The food and beverage industry is enormous, including subindustries like grocery, restaurants, bars, catering, and more. The industry continues to evolve and adapt despite frequently changing consumer preferences and new, complex challenges. So, what’s currently affecting those in food and beverage? In this blog, we’re going to dive into some of the latest trends in the food and beverage industry.

TRENDS IN THE FOOD AND BEVERAGE INDUSTRY

LABOR SHORTAGES IN FOODSERVICE

ARTIFICIAL INTELLIGENCE & AUTOMATION

CONTINUED COLD CHAIN GROWTH

One of the well-known trends in the food and beverage industry is the continued growth of cold chains. Recently, a Grand View Research study shows that the cold chain market was estimated at USD $330,680 billion in 2023. Furthermore, it’s estimated to grow at a Compound Annual Growth Rate (CAGR) of 14.8 percent from 2024 to 2030.

Recently, there’s been an increased demand for temperature-controlled pharmaceutical logistics (think vaccines and biologics), rising demand for better food quality, including more fresh and frozen foods, and a surging need to reduce food waste. All this is anticipated to drive the market’s growth.

In light of the pandemic, the risks of COVID-19 have made consumers more interested in healthier, less processed foods that will boost their immune systems. However, less processed foods mean more food products that will need temperature control.

Additionally, the frozen food sector looks to be growing. Besides filling home freezers, frozen foods are growing in restaurants. Restaurants are also providing new menu items for the frozen grocery aisle. In an American Frozen Food Institute report, 72 percent of frozen food consumers said they combine frozen and fresh ingredients in their meals.

Comparatively, shippers are also using more cold chain services to preserve the shelf life of their products, even when temperature-controlled transportation isn’t needed.

SUSTAINABILITY

Growing climate issues are making sustainability a common trend in almost all industries. Consumers are taking notice of the sustainable practices of companies. From ethical sourcing, carbon neutrality, to eco-friendly packaging, consumers want the brands they buy from to be sustainable. Additionally, food waste is a major contributor to greenhouse gas emissions globally, contributing to cold chain issues. This makes sustainability one of the top trends in the food and beverage industry.

Consumers Care About Sustainability

One way consumers can show their support for the environment is by choosing to purchase from sustainable brands. Consumers have shown they’re willing to pay more and be loyal to brands that invest in their sustainability efforts. In a survey by YouGov, more than half of consumers said they would be willing to pay up to 10 percent more on sustainable versions of regular packaged food and drinks. In another consumer survey, 78 percent of respondents agree that sustainability is import, with 63 percent stating they have adopted greener buying habits.

Food Waste Prevention

In fact, an S&P Global Ratings report says food waste contributes to 10 percent of emissions and that $1 trillion of food is wasted each year. Similarly, according to the U.S. Environmental Protection Agency (EPA), between 73 to 152 million metric tons of food get wasted each year in the U.S. The most wasted foods are fruits and vegetables, followed by dairy and eggs, with over half of all waste occurring in households and restaurants. In addition, the food processing sector generates 34 million metric tons of food waste per year. And over the past decade, the total U.S. food waste has increased by 12 percent to 14 percent.

To put it differently, the EPA said halving food waste in the U.S. would save 3.2 trillion gallons of water, 640 million pounds of fertilizer, 262 billion kilowatt-hours of energy, and 92 million metric ton equivalents of carbon dioxide. According to the Agency, reducing the waste of meats, cereals, and fresh fruits and vegetables would have the most significant impact.

Due to this growing issue, governments and businesses have been working hard to improve sustainability efforts. In July 2021, the Zero Food Waste Act was introduced to provide grants to businesses that significantly reduce their food waste. Additionally, in November 2021, the Food Donation Improvement Act was introduced to lower food waste by making it easier for companies to donate food instead of throwing it out.

Cold chain improvements have seen growing importance even outside the food and beverage industry. One example is UPS Healthcare developing a system and opening facilities to move medicines safely. Part of their plan includes using reusable cold chain packaging. In addition, Amazon is working on insulation packaging to reduce material waste and replace 735,000 pounds of plastic film, 3.15 million pounds of cotton fiber, and 15 million pounds of non-recyclable plastic.

LABOR SHORTAGES In Foodservice

Labor shortages are common among other industries, making this another relatable trend in the food and beverage industry. As a result, hiring workers in the U.S. is becoming near impossible. According to a recent market report, labor shortages are a top concern for 23 percent of food and beverage businesses. The most difficult positions to fill look to be those in the restaurant and foodservice sectors. It’s not just the hiring of new workers, but retaining them as well.

Workers are leaving the industry due to a combination of burnout, low wages, and a desire for better work-life balance. Because of this, restaurants and foodservice companies have had to reduce their hours or limit their menu, while consumers have felt it in longer wait times and less personalized service. With good customer experiences being paramount to a company’s success, resolving this issue is critical.

