competitiveness Report, Mexico ranks 49th out of 141 economies in its road quality. In comparison, the U.S. ranks 17th. Mexico’s lacking infrastructure increases the potential risk of delays and accidents, as well as cargo theft with any truck breakdowns.

Despite all this, Mexican carriers are not required by law to carry cargo insurance. Many choose to opt out of having it and this often results in inadequate coverage of freight. Because of this, it’s recommended to look into securing your own extra coverage and aim to work with carriers that are certified with the Customs Trade Partnership Against Terrorism (CTPAT).

Lost in Translation?

When working with those in other countries, it’s important to know how they operate. This includes Mexico. Understanding the language and business culture is essential to achieving success.

This fact may be well-known, but not everyone in Mexico speaks English! Spanish is the official language, spoken by about 90 percent of its people. According to a 2023 report, only five percent of Mexicans speak English. While larger businesses may have more bilingual employees on hand, dealing with smaller ones can be challenging if you do not have someone who speaks Spanish. Also, much technical or industry-specific jargon doesn’t often translate accurately. Without bilingual representatives available, it can be easy to have miscommunication issues.

Unlike the U.S., where we often like to get straight to business, Mexicans often prioritize building personal relationships before even discussing any professional matters. Due to this, negotiations can often be more indirect. Working with Mexican businesses means you’ll need to invest time in building strong relationships to foster trust and rapport with your contacts.

Facing Cross Border Complexities

Getting your freight across the U.S.–Mexico border can be complex. Many parties are involved, including several carriers and the customs broker. There are also several touchpoints during the shipping process, and disruption can happen at any of them.

Another hurdle shippers must deal with in cross border shipping is the lengthy transit time. Due to inspections, typical wait times for trucks crossing the border, especially from Mexico to the U.S., can range anywhere from three to 10 hours on certain days. Choosing the right crossing point can greatly affect the transit time vastly, and there are 48 points to consider!

Paperwork Troubles

Freight most often gets detained at the border for incomplete documentation.

Shippers are required to fill out many, often repetitive documents. It’s common for this paperwork to get misplaced or for shippers to not even be aware of the exact procedures required by authorities. When any of this important paperwork is left blank or filled out incorrectly, the carrier gets detained at the border until it is resolved. This can add extra days or costs to your shipment.

Ensure all necessary documents are in order, including:

- Commercial invoice (in Spanish)

- Bill of lading

- USMCA certificate of origin (if needed)

- Packing list

- Sales contract

- Proforma commercial invoice

- AES filing

- Customs declaration

- Insurance policy

Having these documents in both Spanish and English can prevent delays and misunderstandings.

Trinity Logistics: The Perfect Partner for Your Nearshoring Strategy

Navigating the complexities of shipping to and from Mexico can be overwhelming! One simple mistake is all it takes to cause delays and additional costs. That’s where finding a reliable logistics provider comes in.

Sure, perhaps you can do it all on your own, but trust us, it’s easier with help. You can outright avoid these four common mistakes when shipping to and from Mexico when you’ve chosen to work with a reputable logistics provider like Trinity Logistics.

We’ve been navigating the waters of cross border shipping for over 45 years, so we understand all the nuances. Our bilingual Team Members and Authorized Agents (some even based in Mexico) get the business culture and fluently speak the language, so there won’t be any miscommunication concerns. Not to mention, our People-Centric service always puts relationships first, regardless of nationality.

We’re customs process experts and have trusted carrier relationships ready to roll. Whether it’s Laredo, El Paso, San Diego, or another major U.S.-Mexico border, we have a variety of transportation modes available.

If nearshoring is part of your supply chain strategy but you’re concerned about shipping to and from Mexico, worry no longer. Instead, consider Trinity Logistics as your cross border copilot. We’ll handle the logistics so you can meet your business goals.

Get a FREE Quote Discover Effortless Cross Border ShippingDon’t let your company get caught off guard by CVSA Operation Safe Driver Week, July 13th to July 19th, 2025!

Shippers and carriers, mark your calendars! Operation Safe Driver Week is approaching. While this annual event is designed to make our roadways safer, it’s also a crucial week for those in logistics. This pivotal time can impact operational efficiency for shippers and carriers alike. To be prepared, it’s important for all those involved in shipping freight to understand what Operation Safe Driver Week entails and its effect on the freight market.

- What is the CVSA?

- What is Operation Safe Driver Week?

- Impact on Shippers

- Impact on Carriers

- How Shippers Can Prepare

- How Carriers Can Prepare

- Let’s Work Together

What is the CVSA? What is Operation Safe Driver Week?

The Commercial Vehicle Safety Alliance (CVSA) is a non-profit organization dedicated to improving commercial motor vehicle safety through collaboration between law enforcement, industry stakeholders, and the public sector. In partnership with the Federal Motor Carrier Safety Administration (FMCSA), the CVSA launched the Operation Safe Driver initiative in 2007. The goal of this initiative is to reduce the number of deaths and injuries from crashes involving large trucks, buses, and cars.

