Whether it’s lumber, piping, hay, palletized goods, or construction supplies, flatbed trailers, also known as open-deck trailers, can handle it all. Flatbed trailers are extremely versatile in their use, but that’s because, unlike enclosed trailers, there are many variations of flatbeds to choose from. If you’re considering a flatbed or open-deck trailer for your shipment, how do you know which one is best for your freight? This article will help you answer just that. Read on to better understand the different kinds of flatbed trailers that are available so you can make an informed decision on which one your freight needs.

Types of Flatbed Trailers

Flatbed trailers come in all shapes, sizes, and load capacities; each designed to carry different types of cargo. The one tricky part of flatbed shipping is choosing and finding the flatbed trailer that is capable of hauling your freight’s weight and size. It’s also important to note that anything exceeding legal dimensions and weight can be considered oversized and may require more to ship, such as state permits, police, escorts, or more.

Shipping oversized? Download our FREE Over-Dimensional Shipping Guide.*Important Note – Trailer capacity, weight, and dimensions mentioned in this article are general specifications and should be used as an estimated guideline. These can vary based on the trailer type, brand, or semi-tractor being used with it.

- Standard flatbed

- Extendable flatbed

- Step deck / drop deck

- Stretch single step deck / drop deck

- Double drop

- Stretch / extendable double drop

- Removable gooseneck (RGN)

- Stretch RGN

- Conestoga

- Side kit

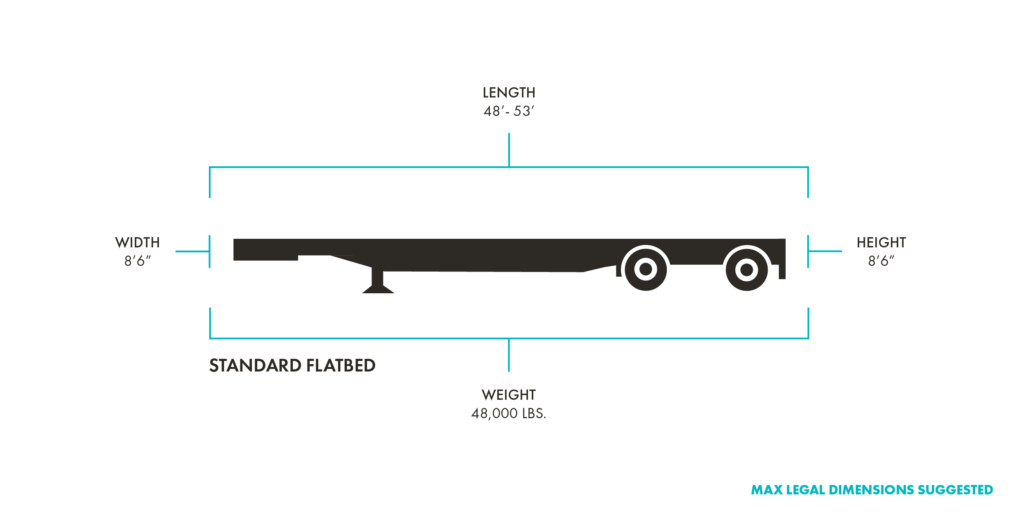

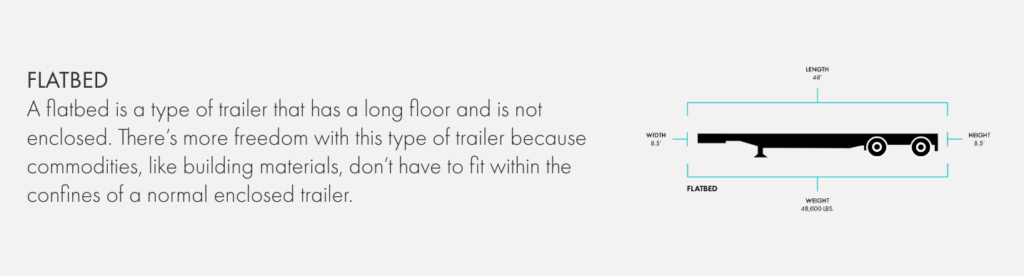

Standard Flatbed Trailers

Maximum Legal Weight: 48,000 lbs.

Maximum Legal Cargo Length: 48 to 53 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 8 ft. 6 in.

Standard flatbed trailers are widely used and versatile, often the most popular of all flatbed trailers. They most commonly haul steel, lumber, and other kinds of building or construction materials.

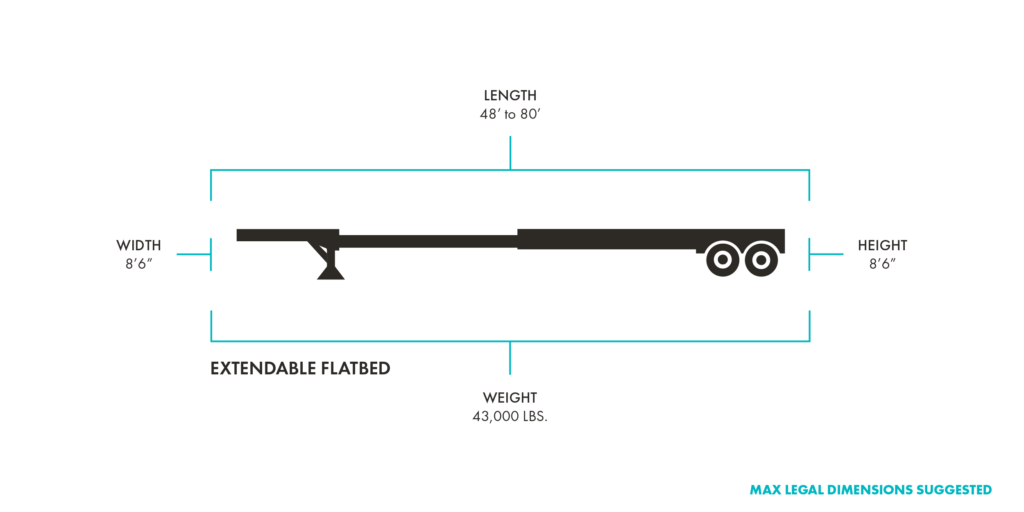

Extendable Flatbed Trailers

Maximum Legal Weight: 43,000 lbs.

Maximum Legal Cargo Length: 48 to 80 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 8 ft. 6 in.

Extendable flatbed trailers can also be known as flatbed stretch trailers. These trailers have an extendable deck to transport cargo that is too long for a standard flatbed, like a piece of large or heavy machinery.

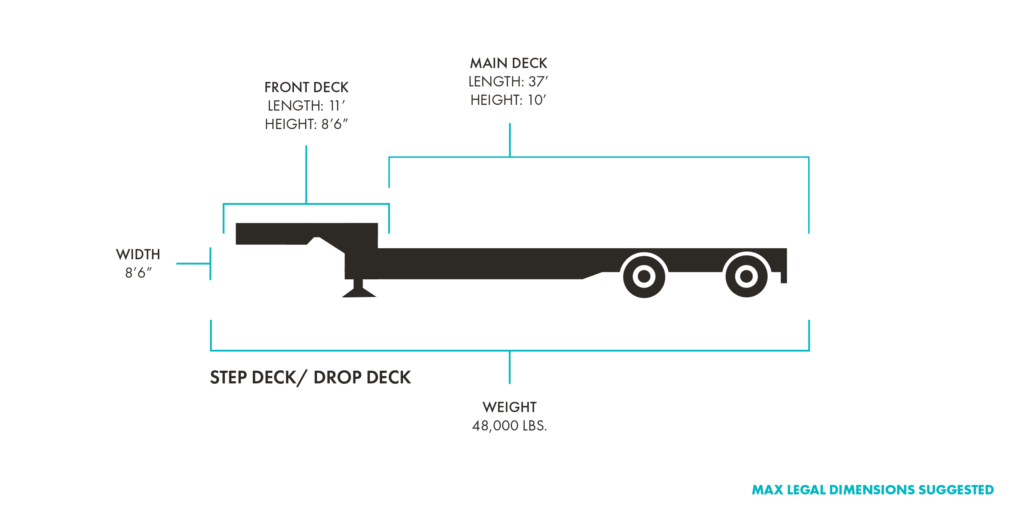

Step Deck/ Drop Deck Flatbed Trailers

Maximum Legal Weight: 48,000 lbs.

Top Deck: Maximum Legal Cargo Length: 11 ft.

Bottom Deck: Maximum Legal Cargo Length: 37 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 10 ft. on the bottom deck, 8 ft 6 in. on the top deck

These trailers are referred to as either a step deck or a drop deck. They consist of a bottom deck and a top deck. These flatbed trailers are great for transporting freight that would exceed the height restriction on a standard flatbed; they are ideal for any tall loads that need to go under low bridges. They also make it easy to use ramps to load and unload freight. A common piece of freight they haul is tractors.

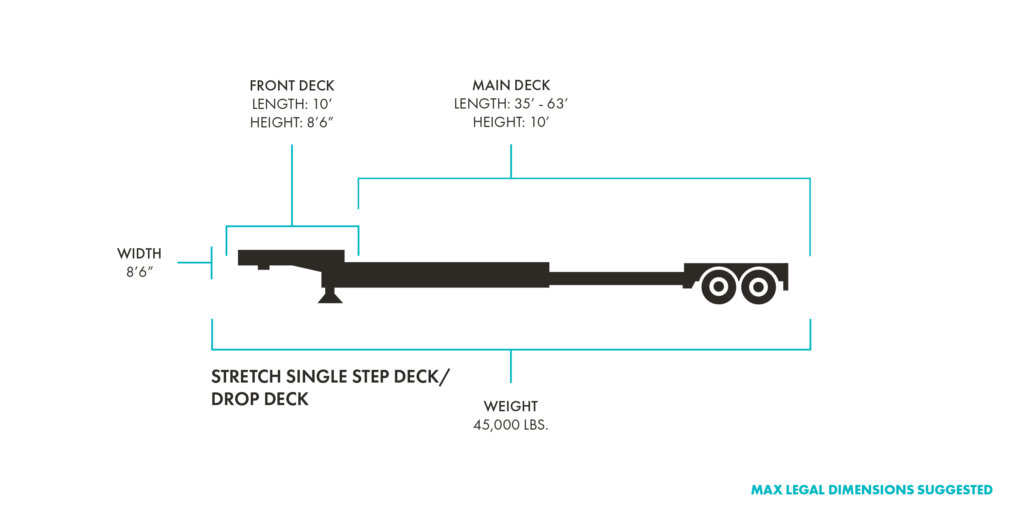

Stretch Single Step Deck/Drop Deck Flatbed Trailers

Maximum Legal Weight: 45,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck: Maximum Legal Cargo Length: 35 to 63 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck: Maximum Legal Height: 10 ft.

