With cold chain logistics, every product that you deal with has very specific temperature requirements that you need to adhere to. These products are ending up on tables across the entire country, so you want to make your product arrives precisely the way it needs to be so it’s safe for human consumption. Because of this, cold chain logistics can be challenging to manage, and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. It would undoubtedly be helpful to find one provider that could offer you end-to-end cold chain management, from production to delivery. And that’s what we’re here to talk about today. Burris Logistics and Trinity Logistics working together could be the solutions you’ve been looking for to simplify your cold chain management. Keep reading to find out how we work better together to serve your complete cold chain.

BURRIS LOGISTICS CAPABILITIES

Let’s start with Burris Logistics. What do they offer that can enable cold chain shippers and their businesses to thrive in the face of its complexities?

Quick Background

Burris Logistics has been around for 96 years. The company started as a produce hauler from southern Delmarva to Philadelphia. They quickly grew and expanded into the frozen food business and found their purpose as a driven food logistics provider. Today, they own 14 cold storage sites up and down the east coast and out into Midwest. Burris Logistics currently has a family of brands including Burris PRW Plus, Honor Foods, and Trinity Logistics.

Burris Logistics offers you logistics technology solutions that never sleep. With a Technology Team of over 100 Team Members, they work around the clock to provide you with technology resources designed to meet your specific needs.

From a Burris asset standpoint, they’re able to track all their trailers with ELD and reefer tracking, with the ability to ping the tractor and trailers to see where each of their assets are in real time. In addition, they have access to technology that can start and stop the units, reset them, or check temps on them, no matter the distance. With the complexities of cold chain transit and the current driver shortage, Burris works hard to put in place any technology that can make a driver’s job easier. They want to cut any obstacles drivers may face on the road while having any data be transparent to help both them and ultimately, any customers.

Burris also has technology for their cold storage warehouses. They focus on providing their customers with freshness, clarity, and visibility. They offer real-time monitoring and any differentiation from setpoints gets recorded. They make sure to get real-time data to those who need it should meaningful decisions need action, and have secondary and tertiary backups available.

Some of their other logistics technology offered are:

· Warehouse management system software

· Enterprise resource management

· Produce inspection tool

· External integrations

· Supply chain portal

· Demand planning

· Order status

· Delivery status

Burris Logistics works with you to create the best possible warehousing and distribution solutions. They’ll support you with a network of strategically located warehouses, 96 years of expertise, and a solution customized for your unique needs.

In a reflection of national trends, the newest and fastest-growing business line within Burris Logistics is their direct-to-consumer to support those in the cold chain e-commerce space. Through current resources and expertise in temperature-controlled logistics, Burris can deliver a premier frozen fulfillment network with cutting-edge technology, thought leadership, and warehouses across the country. Burris’s knowledge of shipping supplies, coolant technology, and two-day parcel shipping capability ensures quality is delivered with every package.

Facility Design is the process of considering new construction via greenfield facility sites or the re-purposing of an existing operation. Many companies are facing changing business needs, including the need for multi-channel execution. This makes the ability to scale up and scale down with various capabilities an essential part of planning. With partners who increase their dependency on Burris Logistics, they’ve been able to scale their operations to accommodate their programs with new locations, modifications to existing assets, and technology to keep the supply chain efficient.

Your customers desire the right products, in place, at the right time. Honor Foods, a Burris Logistics company understands how important it is to have on-menu and on-shelf products available while also minimizing food waste. They can help you plan inbound and outbound freight, using logistics technology and their warehouses to maintain food quality and safety.

With one of their other brands, Honor Foods, Burris offers Private Label In-house brands that have developed into trusted names amongst food service operators. These products undergo scrutinous selection and quality assurance knowing that our restaurant partners only accept the best. Your customers want what is trending, and Burris can help you meet this demand. Their brands come sourced from trusted shippers and can be a noticeable cost saving for you.

Burris Logistics understands that products need different environments, which is why their facilities can provide different temperatures and humidity, depending on your product. Newer warehouses are purposefully being built with ambient/dry storage space to accommodate increased partner needs. Additionally, their warehouses and distribution centers are in strategic locations near major transportation hubs and ports, making it easy to get your freight on the move quickly.

TRINITY LOGISTICS CAPABILITIES

Quick Background

Trinity Logistics has been around for over 40 years. The company was started by the Banning family in Cambridge, Maryland. Throughout the years, the company grew and expanded as a non-asset-based third-party logistics company (3PL) and was acquired by Burris in 2019. The two companies saw similarities in company culture and future goals, deciding to unite for greater opportunities and offer more supply chain solutions for our customers.

Burris + Trinity = Better TogetherURRIS

What’s great for Trinity being part of the Burris Logistics family of brands is being able to offer more help to Burris customers. Trinity’s support helps Burris better assist some of the existing freight business they have for customers either coming back into their buildings or going to other places.

The addition of Trinity also offers Burris customers a wider variety of options in modes and technology, or even help outside of the cold chain. Trinity is very experienced in heavy haul moves or more complicated hazardous moves for the chemical industry. So, no matter the size of your company or freight, we have a solution for you. But, we’re here to talk about the cold chain, so let’s focus on refrigerated and frozen freight.

While it’s not always hard to find a refrigerated carrier, you do want to be selective. There are a lot of carriers out there, but Trinity has a robust vetting process in place. We make sure carriers hauling your freight have the right amount of insurance, requirements, and experience. In addition, we make sure these drivers are representing Burris and Trinity the way we need to and that our customers are getting their products delivered safely.

You might ask, how do we guarantee safety with our carrier network? Well, these carriers mean as much to us as our shipper customers do, so we build just as strong carrier relationships. We offer our carriers many different kinds of technologies for location tracking, temperature tracking, and so on. We make sure to continue to evolve our technology solutions to keep the shipping process easy and safe for both carriers and customers. Additionally, we have our communication. Our communication is one of our strongest assets to ensure both parties have their needs and solutions met. Our bottom line is bringing value and if we can do that, we’ll be successful.

We offer and use several different technologies like Macropoint or Fourkites, so we can ping shipments and know exactly where they are and what the temperature of the product is, giving our customers instant access to look at their freight. That’s just one piece of the technology puzzle.

Even with the technology available, we never lose contact with our customers. We strive to stay very People-Centric. Our technology only helps make it easier for our customers to view information, especially with our Customer Portal, giving them the ability to trace loads without having to reach out. It gives them access to see updates at any time of day and offers backend access to their invoices to answer billing questions, make payments online, or provide them with a breakdown of what each load costs, lumper fees, accessorials, or pallet exchanges. Our Customer Portal allows you to manage that piece of business on your own time and at your own speed. We’ll always be available, but the Portal and any of our technologies are there to bring you even more value and efficiency.

Current logistics technology available:

· Carrier Portal

· My Carrier Packet

· TriumphPay

· FourKites

· Trucker Tools

· MacroPoint

· Customer Portal

· Customized Transportation Management Solutions

· Banyan LTL

· DAT Book Now

· Trucker Tools Book It Now

WAREHOUSING

We know that one size does not fit all when it comes to warehousing. That’s why we have warehouse providers with locations across the nation to allow you to scale your business at your own pace, plus our cold storage solutions with Burris Logistics. Our growing network supports reliable service and premier dry, refrigerated, or frozen solutions so you can focus on what you do best.

TRUCKLOAD

Our truckload service provides you with the means to get your freight moving quickly. Truckload is faster than traditional LTL or intermodal shipments which means your shipments can arrive on time and on schedule.

LESS-THAN-TRUCKLOAD (LTL)

Our LTL service provides you with the means to get your freight hauled through a range of options. By leveraging our volume and extensive network of LTL carriers, we can provide you with lower rates for LTL shipments consisting of 1-10 pallets of either dry or temperature-controlled products.

INTERMODAL

You can add value to your supply chain by using this cost and environmentally-friendly shipping option. By shipping intermodal, you’ll reduce your carbon footprint and have reliable and consistent capacity when over-the-road capacity can be tight.