This initiative includes an annual event, Operation Safe Driver Week. It aims to improve driver behavior through education and increased enforcement efforts, focusing on unsafe driving behaviors. It takes place across North America, so the U.S., Canada, and Mexico. Unlike the CVSA’s other two initiatives (International Road Check and Brake Safety Week), which solely focus on commercial drivers, this event affects all drivers on the road.

Each year has a primary focus with this year’s being reckless, careless, or dangerous driving. This includes actions like:

- Speeding

- Texting while driving

- Drunk or drugged driving

- Following too closely

- Driving too aggressively

- Improper lane changes

- Failure to obey traffic control devices

- Failing to use a seat belt

Those drivers identified are pulled over by law enforcement and issued warnings or citations.

According to the National Highway Traffic Safety Association (NHTSA), drivers’ actions are the reason behind 94 percent of all traffic crashes. Research from the University of Missouri-Columbia has shown that interactions with law enforcement, not just education, are what brings change. During last year’s event, law enforcement interacted with 66,421 drivers! Drivers were informed and educated on how they can improve their driving behavior and do their part in reducing crashes.

Why Should I Be Concerned About Operation Safe Driver Week?

It’s important to be aware of when Operation Safe Driver Week takes place because of the impact it has on shipping freight. Even though it’s just one week out of the year, no one likes to be unprepared for potential disruption or delays to their business.

Operation Safe Driver Week Impact on Shippers

Shippers may face potential delays, see reduced transportation capacity, and likely higher spot rates.

Potential Delays

Increased enforcement activity can lead to potential delays due to any road stop inspections or pullovers.

Reduced Transportation Capacity

The increased enforcement effort sometimes leads carriers to strategically choose to close their business temporarily for the week to avoid any risk of fines or penalties. You might find it more difficult to secure reliable carriers for any last-minute shipments.

Higher Spot Rates

With the potential for fewer trucks available and delays, spot rates can be heightened during this time.

Operation Safe Driver Week Impact on Carriers

Carriers are similarly affected, and there is the potential for delays, less freight volume, and higher scrutiny from law enforcement.

Transportation Delays

Just like shippers, carriers should expect to see potential delays in the movement of traffic due to the increased enforcement. This could disrupt your operations.

Fewer Shipments Available

Shippers may choose to plan around this week, reroute certain shipments, or even look into alternative modes. Less freight may be available during this week.

Increased Law Enforcement

Expect to see increased law enforcement, so more eyes will be looking for unsafe driver behavior, and drivers may receive fines.

How to Prepare for Operation Safe Driver Week:

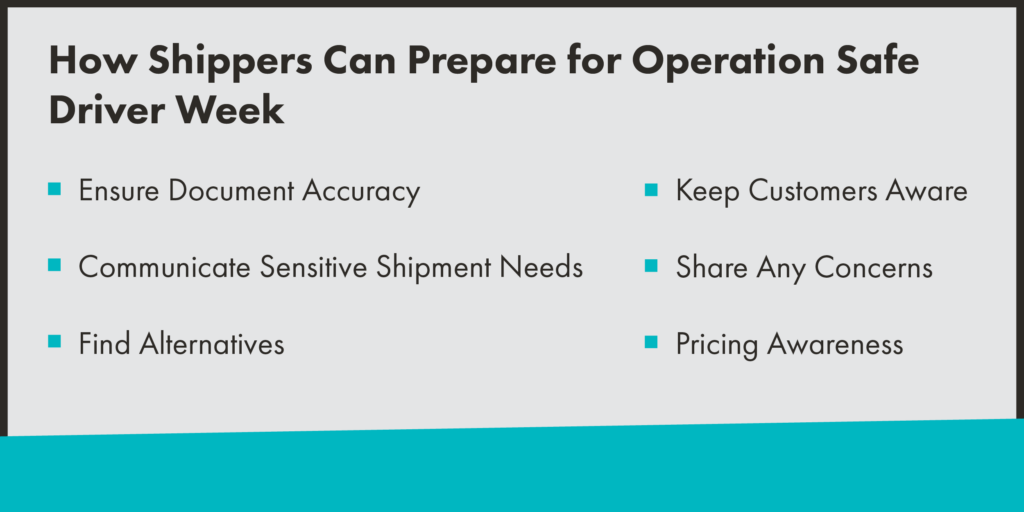

Shippers

Ensure Documentation Accuracy

Double-check all shipment documentation. Ensure it is accurate and complete to avoid delays during any unexpected inspections.

Communicate Sensitive Shipment Needs

If you have any special requirements or time sensitivities, communicate this well in advance. This helps your logistics provider plan effectively. Any last-minute communication risks delays.