These flatbed trailers are like step decks, except they can be extended to transport cargo that can be too long for a standard step deck. This can include goods like scaffolding or drilling and mining equipment.

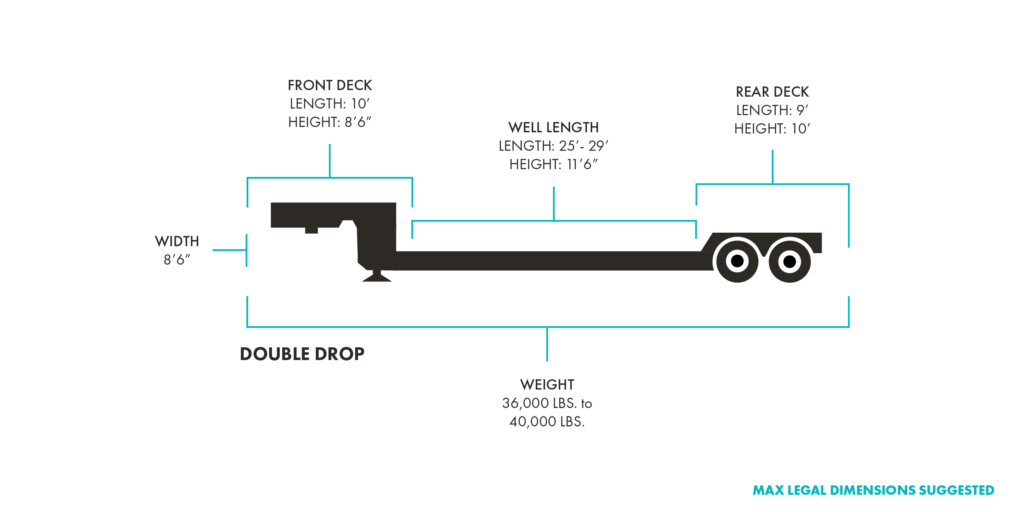

Double Drop Flatbed Trailers

Maximum Legal Weight: 36,000 to 40,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck (well): Maximum Legal Cargo Length: 25 to 29 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

Double drop trailers are also good for cargo that is too tall and generally used to haul oversized freight. Double drop trailers are unique in that they have a longer piece of the trailer called the “well”.

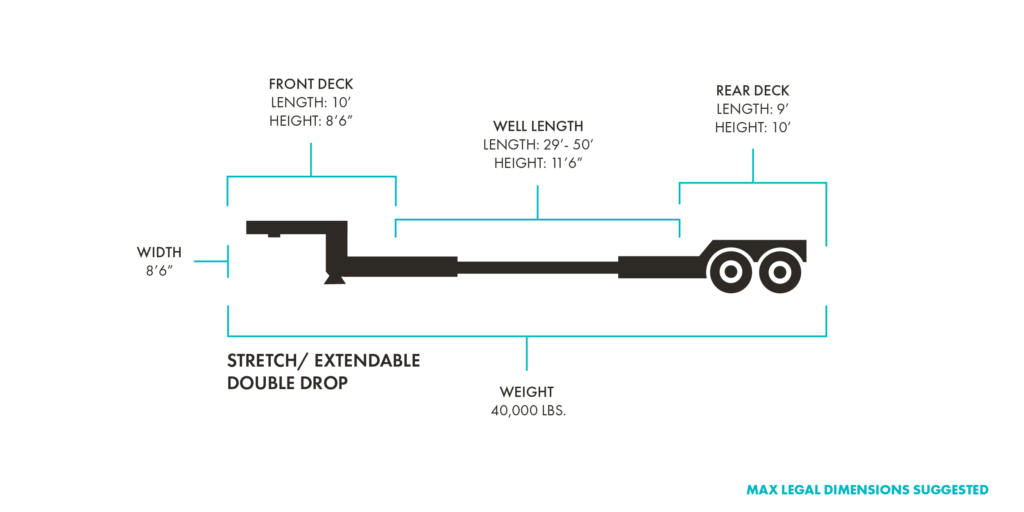

Stretch/Extendable Double Drop Flatbed Trailers

Maximum Legal Weight: 40,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck (well): Maximum Legal Cargo Length: 29 to 50 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

Like the standard double drop trailer, this one is also great for oversized freight. Since this trailer can be lengthened for longer loads, it’s ideal to carrier longer freight since it provides more support and prevents any overhang. It’s also common for this trailer to have two to three axles so it can support more weight. Common freight hauled by stretch double drops are pipes and steel beams.

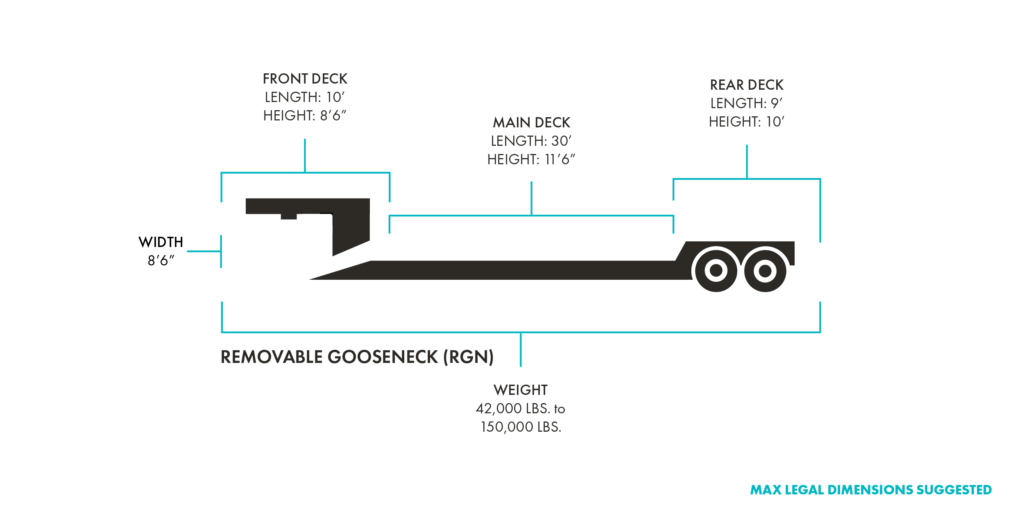

Removable Gooseneck (RGN) Flatbed Trailers

Maximum Legal Weight: 42,000 to 150,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck: Maximum Legal Cargo Length: 30 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

An RGN is one special flatbed trailer. They’re great for long, tall, and heavy freight! They have a detachable front that can be used to create a ramp for loading and unloading and can expand from three axles to over 20, to carry heavy items, like farming combines. However, it’s important to note that since these are more specialized, they can be tougher to find and more expensive to use for your flatbed shipping.

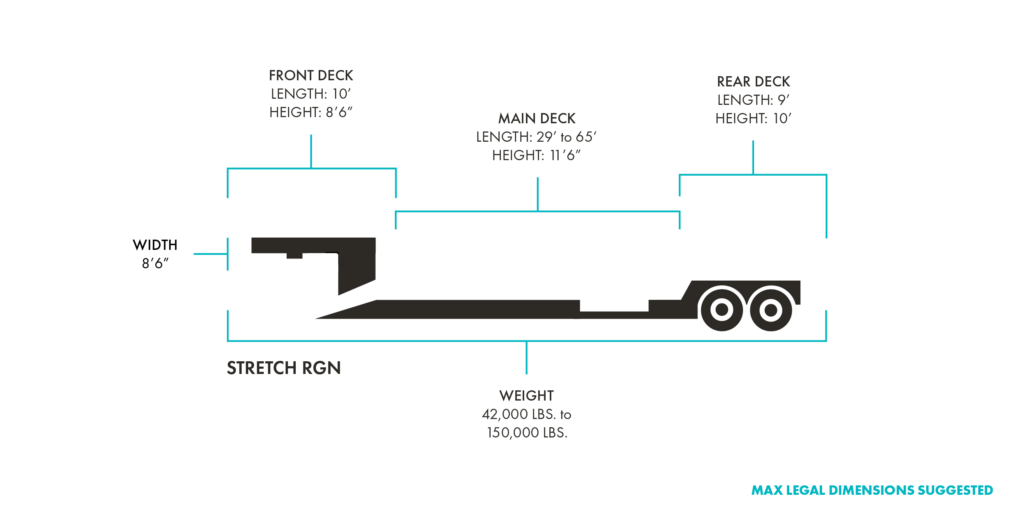

Stretch RGN Flatbed Trailers

Maximum Legal Weight: 42,000 to 150,000 lbs.

Front Deck: Maximum Legal Cargo Length: 10 ft.

Main Deck: Maximum Legal Cargo Length: 29 to 65 ft.

Rear Deck: Maximum Legal Cargo Length: 9 ft.

Maximum Legal Width: 8 ft. 6 in.

Front Deck: Maximum Legal Height: 8 ft. 6 in.

Main Deck (well): Maximum Legal Height: 11 ft. 6 in.

Rear Deck: Maximum Legal Height: 10 ft.

When you need an RGN that can haul longer freight, a stretch or extendable RGN can help. Just like the standard RGN, axles can vary, from three and up, depending on the freight weight. The only real difference with this RGN trailer is the main deck is extendable up to 65 feet long.