EXPEDITED

Sometimes your freight is time-sensitive or needs less handling. When this happens, we can arrange over-the-road or air-expedited shipping. We’ll make sure your freight arrives on time and without stopping at terminals in between.

DRAYAGE

Your freight can be delivered from the port or rail right to your door, or from your door to the port or rail. Either way, we’ll save you money in the process. From servicing imports and exports, returning empty or full containers, helping you avoid unnecessary fees, long drayage options, or more, our Team is ready to help.

INTERNATIONAL

Arranging international shipments can be tricky and requires a lot of communication. If you are looking for help with arranging your Full Container Load, Less Than Container Load, door-to-door, or port-to-port services, we can help. We’ll be your intermediary with freight forwarders to arrange your air and ocean freight international shipments.

MANAGED SERVICES

In this service, we combine our experienced account management and best-in-class transportation management technology to deliver you a customized solution that helps your company achieve its unique supply chain goals.

HOW WE CAN SERVE YOUR COLD CHAIN BETTER TOGETHER

Experience in Cold Chain

For many reasons, Burris Logistics and Trinity work well together for cold chain shippers. First off is our combined years of experience. There are certain things in cold chain you can only learn from the experience of working with temperature-controlled shipments. For example, things like picking and loading fresh produce, understanding what those temperatures are and what they need to be for storage and transit, and keeping track of those temperatures. Or understanding how to move ice cream from the West Coast and knowing that you can’t go over the mountains; that you must travel around them so as not to cause shrinkage. By having years of experience and understanding of those complex situations and small details that make or break a cold chain shipment, you can trust your temperature-controlled freight is handled safely and correctly with Burris and Trinity.

Technology

Between both Burris and Trinity, we have incredible logistics technology available, but what differentiates us from others is that we keep in mind that logistics is still a “people” business. Technology will always be a tool for our Teams to use and bring logistics solutions to other people who need them. Therefore, we try to stay away from technology just for technology’s sake and make sure what we use and offer is always a valuable solution.

Communication

Because of our years of experience, we are well-versed and experienced in many different situations. We know when and how to pivot quickly and keep business moving forward. When issues arise, we work until they are resolved and keep open communication every step of the way. Having a solid relationship with experts like Burris and Trinity will prove to be your largest asset no matter what supply chain bottlenecks you may face

Flexible, Customized Solutions

Because our two businesses offer many options while keeping business People-Centric, it means you can find a solution that’s customized for your growing business and needs and your solution can be flexible. We know the cold chain and solutions aren’t static, they are ever-changing, so you need a provider that can keep up. By working with Burris and Trinity, you’ll never have to worry about changing up your logistics plan as we’re readily equipped to accommodate any changes you may need. In addition, we can help you stay flexible as one sole provider instead of working with several.

Visibility and End-to-End Cold Chain Management

As the cold chain sector continues to grow, there’s been a growing demand for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the logistics of their temperature-controlled freight. Working with Burris and Trinity can not only give you a wide range of technology to gain visibility and provide you with all the logistics services you may need, thus making your cold chain efficient and transparent. We’ll provide you with dedicated, knowledgeable experts, increased productivity and workflows, and reduced complexity by working with Burris Logistics and their family of brands instead of several different providers.

HAVE YOUR COLD CHAIN LOGISTICS TAKEN CARE OF, END-TO-END

Between Trinity and Burris, we have a substantial Team with a lot of experience in cold chain and knowledge about its potential pitfalls. As a result, we’ve created processes and different services so that we get it right the first time, every time we handle a cold chain shipment.

You can find value in our combined companies’ sizes and services offered. Cold chain logistics can be complicated and trying to do it all alone can be frustrating. That’s why we’re here to help you simplify it. You can count on Burris Logistics and Trinity to serve and support your cold chain all the way from production to delivery, and every step between.

FIND YOUR END-TO-END SOLUTION WITH BURRIS LOGISTICS GET A SHIPPING QUOTE FROM TRINITY LOGISTICSIt’s produce season. That time of the year when produce shipments are at their peak and so are produce shipment rejections. According to DAT, up to 12 percent of shipments are rejected or delayed. Produce shipments are most often rejected because of the complexities of fresh food logistics. Because of their perishability, they are more likely to experience damage in transit due to improper handling, temperature variances, or delays.

A produce shipment rejection can cause lost time, added fuel and shipping costs, wasted product, and sometimes even a strained relationship with your customer. In addition, these rejections can cause a domino effect of added issues, costs, paperwork, and make everyone’s day longer than it needs to be. Yet, with attention to detail, planning, and effective communication, you can prevent produce shipment rejections and manage your costs. Here’s some advice on preventing shipment refusal during produce season.

| ARTICLE CONTENTS |

| REASONS TO REJECT PRODUCE |

| WHAT TO DO WHEN PRODUCE IS REFUSED |

| PRODUCE SHIPMENT REJECTION PREVENTION |

| HAVING HELP WITH PRODUCE SEASON |

REASONS TO REJECT PRODUCE

With fresh produce being on average, 90 percent water, it’s a volatile product to ship. It can develop issues at any stage, during growth, harvest, storage, packing, or shipping. This makes the logistics of shipping produce that much more complicated. As a result, there can be many more reasons for produce shipment rejections to happen. So, what are some reasons for a produce shipment rejection?

Paperwork Errors/Wrong Product

The Bill of Lading (BOL) must match the shipment delivered. When the receiver checks the BOL to verify the purchase order (PO) number, skid, case count, and weight of the freight delivered, and it doesn’t line up, then the shipment may be rejected. This could happen for several reasons. For example, the product could be what they asked for but the wrong amount, or the product could be completely different. However, any discrepancy between what they ordered and what arrived will mean a rejected shipment.

*Important to note: A produce shipment should not be rejected if there is less than 50 percent of the product short or damaged.*

Pallet Configuration

Some customers require that the product arrives according to their specific guidelines for packaging. If their requested guidelines are not followed, or anything shifted, fell, or ripped while in transit, then they may refuse the shipment.

Improper Temperature Range

Maintaining integrity and freshness is serious when it comes to a perishable product like produce. If your produce shipment falls out of its needed temperature range, even by one degree, the receiver may reject your shipment. Unlike other types of freight, the chance for spoilage with produce is too high, so a receiver won’t often take on the liability with any temperature variances.

Delivered Late

Often, retail and grocery distributing centers operate on tight schedules, so a delay could impact their other appointments. Unfortunately, this means they rarely make exceptions when it comes to late shipments and your produce will be rejected.

Equipment Issues

The trailer could have been unable to keep the temperature in the range needed for your produce shipment or perhaps the trailer was not washed thoroughly before loading. Maybe the carrier showed up with a van and you needed a refrigerated trailer. There are several issues in which the trailer your shipment is delivered in can have the receiver refusing your product.

Reasonable Time to Reject

One important thing to know about produce shipment rejections is that there is a reasonable time for the receiver to reject the shipment. When shipping by truck, the receiver must not exceed eight hours to inspect and reject. When shipping by rail, the receiver must not exceed 24 hours to inspect and reject.

AS A SHIPPER, WHAT TO DO WHEN PRODUCE IS REFUSED

Many issues associated with rejected produce shipments can often be resolved quickly with extra communication and planning.

You’ll first need to figure out why the receiver rejected your produce shipment, so start with asking your receiver that. Ask for pictures showing any damage and a copy of the BOL. Next, ask for the report by the USDA inspector or another qualified individual, as it’s required for the receiver to have the shipment inspected, note any issues, and detail what the cause of damage was. Additionally, ask your carrier for a reefer unit download or a temperature recorder download so you can see if there were any temperature fluctuations during transit.

If you’re considering filing a cargo claim, you must know that cargo claims for produce will only be paid for proven physical damage.