Find Alternatives

Consider alternative transportation modes or routes if you expect any delays.

Keep Customers Aware

Be proactive and communicate potential delays during this week to your customers to manage expectations.

Share Any Concerns

Discuss any concerns you might have with your logistics provider. They can offer valuable insights and help develop strategies to reduce disruptions.

Pricing Awareness

Be aware of possible higher spot rates during Operation Safe Driver Week. When possible, plan shipments before or after this period to secure better pricing.

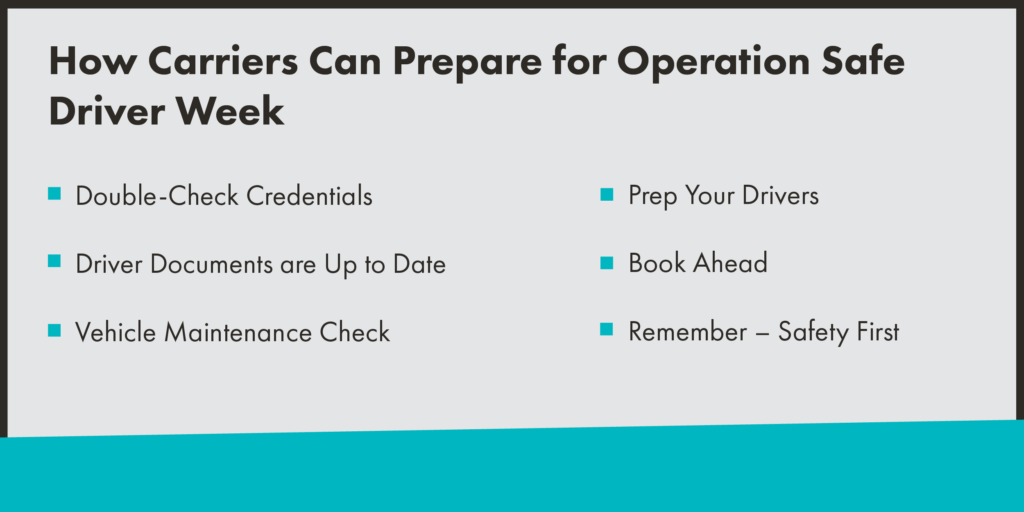

Carriers

Double-Check Credentials

Ensure all company credentials, like operating authority, hazmat endorsements, TWIC cards, and any other relevant permits, are current and accessible.

Driver Documents are Up to Date

Have drivers verify that all paperwork is up to date and accessible in case of inspection.

Vehicle Maintenance Check

Double-check that all vehicles have undergone any necessary preventive maintenance and are in top operating condition to avoid delays due to roadside repairs.

Prep Your Drivers

Make sure drivers are aware of this week and the potential for stops or delays. Train drivers on proper procedures for interacting with law enforcement. Make sure they know the channels to communicate any disruptions to their journey.

Book Ahead

Shippers may choose to reroute shipments, choose alternative modes, or plan around this week. Consider booking shipments well in advance for this week.

Remember – Safety First

The importance of this week is not disruptions but road safety. This is a great time to talk with drivers about safe driving behavior. You could also help educate the public on proper driving behavior when interacting with trucks. Remember, this week benefits everyone who shares the road.

Let’s Work Together to Keep Our Roads Safe

We believe road safety is paramount. While Operation Safe Driver Week might cause some temporary disruptions, it serves a vital purpose in promoting safe driving behaviors.

By staying informed and taking proactive steps, you can likely see minimal effects of Operation Safe Driver Week.

For additional opportunities to stay ahead of disruption to your business during Operation Safe Driver Week, consider working with Trinity Logistics. We have over 45 years of experience helping thousands of shipper and carrier companies conquer more complicated shipping situations, like CVSA inspection weeks. We’re confident in our ability to make this week (and all others) a painless one for your business.

Trinity Logistics, a leading third-party logistics provider (3PL), is proud to announce its recognition as a Green Supply Chain Partner for 2024 by Inbound Logistics. This prestigious accolade highlights Trinity’s commitment to sustainable and eco-friendly logistics practices.

Each year, Inbound Logistics editors select 75 Green Supply Chain Partners, otherwise known as the G75, that go above and beyond in their efforts to improve supply chain sustainability. These companies demonstrate exceptional leadership and dedication to environmental responsibility and are selected based on their initiatives to reduce their impact, improve efficiency, and overall promote a more sustainable future.