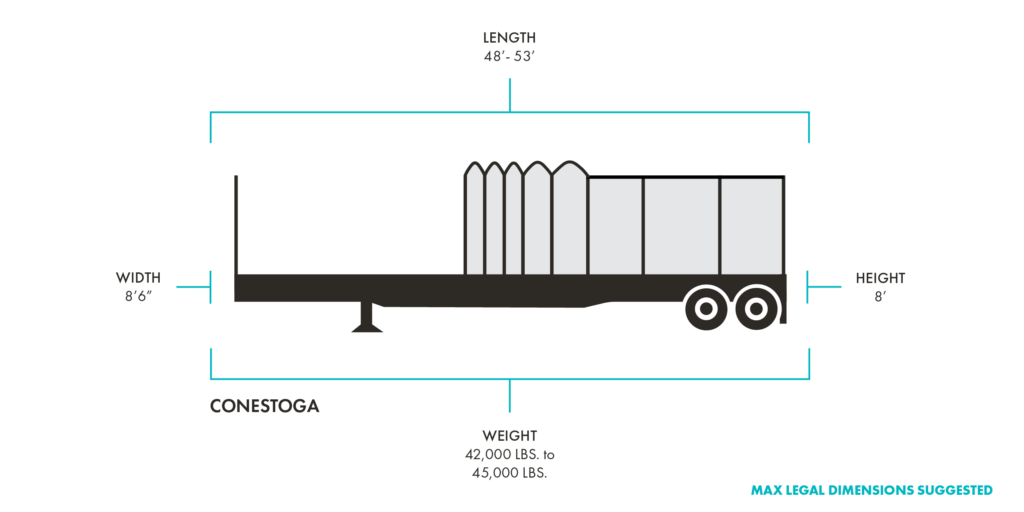

Conestoga Flatbed Trailers

Maximum Legal Weight: 42,000 to 45,000 lbs.

Maximum Legal Cargo Length: 48 to 53 ft.

Maximum Legal Width: 8 ft. 6 in.

Maximum Legal Height: 8 ft.

One interesting fact about Conestoga trailers is that Conestoga is also a brand name for them. Conestogas are specialized, flatbed trailers that have a hard shell and rolling tarp system, which is great for freight that needs better protection from outside elements. These can be one of the most requested flatbed trailers due to their versatility. They can often be seen transporting freight like CNC machinery or helicopters.

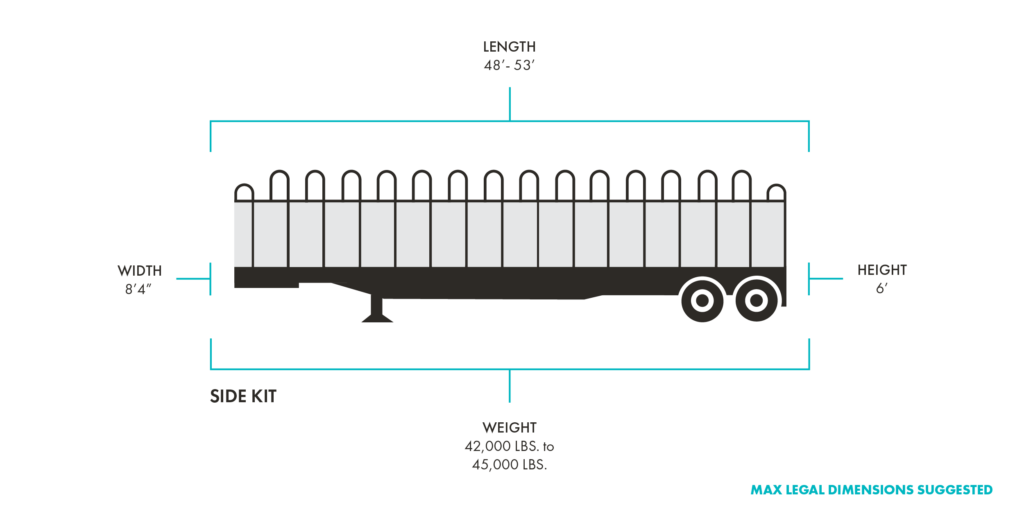

Side Kit Flatbed Trailers

Maximum Legal Weight: 42,000 to 45,000 lbs.

Maximum Legal Cargo Length: 48 to 53 ft.

Maximum Legal Width: 8 ft. 4 in.

Maximum Legal Height: “technically” it’s 8 ft. 6 in. but because of sides, 6 ft. is more easily accomplished

Side kit trailers are like Conestogas in that they are flatbed trailers that offer more protection. These trailers have panels surrounding often made from plywood or fiberglass, allowing for tarping over the top. Side kits are great for freight that is not packaged or crated, like corn or watermelons.

Flatbed Trailer Tips

Match Your Cargo to the Correct Flatbed Trailer

It’s important to know your cargo and that you have the right flatbed trailer to transport it. If the wrong trailer pulls in and it can’t carry your freight, you’ve lost out on precious travel time. Additionally, having the correct trailer ensures safe transport.

Communicate the Details

Regardless of what kind of product you need to transport, a lack of detailed communication with your logistics provider is important to avoid confusion and setbacks. For a logistics provider to effectively support you with your flatbed shipping needs, you’ll need to share specific details such as:

- Dimensions of cargo (length, width, height)

- Cargo weight

- Type of commodity

- Does your freight have any sharp edges?

- Does it need tarped/element protection?

- Is your cargo multiple pieces or singular?

- Is your cargo loose or palletized?

Understanding Your Flatbed Trailer Needs

Understanding the different kinds of flatbed trailers there are helps you make more informed and cost-effective decisions. You’ll better know their limitations and whether they may be more costly and time-consuming to acquire. For example, by knowing that more specialized flatbed trailers like RGNs or Conestogas are tougher to obtain, you’ll know to give your logistics provider advanced notice for those shipments, giving you the benefit of a more successful relationship and potentially cheaper rates.

Access the Flatbed Trailers You Need with Trinity

Now that you know more about the different kinds of flatbed trailers, you’d think you would be set to manage flatbed shipping on your own. However, flatbed shipments aren’t always easy to facilitate. Depending on the type of freight, the flatbed trailer needed, and whether it’s an oversized shipment can all hinder and complicate things.

Flatbed shipping requires proper planning, effective communication, and access to carrier relationships with a variety of flatbed trailers to ensure supply chain success. Luckily for you, Trinity Logistics has over 45 years of experience and trusted relationships with expert flatbed carriers. Working with Trinity is like adding an extra person to your logistics team – one who’s able to take on the workload that comes with arranging flatbed shipments, finding the right flatbed trailer for the right cost, reducing your risk, ensuring the freight you need gets delivered right where it needs to on time and intact.

DISCOVER ALL THE BENEFITS OF SHIPPING FLATBED WITH TRINITY LOGISTICSMost of us over the age of 25 can remember when the World Wide Web made its debut. We remember the “beep-boop” sound of dial-up and the big chunky computers that were as wide as a television set in the 1990’s. It’s been almost 30 years since the dawn of the Internet. It’s mystifying to look at the impact it still has on our everyday lives. Because of the Internet, e-commerce was born, and the need for flatbed shipping has increased.

The Beginning of ECommerce

Over time, ecommerce has taken the baton from traditional brick-and-mortar stores, leaving many big-box store retailers high and dry. Since Amazon Prime’s arrival in 2005, online shopping has exploded in the marketplace. The ease and convenience of it have forced many retailers to develop a strong online presence or risk closing their doors for good.

COVID-19 Creates Rapid Growth

Due to health concerns and social distancing practices, COVID-19 rapidly escalated the use of ecommerce. Total online spending in May 2020 was up 77 percent year-over-year (YOY), according to a report on online spending released in June by Adobe. In that report, Vivek Pandya, Adobe’s Digital Insights Manager, states that it would have typically taken 4-6 years to see the level of growth in online shopping that was seen then. Contactless online ordering helped individuals attempt to limit their exposure to the virus by shopping from home, so it’s easy to see why those reported numbers were so high.

Since the pandemic, the changes in the ways consumers shop have remained. While in-person shopping has increased compared to then, it still lacks in the amount of foot traffic that was received previously. Consumers continue to like the ease of online shopping, and with fewer in-person shoppers, companies are investing less in their brick-and-mortar locations, which has only made people less likely to want to shop in person. In fact, it’s estimated that 40,000 to 50,000 retail stores will close in the next five years, according to the UBS investment bank.

Ecommerce continues to experience growth, with 22 percent of retail sales being online in 2023, the largest U.S. ecommerce sales percentage to date, according to the U.S. Department of Commerce. As e-commerce growth carries on, it’s created a growing need for companies to expand their inventory and improve their ability to distribute their products. What used to be a problem of “too much” storage space for companies before the pandemic has quickly turned into a necessity in today’s time.

The Need for Storage Space

As online distributors continue to see growth, their need for storage space has grown as well. Prior to Covid-19, one or two warehouses could keep a medium-sized company running efficiently. Now, more space is needed to keep up with the increasing demand of companies. Having more than one distribution center can be a huge benefit to a company’s ability to stay successful these days.

This all trickles down to the construction industry. As demand grows for new or renovated warehousing, the need for building materials to meet that demand has also increased.

How ECommerce Growth Affects Flatbed Shipping

Flatbed shipping has always been a leading mode of transportation for industrial freight. Lumber, stone, racking, and other building materials travel best on an open trailer due to their odd dimensions and additional weight requirements.

Looking for an extensive guide to keep on hand for your over-dimensional shipping?

Download our FREE guide!Usually, flatbed shipping sees an increase in volume in the summer months. Construction companies take advantage of the warmer weather, which is most suitable for outdoor construction work. During this peak shipping flatbed season, it’s not unusual to see tightened capacity and higher freight rates, but any added demand for warehousing can add to that, making securing a flatbed carrier more difficult.

Strong Relationships Help

Having a relationship with a third-party logistics company (3PL can be a benefit to those who coordinate freight to be delivered to a job site. Typically, job site freight is very hands-on and has a perpetual knack for being time-sensitive. Installation crews are on-site to receive and install the material scheduled to be delivered. Even the slightest delay can cause significant ramifications to the completion of the construction project. Having a strong relationship with a 3PL can help companies mitigate risk, reduce costs, and provide peace of mind to those who are coordinating the freight.