For this reason, advanced technology can help remove some redundant tasks and help supplement amidst labor shortages. For example, those in the bar sector are being introduced to self-pour technology, which uses RFID tracking and allows customers to pour their own beverages. .

CONSUMERS ARE MORE COMPLEX

Over the years, consumers and their choices in food and beverage and their preferred shopping habits, have become more complex. Because of this, there is a greater assortment of products than ever, with more items requiring temperature control as consumers move away from processed foods and look for fresher, healthier items. Consequently, the supply chain for grocery continues to evolve as the message from consumers is clear. They want what they want, when they want it, where they want it, and expect businesses to respond to their demands.

Continued Decline of In-Person Shopping

In speaking to consumer shopping preferences, it looks like online grocery shopping, food delivery, and food subscription boxes are here to stay. Many consumers prefer the option to receive food and beverage products at their door. For instance, in recent a study by Drive Research, the use of grocery delivery services in 2024 have risen 56 percent compared to 2022. Additionally, the use of grocery curbside or pickup in 2024 have risen 100 percent compared to 2022, further showing the decline of in-person shopping for food and beverage items.

Cost of Food and Beverage Products a Large Concern

Additionally, inflation and rising costs for everyday items, including food and beverages, have consumers rethinking how much and what brands they buy. For example, a recent study showed 54 percent of respondents stating they’ve reduced how much, and unfortunately, 20 percent said they were skipping meals to save money on food. Data from another survey found that 43 percent of consumers are cooking dishes with less meat to save on grocery costs. Others are choosing to purchase cheaper cuts of meat.

Private label brands continue to see growth as shoppers look to save money whenever possible. In fact, according to Numerator, private label brands hold almost a quarter of sales in the grocery sector. The Private Label Manufacturers Association shows that private label sales saw 2.5 percent growth compared to a decline of 0.8 percent by national brands in 2024.

Taste and Experience is a Must

Consumers want to feel good about what they eat. They want nutritious options that alight with their dietary preferences or health goals. In a survey but the International Food Information Council, 54 percent of consumers consider the healthfulness of food in their purchasing decision. Yet, even with the health benefits, they still want their products to taste good, as Datassential shared 35 percent of them purchase items that sound both delicious and healthy.

Consumers are interested in trends like unprocessed foods, natural ingredients, anti-inflammatory, and hydration. Alcohol-free and non-alcoholic beverages are also a rapidly growing trend, with 2 in 5 consumers abstaining from drinking alcohol.

Consumers generally want a positive experience with food and beverage products. While it’s fuel for the body, it can also serve as a source of community, entertainment, and more. In one study, 53 percent of consumers see experiences as essential to their personal lives, especially among the younger generations since the pandemic. They’re interested in trying to tastes and spices, products that bring a sense of nostalgia, or food and beverages that tie in with a story, as shown by the recent increase in pop-up restaurants and bars.

supply chain Challenges

Since the pandemic, supply chains have been seen more of the limelight. As shown by rising costs faced by consumers, food and beverage supply chains have been challenged by shortages of raw materials, disruptions like strikes or a bridge collapse, and a growing demand by consumers for transparency and speed.

Consumers are also becoming more interested in knowing where the products they buy come from. According to a study by IBM, nearly 70 percent of consumers want to see a brand’s sourcing practices. They want to know how the products they buy were manufactured. They’re looking for companies who show concern to how their manufacturing affects the planet’s life span and how their product is raised or grown. Consumers want to feel like the products they choose to buy will make a difference.

According to a Mckinsey report, food and beverage supply chains see supply chain disruption roughly once every three years. A 2023 risk report shows that supply chain executives are concerned about disruptions from climate change, environmental factors, and geopolitical conflicts. Another risk report shows that 73 percent of companies experienced higher supply chain losses within that past two years. Because of this, building supply chain resiliency is a huge trend for food and beverage companies.

ARTIFICIAL INTELLIGENCE & AUTOMATION

Artificial intelligence (AI) is a buzzword across all industries, but how could it affect food and beverage? One way is through providing clearer insights into shopper preferences, helping companies better market to them to grow brand loyalty. It can help with supply chain optimization, helping businesses better understand consumer demand and optimize production planning and management, reduce overstocking, and minimize waste. Some companies, like Campbell Soup Co., are using AI to help with product development, tracking data and discovering what its customers want next.

According to WifiTalents, 62 percent of food and beverage executives believe AI will have a significant impact on their industry within the next five years. With the uses for AI in the food and beverage industry being so extensive, it will be interesting to see how companies make use of it.

There’s also a lot to be talked about in AI and automation for the customer experience. Companies are looking into AI-driven customer service opportunities and ways to streamline customer interactions. You see a lot of this in the restaurant industry with the use of table side tablets, interactive menus, and mobile ordering and payment. AI is used in mobile apps to personalize menus and promotions based on customer preferences.