Trinity has a long history of implementing innovative solutions to minimize its environmental footprint including:

- Reducing emissions with an Environmental Protection Agency’s (EPA) SmartWay Transport Partnership

- Practicing chemical safety as a member of Responsible CareⓇ

- Offsetting carbon emissions by collaborating with ClimeCo

- Making sustainable choices in Trinity’s owned offices

- Offering environmentally friendly transportation options, like intermodal

“At Trinity, we’ve always believed in doing the right thing,” said Kristin Deno, Director of Operational Risk at Trinity Logistics. “Being so exclusively recognized for our sustainability efforts is a true testament to our focus in this area. This recognition provides additional drive for us to continue improving practices to support building a greener future.”

LEARN MORE ABOUT TRINITY'S SUSTAINABILITY INITIATIVESAbout Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 45 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized as a Top 100 3PL by Inbound Logistics, and as a Top Company for Women to Work for in Transportation by Women in Trucking.

Stay up to date on the latest information on conditions impacting the freight market, curated by Trinity Logistics through our Freightwaves Sonar subscription.

A LOOK AT THE PAST AND FUTURE OF THE FREIGHT MARKET

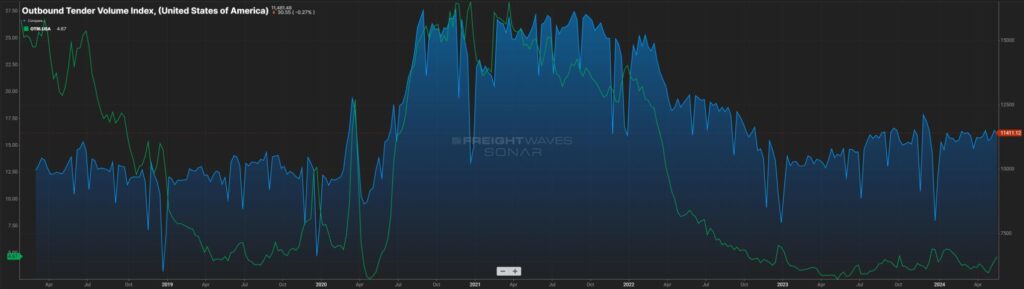

The Outbound Tender Volume Index (OTVI) measures the volume of contracted freight in the U.S. While this does not account for the spot market, ebbs and flows in contract freight have a direct impact on spot market volume and pricing. The outlier on the graph below (Figure 1.1) is the yellow line, representing calendar year 2021. This was an unprecedented year for freight volume, primarily influenced by consumer spending. While many feel the freight market is suppressed, that is not necessarily the case. 2024 will follow a more traditional freight flow pattern, with volumes up five to eight percent, year-over-year (YoY).

Measuring the freight volume is not enough to predict swings in pricing. Being able to overlay the frequency in which carriers say “no” to freight tenders via the Outbound Tender Rejection Index (OTRI) gives a good picture whether the capacity side of the market can handle those swings.

The below chart (Figure 2.1) looks at the amount of contracted freight volume (blue line) with the frequency of tender rejections (green line) overlayed. As can see, most of 2019 and the first part of 2020 saw a market where freight volumes were easily handled. This was a result of lower than anticipated freight volumes versus a glut of carriers in the market.

Then March 2020 happened. Everything went on lockdown. Volumes and rejection rates plummeted. That was quickly followed by a freight injection and for the latter part of 2020, and all of 2021, the market struggled with a lack of capacity to handle the record freight volumes.

For example, most LTL carriers were operating at 105-107 percent of capacity when they normally are in the low to mid-90s range. The freight market pendulum was in favor of the carriers. When the market gets hot, everyone wants in, which is what was happening in 2021, and 2022 – new carriers raced to get in on the action while existing carriers looked to soak up as much rolling stock as they could to capitalize on the market.

2023 saw a return to more traditional levels, but the capacity remained. As a result, rejection rates for freight tenders took a dive to below five percent, indicating carriers were eager for any freight that kept their fleets moving. This caused freight rates to take a dive (Figure 3.1) and then stabilize as of late.

But how long will shippers be able to rely on rate stability? Most likely the best determination will be the pace at which carriers exit the market.

Figure 4.1 clearly shows capacity has been coming out of the market (blue line) for the past year. Most of that capacity is small – micro-fleets and owner operators. Certainly, this is dwindling capacity, but not to the extent of a large carrier pulling out of the market. A slow drip for sure.

The orange line represents the OTVI (volume) in the market, and that has slowly climbed over the last 12 months with the normal seasonal up and downs. At some point, as the volume inches up and capacity comes down, it’s simple supply and demand. Many are pointing to the end of this year, more likely spring of 2025 when that balance starts to shift. Now is the time for shippers to learn the contingency plans that are in place with their carrier and broker providers to account for this.

Stay Up To dAte

Looking for a more frequent update? Subscribe to our newsletter and receive the top five logistics articles of the week every Friday morning by selecting “Weekly News Update” when you select your preferences.