Be Ready for Anything

It appears online shopping is here for the long-haul and whether it’s causing you to expand your warehousing or not a 3PL like Trinity Logistics can help you be prepared for any changes that may come your way. With Trinity, you’ll gain a Team of experts that can help you optimize your supply chain and arrange shipping for various of transportation modes, including flatbed, while offering end-to-end visibility of your shipments. No matter what changes the future brings, you can stay one step ahead when you choose to have Trinity Logistics by your side.

Many of today’s manufacturing trends are in line with the industry’s goals to improve processes, create more efficiency, and meet consumer demand.

The manufacturing industry has seen challenges, from changes in the way people work to the rapid growth in demand, with many of these challenges accelerated by the recent covid-19 pandemic.

So, what evolutions and challenges are the manufacturing industry currently facing? Let’s dive into the latest manufacturing trends.

WHAT ARE THE LATEST TRENDS IN MANUFACTURING?

- DIFFICULTY FINDING LABOR

- DIVERSIFYING WORKFORCE

- TECHNOLOGY IS TAKING OVER

- INCREASING CYBERSECURITY

- CARBON NEUTRALITY

- BUILDING RESILIENT SUPPLY CHAINS

DIFFICULTY FINDING LABOR

Manufacturers are still struggling to find labor, with a recent Deloitte survey estimating that the manufacturing sector will be short 2.1 million skilled workers by 2030. It’s difficult for manufacturers to fill open positions, with respondents claiming it is 36 percent more difficult to recruit than in 2018.

To combat the shortage, manufacturers are looking for ways to recruit and retain skilled talent, by raising wages and reskilling current talent to meet company needs. According to the Manufacturing Institute, young employees are attracted to companies that look to train and invest in them. 70 percent of manufacturing workers under 25 said they will stick with an employer because of these opportunities to grow.

Additionally, technology is advancing and should help manufacturers combat their labor challenges. With tools like artificial intelligence (AI) and the Internet of Things (IoT) becoming more accessible, companies should be able to become more efficient and able to produce more with fewer people.

DIVERSIFYING WORKFORCE

Diversifying the workforce is one of the growing manufacturing trends because the industry has held a reputation for being a male-dominated industry. According to a study by the Manufacturing Institute, less than 30 percent of manufacturing workers are women. So, in 2021, the Building Economic Strength Through Manufacturing Act was passed. This bill seeks to double the number of women-owned and minority-owned manufacturers.

According to Glassdoor, when applying for jobs, 76 percent of applicants look for company diversity. Diversifying the workforce is a trend that goes in hand with employee recruiting. It creates opportunities for new talent and can help make operations more resilient.

TECHNOLOGY IS CHANGING THE INDUSTRY

Technology changing the industry has been and will be a manufacturing trend for some time. Technology is improving, becoming more accessible, and showing its benefits, so many manufacturers are investing in it more. Manufacturers need technology to keep up with the challenges of increased demand while facing a labor shortage.

Some technology tools companies are using include AI, automation, sensors, IoT, robotics, predictive maintenance, and remote monitoring. These tools help manufacturers with the manual and repetitive tasks that they struggle to find the labor for. In addition, companies are evaluating their operations to make the best use of technology and people.

Frontline workers will likely expand their roles to take on new responsibilities. As technology automates processes, workers will need to use more communication, collaboration, and analytical skills. Technology will also offer more flexibility and safety for frontline workers, further helping with employee recruiting and retention.

Some manufacturers are even pushing the limit and testing our “dark factories”. These are fully automated factories without any human workers on site.

Industry 4.0 is what many refer to as this trend of technology. It’s a shortened term for what is being called the fourth industrial revolution. Industry 4.0 technologies, such as the above examples, can raise productivity by 40 percent.

INCREASING CYBERSECURITY

As technology use increases and manufacturing processes get more connected and complex, a growing challenge is cybersecurity. In 2021, manufacturing was the industry that suffered the most cyberattacks, according to IBM’s X-Force Threat Intelligence Index. In fact, according to a survey by Omdia, the increasing risk of cyber attacks are one of the main challenges slowing down the implementation of more analytics, automation, and AI in manufacturing.

Because of its increased risk for cyber attacks compared to any other industry, manufacturing companies are investing more in the cybersecurity strategies and monitoring, implementing the use of multi-factor authentication, issuing employee training on cybersecurity, and building recovery plans to be prepared should any attacks take place.

CARBON NEUTRALITY

Combatting climate change is a priority on everyone’s mind and the manufacturing industry is no exception. The manufacturing industry produces almost a quarter of global greenhouse emissions. However, with the government pushing industries towards sustainability, manufacturing companies are rethinking their operations.

One manufacturing trend is carbon neutrality. Carbon neutral is when a company removes the same amount of carbon dioxide it emits into the atmosphere.

Manufacturing companies can become carbon neutral by purchasing carbon offsets. An example of this would be a company sponsoring a solar energy farm or a project for reforestation.

Did you know Trinity is ranked in the top 50 percent of all companies for sustainability by EcoVadis?BUILDING SUPPLY CHAIN RESILIENCE

Since the start of the covid-19 pandemic and the supply chain bottlenecks we continue to face, supply chain resilience remains a top manufacturing trend.

Supply chain bottlenecks like the covid-19 pandemic, high container costs and delays, severe weather, protests, and new regulations are a few of the disruptions that have shed light on manufacturers’ fragile supply chains.

Manufacturers continue to look for more resilience to keep up with consumer demand despite these challenges.

Improving communications with supply chain partners, onshoring or reshoring, and investing in supply chain technology are some of the ways manufacturers are making their supply chains more stable.

STAY AHEAD OF MANUFACTURING TRENDS

Whether you know the latest manufacturing trends are or not, having an expert on your side is one easy way to stay ahead. And that’s just what Trinity Logistics aims to be.

Yes, our primary focus is as your logistics partner, but our People-Centric culture means we’re more than that. As a business relationship, we’re invested in your company’s success. We stay knowledgeable on what’s going on in your industry to help keep you updated. And we stand at the ready to offer your business any logistics support and expertise that you need.

Don’t miss your opportunity to gain a business relationship that stays on top of your industry’s trends and is people focused. Let’s get connected.

SEE WHY YOU SHOULD WORK WITH TRINITY LOGISTICSHVAC contractors and plumbers continue to face supply chain woes like material shortages and rising costs.

Battling these issues is making it tougher for HVAC contractors and plumbers to meet their customer’s demands in the short term and perhaps even longer. Here’s what HVAC contractors and plumbers can do to rise above.

WORK WITH MANY SUPPLIERS

If current suppliers can’t meet your needs, then it’s a good time to explore other ones. Many suppliers are ready to strike up new relationships and may be willing to be more flexible with contracts. Shopping with multiple suppliers will not only gain you access to more resources but can offer you more varied pricing options to consider.

CONSIDER ALTERNATIVE MATERIALS

It might be worth checking into other materials as they may be easier to get your hands on. Considering other brands of materials or equipment can keep your projects from staying stagnant.

COMMUNICATION IS KING

In difficult times like these, communication can be something that gives your company a competitive edge. Not only is it a vital aspect of a successful business, but it helps build trust and long-lasting relationships. While no one likes delivering bad news about backorders or delays, keeping your customers informed will go far, as they’ll appreciate your honesty and transparency.

IMPROVING CUSTOMER SERVICE

While material shortages and delays are out of your hands, great customer service will keep your current customers and help you gain new ones. In addition, extra attention to customer service can help address any frustrations among your customers. While these challenges may not last forever, your reputation will, so make sure yours remains good, if not great.

PRE-ORDER MATERIALS AND EQUIPMENT

Many HVAC contractors and plumbers often only order the materials and equipment as needed. Instead, plan and stock up on the materials you most often use for your projects. This way, you’ll have what you need ready instead of waiting for materials to deliver.

CONSIDER MODE DIVERSIFICATION

Trying different modes of transportation could help you offset your increased costs. Keep an eye on transportation costs across the different modes available. Being more flexible with your freight shipping can give you some financial benefits.

INVEST IN TECHNOLOGY

Logistics technology, like a transportation management system (TMS), has tools available to help you stay on top of your supply chain and plan efficiently. One example is helping you with your routing decisions by matching your freight with the best carriers, lanes, rates, and transit service. It will also enable you to better track and manage any service disruptions or shipment delays in real-time, thus increasing your service levels and improving your customer relationships.

THINK ABOUT ONSHORING

Onshoring is a strategy that HVAC contractors and plumbers can use to mitigate supply chain woes and improve competitiveness. Onshoring strategy can ensure resilience in your supply chain and give your company a competitive edge.

Onshoring refers to the overall practice of moving manufacturing operations from foreign soil back to the United States or outsourcing to domestic contract manufacturers rather than overseas. An example of onshoring would be having operations moved to Mexico versus China.

Onshoring allows your supply chain shorter travel times since materials and products are much closer than if they were overseas. This not only keeps your projects moving that much quicker but reduces your transportation costs. Additionally, you’ll also have the benefit of being greener due to less fuel being used.

CONSIDER OUTSOURCING YOUR LOGISTICS

According to the 2020 Annual Third-Party Logistics Study, 67 percent of shippers stating using a 3PL contributed to reducing their logistics cost, while 83 percent said it improved their service. By outsourcing to a 3PL, like Trinity Logistics, you won’t have to spend hours worrying about your logistics and get the help you may need to be more flexible with your shipping options.

“In this market where it’s difficult to meet demand and project deadlines due to material and product shortages, it may not be the best option to send it via LTL as you may save a few dollars on the front end but pay for it with extended estimated transit times, and the possibility of the parts being damaged as they go from terminal to terminal throughout transit. Working with a 3PL, like Trinity Logistics, can bring you other possibilities on how to move your freight efficiently, such as dedicated full truck options, expedited (straight trucks/sprinter vans), partial, and hot shot options to keep your freight moving to arrive on time so you can achieve your project deadlines.”