Growing Cold Storage Demand

The demand for refrigerated warehouses is continuing to soar to new heights. A report from Skyquest forecasts the U.S. cold storage market to increase with a compound annual growth rate of 13.5 percent through 2031, expecting to reach a value of $118.8 billion.

Temperature-controlled storage is critical to many sectors, from grocery to pharmaceutical companies. The growing demand for cold storage facilities comes the adoption of automation and technology, the popularity of ecommerce and demand for faster delivery, as well as online grocery platforms. There’s also a thriving demand for convenience foods – those that are usually chilled but ready to eat with little to no preparation.

STAY AHEAD OF TRENDS IN THE FOOD & BEVERAGE INDUSTRY

No matter the trends in the food and beverage industry, having a logistics resource, consultant, or expert is one way to stay ahead. Whatever phrase you want to use but ultimately, have support on your side for any complex situation. This is where a third-party logistics company (3PL), such as Trinity Logistics, can come in. We can help you find creative solutions to your logistics challenges.

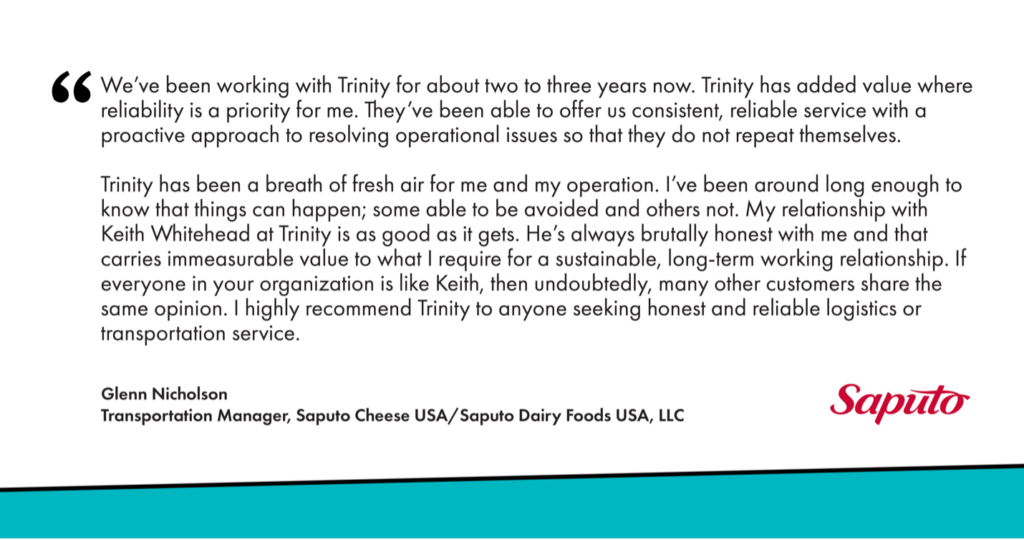

Now, you’re likely wondering, “why work with Trinity Logistics?” For one, we’ve been serving cold chains for over 45 years! Whether you have a complex challenge or just need help with one shipment, we have the experience and quality carrier relationships to meet your needs.

You can also count on us to stay knowledgeable on what’s going on in your industry so you can stay updated too. We know that even in times of supply chain disruption, your industry doesn’t stop, so neither do we.

And lastly, what makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

If you’re ready to have Trinity Logistics on your side for logistics support and expertise, no matter the industry trends, then let’s get connected.

DISCOVER HOW WORKING WITH TRINITY CAN BENEFIT YOUR COMPANY STAY UP-TO-DATE VIA OUR EMAILWhether your product is coming straight from the farm, is moving between processing, or heading off to the consumer, the dairy industry needs first-rate cold chain solutions to meet their complex supply chains.

Dairy products such as milk, cheese, and butter are household staples and essential in many people’s diets. It’s no surprise that the dairy industry is considered one of the fastest-growing industries, almost doubling in value every five years. To keep up with consumer demand, the dairy industry needs exceptional cold chain solutions to keep their products cold and safe for consumption.