Now, if a produce shipment is rejected and not unloaded, there are a couple of options for you to try to recoup the loss. You can reroute the shipment to a different facility that will accept it, donate the shipment, or have the carrier dispose of it. Regardless of which option you choose, you are responsible for handling where the shipment will go next.

What are any secondary markets the produce can go to if messed up? What’s the disposition? You’ll be the best resource for the area’s market. Be familiar with your shipping lanes and the secondary markets within your location to best salvage the produce if refused.

Secondary Facility

As long as your produce is still safe for consumption and solely rejected for the way it looks, you might be able to sell the shipment to a secondary facility. For example, a sauce maker or a french fry company might be willing to buy a shipment of tomatoes or potatoes that are still edible but visually unappealing.

Donation

It can be possible to reuse a rejected produce shipment through local donation, though there are still high standards for products if donated. Any food and beverage products donated must be safe enough to consume. Donations can be optimal as your produce can still be used, and you can receive tax credits for your donation.

Disposal

If your produce shipment is rejected due to a temperature violation or clear spoilage during transit, disposal may be your solution. When your produce is determined to be unsalvageable, it may be best to dispose of it. Although the other two options are better for the environment and your bottom line, it’s sometimes a necessary evil to dispose of the product. While recycling and reusing are ideal, they may not be workable due to compliance and safety standards. One of the benefits of disposal is that scheduling disposals are often quicker than scheduling to another facility.

Maintaining a Good Customer Relationship

Shipment rejections can stress even the best relationships. It’s best to keep in mind that you are in it for the long haul and produce shipment rejections that can happen even to the best of shippers due to its complexity.

It’s best to acknowledge the rejection, replace the product as soon as possible, and find the source of the issue to help reduce the chance of another produce rejection happening anytime soon. Take ownership of the problem and control of your shipment so you can manage your money from the salvage. Taking control over the disposition will help you maximize your return, reduce claimed damages, and reduce your risk of customer relationship loss.

While these are all great solutions for handling produce shipment rejections, it’s ideal to prevent them in the first place. For companies looking to focus on their bottom line, it’s important to know all necessary prevention measures for produce shipment rejections and plan for when they do happen.

PRODUCE SHIPMENT REJECTION PREVENTION

Paperwork and Communication

The first step to preventing produce shipment rejections is to have your paperwork and communication in order. Your agreement must be clear on the condition of the produce your buyer will receive. Being able to present your buyer with evidence that your produce is safe and of the quality you stated it’s in before transit will prevent most cases of rejection.

Communication with your buyer and your logistics team on how your produce is being handled before loading, during loading, and during transit must be done effectively and properly. This is especially crucial because of the Food Safety Modernization Act (FSMA). Be sure to provide photos, diagrams, or any other examples of proper pallet configuration to your warehouse and trucking partners. This kind of communication will help them pack and load your freight correctly from the start.

Carrier Selection

Produce shipments, especially during produce season, often pay a lot. This means you’ll have a lot of carriers bidding to haul for you. Therefore, quality carrier selection and additional insurance requirements, like reefer breakdown, are crucial aspects to prevent rejected produce shipments.

Make sure you confirm with your motor carrier that they are both authorized and experienced to haul your produce.

Additionally, make sure they understand all your shipments requirements, including FSMA. For example, do they need washout receipts? Do they have a good quality truck, updated trailer, or a quality reefer? Do they have or need temperature-monitoring devices or other technology to ensure the temperature is controlled and the cold chain uninterrupted? Can they pull a reefer download if required?

By finding a quality carrier and building a strong relationship with them, you’ll gain a dependable carrier to use regularly. This can help you reduce any transportation-related issues that could later result in a shipment rejection.

Loading

Don’t Overstack

When it comes to produce season, the number one cause of claims that we see comes from over-stacking your boxes or bins of produce when loading them onto the trailer. An example of this would be triple or quadruple stacking your boxes when they need to be double-stacked. While this depends on each shipping location, not all may be aware that each box has a maximum capacity it can withstand and not damage your produce. You need to know the weight-bearing amount of your boxes so you can place no more than that. When you over-stack, it’s will increase the risk of your produce getting squished and damaged. Certain produce can be very fragile, like berries, tomatoes, asparagus, or bananas. They tend to bruise easily, so single-stacking boxes are even more ideal for them.

No Hot Loads

Industry experts say that as much as 32 percent of all cargo is loaded at the wrong temperature.

This is often due to poor loading practices, like loading from a hot field. When it comes to produce, loading from a hot field is a HUGE NO. This causes the driver to start traveling with your produce at the wrong temperature, which puts compliance and financial pressure on carriers, as the load is at a high risk of spoiling. Your produce should be safely brought down to its required transit temperature before loading to prevent any spoilage.

Have the Proper Equipment

While this may seem silly, it still needs to be said: If a motor carrier shows up with a dry van and your produce requires a refrigerated trailer, DO NOT LOAD. While losing some time or causing a bit of a delay is not ideal, it’s better to have the proper trailer needed to keep your risk of shipment rejection from spoilage or damage low. Additionally, make sure your carrier’s refrigerated temperature monitoring system has the proper temperature, date, and time set. If there is a rejection due to temperature variance and the date and time are wrong, you’ll take the blame due to current regulations.

When it comes to your motor carrier and loading, it’s also ideal to allow them to inspect and pulp your product before loading. They have the right to do so, and the opportunity can give your carrier the confidence to haul your product safely. It also helps build a strong and loyal relationship, while helping you gain more insight that your product is okay before it’s in transit.

Keep Clean of Debris

Another way to help prevent produce rejections is to have a shipping platform that can be cleaned without leaving any splinters or debris in vehicles. Food-grade plastic pallets are ideal for solving many hygiene issues while helping reduce product damage during transport. Unlike wooden pallets, they don’t splinter or leave behind debris, and their nonabsorbent surface can be easily cleaned and dried.

Transit and Delivery

As mentioned during loading, make sure you have a way to track temperatures throughout the shipment and be able to receive notifications in real time. By getting early warning signs of issues, temperature variations can be quickly detected and dealt with right away instead of learning about them later at delivery.

Additionally, make sure you have a qualified inspector on-site at delivery. This will help should the receiver decide to reject your produce shipment to determine if your product is salvageable for you to recoup costs.

Before transit, it’s best that you set up the potential for rework facilities to accept your produce should the receiver refuse it. Talk to nearby receiving facilities to establish accounts, processes, and pricing ahead of time. This way, if there has been some visual damage or slight shifting, it can quickly reroute to the other location and be reworked, being proactive rather than reactive. This is especially important when it comes to produce since time is of the essence.

HAVING HELP

Produce shipment rejections can be complex and confusing at times. This is where working with a third-party logistics company (3PL), like Trinity, can come in handy. We have Teams to help you with the prevention of rejections as well as when one does happen.

Carrier Compliance

Our Carrier Compliance Team is here to vet our carrier network and make sure they have what you need to get your shipment delivered safely. Not only do we have a rigorous vetting process, but depending on your shipment requirements, we’ll make checks for extra insurance needs like reefer breakdown and make sure they are FSMA compliant.