Get Weekly News Updates in Your InboxIt’s a simple fact. People can’t survive without food. When times are tough, we can certainly make sacrifices in other parts of our lives, like our online shopping habits or a remodel we wanted, but not food. This makes food manufacturing a reliable and even diverse industry to run a business in. Yet, it doesn’t come without its own set of unique challenges, especially with its logistics.

Today, the demand for fast and reliable shipping is higher than ever. Food and beverage companies need to meet the rising pressure to provide quicker turnarounds and deliver their products at optimal freshness to stay competitive. With already complex supply chains, how can a company keep up? Not to mention, what if there’s an issue found or a delay? Don’t stress. We’ll cover logistics challenges that commonly hurt food manufacturing businesses and how working with a third-party logistics (3PL) company, like Trinity Logistics, can solve and simplify your processes for shipping food.

Common Shipping Challenges Faced by Food Manufacturing

Diversity in Scheduling Applications Introduces Challenges

One of the biggest headaches for food manufacturers is self-imposed. Each shipper or distributor could be using a different scheduling portal or application. Some even just use Excel spreadsheets. Because of this, scheduling conflicts and communication gaps are often seen when shipping food. This can be very frustrating to the logistics departments arranging the shipments.

Furthermore, the carriers they aim to work with may not know how to use the application or might not even have access to it. This inefficiency can cause issues with them scheduling their pickup or delivery appointments. It also can limit access to capacity, something that is truly needed for those requiring temperature control during peak produce season!

Plenty of Time-Sensitive Freight in Food Manufacturing – Beat Must Arrive by Dates

As previously mentioned, food manufacturers face a growing demand for products that are at peak freshness, especially for those needing temperature control. It’s not unusual for these time-sensitive shipments to be last-minute orders requiring immediate action. Some of these can come in just the day before or even the day before and need shipping right away. Sometimes to help manage the influx of shipments, freight can be assigned with a “Must Arrive by Date” (MABD). This can put pressure on food manufacturers, and missed delivery windows can result in costly penalties. These fees, called chargebacks, usually get pushed back onto the customer and impact your bottom line and service.

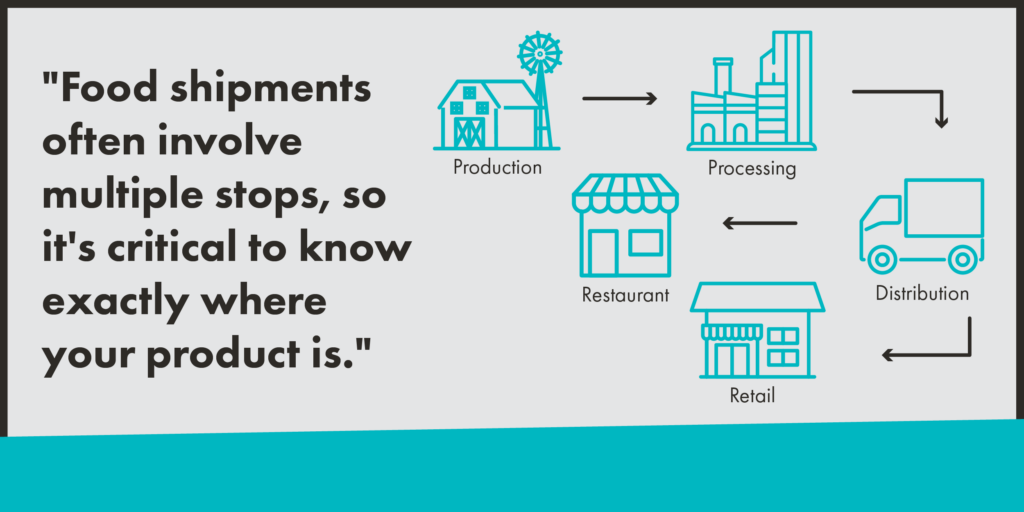

Identify Visibility Gaps When Shipping Food

With many time-sensitive and temperature-control requirements, it’s important for food manufacturers to have complete visibility into their shipments. Food shipments often involve multiple stops, so it’s critical to understand where your product is and when it’s expected to arrive. Even though it is valuable, many food manufacturers find they have limited visibility of their shipments. This creates a lot of uncertainty, causing additional gaps in communication and possible delays or disruptions. Most importantly, it can jeopardize the safety of your food product, an important piece to meet the Food Safety Modernization Act (FSMA) regulation.