Why the Dairy Industry Needs Cold Chain Solutions

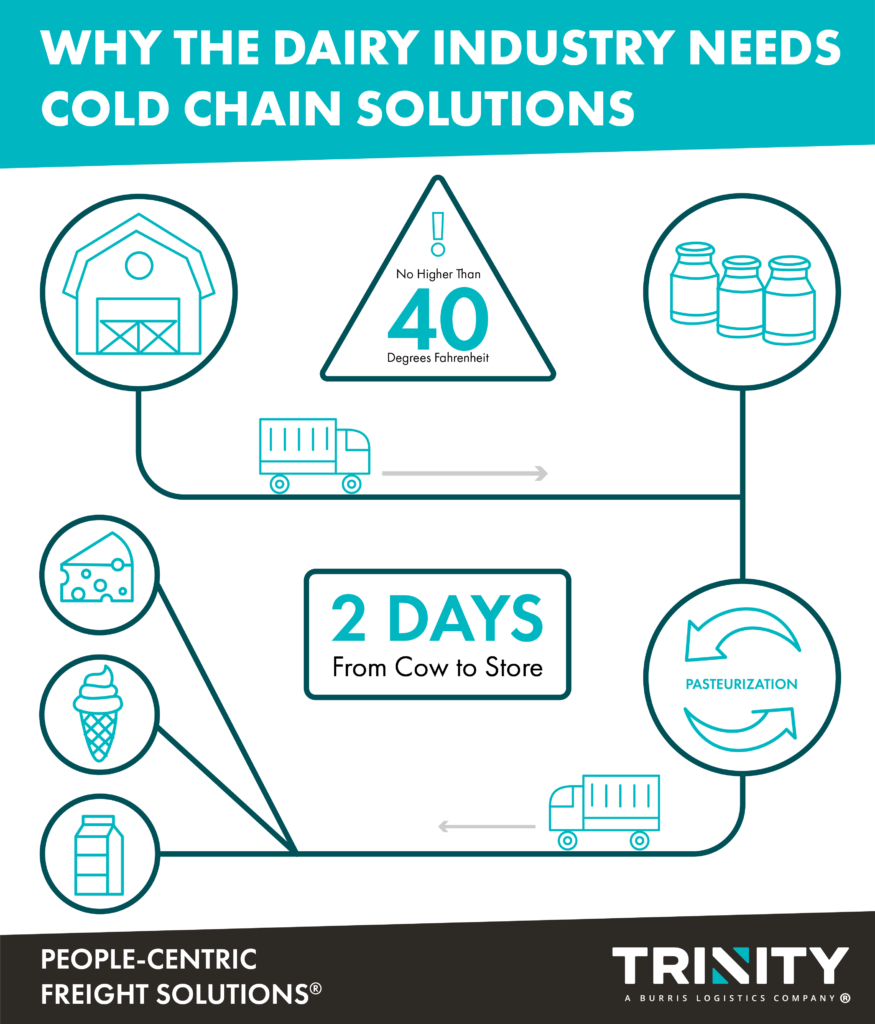

Dairy products all start with milk, and it has a short shelf life. After the cows have been milked, it immediately transports to cooling storage tanks or a chilled trailer. To ensure the milk doesn’t spoil, it must be stored at a temperature no higher than 40 degrees Fahrenheit. It’s then transported to a processing facility, pasteurized, and transported again to consumers.

Usually, this process alone, from cow to store, takes place in about two days. Now, milk is often a starting point for the many diverse dairy products available. Depending on the final product, dairy supply chains have more steps and complexities added.

Common Issues Requiring Cold Chain Solutions

- Temperature Control Needed for Most Dairy Products

- Capacity During Peak Shipping Seasons

- Managing Milk Production with Dairy Demand

- Supply Chain Disruptions

- Dairy is Highly Regulated

- Supply Chain Visibility

- Potential High Value Dairy Products

Temperature Control Needed for Most Dairy Products

Most dairy products need storage at specific temperatures to keep from spoiling. Dairy products need strict attention because of the risk posed to consumers if the cold chain is broken. If not consistently kept cold and free of humidity, bacteria in the dairy can cultivate and dairy products can become harmful.

Capacity During Peak Shipping Seasons

While some dairy products can seek out alternative transportation modes, most find shipping truckload is the most viable option. It’s usually the fastest and cheapest way to move the product because of its weight. It’s also the most viable due to freight security and nature of the product, and because it reduces the risk of claims due to temperature fluctuations or shifting. Since most dairy products need refrigerated trucks for their shipments this can make capacity an issue at times, such as produce season, when reefer capacity can be tighter. It can not only be more difficult to secure a refrigerated truck, but more expensive to do so.

Managing Milk Production with Dairy Demand

Dairy product demand can fluctuate. Yet, even when consumers want fewer dairy products, the cows don’t stop making milk. They can’t be turned on and off like machines, giving the dairy industry a unique balancing act to handle.

Additionally, when it comes to shipping milk, most of that is kept regional given the short shelf life and cost to ship, making dairy demand management even trickier.

Supply Chain Disruptions

As we’ve learned in recent years, there’s always the chance for supply chain disruption to happen. Whether that’s a truck breaking down, a roadblock, or some other instance that would cause delays. With several dairy products (like milk) having a short shelf life, any delays can risk product spoiling and going to waste. Companies in the dairy industry need to be able to act quickly if any disruption happens.