Claims

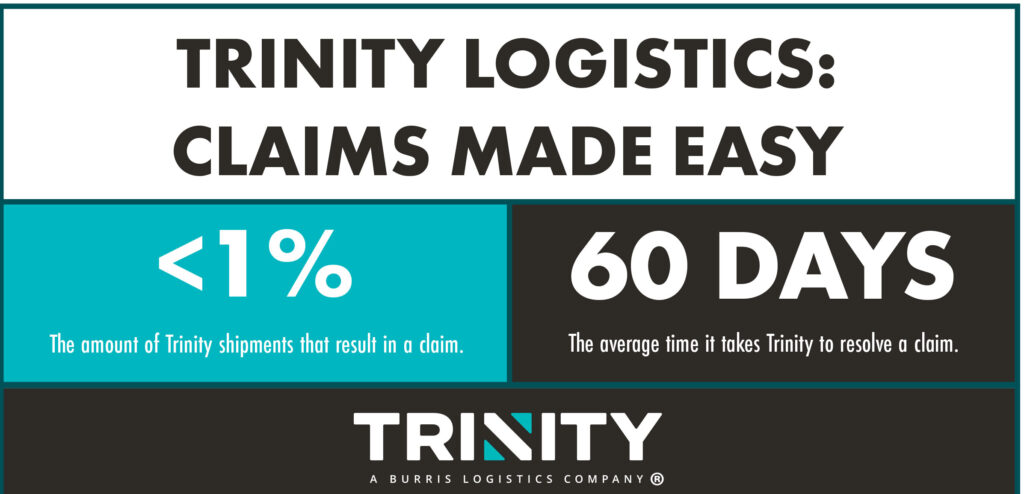

No matter how prepared one can be, unexpected things can still happen. Shipments may get refused and so that’s why we have a Claims Team here ready to assist you. It can be a real lifesaver to have a Team of certified professionals to help take the stress out of the claims process. Should it be needed, our Claims Team will help you start the process, be there to track progress, and assist until a resolution is met between all involved parties.

DON’T GO THROUGH PRODUCE SEASON ALONE

With proper prevention, compliance, and planning, produce shipment rejections can become less of a thorn in your side during produce season. Even still, they can and will happen at times. Make sure you’re ready and have the support you need by working with an experienced provider such as Trinity.

You’ll have the advantage of working with and trusting our risk departments, who work hard to help mitigate any risk to your shipments. In addition, you can trust that each of our carrier relationships is properly vetted for things like reefer breakdown coverage. Should you need it, you’ll have a whole Claims Team ready to help you sort through any unexpected shipment issues.

Gain the support you need to navigate the complexity of produce season with less stress.

LEARN HOW WE SUPPORT PRODUCE SHIPPERS HELP ME WITH PRODUCE SHIPMENTSHow does the cold chain process differ from your typical supply chain? The cold chain is a variation of your standard supply chain. It involves the movement of refrigerated or frozen products from temperatures of two degrees Celsius (35 degrees Fahrenheit) all the way down to negative 70 degrees Celsius (158 degrees Fahrenheit). The cold chain involves industries such as food and beverage, pharmaceuticals, and chemicals.

WHAT IS THE COLD CHAIN PROCESS?

The cold chain process is a logistics management process for perishable products that need refrigerated temperatures to maintain quality and safety from end to end. It involves performing a chain of tasks to prepare, store, and transport products in the cold supply chain.

Logistical planning and management protect the integrity of cold chain shipments. This involves using proper packaging, proper transportation equipment, carefully chosen transportation routes, perfect timing, and visibility throughout to ensure that what’s expected is what happens. The cold chain process is best done by using technology and data at every point of the process.

WHY IS THE COLD CHAIN IMPORTANT?

The cold chain ensures perishable products are safe, of high quality, or potency at the point of consumption or use. Failure to keep those products at correct temperatures results in degradation, discoloring, bruising, or microbial growth. When you have quality cold chain products, you’ll have satisfied customers, meaning greater demand, and the protection of public health.

Additionally, cold chain providers contribute a great deal to the economy and workforce. According to GCCA, approximately $6.1 billion is generated by the refrigerated warehousing industry annually. Not to mention, the North American refrigerated warehousing industry employs more than 62,774 people annually on a full-time basis, with 92 percent being permanent employees versus contract or temporary.

WHAT ARE THE MAIN ELEMENTS IN THE COLD CHAIN?

Storage

The cold chain starts with the storage of the product at a refrigerated facility. If manufacturers of cold chain products don’t have storage equipment needed to keep their products regulated, they’ll have to outsource their cold chain operations to a partner who can provide the proper equipment.

Common cold storage equipment and facilities include refrigerated containers, cold rooms, chillers, cold boxes, blast freezers, and vaccine carriers.

Packaging

Temperature-controlled products need correct packaging to maintain their quality. Proper packaging helps reduce the risk of product contamination and ensures energy-efficient storage along the cold chain.

The most common refrigerants used in packaging are dry ice, gel packs, gel bricks, phase change material (PCM), and EPS panels (expanded polystyrene or Styrofoam).

Monitoring

Tracking certain information for specific cold chain products is a necessity. This includes temperatures and other environmental parameters, like humidity levels. Without monitoring, suboptimal conditions can happen and damage the quality of the product.

Cold chain monitoring often refers to the use of the Internet of Things (IoT) or other sensor software. These monitoring systems can detect temperature problems, keep track of all cold chain products on one platform, and improve predictive maintenance through the integration of sensor data with supply chain management software, like a transportation management system (TMS).

Delivery

Cold chain management also involves the delivery of shipments. Delivery is based upon the end-user consumers’ preferred methods for receiving cold deliveries.

WHY IS AN EFFICIENT COLD CHAIN PROCESS IMPORTANT?

Unlike shipping non-perishable products such as furniture, interruptions in the cold chain can result in damage to the quality of the product, making it unusable. An efficient cold chain process uses monitoring and reduces the amount of handling from end to end.

The cold chain industry has standardized temperature zones classified to maintain the quality of products. These classifications are:

Banana

Bananas and other tropical fruits like oranges, pineapples, or even potatoes have a temperature range of 12 degrees to 14 degrees Celsius (53 to 57 degrees Fahrenheit). This helps control ripening during transport.

Pharmaceutical

Most pharmaceutical products need temperatures between two and eight degrees Celsius (35 to 46 degrees Fahrenheit).

Chill

This classification is between two and four degrees Celsius (35 to 39 degrees Fahrenheit) for many other fruits, vegetables, and fresh meat.

Frozen

This temperature range is between minus 10 to minus 20 degrees Celsius (50 to 68 degrees Fahrenheit) for frozen meat, cakes, and bread.

Deep Frozen

Seafood, ice cream, and other frozen foods need colder temperatures at minus 25 to minus 30 degrees Celsius (minus 77 to minus 86 degrees Fahrenheit).

Ultra-Low

This is a new and growing temperature range often for pharmaceutical products that need temperatures reaching minus 70 degrees Celsius (minus 158 degrees Fahrenheit), like certain vaccines.

WHAT ARE SOME INDUSTRIES THAT USE COLD CHAIN?

Food and Beverage

Controlled temperatures are needed for transporting food and beverage products such as milk, produce, or meat. Interruptions in the cold chain can lead to spoilage or bacteria or mold growth. As mentioned above, many fruits like bananas ripen during their shipment.

Pharmaceutical

Many pharmaceutical products need temperature control. This includes products like vaccines, medication, or biologicals, like blood or plasma. Spoilage of these products can mean a loss in efficacy and can become a public health hazard if not caught.

Chemical

Temperature control is critical when it comes to some hazardous chemicals. Specifically, ones that can be susceptible to reactions due to heat release. If heat escapes from a chemical good that requires it to remain at a certain temperature, it can cause a spark, flame, or explosion to occur, not only damaging the product but potentially harming others.

Oil and Gas

This sector uses explosion-proof refrigerated containers on oil rigs, oil tankers, and offshore locations.

Military

The U.S. military must control the temperature of its medical supplies, which often travel long, hard-to-reach areas. Because of this, the cold chain process can become more complicated when handling products for the military.

WORK WITH AN EXPERIENCED PROVIDER

Not all temperature-controlled products are the same. Each product is unique and requires specialized solutions throughout the cold chain. Many cold chain manufacturers are turning to third-party logistics companies (3PLs) to handle their complex challenges in the cold chain process. For your cold chain to be successful, you need to be sure to work with a provider who understands your industry, regulations, and product requirements.

Luckily, you don’t have to look very far to find one. Here at Trinity, we have more than 40 years of experience in specialized industries such as cold chain.

Contact us today to find your customized logistics solution for your cold chain process.

REQUEST A QUOTEAuthor: Christine Morris

Interruptions to the cold chain create problems such as spoilage, changes in the appearance, taste, or smell of a product, growth of harmful bacteria, or lost potency. Preventing any interruption of the cold chain is one of the main responsibilities of a logistics manager. Let’s look at some of the significant cold chain challenges you may have to face, and how you can keep issues at bay.