– Michael Whitaker, Business Development Representative at Trinity Logistics

If you’re looking for a reliable 3PL provider to help with your HVAC supply chain, consider Trinity Logistics. With Trinity, you gain a Team of experts to help optimize your supply chain, help arrange shipping using other modes, and end-to-end visibility through our available technology.

DISCOVER TRINITY LOGISTICSStone materials are very versatile and often used in industries like construction, interior decorating, and landscaping. However, transporting stone can be a difficult task for many reasons. Stone materials can be heavy and bulky and yet surprisingly fragile at times and easy to chip or crack. Just as there are various uses of stone, there are just as many challenges to shipping it. If you’re a shipper handling stone material, bookmark this guide for all you need to know about stone transport.

WHAT’S INCLUDED

- Types of Stone Materials

- Uses for Stone Materials

- Packing for Stone Transport

- Equipment Needed for Stone Transport

- Oversized Stone Transport

- How to Ship Common Stone Materials

- Shipping Stone Costs

- Finding the Right Carrier

TYPES OF STONE MATERIALS

When arranging stone transport, you need to consider the type and shape of the stone material you are shipping. Stone materials can be in the shape of slabs, blocks, bricks, tiles, or crushed stone. Each shape and type of stone material requires different handling to be shipped safely and securely.

- Concrete Pavers

- Flagstone

- Limestone

- Granite

- Marble

- Crushed stone

- Slate

- Sandstone

- Landscaping stone

USES FOR STONE MATERIALS

Stone materials are used across many industries. Stone is commonly used as:

- Countertops

- Floor tiles

- Landscaping

- Roadwork

- Fireplaces

- Stairs

- Bridge construction

- Sidewalks

- Statues and decorations

- Interior Design

- Gravestones and cemetery monuments

With such a wide variety of use, it’s no surprise that stone transport often occurs across long distances.

PACKING FOR STONE TRANSPORT

Proper packing and packaging materials are very important for stone transport. Packaging stone materials the wrong way can lead to damaged product upon arrival.

Smaller stone materials, like tile, can be packed in crates with foam material for cushioning to prevent any scraping or breaking. The crate shouldn’t be too large, with minimal extra space to limit the movement of your stone product. Make sure not to stack the stone material too high or load them vertically. Using short stacks or horizontal loading will help with structural integrity.

For larger stone materials, like granite slabs, palletizing is another option, and the stone product should be wrapped around and between with cushioning to prevent scraping or chipping.

EQUIPMENT NEEDED FOR STONE TRANSPORT

Certain pieces of stone materials will need more equipment than others.

For smaller stone material shipments, a 53’ dry van can work for most, especially those shipping less-than-truckload (LTL) and packaged in crates. Stone shipments can be loaded using a loading dock and forklift. If a loading dock isn’t available, a lift gate can be used, but this additional service costs extra and makes it more difficult to find an available truck. Generally, palletized stone shipments are not recommended for LTL unless there are plenty of packing materials wrapping the product.

If you’re shipping large pieces of stone, like granite slabs, you’re going to need to find a flatbed with an A-frame to securely hold it. An A-frame is a piece of wood or metal shaped into the letter “A” and is needed to transport stone slabs to prevent damage. Stone slabs are prone to breaking or cracking when moved horizontally, so the A-frame helps prevent any damage.

Before the granite slab or other stone material can be loaded onto the truck, the A-frame must be placed on the flatbed with a forklift or crane. When it’s ready to move, make sure that the material is secure and strapped in. Moving straps help prevent the stone material from shifting during transportation, preventing damage, and reducing any risk.

Don’t make the straps too tight because doing so could cause damage upon delivery. Everything should be checked thoroughly before transport to make sure a costly incident doesn’t happen when moving over the road.

Intermodal containers can also be an option for stone transport. Not only do these containers reduce the need for any excessive handling and thus, the chance for damage, but many popular bulk stone products used in the U.S. are mined from locations far away from the country, making this an ideal mode for global stone supply chains. When the stone material is ready to head to its destination, drayage carriers can transport the container or freight can be loaded onto a flatbed for its final stretch of travel.

OVERSIZED STONE TRANSPORT

One of the other main challenges with stone transport is it can be heavy, and sometimes oversized, like those granite slabs we mentioned earlier. Often with stone shipments, you’ll find that you need to get an oversize or overweight permit to travel on state highways.

Most often, the state’s Department of Transportation (DOT) issues these permits, but sometimes they can be handled by another department, depending on the state. These permits are only good for a short window and are the only time your shipment can be on the road. Therefore, it’s important to make sure you have all your ducks in a row, so your shipment stays on schedule, and you don’t end up with a costly violation fee.

What Qualifies as Oversize?

Each state has different regulations on its specifics, but most shipments will be considered oversized if it exceeds 80,000 pounds gross weight or if dimensions exceed:

- 14 feet in height

- 8 feet 6 inches in width

- 53 feet in length

Overweight and oversized shipments can be more comprehensive as, besides the permits, you may need oversized banners, flashing lights, civilian escorts, police escorts, route surveys, bucket trucks, or even a road closure. It’s important that you always take the time to double-check that you’re in compliance with DOT rules and regulations for your stone transport.

Looking for one place to find all you need to know about oversized shipment regulations?

HOW TO SHIP COMMON STONE MATERIALS

Shipping Crushed Stone

Crushed stone can easily be transported using a container. A freight truck pulling an empty container can be used and loaded on site, or the crushed stone can be packed into a shipping container and then loaded onto the truck with the help of a crane.

It’s important to note that unless covered, the top of the container will still be exposed during transportation. If uncovered and depending on the kind of crushed stone, sometimes some stone material can fly out of the container during transportation, resulting in damages, injuries, or loss of product. For this reason, it’s often best to have your motor carrier cover and secure the top of the container with a tarp.

Shipping Stone Bricks and Tiles

Unlike crushed stone, shipping bricks or tiles need more careful handling. Palletizing or banding into cubes is the best way to transport these stone materials. However, you can’t pack them the same as other products due to their ease of chipping or cracking during transit.

When packing stone bricks or tiles, it’s best to stack them with layers of cardboard or foam between the layers of the product, cushioning them and preventing any scraping, scratching, or other damage. When banding into cubes, usually the last two cubed loads are placed on rubber mats to further prevent them from shifting.

Additionally, it’s recommended to avoid shipping these products via less-than-truckload (LTL). These stone materials are brittle and susceptible to damage from other products, but also hazardous to other items should they come loose during shipping. To keep your stone products safe, it’s always best to ship full truckload whenever possible.

Shipping Stone Slabs, Like Granite

While nearly indestructible once installed, slabs of granite and similar stone material are quite fragile during transit. Any incorrect handling can result in damage. Like glass, these stone materials will likely crack if laid vertically. Transporting heavy slabs of stone, like granite transportation, requires specialized equipment to keep them vertical during transit.

You’ll need an A-frame to hold up the heavy slabs of stone and make sure they are secured with durable straps. When properly supported, slabs of stone can be sturdy and resistant to cracking.

Shipping Irregularly Shaped Stone Products

Let’s say you need to transport an irregularly shaped stone product, like statues or headstones. Certain products might have sharp corners that can easily chip or have smooth surfaces you don’t want to be scratched, like memorials. It can be tough to figure out how to ship these unusual stone materials.

The best option to transport these stone products safely is to order custom packaging for them, like a sturdy box with Styrofoam pieces sculpted to fit around it so your product is secured from any movement during transit.

As with shipping tile, it’s best to ship full truckload instead of LTL, so your product isn’t handled more than it should be and isn’t at risk from other products.

SHIPPING STONE COSTS

Stone transport can be more expensive to ship due to its heaviness and fragility. Any time you have a shipment that requires more attention to detail or more specialized equipment, it’s going to be more costly.

If you typically ship large volumes of stone materials often, a Request For Proposal (RFP) or contract with a carrier or logistics company can be one way to find savings versus working with the spot market.

FINDING THE RIGHT CARRIER FOR YOUR STONE TRANSPORT

Because of how delicate transporting your stone materials can be, you want to make sure the motor carrier you select is experienced. This is where cutting costs here isn’t always worth it. You also want to make sure your provider has enough insurance and that your commodity is covered should something happen.

TAKE THE GUESSWORK OUT OF YOUR STONE TRANSPORT

Stone transport can be one of the most challenging types of freight to arrange. However, you can choose to simplify your shipments by working with an experienced third-party logistics (3PL) company like Trinity Logistics.

Working with Trinity saves you time from finding and vetting carriers, figuring out what equipment is needed, and gives you full visibility of your product’s transit, from pick up to delivery. Experience our best-in-class customer service and sit back, knowing that we’ll get your product safely delivered.

LEARN MORE ABOUT TRINITY'S SHIPPING SOLUTIONSWhether owning or renting, heavy equipment is a big investment in your business – and you don’t want to take unnecessary risks that can lead to loss or damage during transportation. Heavy equipment shipping can be challenging, but it’s not as complicated as it appears when you have the right provider. To help you ship your heavy equipment safely, here’s some additional information you may need.

What We Cover in This Article

- What is heavy equipment shipping?

- Common types of heavy equipment

- Rules and regulations for heavy equipment shipping

- Trailers used for heavy equipment shipping

- What should I know about my heavy equipment shipping?

- How much does it cost?

- Preparing for heavy equipment shipping

- Shipping heavy equipment internationally

- Choosing the right provider

What is Heavy Equipment Shipping?

Heavy equipment can be a broad term, but it usually consists of a piece of large machinery or equipment of at least 40,000 pounds or more. Due to its size and weight heavy equipment is often loaded and unloaded by a crane if it cannot be driven on/off the trailer. Often, these kinds of shipments can be oversized and/or overweight, requiring permits, escorts, route surveys, and an experienced motor carrier with specialized trailers to transport your equipment safely and effectively.