Dairy is Highly Regulated

Dairy products are associated with foodborne illnesses, so it’s no surprise that they’re highly regulated. Right from the start, milk is tested to ensure it’s of safe quality to consume and make other products from. There’s also the Food Safety Modernization Act (FSMA), which places strict requirements on sanitary transportation and the handling of dairy products.

Supply Chain Visibility

Because of so many factors mentioned above, it’s important for dairy companies to have full, real-time visibility of their supply chains. Additionally, many wholesale food distributors and grocery warehouses hold very strict requirements for appointments with very strict product quality inspections to be accepted into their inventory. Without it, dairy companies are at risk of losing products and money due to spoilage, disruptions, delays, or regulation requirements.

Potential High Value Products

Certain dairy products can be high value, like some cheeses for example. This can make the overall value of the load to be costly should there be any potential claims. It’s best for shippers to work with expert providers who have the experience and knowledge to handle any high value dairy products.

Leading Cold Chain Solutions from Trinity Logistics

Shippers in the dairy industry looking for first-rate cold chain solutions can find all they need with Trinity Logistics. We’re a leading third-party logistics (3PL) provider with over 40 years of experience serving logistics solutions to some of the top-known brands in the food and beverage sector.

Standard Operating Procedures for Temperature-Controlled Shipments

One of the reasons we excel in cold chain solutions is our standard operating procedures in place for every temperature-controlled shipment we arrange. This includes:

- Only working with carrier relationships that have downloadable reefer units

- Requiring carriers to pre-cool trailers a minimum of one to two hours before pickup

- Requiring carriers to run their reefer units on continuous

- If necessary, requiring carriers to pulp product before loading

- Requiring carriers to use one of our tracking and tracing partners for real-time shipment visibility

- Only using carriers that have refrigerated trailers that are 2015 or newer

We understand just how critical it is that your product stays at its required temperature. That’s why we work with our trusted, experienced carrier relationships to ensure your product arrives fresh.

Multi-Modal Cold Chain Solutions

No matter what transportation mode you need your product to ship, we have the logistics solutions to support your business now and in the future, including;

- Truckload

- Expedited

- International

- Cross-broder

- Air or ocean shipping

- Drayage

- Less-than-truckload

- Managed Transportation

This enables your business to seamlessly run regardless of what change or growth you experience.

In-Depth Transportation Management

Whether you need a transportation management system (TMS), to fully outsource your logistics, or your own customized managed transportation solution, we can help. We know each business is unique, which is why our system is highly configurable so we can meet your exact needs. Our Trinity experts will work as part of your business, offering in-depth reporting and data to help get you ahead of your competitors.

No Need to Worry About Disruptions

Did I mention that Trinity has been serving cold chains for over 40 years? We’ve seen it all when it comes to supply chain disruptions and delays. We know how to quickly adapt plans to keep your freight moving. While you’ll have your sole Trinity relationship to lean on for updates, we also have a 24/7 Team in case we need any additional support. You can learn to rest easy whenever your shipment is in our care.

Experts in Temp-Controlled Logistics and Dairy

Trinity Logistics has been serving cold chains for 40-plus years, in addition to our parent company, Burris Logistics, that was built on its expertise of handling temperature-controlled commodities.

There’s also Honor Foods, another Burris Logistics company you can lean on for food redistribution if needed. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They specialize in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers.

Our People-Centric Service

What makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

I’D LIKE LEARN MORE ABOUT TRINITY'S COLD CHAIN SOLUTIONSTrinity Logistics, a Burris Logistics company, is proud to share that Food Logistics has named the company as a recipient of the 2022 Top 3PL & Cold Storage Providers Award.

Food Logistics is the only publication exclusively dedicated to covering the movement of products and information through the cold food and beverage supply chain. The Top 3PL & Cold Storage Providers list recognizes leading third-party logistics and cold storage providers in the food and beverage industry. Companies on the list play a pivotal role in keeping the food and beverage industry’s products stored, transported, and stocked while maintaining the product’s quality.

“These past 18 months have been so challenging for U.S. supply chains. It’s the continuous bottlenecks that require fleets to re-tool and pivot accordingly. But it’s the drivers, the fleet, the warehouses, and software/technologies that really keep today’s supply chains in line,” says Marina Mayer, Editor-in-Chief of Food Logistics and Supply & Demand Chain Executive. “These 3PLs and cold storage providers have collaborated on all facets of their operations to achieve full visibility, complete forecasting, end-to-end leverage, and the ultimate in sustainability. Now is the time to honor and celebrate those companies making magic happen behind the frontlines.”

Trinity works with thousands of shippers in the food and beverage industry, making the company well-versed in its requirements and regulations. Equipped with state of industry technology and with Burris Logistics, one of the top cold storage providers in North America, as its parent company, Trinity provides exceptional service to those in the cold chain.