REGULATIONS

Regulations for the cold chain are ever-changing and complex, which is why they are one of the major challenges faced today. If your cold chain is worldwide, it can be more complicated as there is no one entity to regulate on a global scale. Each region has its own regulations, compliance mandates, and enforcement agencies. Some examples of these are:

U.S. Food and Drug Administration (FDA)

In the U.S., the federal regulatory agency for food and pharmaceuticals is the FDA.

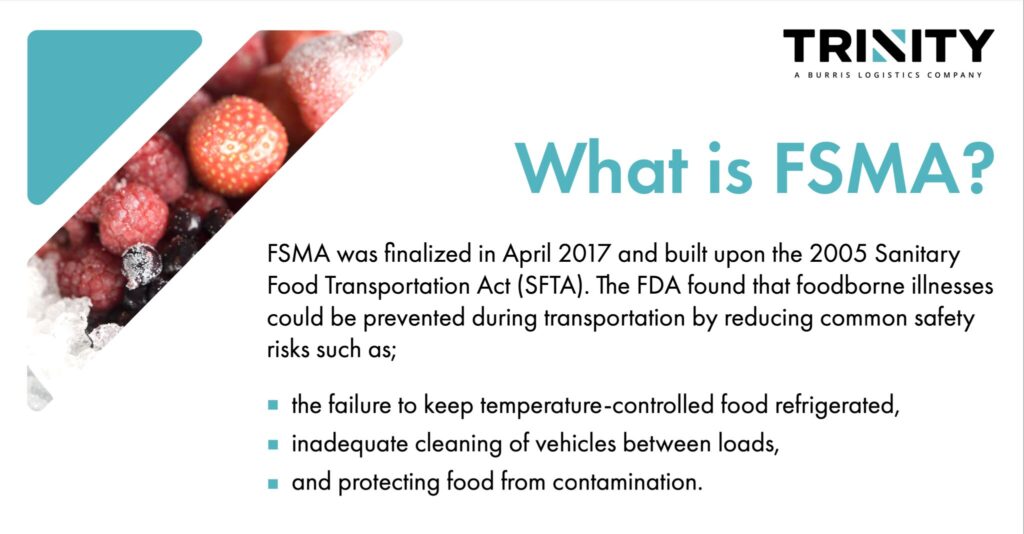

Most cold chain food regulations come from the FDA’s Food Safety Modernization Act (FSMA) of 2017. This regulation covers the cleanliness and function of equipment, protocols set in place for transportation, employee training on the proper handling of food in cold chains, and records of all FSMA compliance.

When it comes to pharmaceutical products, many regulations affect the cold chain. Some of those include:

- 21 CFR 203.32

- Addresses the need for maintaining drugs under stable conditions and meeting manufacturer’s specifications.

- 21 CFR 211.150

- Provides guidance on the written procedures for managing expirations and a reliable system for identifying the distribution of drug samples in the event of a recall.

- 21 CFR 203.36

- Outlines the responsibilities of manufacturers and authorized distributors.

- 21 CFR 205.50

- Minimum requirements for storage and handling of prescription drugs and maintenance of distribution records

Canadian Food and Drugs Act

In Canada, the regulatory authority is the Government of Canada. The Canadian Food and Drugs Act was passed in 1920 and revised in 1985. It regards the production, import, export, and transport across provinces for food, drugs, and cosmetics including products like soap and toothpaste. It ensures products are safe, ingredients disclosed, and drugs are effective.

International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH)

Many other countries, refer to ICH guidelines gathering data on a product’s safety and efficacy to establish a cold chain strategy. ICH brings together many regulatory authorities to discuss data and establish those guidelines. Gathered data is used to consider the duration of temperature excursions that can occur across distribution channels.

Regulations can be complex and demanding at times, but they all have the same goals of retaining the safety, quality, transparency, and efficacy of cold chain commodities. The biggest key to keeping compliance with cold chain regulations is increasing end-to-end visibility in your cold chain. Keeping proper documentation of data throughout your supply chain can seem difficult but modern technology like a transportation management system (TMS), can simplify this cold chain challenge. Current technology applications like GPS tracking, ELD data, Internet of Things (IoT), and a TMS can give you advanced analytics and reporting that would otherwise be comprised of manual processes. Not only does technology offer you savings in time but of human error as many processes become automated.

SUSTAINABILITY

Another significant cold chain challenge is the increasing spotlight on sustainability. The distribution and transportation of temperature-controlled products have shown to be major causes of greenhouse gas emissions. In comparison to other supply chain transportation, cold chain transport consumes 20 percent more fuel than other heavy vehicle types due to the refrigeration equipment. The biggest issue facing sustainability is the high-power consumption or combustion of fossil fuels necessary to power the cold chain’s cooling systems.

There are also growing issues and increasing regulations on refrigerant gases used in cooling systems like hydrofluorocarbons (HFCs) as they are responsible for high greenhouse gas emissions. In 2015, the European Union set strict limits on the production and sale of high global warming potential HFC refrigerants. In the U.S., the Manufacturing Act of 2019 was passed which established a timeline of phasing down the use of HFCs by 2036.

Because of the increasing pressure of sustainability and its regulations enacted on the cold chain, many large food and pharmaceutical companies have plans in place to reduce their carbon emissions. In 2015, more than 150 businesses in the U.S. signed the Business Act on Climate Pledge which launched for private sector businesses to express their support on international action on climate change. Also, in 2015, the Paris Agreement was created, signed by 195 countries at the United Nations climate change summit. This agreement aims to reduce greenhouse gas emissions to prevent the planet from warming by more than 2 degrees Celsius.

Being sustainable in the cold chain is also something you can be recognized for now with awards such as the Supply & Demand Chain Executive Green Supply Chain Award or the Council of Supply Chain Management Professionals’ Supply Chain Sustainability Award. Some ways to consider in adding sustainability to your cold chain is improving your cold chain management to reduce waste and your carbon footprint or considering alternative transportation modes like intermodal versus truckload when shipping your products. While you’re working on improving sustainability in your cold chain, make sure the providers you work with are equally interested in sustainability as well. Here at Trinity, we are proud of our sustainability efforts and to be recognized as a SDCE Green Supply Chain Award winner and as a Food Logistics’ Top Green Provider.

TEMPERATURE VARIANCES

It’s one of the biggest and most common cold chain challenges: maintaining the required temperature of the product throughout the entire supply chain. Any temperature that is higher than the set temperature can affect a product’s quality. Not all products that get exposed to a temperature past their threshold will spoil right away, as it depends on how steep and frequent the exposure was. Once a product has begun to thaw, it is considered contaminated. Depending on the product and temperature, that window of time can be very short. There are many times during cold chain in which a product can be exposed to a temperature variance: during unloading and loading of the product, from poor packaging, handling, or broken equipment.

Loading and Unloading

As your product moves through the cold chain, it can get exposed to temperatures outside its set temp. Whenever loading and unloading your product, handling should be as quick as possible. Preventing prolonged exposure to temperature changes prevents having problems with quality.

Poor packaging or handling

There are many different ways to package your cold chain freight so it can keep its cool. If it’s not done right or in mind of your transit time, your goods can spoil before arrival. When handled poorly, they can become damaged, causing lost product.

Equipment problems

One way the cold chain can be interrupted is when your equipment breaks down. Refrigeration equipment can malfunction due to damage, inadequate maintenance, or losing power.

In cold storage, doors becoming damaged are one of the common challenges they face. When cold storage doors become damaged, they can’t maintain their specified temperatures.

Due to inadequate maintenance, there can be a buildup of condensation in coolers and freezers, causing slippery surfaces and unsafe conditions for workers, as well as a spoiled product. Another maintenance challenge is handling the growth of mold or mildew, which can happen with poorly maintained temperatures. Should this happen, the freezer will need to be cleaned thoroughly and inspected for any problems.