Common Types of Heavy Equipment

- Agricultural Equipment and Machinery

- Construction Equipment

- CNC Machinery

- Crawler Cranes

- Gas & Oilfield Equipment

- Industrial Plant Machinery

- Military Equipment

- Mining Equipment Oilfield Equipment

- Renewable Energy Parts and Components

Heavy Equipment Shipping Rules and Regulations

When it comes to heavy equipment shipping, you should have knowledge of U.S. Department of Transportation (DOT) rules, regulations, and restrictions. Overlooking DOT regulations and restrictions surrounding OD/OW transportation can be both costly and time-consuming.

Heavy equipment shipping is regulated by the Federal Motor Carrier Safety Administration (FMCSA), the U.S. DOT, and state governments. Each state varies its rules, regulations, and restrictions for permitting OD/OW travel. Be sure to double-check state regulations before transporting your equipment. Or work with an expert in the field of over-dimensional shipping.

Looking for one place to find all you need to know about oversized shipment regulations?

Download our free over-dimensional shipping guide!

Overweight and oversized shipments can be more comprehensive as, besides the permits, you may need oversized banners, flashing lights, civilian escorts, police escorts, route surveys, bucket trucks, or even a road closure. It’s important that you always take the time to double-check that you’re in compliance with DOT rules and regulations when transporting your heavy equipment.

Need help with your oversized shipping? We have experts ready to help you.

Request a Shipping Quote with Trinity logistics.

Trailers for Heavy Equipment Shipping

Heavy equipment shipping is made possible by the various types of flatbed and specialized trailers available.

Flatbed Trailers/Open-Deck Trailers

Flatbed trailers allow for easy loading and unloading and can carry up to 48,000 pounds. When choosing your flatbed carrier, make sure to confirm that the trailer will be able to haul the weight of your equipment. Trailer dimensions are approximate: 48’ L x 102’’ W x 58’’ H

There are other open-deck trailers to consider, like step-decks or drop-deck trailers. They can accommodate around 46,500 pounds and can legally haul taller products, up to 10’6’’ tall, and can be fitted with permanent or removable ramps to drive equipment on and off the trailer. Trailer dimensions range approximate: 48’ or 53’ L x 102’’ W x 36’’ to 42’’ H.

Specialized Trailers for Heavy Haul Trucking

Due to the size, some heavy equipment may need a specialized trailer to accommodate its transportation.

Double-drops and Removable gooseneck (RGN) trailers are ideal for heavier machinery and equipment that needs easy loading and unloading or drive-on drive-off capabilities, and they are great for freight exceeding the legal height and weight maximums.

What Should I Know About My Heavy Equipment Shipping?

You’re ready to get started with heavy equipment shipping. What should you be prepared to answer when looking for a provider?

Know the Dimensions of Your Heavy Equipment

Size matters. The equipment’s dimensions and weight will help determine what kind of trailer the carrier will need to transport your freight and if any permits, escorts, or other accessorial charges are required that will ultimately determine the total shipping costs.

Breaking Down or Shipping in One Piece?

Does your equipment need to be taken apart to ship and then reconstructed upon delivery? Can your equipment be crated or boxed? Is it more effective to break down your equipment into smaller components for shipping? If shipping in one piece, what are the things that need to be done before shipping, such as having any fluids discharged or batteries removed? These are all important questions you should know so all parties involved know what is to be expected throughout the entire shipping process.

What Equipment is Needed to Load and Unload Your Freight?

This is very important information that is needed for your shipment. Do you need a ramp, forklift, or crane to load and unload your equipment? Do you have the required equipment ready to unload and load your freight? Or can the equipment be driven on and off of the trailer?

Know What is Covered by Your Provider’s Insurance

It’s important you know what is covered by your provider’s insurance, so you know whether you will need to buy any supplementary insurance to make sure your heavy equipment is fully protected in case of any issues.

How Much Does Heavy Equipment Shipping Cost?

While we’d love to give you exact numbers, there can be quite a few factors involved that make each quote unique, such as:

Size of Your Heavy Equipment

The larger or more oddly shaped your piece of equipment means it may need specialized trailers, permits, or routing requirements, likely raising your shipping price.

Time of Delivery

If you need your equipment delivered at a specific time, this will likely raise the shipping price as well.

Pick-up and Delivery Location

The further distance your equipment must travel, the higher it will cost you. Additionally, more congestion (think cities) in or around your pick-up or delivery location can increase your shipping costs.

Time of the Year

Adverse weather conditions, such as during the snowy and icy winter months or hurricane season, can affect your pricing if certain routes are shut off, making your equipment’s journey longer. There’s also flatbed peak shipping season, which ranges from April to October, which increases flatbed demand – and rates.

Current Fuel Rates

The more fuel costs motor carriers, the higher your shipping cost will be.

Permit or Licenses Required

When transporting heavy equipment, oversize or overweight permits may be required. Costs can vary by state and province, and some states may take longer to issue permits due to each state’s unique regulations and infrastructure.

Escorts Required

Escorts will increase your shipping costs as they need to be paid too! When freight is over 12ft wide or tall, it’s a good idea to check routing to see if escort cars are required.

Preparing Heavy Equipment for Shipping

You’ve got your quote and provider selected. What’s next? Here are the steps you should take to ensure your equipment remains safe and secure during shipping.

Have Documentation Ready

You’ll want to ensure all required documentation and permits are sorted and ready before pick up. Make sure to confirm with your shipping provider what permits are required and that they are in place to limit the chance of any shipping delays or fines.

Planning Transportation Routes, If Needed

Planning your route is necessary if your shipment is considered Oversized. Depending on the dimensions of your equipment, you may need to have your provider avoid bridges with low clearances, sharp turns, or even roads of a particular width.

Check the Condition of Your Heavy Equipment

Just as car rental services do before lending their vehicles, inspect your equipment, and take photos before shipping, so, should anything happen during the transportation process, you have it documented.

Make Sure Any Loose Parts or Tools are secured

You don’t want to lose anything important during the transportation of your equipment!

Cover Any Important Parts

Your equipment will likely be hauled through open air, facing the wind and other elements. Covering any vulnerable or important parts is a great way to ensure that your equipment stays safe and functional.

Check Your Equipment’s Manual

The manufacturer’s manual is a great resource for getting your equipment ready for shipping. It will help you determine exactly what steps you need to take before pick-up.

Ask Your Provider How You Can Help

If you’re unsure, ask your provider how you can help make your equipment’s transportation a smooth process. Based on their experience and expertise, they can give you tips and advice and will appreciate you taking this extra step to work together as a team so your equipment can be delivered safely.

Shipping Heavy Equipment Internationally

What if you need to ship your heavy equipment internationally? There can be many challenges to overcome, which you may find incredibly difficult to do alone. In this case, it makes the most sense to hire an expert to help you. While it can be costly, it’s the most stress-free way to safely transport your heavy equipment internationally.

Here are some tips to ensure your international heavy equipment shipping is successful.

- Make sure the provider you select to help you with your international shipping is experienced, has relevant credentials, and has a good reputation.

- Just like shipping inland, know the dimensions and weight of your heavy equipment to inform your provider.

- Determine the best shipping method for you. Your expert provider can help you figure this out. Your options are

- Roll on/Roll off (RoRo) is popular and involves driving the machinery onto a flatbed style truck at the pick-up location and rolling it off after it arrives at its destination. RoRo is speedy, efficient, and often less costly than your other shipping methods.

- Flat rack containers have walls or support posts on the ends, allowing loading from the top or sides. Flat racks mean your equipment is exposed to open air and so this method can be less costly, but then your equipment is exposed to the elements throughout its transport.

- Lift on/lift off (LoLo) is a method of loading and unloading containerized cargo over the top of a shipping vessel using cranes or derricks. LoLo ships usually have onboard cranes and can often carry a larger container capacity.

- Be prepared for the costs. With international shipping, you have extra costs such as taxes, tariffs, and customs checks.

Choosing the Right Heavy Equipment Shipping Provider is Important

You have many options for selecting a provider to help you with your heavy equipment shipping needs. Though too many options can feel overwhelming. How do you know you’re making the best choice for your company and freight?

Here are some qualities you should consider when looking for a provider.

Extensive Experience in Heavy Equipment Shipping

You’ll want to look for a company that has been in business for a long time, has the experience transporting the heavy equipment you’re shipping, and has a good reputation. This is a great opportunity to ask for references and contact them for their feedback.

Offers Flexible Shipping Solutions for Your Unique Needs

Do you need help with prepping your equipment for shipping, obtaining any necessary permits, or any other specialized services? Make sure the provider you’re considering has all the solutions you may need.

Carries the Proper Insurance

You want to make sure your heavy equipment is protected should anything happen during the shipping process. Verify that the provider you’re considering has the appropriate insurance to cover your equipment and enough liability insurance should anything else occur.

Trinity can help with Your Heavy Equipment Shipping

It’s easy to see that heavy equipment shipping has the potential to be a complicated process. If you’re looking for a provider that can help simplify your shipping, saving you time and stress, please consider working with Trinity Logistics.

Trinity Logistics is an industry-leading third-party logistics company with expert knowledge, ready to help you with your oversized, heavy haul, or any other flatbed shipments. We do this by providing our best-in-class People-Centric service and building strong relationships with skilled and experienced motor carriers.

We have the experience you’re looking for and the reliable carrier relationships you need to move your heavy equipment safely, securely, and on time.

Learn how Trinity can help you with your shippingFlatbed shipping is an essential part of the logistics industry.

Flatbed trailers are incredibly versatile and offer many benefits to shippers. Not to mention, flatbed shipping has been on the rise in recent years. In this blog, we’ll divulge to you our comprehensive knowledge of flatbed shipping so you can master this transportation mode.

WHAT IS A FLATBED TRAILER? FLATBED SHIPPING?

Flatbed Shipping

Flatbed shipping is often the transportation choice for cargo that doesn’t need the enclosure of a dry van. It’s ideal for cargo that cannot be loaded or unloaded from a dock as the shipper or receiver can load or unload from a variety of ways. The design of a flatbed trailer allows for cranes and forklifts to unload and load goods from a loading dock, from the side with a forklift or crane, or from above with an overhead, gantry, or crawler crane. This makes a flatbed trailer versatile and critical for numerous loading and unloading scenarios including at job sites, warehouses, and distribution centers.