“We are honored to be named a Top 3PL & Cold Storage Provider, and very fortunate to be part of the Burris Logistics family,” said Mark Peterson, SVP of Sales at Trinity Logistics. “Having a parent company with 90+ years of cold storage & food distribution experience gives us a distinct advantage. From the 3PL viewpoint, our focus is on optimizing the efficiency of our distribution network. The pillars of that effort are gathering and analyzing the right data; clear and consistent communication with our partners; and the highly educated and motivated team of professionals at Trinity Logistics.”

The full list of 2022’s Top 3PL & Cold Storage Providers will appear in Food Logistics’ August issues, as well as online at www.FoodLogistics.com.

Learn how Trinity supports food and beverage companies.About Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 40 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized on Transport Topics’ Top 100 Freight Brokerage List, a Top 3PL and Cold Storage Provider by Food Logistics, and a Top Company for Women to Work for in Transportation by Women in Trucking.

With cold chain logistics, every product that you deal with has very specific temperature requirements that you need to adhere to. These products are ending up on tables across the entire country, so you want to make your product arrives precisely the way it needs to be so it’s safe for human consumption. Because of this, cold chain logistics can be challenging to manage, and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. It would undoubtedly be helpful to find one provider that could offer you end-to-end cold chain management, from production to delivery. And that’s what we’re here to talk about today. Burris Logistics and Trinity Logistics working together could be the solutions you’ve been looking for to simplify your cold chain management. Keep reading to find out how we work better together to serve your complete cold chain.

BURRIS LOGISTICS CAPABILITIES

Let’s start with Burris Logistics. What do they offer that can enable cold chain shippers and their businesses to thrive in the face of its complexities?

Quick Background

Burris Logistics has been around for 96 years. The company started as a produce hauler from southern Delmarva to Philadelphia. They quickly grew and expanded into the frozen food business and found their purpose as a driven food logistics provider. Today, they own 14 cold storage sites up and down the east coast and out into Midwest. Burris Logistics currently has a family of brands including Burris PRW Plus, Honor Foods, and Trinity Logistics.

Burris Logistics offers you logistics technology solutions that never sleep. With a Technology Team of over 100 Team Members, they work around the clock to provide you with technology resources designed to meet your specific needs.

From a Burris asset standpoint, they’re able to track all their trailers with ELD and reefer tracking, with the ability to ping the tractor and trailers to see where each of their assets are in real time. In addition, they have access to technology that can start and stop the units, reset them, or check temps on them, no matter the distance. With the complexities of cold chain transit and the current driver shortage, Burris works hard to put in place any technology that can make a driver’s job easier. They want to cut any obstacles drivers may face on the road while having any data be transparent to help both them and ultimately, any customers.

Burris also has technology for their cold storage warehouses. They focus on providing their customers with freshness, clarity, and visibility. They offer real-time monitoring and any differentiation from setpoints gets recorded. They make sure to get real-time data to those who need it should meaningful decisions need action, and have secondary and tertiary backups available.

Some of their other logistics technology offered are:

· Warehouse management system software

· Enterprise resource management

· Produce inspection tool

· External integrations

· Supply chain portal

· Demand planning

· Order status

· Delivery status

Burris Logistics works with you to create the best possible warehousing and distribution solutions. They’ll support you with a network of strategically located warehouses, 96 years of expertise, and a solution customized for your unique needs.

In a reflection of national trends, the newest and fastest-growing business line within Burris Logistics is their direct-to-consumer to support those in the cold chain e-commerce space. Through current resources and expertise in temperature-controlled logistics, Burris can deliver a premier frozen fulfillment network with cutting-edge technology, thought leadership, and warehouses across the country. Burris’s knowledge of shipping supplies, coolant technology, and two-day parcel shipping capability ensures quality is delivered with every package.

Facility Design is the process of considering new construction via greenfield facility sites or the re-purposing of an existing operation. Many companies are facing changing business needs, including the need for multi-channel execution. This makes the ability to scale up and scale down with various capabilities an essential part of planning. With partners who increase their dependency on Burris Logistics, they’ve been able to scale their operations to accommodate their programs with new locations, modifications to existing assets, and technology to keep the supply chain efficient.

Your customers desire the right products, in place, at the right time. Honor Foods, a Burris Logistics company understands how important it is to have on-menu and on-shelf products available while also minimizing food waste. They can help you plan inbound and outbound freight, using logistics technology and their warehouses to maintain food quality and safety.

With one of their other brands, Honor Foods, Burris offers Private Label In-house brands that have developed into trusted names amongst food service operators. These products undergo scrutinous selection and quality assurance knowing that our restaurant partners only accept the best. Your customers want what is trending, and Burris can help you meet this demand. Their brands come sourced from trusted shippers and can be a noticeable cost saving for you.