Transportation Breaks Down

Vehicles can break down at any time. Any hold-up in your cold chain shipment could mean more than just a time delay, it can mean a spoiled product. Make sure you’re working with a qualified carrier who inspects their truck or other modes of freight before the journey begins.

Keeping track of the temperature throughout your cold chain is another way to combat having your products exposed to changes in temperature. Temperature monitoring systems are quickly replacing any manual processes of collecting temperature information, saving time, and preventing spoiled products. This also allows cold chain managers insight into their problem areas and being able to fix them.

Some of these temperature monitoring systems are RFID or wireless sensor network, thermal imaging, and temperature loggers. RFID or other wireless sensor networks are the most common in the cold chain. These sensors capture the location and temperature, communicating the information back to a database and allowing parameters like an estimated shelf life to be calculated. You’ll often find these in warehousing and cold storage. Thermal imaging is exactly what you think it is; imaging that is taken showing the different temperatures of everything in the photo. Thermal imaging uses a sensor to convert the radiation given off at different temperatures into a visible light picture. This is also often used in warehousing and cold storage. Lastly, temperature loggers are another type of sensor placed next to cargo in transportation. They can be set to record as frequently as every second, minute, or hour. Once removed, they can be plugged into a computer so the temperature data can be transferred and analyzed.

TEMPERATURE-CONTROLLED SHIPPING CAPACITY

Another significant cold chain challenge is available capacity. Capacity is always a challenge for any industry, but even more so for the cold chain, especially right now. With freight in high demand across all industries and capacity slim, drivers can pick and choose what shipments they want to take based on (already) high rates. Reefer trailers are already limited with the increased demand on cold chain, but when rates for moving other high-demand commodities such as lumber or retail keep increasing, those drivers can choose to utilize their reefer trailer as a dry van to haul should those rates be better paying, further reducing cold chain capacity. Cold storage warehousing is seeing the strain as well because of the growing freight demand. More storage space is needed in the supply chain and new buildings are being built, but those currently in production or needing their building supplies (which are also in high demand), puts yet another strain on shipping capacity until that demand has decreased. With the cold chain demand increasing and available equipment and drivers doing quite the opposite, can the logistics sector keep up? Read more in our current whitepaper.

DON’T LET THE COLD CHAIN SCARE YOU

There is a lot of juggling to do when managing the cold chain. If even one ball is dropped, it can affect the whole cold chain. You can prepare as best as you can for these cold chain challenges, but sometimes it’s nice to know you have backup when you need it most.

Luckily here at Trinity, we’re experts in complex situations. In fact, I would say it’s our specialty. We’ve seen every possible problem there could be and are happy to help. By working with Trinity, you can gain access to the data you need to improve your performance and output, find equipment and capacity when you’re finding it difficult, and work with someone who understands current regulations, no matter the region or type of commodity you work with. We’re here to have your back regardless of what cold chain challenge comes your way.

Simplify your cold chain challenges.Not ready to request a quote? Subscribe to our YouTube channel and watch our latest State of the Industry and Freight Market Update videos to stay on top of what’s going on in cold chain.

Author: Christine Morris

If you haven’t already noticed, cold chain logistics is currently a hot topic. The demand for fresh products and quality supply chain processes are at an all-time high. Recognizing these trends in cold chain and taking action will help you fulfill your customer’s needs. Let’s look at five trends going on in the cold chain industry.

1. An Increased Demand on Quality Products

Big trends in cold chain, specifically the food industry, has been the demand for fresher and higher-quality products. Consumers want their peaches to be juicier and their avocados to be riper. To satisfy the customers’ wants, you need to make sure the carrier that is shipping your product is well versed in cold chain management. They need to know how to avoid changes in the texture and taste of the produce when a shipment fluctuates beyond the required temperature. The focus on quality products means that refrigerated warehouses will need to maintain temperature zones.

Quality products don’t stop at fresh food. With the COVID-19 vaccine being administered, people want to make sure that what they’re getting injected into their bodies is safe. In addition, the amount of biological drugs and gene therapies is growing. Because of this, logistics companies are also widening their capacity for temperature-controlled transportation to meet the demand.

As we’ve stated in our Shipping Pharmaceuticals blog, cold chain logistics play significant role in the pharmaceutical supply chain. Manufacturers of these vaccines and medications need the cold chain to run smoothly to prevent any damage to the expensive drugs. Pharmaceuticals also need to arrive as good as new because medicine that has sat in incorrect temperatures for an extended period can be ineffective or detrimental to a patient’s health.

2. The Global Cold Chain Market is Booming

A recent report by Grand View Research shows that the global cold chain market size is expected to grow 14.8 percent from 2021 to 2028. Many nations have recognized a rising need to avoid food waste and loss of healthcare products due to spoilage. Moreover, the demand for fresher products is on the rise. Nations such as China and India are boosting their global cold chain efforts to meet the demand for their exports. International trade liberalization has also boosted the use of cold chain, globally. Because it is the global cold chain is rising, manufacturers need to become more specialized in their products so they can ship their goods to a wider variety of customers across the globe.

3. Stronger Regulations

Another trend in the cold chain has been stricter regulations on shipped products. Both globalization and the recent rise of food and pharma counterfeit incidences have caused production and cold chain rules to be reevaluated. The beginning of these rules started with the Food and Drug Administration’s Food Safety Modernization Act. This act requires anyone in the food supply chain to document every step of the process. Certain products like fruit must be traced all the way back to the point of origin.

Being proactive with these firm rules and regulations has also been a common trend across cold chain logistics. Manufacturers are strengthening their processes in-house to help mitigate any issues with their cold chain. Safety should be a top priority for the manufacturer when shipping through cold chain.

4. Innovative Packaging

Specialized packaging has been a trending topic in the cold chain industry. Whether it be for pharmaceuticals or food and beverages, manufacturers have been more specific on how they want their products packaged.

For pharmaceutical companies, there has been a conflict between packaging and transportation costs. For smaller shipments moving through the supply chain, a company can choose either a 24, 48, or 72-hour packaging that will protect the products from becoming ineffective. The more insulated the packaging is, the higher the cost. Globalization is also a major factor in this dilemma. If the U.S. ships cold chain products like pharmaceuticals overseas, it is imperative that the carrier knows to re-ice the shipment if any delays occur.

Companies that specialize in temperature-controlled packaging are making single-use or reusable packaging for all your cold chain needs. There are new refrigerated shipping systems that don’t require gel coolants, and they weigh much less than typical cold chain packages. These systems use evaporative, reactive cooling technology that responds and adjusts to fluctuating temperatures.

Whether it be significant innovations such as evaporative cooling technology or something as simple as adding handles and straps to your packaging, traditional packaging is starting to become a thing of the past. Companies are trying to gain that competitive advantage of being the most innovative packaging company for your cold chain needs.

5. Outsourcing to a Third-Party Logistics Company

Another demand in the cold chain has been for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the transportation of their products. That is why a 3PL provides a wide range of technology services to promote transparency within the supply chain.

Consumers today are becoming more conscientious about their needs. No one wants to settle for spoiled milk or ineffective pharmaceuticals. It is imperative that manufacturers stay up to date on these current trends in the cold chain in order to satisfy their customers. Doing research and staying in the know are both imperative ways for your business to be successful. Being proactive and listening to what customers want is the best way to stay on top in the cold chain industry.

Interested in learning more about Trinity’s experience in cold chain?

Speak With an expertWhether those buying your product are meat-eaters or vegetarians, gluten-free, or dairy-free or they’ll try anything under the sun – we all have to eat. All food must make its way from farms and factories to the dinner table. We all know that this multi-step process is particular and sensitive. Shipping frozen and refrigerated food together can be a recipe for disaster if not done right. The technicalities involved in packaging, warehousing, and transporting these goods are specific and time–sensitive. Let’s look at the logistics of frozen and refrigerated shipping and see how your product ends up safely on dinner tables.