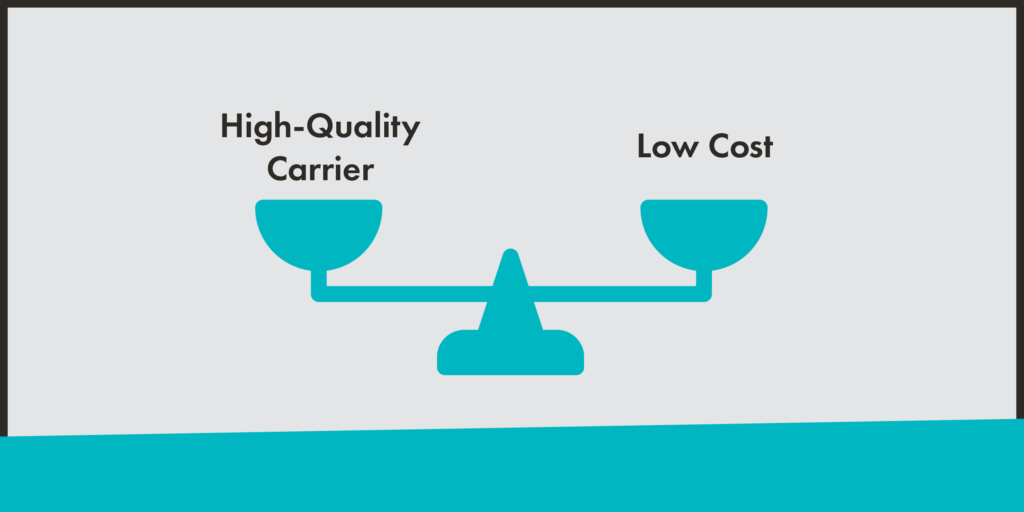

Keeping Food Shipping Logistics Budget in Control

Carrier selection for shipping food products can be a puzzle for food manufacturers to figure out. On one hand, you want to work with high-quality carriers to ensure your food products arrive at peak freshness. On the other hand, they cost more. One certainly wants to budget and find balance. Look to pay too little, and you may not find the quality service your products need. Finding that balance between the two can be difficult.

Market trends can also cause unexpected price fluctuations, further challenging their logistics budget. This can really hurt those needing to meet peak freshness as it’s not like they can’t ship their products as they may perish. Instead, they’ve got to adjust and pay the current price.

Food manufacturers must be creative and find solutions to keep their costs down but their quality up. They can consider other transportation modes as options to manage costs, but understanding which one makes the most sense for their product can be overwhelming.

Embracing Sustainability in Food Shipping

Sustainability is on everyone’s minds, including consumers. With global food and beverage production causing roughly 34 percent of greenhouse gas emissions, consumers are holding food manufacturing companies to higher standards. They’re researching more about the companies they purchase food products from. They want to know what positive practices they implement, such as sustainable fishing, the use of ecological pesticides, reforesting, fair trade, or the use of compostable packaging.

TRINITY Logistics SOLVEs Food Shipping PROBLEMS

With over 45 years of serving customized logistics solutions to thousands of food manufacturers, we’re fairly confident in our ability to help you overcome any of these challenges.

We Speak Your Food Shipping Scheduling Language

We’re in tune with most if not all, scheduling portals that food and beverage shippers use. You don’t have to worry about training us! Yes, we could even say we know how to navigate those scheduling apps “with our eyes closed.” Even if we have a newer Team Member who is unfamiliar with it, we can guarantee that at least one of our 400+ Team Members or 135+ Authorized Agents know it and can assist.

Time-Sensitive Titans: We Deliver Your Food Products When It Matters Most

At Trinity Logistics, we understand the urgency of time-sensitive food deliveries. Our Team excels in handling quick turnarounds, making us the “emergency room” for your time-critical freight. We are acutely aware of the potential repercussions of missed deliveries and leverage our strong carrier relationships to secure the capacity you need. These established partnerships allow for better planning and ensure that carriers are familiar with the specific needs of food commodities, pickup, and delivery locations.

Furthermore, in the unfortunate event that fees do arise due to carrier issues, Trinity acts as your advocate. We hold our carriers accountable and ensure that any associated charges are passed along to the responsible party. Our meticulous investigation process guarantees that only the root cause of the problem bears the financial burden.

Expand the View into Your Food Shipments

We’re champions of end-to-end visibility, great communication, and transparency because we know you deserve it. Our commitment to People-Centric service isn’t just our slogan; it’s our philosophy.

We leverage a combination of cutting-edge technology and a dedicated Team Member to keep you informed every step of the way. Use our Customer Portal to see real-time tracking of your shipments. If you’re looking for even more transparency, there’s our Managed Transportation service, offering you a customized Transportation Management System (TMS) solution that works for your business. Between our technology and our Team Members, you’ll find this proactive approach ensures you’re not left in the dark until delivery.

Find Balance in Your Logistics Budget

Starting out, our established carrier relationships not only gain you access to capacity but to leverage our competitive rates. Additionally, we have multiple modes to choose from and our Experts can help you explore which one suits your product and budget.

Now, we understand balance isn’t easy to obtain, so that’s why Trinity Logistics goes a step further in our service to help you find it. For those food manufacturers that build a shipping history with us, we’re able to review your data and conduct a comprehensive review of your logistics. This will give you a clearer insight into your logistics to find room for improvement. We won’t come empty-handed, either. We’ll make recommendations to add efficiencies and see if we’re on the right track for your company’s success.