Burris Logistics understands that products need different environments, which is why their facilities can provide different temperatures and humidity, depending on your product. Newer warehouses are purposefully being built with ambient/dry storage space to accommodate increased partner needs. Additionally, their warehouses and distribution centers are in strategic locations near major transportation hubs and ports, making it easy to get your freight on the move quickly.

TRINITY LOGISTICS CAPABILITIES

Quick Background

Trinity Logistics has been around for over 40 years. The company was started by the Banning family in Cambridge, Maryland. Throughout the years, the company grew and expanded as a non-asset-based third-party logistics company (3PL) and was acquired by Burris in 2019. The two companies saw similarities in company culture and future goals, deciding to unite for greater opportunities and offer more supply chain solutions for our customers.

Burris + Trinity = Better TogetherURRIS

What’s great for Trinity being part of the Burris Logistics family of brands is being able to offer more help to Burris customers. Trinity’s support helps Burris better assist some of the existing freight business they have for customers either coming back into their buildings or going to other places.

The addition of Trinity also offers Burris customers a wider variety of options in modes and technology, or even help outside of the cold chain. Trinity is very experienced in heavy haul moves or more complicated hazardous moves for the chemical industry. So, no matter the size of your company or freight, we have a solution for you. But, we’re here to talk about the cold chain, so let’s focus on refrigerated and frozen freight.

While it’s not always hard to find a refrigerated carrier, you do want to be selective. There are a lot of carriers out there, but Trinity has a robust vetting process in place. We make sure carriers hauling your freight have the right amount of insurance, requirements, and experience. In addition, we make sure these drivers are representing Burris and Trinity the way we need to and that our customers are getting their products delivered safely.

You might ask, how do we guarantee safety with our carrier network? Well, these carriers mean as much to us as our shipper customers do, so we build just as strong carrier relationships. We offer our carriers many different kinds of technologies for location tracking, temperature tracking, and so on. We make sure to continue to evolve our technology solutions to keep the shipping process easy and safe for both carriers and customers. Additionally, we have our communication. Our communication is one of our strongest assets to ensure both parties have their needs and solutions met. Our bottom line is bringing value and if we can do that, we’ll be successful.

We offer and use several different technologies like Macropoint or Fourkites, so we can ping shipments and know exactly where they are and what the temperature of the product is, giving our customers instant access to look at their freight. That’s just one piece of the technology puzzle.

Even with the technology available, we never lose contact with our customers. We strive to stay very People-Centric. Our technology only helps make it easier for our customers to view information, especially with our Customer Portal, giving them the ability to trace loads without having to reach out. It gives them access to see updates at any time of day and offers backend access to their invoices to answer billing questions, make payments online, or provide them with a breakdown of what each load costs, lumper fees, accessorials, or pallet exchanges. Our Customer Portal allows you to manage that piece of business on your own time and at your own speed. We’ll always be available, but the Portal and any of our technologies are there to bring you even more value and efficiency.

Current logistics technology available:

· Carrier Portal

· My Carrier Packet

· TriumphPay

· FourKites

· Trucker Tools

· MacroPoint

· Customer Portal

· Customized Transportation Management Solutions

· Banyan LTL

· DAT Book Now

· Trucker Tools Book It Now

WAREHOUSING

We know that one size does not fit all when it comes to warehousing. That’s why we have warehouse providers with locations across the nation to allow you to scale your business at your own pace, plus our cold storage solutions with Burris Logistics. Our growing network supports reliable service and premier dry, refrigerated, or frozen solutions so you can focus on what you do best.

TRUCKLOAD

Our truckload service provides you with the means to get your freight moving quickly. Truckload is faster than traditional LTL or intermodal shipments which means your shipments can arrive on time and on schedule.

LESS-THAN-TRUCKLOAD (LTL)

Our LTL service provides you with the means to get your freight hauled through a range of options. By leveraging our volume and extensive network of LTL carriers, we can provide you with lower rates for LTL shipments consisting of 1-10 pallets of either dry or temperature-controlled products.

INTERMODAL

You can add value to your supply chain by using this cost and environmentally-friendly shipping option. By shipping intermodal, you’ll reduce your carbon footprint and have reliable and consistent capacity when over-the-road capacity can be tight.

EXPEDITED

Sometimes your freight is time-sensitive or needs less handling. When this happens, we can arrange over-the-road or air-expedited shipping. We’ll make sure your freight arrives on time and without stopping at terminals in between.

DRAYAGE

Your freight can be delivered from the port or rail right to your door, or from your door to the port or rail. Either way, we’ll save you money in the process. From servicing imports and exports, returning empty or full containers, helping you avoid unnecessary fees, long drayage options, or more, our Team is ready to help.

INTERNATIONAL

Arranging international shipments can be tricky and requires a lot of communication. If you are looking for help with arranging your Full Container Load, Less Than Container Load, door-to-door, or port-to-port services, we can help. We’ll be your intermediary with freight forwarders to arrange your air and ocean freight international shipments.