Refrigerated/Frozen Food Shipping: LTL vs. Truckload

The process of shipping food differs between truckload and less-than-truckload (LTL) shipments. Let’s look at how these two modes differ when it comes to shipping your frozen food.

LTL

When you work with a refrigerated LTL carrier, you likely know that they have specific days that they pick up, depending on the region. Other temperature-controlled products traveling within that region in the same temperature range will be on that truck.

The LTL carrier will pick up all these shipments within a specific window and deliver them the following week. Depending on the size of your business and the frequency of shipments, you may find it challenging to keep track of the various pick-up and delivery windows for specific carriers. Visibility of your shipment is imperative to ensure your product arrives safely to the store and in peak condition.

Truckload

Large shipments of dairy, frozen meats, boxes of bananas, lettuce and watermelons, cans of soup, ketchup, you name it, can be shipped via truckload from distributors to grocery stores. Truckloads full of items leaving one location and heading to the same destination with the exact temperature requirements can be shipped together. However, if this isn’t the case for your product, remember to note this on your instructions for the carrier moving your freight.

Since these trucks typically have one origin, one destination, and one driver, there aren’t necessarily specific days of the week that these are picked up. However, receivers may have specific days for delivery. Ensure your product arrives in peak condition by coordinating the pick-up and delivery times appropriately so food does not spoil.

Grocery Delivery Services

The typical grocery store shipments are pretty cut and dry with how goods arrive at the loading docks. The waters get muddied up when it comes to services designed to help busy people get groceries without ever stepping foot into a store.

Consumers can buy everything else online, so why not food? Grocery delivery services like Peapod, Walmart Grocery Delivery, Instacart, Freshdirect, and Amazon Fresh have turned e-commerce into a giant food pantry for busy people. In a five-minute website visit, people can add their groceries to a virtual cart and have the goods arrive on their front step the following day.

While grocery deliveries are incredibly convenient and competitive price–wise for the average consumer, it’s a rather complicated process with a small profit margin for shippers.

These last-mile grocery shipments are so tricky because of the precise instructions and temperatures for the items within a single shipment. Companies have a window of around 20 hours to get groceries from the warehouse to a customer’s fridge. Any moment that the temperature dips below the requirement could zap away the shelf life of your product.

There’s also difficulty with grocery delivery because certain products cannot be shipped with others. Some produce items can’t be packaged in the same bag as others. Refrigerated items such as milk and cheese shouldn’t reach the temperatures that frozen microwavable meals demand and vice versa.

Some of these grocery delivery services have refrigerated trucks that carry the groceries from house to house, while others do the temperature control within the grocery totes, using insulated boxes, large ice packs, or dry ice.

Drivers who deliver these shipments must be more conscious about delivery windows to ensure that each food stays exactly how it is supposed to be, so the integrity remains when the bags make their way from the front step into the kitchens of consumers worldwide.

Meal Service Delivery Kits

Meal Service Delivery Kits from providers like HelloFresh, Blue Apron, Green Chef, Sun Basket, and Plated are handled a little differently from grocery delivery service.

Shoppers who want pre-portioned ingredients to prepare two or three meals a week for their family will sign up for these services. Ultimately, the providers, like HelloFresh, will have a preselected menu for the week.

In this case, the providers are the ones deciding what produce, grain, dairy, and meat can be packaged together. These deliveries arrive at customers’ homes in insulated cardboard boxes. Meats are typically at the bottom of the box covered by large ice packs, with produce and dry items packaged on top.

These deliveries are a little less complicated and don’t require immediate attention from the customer to stay fresh. While there are instructions to unpack in the fridge as soon as possible, food can stay cold with gel ice packs if customers are not home at the time of delivery. Typically, these items are kept at refrigerated temperatures and don’t fall into the realm of frozen food shipping. Proper packaging during this time helps maintain the integrity of your product.

Multiple carriers still come into play to get food delivered from the meal service distribution centers to the doorsteps of customers, many times parcel companies like UPS and FedEx complete the last leg of delivery. These carriers need to have the knowledge and expertise of shipping frozen and refrigerated food. This will ensure that the meal kits are delivered properly and are safe for the customer to eat.

Categorized Subscription Boxes

Subscription boxes have become a major trend in the food industry. Unlike the full grocery delivery services, these boxes differ as they often only offer a specific type of commodity. Examples of food subscription boxes are Butcherbox, Misfits Market, Jeni’s Pint Club, Carnivore Club, and Wine Down.

These categorized subscription boxes are even less complicated to package and deliver than the Meal Service Delivery kits. Since all items are in the same category and require similar packaging and temperature control, there is no need to make sure certain items are at the bottom with more sensitive items at the top of the box.

All items are packaged like the meal kits inside an insulated cardboard box covered by large ice packs and delivered the same way. Companies like ButcherBox can warehouse and deliver their boxes in one to two days with services like Direct-to-Consumer through our parent company, Burris Logistics.

Third-Party Logistics Frozen Food Shipping

Even with changing trends in the way food and groceries make their way into consumers’ cabinets and refrigerators, your food product still has to travel from distribution centers, warehouses, and farms around the world.

Whether you have a full truckload of refrigerated or frozen food to ship or just a few pallets, you can work with a third-party logistics (3PL) company to help coordinate your shipments.

Whether you’re shipping multiple trailer loads of food to grocery stores across the country, or you’re just starting to ship several pallets of your bakery goods to markets, Trinity Logistics is uniquely qualified to help you find solutions for your cold chain specific needs.

Trinity arranges the shipment of food, produce, and frozen meat and seafood on a regular basis. We work with a vast array of carriers with reefer and frozen food equipment at the ready. With innovative technology and Account Management expertise, frozen food shipping arrangement has become a specialty of Trinity.

Want to learn how Trinity can arrange your refrigerated shipments?

Connect with us today by submitting a quote request.

Originally published July 7th, 2017 By Brittany Siegel. Updated by Victoria Dalton.

Frozen food is considered one of the safest forms of food preservation because the freezing temperatures prevent harmful bacteria. This doesn’t necessarily mean that frozen food is foolproof. Several situations that could cause your frozen food to go bad and ways to prevent them from happening. If you’re new to shipping frozen food, or you’re a seasoned veteran staying up to date with the ever-changing world of cold chain logistics, here are a few things to keep in mind that can impact your company’s bottom line.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

Improper Packaging

Improper packaging is the most common mistake in frozen food shipping. It may also be the most involved part of your process. Multiple layers of packaging and ensuring an airtight seal to eliminate any heat or humidity penetration is critical. Your packaging’s inner layer should be waterproof to prevent any leakage from melting refrigerant causing damage to your outer packaging.

The person responsible for packaging your frozen food should have a strong understanding of dry ice and how to store it in proper containers. Although it a great source for cold chain packaging, it could be detrimental to your shipment if misused. If dry ice is packaged in an airtight container, there could be a pressure build up and cause that entire container to burst.

Package your frozen food with the proper amount of dry ice or frozen gel packs to prevent temperature fluctuations from happening. You should also ensure that you have the proper sized box to store your products. Too large with extra space means your goods could become damaged in the process of moving.

To prevent improper packaging, ensure that you have full knowledge of the temperatures required for that shipment and what type of insulation you want to use. Partnering with a 3PL that works with vetted carriers that have a strong understanding of how to transport frozen food will also save your shipment from spoiling or getting damaged.

Underestimating Shipping Times

When you underestimate shipment times, the result could impact your bottom line. If your product arrives to its destination melted or spoiled, you’ll end up with rejected products. This means money lost.

Plan your frozen food shipments ahead and research estimated transit times so you can pack enough coolant material. This will also provide insight on which refrigerant choice would work better for that shipment. One to two blocks of dry ice will last between 18-36 hours in a small Styrofoam shipping container. In a larger shipping container, dry ice can last between two to three days. It’s never a bad idea to make sure you have enough refrigerant packed so that it could last an extra day or two should your shipment have some unforeseen delay. Communicate the estimated transit time with your third-party logistics provider to ensure that the carrier shipping your frozen food has all the necessary information.