Adding Sustainability into Your Logistics

We understand the importance of sustainability and are committed to helping you implement it throughout your supply chain. This includes connecting you with carriers that prioritize eco-friendly practices, finding sustainable shipping options, and exploring carbon offsetting programs. If you need further proof, Trinity currently holds a bronze medal rating by EcoVadis, the world’s largest and most trusted provider of sustainability ratings.

Learn more about Trinity's sustainability initiativesBonus Benefit for Food Manufacturers! Trinity’s Relationship with Honor Foods

As a Burris Logistics Company, we have a direct relationship with Honor Foods. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They have access to thousands of reputable brands and can simplify your purchasing process. Honor specializes in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers. Speed up your lead times and increase profitability with no extra storage space needed. Working with Trinity and Honor, you can get the best of both Burris Logistics brands and gain additional success in your business.

Operating in food manufacturing can be complex, but it doesn’t have to be. Try Trinity Logistics for your shipping and see just how easy it can be.

Discover how Trinity exceptionally serves those in food and beverage Get a quote to see if our solutions are right for your businessDo you feel like you could be spending less on your less-than-truckload (LTL) shipping rates? Most likely, you’re right. LTL shipping rates are affected by many different factors, so it can be pretty easy to make these simple changes and see your shipping costs decrease. While these tips may not be possible for everyone or every shipment, hopefully, you’ll find one you can start implementing to reduce your freight costs.

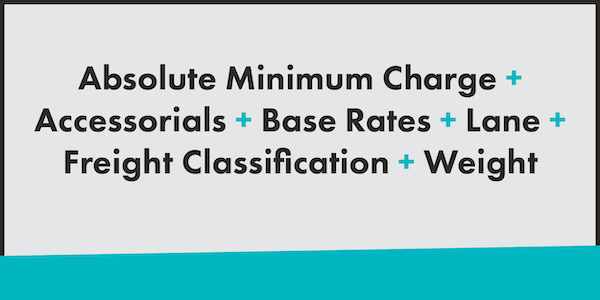

HOW LTL SHIPPING RATES ARE CALCULATED

Compared to truckload rates, LTL shipping rates can be very confusing. To make it simpler, here’s what goes into your LTL costs.

Absolute Minimum Charge

This is the lowest rate a carrier will charge.

Accessorials

These are extra charges for any services provided by the carrier that are beyond simply shipping from one point to another. Examples of common accessorials include:

- Inside pickup or delivery

- Lift gate service

- Residential delivery

- Detention storage

Base Rates

Each LTL carrier sets its own base rate, often quoted per 100 lbs., and based on the freight classification, weight of the shipment, distance traveled, and the origin and destination zip codes.

Lane

The lane plays a role in the base rate. The further the distance traveled in the lane, the more costly the LTL shipping rate can be.

Freight Classification

The product you ship has its own classification based on the National Motor Freight Classification (NMFC). Freight that is dense and difficult to break is in a lower class, making it the least expensive. Lighter and more fragile freight is at a higher freight class and thus, costs more.

Weight

LTL shipping rates are based on the total weight and number of pallets. The heavier a shipment, the less it costs per hundred pounds, as factored by the base rate calculation.

HOW TO SAVE ON YOUR LTL SHIPPING RATES

Maximize Density

LTL carriers make a profit by fitting as many different LTL shipments into their trailers as safely as possible. So, which do you think they prefer – a shipment that takes up 25 percent of their trailer or a shipment that takes up 10 percent? The less space your shipment can take up, the less it could cost to ship it.

While the weight of your shipment may be out of your control, the density is not. Increasing density starts with how you pack your LTL freight. Experienced shippers know that doing everything they can to compactly pack their freight on pallets will reduce their LTL shipping rates.

So, do everything you can to make your shipment take up less space. If your current pallets are not stackable, find a way to make them, if possible. Reduce any empty space between cases or products on the pallet. If possible, stack an extra row on top of each pallet to eliminate using an extra pallet. Brainstorm all the ways to make your shipment take up less space, and you’ll likely see savings.

*It’s important to note that you should never negate safety or product quality to reduce your shipping rates!

Aim to Avoid Peak Shipping When Possible

While this may not always be possible, avoiding peak shipping times is an easy way to reduce your LTL shipping costs. When you can, plan and ship early or after peak times.

Evaluate Packaging and Product Design for Logistics

Now this tip is more of a hefty task, but it’s certainly one to consider. When in the early stages of product and packaging design, or even when re-evaluating, it’s ideal to get one of your logistics professionals involved. This will help your product and package designers consider details that can make your product easy to ship, stack, and organize. There’s nothing worse than having a great product only to end up with it being too cost-prohibitive to transport.