Flatbed Trailer

A flatbed trailer is the most common type of open-deck trailer used in commercial, over-the-road, long-haul, and specialized trucking such as oversized or over-dimensional shipments. A flatbed trailer is a 48ft or 53ft trailer, that can accommodate loads up to 48,000lbs. They typically have two axles, air-ride suspension, and kingpin for a standard 5th wheel hook up.

Flatbed Freight

Flatbed freight tends to be more industrial than truckload dry van freight. There is a wide variety of flatbed freight in the marketplace. Some higher volume products like lumber or building supplies will generally pay less than more industrial items that support our country’s energy and core infrastructure needs, like construction equipment, generators, fabricated steel, and other project or job site-related freight.

WHAT CAN BE HAULED ON A FLATBED TRAILER?

The most common freight shipping uses for flatbed trailers are:

o Formed concrete items

o Lumber

o Construction materials

o Steel beams

o Scaffolding

o Trusses

o Electrical transformers

o Oil, gas, and petrochemical equipment

o Solar panels or wind turbines

o Commercial heating and air conditioning units

o Landscaping materials

o Large quantities of wrapped and stackable products

WHAT INDUSTRIES USE FLATBED TRAILERS?

Because flatbed trailers have no enclosure, the freight they carry can be versatile and their use extends across several industries, such as;

o Housing

o Construction

o Renewable energy

o Agricultural

o Warehousing

o Manufacturing

o Mining and drilling

o Military

o Automotive

o Landscaping

WHAT ARE THE BENEFITS OF A FLATBED TRAILER?

There are several benefits to using a flatbed trailer for your freight. With a flatbed trailer, there is dimensional flexibility for loading or unloading freight since there are no physical walls or a ceiling to restrict its use. Any cargo that is oddly sized or irregular-shaped can be easily moved with a flatbed trailer.

WHAT ARE THE DISADVANTAGES OF USING A FLATBED TRAILER?

When selecting the type of trailer your freight needs, you should know the disadvantages of each. Compared to traditional hauls, all flatbeds take considerable skill, effort, and time.

Since there are no physical walls to restrain freight, cargo securement and balance are two significant concerns with flatbeds. The FMCSA has a lengthy section in rules specifically for securement, as insecure cargo is a serious safety hazard.

Proper securement is needed for your freight too because if not done correctly, your freight can get damaged from the securement itself. Also, shipments often shift some during transportation, so even weight distribution and securement are necessary.

Another disadvantage to flatbed trailers is that there are no physical walls. It’s a positive for loading and unloading. Still, it can also be a negative as no enclosure means dealing with the elements (wind, rain, snow, sun, animal or human interference, truck smoke/smog, dust, and road debris). To combat this, there is the option of tarping your freight or using a Conestoga trailer.

There are even more significant risks and responsibilities with any oversized freight as these shipments have even more strict regulations to follow.

Looking for all you need to know about Over-Dimensional Shipping?

FLATBED SHIPPING TIPS

Know your cargo

Be sure to know all the details of your shipment. This includes commodities, value, dimensions, and weight. This information will help logistics providers know how to properly secure your cargo ahead of time.

Understand what trailer you’ll need

Familiarize yourself with the different types of flatbed trailers before booking a shipment so you can make the most cost-effective and safe choice. Each type of flatbed trailer has certain limitations. For example, a specific flatbed trailer like extended trailers and Conestogas can be harder to find so your provider may need advanced notice when they are required.

Be aware of accessorial charges

Flatbed shipping may involve moving specialized loads which can need special equipment or extra services. Make sure you have the proper equipment and services needed for your freight to avoid extra charges, freight damage, or delays.

Choose to work with an expert

Arranging flatbed shipments on your own can be time-consuming and expensive, making sure all regulations are met and your cargo travels safely. Consider working with an expert in flatbed shipping to help secure capacity and locate the right equipment for your freight.

FLATBED RATES AND SEASONALITY

Freight shipping demand, which includes flatbed demand, is something that is often based seasonally. No matter the market, shipping rates fluctuate throughout the year and rise as the demand for freight rises.

Flatbed shipping is very closely connected to construction and industrial production, which can be highly dependent on the weather. These industries often slow down in the winter months, so normally, the demand for flatbed shipping will soften at the end of the year.

Smaller to medium-sized companies often slow down during winter and resume activity when warmer weather returns. However, larger companies are affected less by the seasonality and continue to move their commodities regardless of the time of the year.

Because of the seasonal rise and fall, you’ll find volume and rates lowest in the late fall/early winter, with the peak flatbed season being from April to October. This is when the volume of flatbed loads is highest, as are the rates.

FLATBED SHIPPING WITH TRINITY LOGISTICS

Did you know Trinity Logistics is an industry leader in brokering flatbed freight to small and midsize carriers throughout North America?

Our vast network of Independent Freight Agents, combined with our Regional Service Centers deliver the best-in-class flatbed shipping through our expert carrier relationships. We accomplish this by supporting core energy and infrastructure clients with their project-based, unique, and often specialized freight.

Learn more about Trinity's servicesOversized shipping can take a lot of work. Since oversized shipments require extra handling and planning, it’s easy to run into some challenges with them. In this blog, we’ll cover the top five challenges that come with oversized shipping and solutions, so you’ll know how to overcome them.

- Oversized Shipping Challenge 1: Late or Lost Freight

- Oversized Shipping Challenge 2: Meeting Regulations

- Oversized Shipping Challenge 3: Finding the Right Carrier and Equipment

- Oversized Shipping Challenge 4: Safety

- Oversized Shipping Challenge 5: Lack of Communication Among Partners

Oversized Shipping Challenge 1: Late or Lost Freight

The construction and manufacturing industry is one that relies on oversized shipping. This industry has tight schedules to meet to keep their projects moving. This is why professionals, such as construction project managers are responsible for coordinating shipments of equipment or material to and from job sites. When planning, transit and arrival times must be clear and transparent to coordinate labor and proper personnel to be onsite when deliveries arrive.

Because freight must arrive at the right time and place, it’s important not to fall behind or incur additional labor costs. Project managers also often juggle multiple projects, and without the right processes in place, this can become overwhelming. Too often, project managers receive too late notice on delayed freight causing them to have to push back their project schedule. Additionally, at times shipments somehow don’t reach their delivery location or may arrive at the wrong one.

Your Solution: Use Logistics Technology for Visibility

Adopting logistics technology will allow you to easily track all your shipments, no matter how many projects you must manage. There are many logistics technologies options you can choose from for visibility. For example, a Transportation Management System allows you to not only receive tracking notifications, but automatically share them with you external partners. Additionally, you can use outside tracking vendors such as Fourkites or TruckerTools.

While searching for the right technology for your company’s needs can be daunting, consider working with a third-party logistics provider (3PL), like Trinity. It can be less costly to access the technology you need through them, and you’ll have experts on your side to help you.

Oversized Shipping Challenge 2: Meeting Regulations

Drivers hauling any load that exceeds legal limits in weight or size MUS get a permit for the state they are traveling through. If an oversized shipment travels through multiple states, that may mean multiple permits, or else it can result in fines.

Oversized shipments may also require pilot cars and/or police escorts depending on the characteristics of the load and states they travel through. Both permit and escort regulations vary by state, and depending on what is needed, the processing time could take several hours or days to obtain. As a result, planning shipments and making sure guidelines are adhered to can be both frustrating and time-consuming.

Solution: Simplify your workload by outsourcing

Take the weight off your shoulders and let someone else handle the logistics. Outsourcing opens up your schedule so you can focus on what you do best. But, don’t just outsource to anyone. Instead, make sure to choose a logistics provider who understands your freight’s regulations and has experience in doing so.

Oversized Shipping Challenge 3: Finding the Right Carrier and Equipment

Besides meeting legal regulations, oversized freight needs the right equipment and carrier to move it, at the right price for your budget. Sometimes that can be tough to find on your own, especially when capacity is tight.

Solution: Make Use of a 3PL’s Network

What’s another reason to consider outsourcing? Using a 3PL means you’ll have the advantage of their vast carrier network. A 3PL’s sole service is logistics, so they need relationships with carriers to move freight. A quality 3PL will often have an extensive carrier network with a nationwide presence.

Oversized Shipping Challenge 4: Safety

Safety equipment for oversized shipments includes warning signs, flags, and lights to give visibility to other drivers of the oversized load and its edges. Rules and regulations vary again by state. Additionally, there is proper tarping, strapping, and securement of your freight on the truck that is needed. Loose cargo that falls off can cause traffic problems and has the potential to be deadly or hurt someone. Making sure the right materials are used to tie down the freight and make it visible to everyone is important.

Solution: Make Sure Who You Work with Has Experience

You don’t want just anyone moving freight: you want the best. Unfortunately, it can take a lot of your tome to find the best carrier to safely move your shipments. 3PL’s have experience working with carriers and have built relationships over time with ones who provide the best service. We properly vet our carriers during the shipment selection so that we can guarantee your freight will arrive at its destination safely.

Oversized Shipping Challenge 5: Lack of Communication Among Partners

Too often, there will be lack of communication between shipper, receiver, and carriers. It could be a lack of communication about a needed permit and who has to get it, or about the proper equipment that is needed to unload at the receiver. This can lead to frustrated parties and delays in a project.

Solution: Gain Help with Managing your Logistics

A 3PL can be described as the middleman between customer and carrier. We help manage your logistics so jobs run smoothly, and you can focus on other aspects of your business.

At Trinity, we pride ourselves on proper and extensive communication before, during, and after a shipment. If making use of a TMS, you can choose how extensive you want to integrate the technology with your supply chain, allowing both you and your external partners more visibility and coordination with your shipments. This allows everyone the ability to stay connected and up to date.

It seems like many of oversized shipping challenges can be solved by selecting to work with a 3PL. of course, you can choose to try to solve them all on your own manually, but why not save the time and consult an expert, like Trinity, for help? We offer you a range of services and technology to make your workload easier. We’ve been in the business forever 40 years and take pride in what we do – solving complex logistics problems for companies like you.