Not Properly Recording Information

Keep record of every detail about your shipment. This is paramount to staying compliant with the Food Safety Modernization Act (FSMA) and proving that your business has done everything possible to prevent the spread of foodborne illness. This includes the proper labeling of packaging, any providers used, and temperature records from before, during, and after transit.

The FDA Food Safety Modernization Act (FSMA) is transforming the nation’s food safety system into one that is based on the prevention of foodborne illnesses. Our team stays updated on these regulations and have processes in place to stay compliant.

Not Using a Qualified Provider

Maintaining the correct temperatures when shipping frozen food means maintaining its quality. You should make sure you choose a provider who is experienced with your frozen food product. Don’t make the mistake in trying to lower shipping costs by shipping mixed temperature goods together, which if not done properly, can compromise their quality and result in rejection of your product. Shipping mixed loads can be done, but you need to make sure it’s with a provider that has trucks with separate compartments capable of holding different temperatures, and the experience to handle it.

Finding and building a relationship with a qualified, experienced carrier to haul your frozen food products can be a long and time-consuming process. At Trinity, we have a network of over 70,000 qualified carrier relationships to help you.

Why not choose to save some time?

Request a QuoteIf you find it difficult to juggle multiple providers for your cold chain logistics, there’s a better, even seamless, way of doing business. Cold chain logistics can be difficult to manage and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. Often you may find yourself with many providers and contacts to sort through. What if you could reduce all your cold chain logistics companies down to one? What if you could replace the rest by finding one with a range of modes for your cold chain freight, including warehousing, transportation management, and more? Sound too good to be true? Keep reading.

RISKS OF MULTIPLE PROVIDERS

When you ship and manage temperature-controlled freight, you often find yourself working with more than one logistics provider. This means there can be more handling, which can become a cause for safety concerns.

Manual processes in the transportation of cold chain freight can cause decreased visibility along your freight’s journey. The majority exists within the food industry due to the Food Safety Modernization Act (FSMA). Because of this, shippers need to practice diligence when selecting and vetting the carriers they choose move their freight. They must make sure to communicate responsibilities such as required temperature requirements, having access to temperature readings, and making sure equipment is inspected before moving.

When you work with more than one carrier the process becomes more complicated. Each one adds complexity to your cold chain and every handling adds risk. Take time to map out your supply chain end-to-end, identify gaps, simplify your processes, and reduce the number of providers that move your freight. This can reduce your cold chain safety risks.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

HOW WORKING WITH TRINITY CAN BENEFIT YOUR COLD CHAIN

This is where partnering with Trinity Logistics can help. As a Burris Logistics Company, we’re uniquely qualified to arrange solutions across your entire cold chain. Working with us means you can feel at ease knowing your cold chain products are well taken care of during transportation. Stop searching for and working with multiple cold chain logistics companies. We vet every carrier in our network, reducing your risk and time spent finding providers. Some of the benefits of working with one 3PL include:

…INCREASED FLEXIBILITY

The ability to be flexible and quickly adapt to change is important for your cold chain business to stay competitive. When you partner with Trinity it gives you that flexibility of having a whole network of vetted, qualified carriers at the ready. And because we’re under the Burris Logistics umbrella, should you need other logistics solutions outside of our range, we can still support you by working with Burris to arrange those cold chain solutions that fit. We can help you stay flexible as one sole provider, instead of working with several.

…REDUCED WASTE

When you work with only one cold chain logistics provider, you can reduce your waste. At Trinity, you’ll build a relationship with a logistics expert. We can help you reduce supply chain inefficiencies through transportation management or reduce emissions by finding better routes. We can help you use trucks efficiently, such as reducing deadhead miles or suggesting intermodal when it makes sense.

…SAVE MONEY

When you work with a cold chain logistics company, such as Trinity Logistics, you can save money. With more flexibility, increased efficiencies, and reduced waste, you’ll be able to use your money better and reduce your logistics costs. By working with one provider instead of several, you’ll save time in billing and invoices. We provide a Team of dedicated, knowledgeable, and flexible experts, bringing you increased productivity and workflows within your logistics. Working with a provider such as Trinity, is a great way to cut costs without losing quality, time, or deadline requirements when it comes to your freight management and transportation.

WORKING WITH A COMPANY LIKE TRINITY, A BURRIS LOGISTICS COMPANY

When choosing to work with Trinity Logistics, you’re choosing to cut complexity. Cold chain logistics is complicated in itself and trying to do it alone can be frustrating. Choose to reduce your frustration with cold chain logistics companies by choosing the right one.

With Trinity, you’ll gain end-to-end supply chain management. Trinity is one part of the Burris Logistics umbrella, so working with us offers you access to other Burris options such as cold storage or direct-to-consumer fulfillment should you need it.

With Trinity and Burris combined, you’ll gain a greater level of flexibility in your cold chain with customized solutions. You’ll have a greater level of agility in your logistics execution while reducing cost. Since we focus on how you operate as a shipper, we make sure we fit your mold and help to solve your problems, not the other way around. You can count on Trinity Logistics to be able to serve and support your cold chain all the way from production to delivery.

Simplify your cold chain logistics today.

REQUEST A QUOTENeed more info?

WATCH OUR COLD CHAIN WEBINARFinding and selecting a cold chain logistics provider can be a tough and lengthy process. You want to make sure you find the right one. The one who you can trust in understanding your freight’s regulations and has the quality of the transportation you need for your temperature-controlled freight. Here at Trinity, we consider ourselves uniquely qualified within the cold chain. We’ve worked with thousands of shippers with temperature-controlled products, making us well-versed in the requirements and regulations.

Don’t just take our (written) word for it. Join us and our parent company, Burris Logistics, for an educational webinar to discuss our Fully Connected Cold Chain. In this webinar, you’ll hear from three experts in the industry: Mark Peterson and Mo Shearer of Trinity Logistics and Nick Falk of Burris Logistics. They’ll all speak to the intricacies you can experience in cold chain distribution and their personal stories of expertise with commodities like seafood, produce, and more.

Find out why Burris Logistics has become a well-known cold storage provider and how they have further grown within the cold chain industry by finding support in other areas of logistics, such as freight management with Trinity Logistics. Learn from our panelists why cold chain logistics is often best left to the experts.

If you’re in the cold chain space and have any questions or concerns about your logistics, this is the webinar to attend. Don’t miss out on the chance to learn more about our people-centric and servant approach, together with Burris, straight from some of our top members of the company.

Join us for “A Fully Connected Cold Chain”

February 2, 2021 at 1:00pm EST.

REGISTERDoes the COVID-19 vaccine have your cold chain logistics worried? If not, you should be taking it into consideration.

Everyone’s over the pandemic. We’re ready to be back attending public events, traveling to popular destinations, have our kids in school full time, and more. So much of 2020 has had to cancel or make the move to virtual and it’s not the same. Additionally, here at Trinity, the health and wellbeing of our Team Members, Authorized Agents, Carriers, and Customers is our number one priority.

Pfizer, Moderna, and others have quickly turned around vaccine solutions, making the light at the end of the tunnel seem in reach. With everyone looking to gain some sense of normal back into their lives, it means all hands will be on deck for the upcoming vaccine distribution. That means other cold chain commodities, will fall lower in priority. How will this affect your cold chain logistics?

THE IMPORTANT ROLE OF COLD CHAIN LOGISTICS FOR A COVID-19 VACCINE

Vaccines are fragile. Most have to store at specific colder temperatures to protect them from deterioration. If left out too long or exposed to fluctuating temperatures, vaccines can lose their effectiveness. According to the World Health Organization, one in four vaccines loses its integrity during transit. Due to their fragility and the extensive attention to detail that the logistics sector has to maintain, roughly 80 percent of a vaccine’s cost comes from its storage and transport.