Consider “Economy Class” LTL Carriers

If your shipment isn’t time-sensitive, using “economy class” LTL carriers is an easy way to reduce your LTL shipping rates. Their rates are often cheaper but their transit times are longer, so you’re trading off higher costs for more time. If you have time to spare, this is a great option for savings.

Ship Larger Loads Less Often

As you likely know, it’s cheaper to ship several pallets at once than one at a time over a few weeks. However, to use this strategy, you’ll have to convince your customers to take on larger orders. You can offer them a price break or agree to share some of the savings you see in shipping to do so.

Consolidate to One Truckload

Eliminating a shipment altogether is a surefire way to reduce your freight costs.

Have you ever considered consolidating your LTL shipments into a multi-stop truckload shipment? Shipping a full truckload of freight is often far less expensive than shipping multiple LTL shipments.

Of course, it depends on where your shipments are delivering. For example, a multi-stop truckload picking up in Maine and delivering in Florida, Minnesota, and California might not make financial sense compared to shipping LTL. But if your delivery points are close to each other, or if they form a line across the country (at least vaguely), getting a quote on a consolidated truckload shipment would be very wise

If you don’t have enough for a full truckload, you could still consolidate and combine two or more LTL shipments into one. It’s worth it to see if any sort of consolidation can reduce your LTL shipping rates.

Negotiate with LTL Carriers

It never hurts to ask or negotiate for a discounted rate with your LTL carrier. Perhaps you can have an accessorial fee waived or reduced based on shipment frequency.

If you ship all kinds of freight, you may be able to negotiate freight of all kinds (FAK) for reduced LTL shipping rates. Rather than getting a rate for different classes of freight (which can be time-consuming and complicated), you negotiate to have all your LTL freight rated in the same class, with FAK, which not only saves you time but money.

You could also negotiate for Customer Specific Pricing (CSP). This is contracted pricing, which could include a FAK structure if needed. LTL CSP allows carriers to have a better picture of your freight which not only results in more efficient, but often cheaper, pricing since the rate contracts are ONLY based on your shipments.

Interested in LTL CSP? Let Trinity negotiate with LTL carriers on your behalf.

Avoid Accessorials When Possible

Accessorials in LTL shipping are common and some may be unavoidable, but many can be avoided when planning ahead. To avoid these extra charges, make sure to educate yourself on your LTL carrier’s guidelines and accessorial fees, aim to avoid weight, dimension, and oversizing adjustments, and ensure your bill of lading (BOL) is accurate. Taking these extra steps will ensure you don’t get hit with unexpected charges and keep your LTL shipping rates low.

Provide Accurate Information

Most shippers are aware that the rate for shipping their LTL freight is highly dependent on the size and weight. For this reason, some people are tempted to slightly underestimate the dimensions or weight of their shipment in the hopes it will result in a slightly lower shipping cost and the LTL carrier will be none the wiser.

Whatever you do, don’t do this! Rather than saving money, you may be opening yourself up to extra charges. Most carriers will double-check that the dimensions and weight of your shipment match what’s on the BOL. If it doesn’t match, you’ll be faced with extra, unexpected charges. Your shipment cost will be raised accordingly, but you’ll also be charged with an inspection or reweigh fee, and it’s possible the carrier will red flag your freight to be inspected every single time you ship with them, meaning you just caused increased LTL shipping rates for the future – the opposite of what you wanted.

Use a TMS for Efficiencies

Controlling your shipping costs can be difficult without having full visibility of your freight spend. So, if you’re really looking to take control of your freight costs, a transportation management system (TMS) is what you need. A TMS can give you clear insight into your logistics with comprehensive reporting so you can find more ways to save on your LTL shipping rates while also finding efficiencies in your operations.

WORK WITH A 3PL

Probably the quickest and easiest way to save on your LTL shipping rates and your time is working with a third-party logistics company (3PL), like Trinity Logistics.

Because of the high volume of freight that 3PLs arrange for all their customers, means we have lower contracted rates (aka deeper discounts) available that you otherwise wouldn’t be able to access. This will result in significant cost savings, especially over time.

Working with Trinity Logistics also gives you the benefit of working with logistics experts who can help you not only with your LTL shipping but any other modes you may need or be interested in. We’ll help you determine what other modes make sense and what other benefits or savings they could offer your business. We also have a dedicated Team to assist you with Managed Transportation or implementing a TMS if that’s something you may need now, or in the future as you grow.

Whether you simply need help saving on your LTL shipping rates or would like a valuable logistics partner on your side for all your logistics needs, our Team is ready to help you and your business succeed.

LEARN HOW TRINITY CAN HELP YOU WITH LTL SHIPPING START SAVING ON LTL SHIPPING RATES-GET A FREE QUOTE