By: Christine Morris

All industries are currently facing challenges with their logistics and the supply chain. Challenges that include overwhelming demand, tight capacity, rising freight rates, and shortages in materials, products, labor, and drivers. However, industries facing high flatbed demand, like construction and manufacturing, are seeing more difficulty than others.

These industries have been dealing with capacity challenges throughout the pandemic as they have remained in high-demand. As it continues to rise, the needs for their supplies have increased, creating a surge of flatbed demand that’s weighing on the supply chain. Let’s take a deeper look into these challenges and present some considerations for how those in the industry can overcome them.

FLATBED DEMAND VS. VAN AND REEFER

Finding truck capacity of any type is proving to be difficult. Flatbed capacity seems even more challenging because of the continued demand in construction and manufacturing. As a result, flatbed spot rates are reaching new highs and convincing more shippers to look for solutions.

According to DAT, the flatbed load-to-truck ratio is up 169.3 percent year-over-year (YOY) from June 2020 to June 2021. In comparison, reefer’s load-to-truck ratio is up 111.7 percent YOY. Van load-to-truck ratio is up 57.8 percent YOY.

The monthly national average flatbed spot rates have risen for eight consecutive months, reaching $3.15 per mile in June. There’s not looking to be any fall soon, as the industries pushing the flatbed demand are cranking it into the next gear.

FACING DISRUPTION AFTER DISRUPTION

The return to normal may be farther away than you think. With demand, there are still projects waiting in the wings until materials can be properly sourced and shipped. And demand already has construction projects beyond their pre-pandemic heights. Just look at the Associated Builders and Contractors’ Confidence Index, which is now positive for sales, profit, and staffing level expectations for the next six months.

Covid-19 Hit First..

When the pandemic hit, people had found they had nothing to do while staying home. And so, we saw a rapid uptick in those wanting to buy a new house or remodel. Demand quickly exceeded supply. Supply shortages and delays have put pressure on contractors as the demand rose despite a lack of supply.

..Then There was the Texas Freeze..

In February and March 2021, Texas saw their lowest temperatures in years and were not prepared for the intense weather conditions that they experienced. Many manufacturing plants in the area had to shut down, which created more disruption in the supply chain.

..Then the Suez Canal Blockage..

The ship that blocked the Suez Canal for several days caused severe delays in the imports of many products needed. This created many shipping bottlenecks that we’re still experiencing the aftermath of today.

..Now the Wildfires.

Currently, the raging wildfires on the west coast are causing further disruption and delays to an already stressed supply chain.

Issues such as these are causing supply chain disruption after disruption, resulting in increased costs and delays. Many companies rely on materials that come from delayed or now-unavailable, global manufacturers. This has shifted companies to search for regionally based suppliers, creating higher demand on smaller supply chains. After over a year of continuous supply chain disruptions, there’s been an industry-wide realization that building resilience into supply chains is vital.

RISING FUEL PRICES

One of the areas affecting logistics cost are the continuing rise in the costs of fuel. The latest Energy Information Administration data shows the national average diesel price is at $3.34 per gallon, a $.05 increase from one month ago. Regional diesel prices range from $3.08 in the gulf coast states to $3.48 in the central Atlantic region. California diesel prices are averaging $4.19 per gallon.

SHORTAGES AND DELAYS

Lumber shortages continue to be a significant problem nationwide. Both steel and electrical supplies have faced steep price increases in the past year. According to the U.S. Census Bureau’s Small Business Pulse Survey, 59.7 percent of respondents reported domestic supplier delays which is a huge jump over the national average of 36.3 percent. These aren’t domestic only issues as 19.1 percent of respondents are also dealing with foreign supplier delays.

MATERIALS THAT HAVE BEEN EXPERIENCING SHORTAGES

- Timber

- Steel

- Roof tiles

- Cement

- Electrical components

- Paints and sealants

- Plaster and plasterboard

- Concrete

- PIR insulation

- Bricks and blocks

- Aggregates

- PE and PP plastics

- Screws

- Plumbing items

THE RAW MATERIAL SHORTAGE

There is currently a global shortage of raw materials. This comes from factory slowdowns and, in some instances, factory closures due to many reasons. The shortage of raw materials continues to put a strain on the production of products, like insulation, paints and adhesives, and packaging.

THE LABOR & DRIVER SHORTAGE

Another cause of rising costs and delays is the shortage of labor and drivers. Labor rates have skyrocketed in recent months. This is due to the high labor demand and trades raising their rates because of the overwhelming amount of work. The big challenge these industries face is finding qualified labor to perform work, whether that be driving a truck to deliver materials and products, painting a house, or installing plumbing. In logistics, driving a flatbed truck, especially one hauling an oversized load, requires a different skill set than your typical van trailer trucking.

HIGH PRICES KEEP HEADING HIGHER

The Associated General Contractors of America (AGC) released a survey recently showing 93 percent of more than 1,400 respondents reported higher costs for materials, parts, and supplies. Construction material prices have increased so much in 2021 that the AGC issued a rare Construction Inflation Alert. This hasn’t taken since place 2008, citing a 12.8 percent jump of input costs for projects since the pandemic began. While that number is notable, some materials have risen even more. Lumber and plywood jumped 62 percent and steel recorded a 20 percent rise since April 2020. Diesel fuel, the lifeblood of the heavy equipment and transportation haulers needed to build major projects, has surged 114 percent. Even when materials are ready to be shipped, the transportation market is trying to play catch up. As mentioned earlier, there is currently more demand than there are trucks available.

Rising costs and supply chain disruptions have pushed more hardships on the construction and manufacturing industries, slowing down their projects and business progress. Data found that more than three-fourths of construction firms have indicated projects are being postponed or canceled due to unavailable materials or cost overruns.

POSSIBLE SOLUTIONS

Experts are estimating that the high demand in these industries and flatbed demand may continue through 2022. Not to mention, who knows what other possible disruptions we may see soon. Hurricane season is upon us and could cause some more delays.

It’s never too late to find ways to improve your supply chain and keep costs budgeted. Here are some suggested solutions to facing this difficult time we’re in.

LOOK FOR ALTERNATIVE ITEMS

It might be worth checking into other materials to offer your customers. Many other companies are doing what they can to keep their projects moving forward and communicating this with their customers. For example, with rising lumber costs, you may find redwood or cedar to be more affordable alternatives. They may also be much easier to get your hands on.

INTEGRATE TECHNOLOGY

Integrating technology has become a necessity for all stakeholders to maintain real-time communication and visibility. Gain total visibility and trust from your stakeholders with logistics technology like a transportation management system (TMS). A TMS can help you with routing decisions by matching your freight with the best carriers, lanes, rates, and transit service.

Having a best-in-class TMS also provides you with data-driven insight to better manage disruptions and budget your logistics spend. By using data analytics, you’ll be able to recognize which carriers are most likely to have capacity and have a full view of your transportation management and what’s happening across all markets.

CONSIDER NEW OPTIONS

When possible, see if you can use van options for your transportation, considering the load-to-truck ratio shows less demand and lower freight rates. You may also be able to consider other modes, if possible, but any oversized freight must be hauledwith a flatbed trailer.

PLAN IN ADVANCE

Many other companies are stocking up on available supplies or finding other ways to look far ahead. Consider doing the same. Stock up on what materials you use most often for your projects. Do keep in mind that the more you stock up on, reduces the overall supply, increases demand, and thus pushes prices higher. Don’t go overboard and hoard ALL of it but do try to keep some stock in supply. Try planning your projects far enough out, correlating with the longer lead times we’re experiencing. If the material you need says it will take nine to ten months, then plan your project around that time frame.

BUILD A STRONG NETWORK OF CARRIER RELATIONSHIPS

Due to the over-demand of freight, load boards don’t move shipments the way they once did. Strong relationships will get you the coverage you need, better pricing options, and often better service. If building a large enough network for you seems daunting, you can always partner with a third-party logistics company (3PL), whose main role is their relationships among shippers and carriers. Here at Trinity Logistics, we have over 70,000 qualified carrier relationships to help haul your freight.

BUILD A RESILIENT SUPPLY CHAIN

At a time when your costs are a critical issue, reimagining your supply chain could be a way to build resilience and reduce costly disruptions before they happen. Now is the perfect time for companies to build resilience into their operations to be better prepared for future disruption we may see.

Opportunities to do so range from reevaluating your business models and building efficient industrial supply chains, to building new and more regional manufacturing and distribution facilities to help with the vulnerabilities the pandemic brought to light. You could put in place more flexible sourcing and distribution strategies, including shifting your suppliers closer to home.

WORK WITH A QUALITY 3PL, LIKE TRINITY

We do more than arrange your freight. Consider us your logistics consultants. As logistics experts, we keep a close eye on the market, keeping you educated so we can help you plan and forecast.

No matter the market, you can use your Trinity relationship and discuss your current and upcoming projects, even if they are in the planning stages. This helps us give you things to look out for to keep your transportation aspect of business more stable and reliable. When markets fluctuate, having a solid relationship with experts such as Trinity will prove to be your largest asset.

Should issues arise, we at Trinity, work until they are resolved through and communicated. In the logistics industry, things will happen, and bad news doesn’t get better with time. We stay upfront with any challenges, and we bring solutions. When given the chance to prove our communication and service, we make sure to set the bar high.

If you’re ready for a reliable provider to help you with your shipping needs and logistics management through People-Centric Freight Solutions®, then request your first quote to get started.

Author: Paul Nelson

The manufacturing industry faces several challenges with their logistics. Laws and regulations in the manufacturing industry are always fluctuating. Some companies’ inventory management is not as advanced as it needs to be. An experienced third-party logistics company (3PL) that has strengths in logistics for the manufacturing industry can help you overcome these obstacles.

Leave Logistics to the Experts

Partnering with a 3PL to take care of your supply chain needs can lift weight off your shoulders. There are many moving parts in the manufacturing supply chain and each part is very specific. Choosing to outsource tasks will benefit your company in the long run. With the help of a 3PL, you’ll be able to focus more on getting your product on shelves rather than the logistic components.