MANAGED SERVICES

In this service, we combine our experienced account management and best-in-class transportation management technology to deliver you a customized solution that helps your company achieve its unique supply chain goals.

HOW WE CAN SERVE YOUR COLD CHAIN BETTER TOGETHER

Experience in Cold Chain

For many reasons, Burris Logistics and Trinity work well together for cold chain shippers. First off is our combined years of experience. There are certain things in cold chain you can only learn from the experience of working with temperature-controlled shipments. For example, things like picking and loading fresh produce, understanding what those temperatures are and what they need to be for storage and transit, and keeping track of those temperatures. Or understanding how to move ice cream from the West Coast and knowing that you can’t go over the mountains; that you must travel around them so as not to cause shrinkage. By having years of experience and understanding of those complex situations and small details that make or break a cold chain shipment, you can trust your temperature-controlled freight is handled safely and correctly with Burris and Trinity.

Technology

Between both Burris and Trinity, we have incredible logistics technology available, but what differentiates us from others is that we keep in mind that logistics is still a “people” business. Technology will always be a tool for our Teams to use and bring logistics solutions to other people who need them. Therefore, we try to stay away from technology just for technology’s sake and make sure what we use and offer is always a valuable solution.

Communication

Because of our years of experience, we are well-versed and experienced in many different situations. We know when and how to pivot quickly and keep business moving forward. When issues arise, we work until they are resolved and keep open communication every step of the way. Having a solid relationship with experts like Burris and Trinity will prove to be your largest asset no matter what supply chain bottlenecks you may face

Flexible, Customized Solutions

Because our two businesses offer many options while keeping business People-Centric, it means you can find a solution that’s customized for your growing business and needs and your solution can be flexible. We know the cold chain and solutions aren’t static, they are ever-changing, so you need a provider that can keep up. By working with Burris and Trinity, you’ll never have to worry about changing up your logistics plan as we’re readily equipped to accommodate any changes you may need. In addition, we can help you stay flexible as one sole provider instead of working with several.

Visibility and End-to-End Cold Chain Management

As the cold chain sector continues to grow, there’s been a growing demand for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the logistics of their temperature-controlled freight. Working with Burris and Trinity can not only give you a wide range of technology to gain visibility and provide you with all the logistics services you may need, thus making your cold chain efficient and transparent. We’ll provide you with dedicated, knowledgeable experts, increased productivity and workflows, and reduced complexity by working with Burris Logistics and their family of brands instead of several different providers.

HAVE YOUR COLD CHAIN LOGISTICS TAKEN CARE OF, END-TO-END

Between Trinity and Burris, we have a substantial Team with a lot of experience in cold chain and knowledge about its potential pitfalls. As a result, we’ve created processes and different services so that we get it right the first time, every time we handle a cold chain shipment.

You can find value in our combined companies’ sizes and services offered. Cold chain logistics can be complicated and trying to do it all alone can be frustrating. That’s why we’re here to help you simplify it. You can count on Burris Logistics and Trinity to serve and support your cold chain all the way from production to delivery, and every step between.

FIND YOUR END-TO-END SOLUTION WITH BURRIS LOGISTICS GET A SHIPPING QUOTE FROM TRINITY LOGISTICSHow does the cold chain process differ from your typical supply chain? The cold chain is a variation of your standard supply chain. It involves the movement of refrigerated or frozen products from temperatures of two degrees Celsius (35 degrees Fahrenheit) all the way down to negative 70 degrees Celsius (158 degrees Fahrenheit). The cold chain involves industries such as food and beverage, pharmaceuticals, and chemicals.

WHAT IS THE COLD CHAIN PROCESS?

The cold chain process is a logistics management process for perishable products that need refrigerated temperatures to maintain quality and safety from end to end. It involves performing a chain of tasks to prepare, store, and transport products in the cold supply chain.

Logistical planning and management protect the integrity of cold chain shipments. This involves using proper packaging, proper transportation equipment, carefully chosen transportation routes, perfect timing, and visibility throughout to ensure that what’s expected is what happens. The cold chain process is best done by using technology and data at every point of the process.

WHY IS THE COLD CHAIN IMPORTANT?

The cold chain ensures perishable products are safe, of high quality, or potency at the point of consumption or use. Failure to keep those products at correct temperatures results in degradation, discoloring, bruising, or microbial growth. When you have quality cold chain products, you’ll have satisfied customers, meaning greater demand, and the protection of public health.

Additionally, cold chain providers contribute a great deal to the economy and workforce. According to GCCA, approximately $6.1 billion is generated by the refrigerated warehousing industry annually. Not to mention, the North American refrigerated warehousing industry employs more than 62,774 people annually on a full-time basis, with 92 percent being permanent employees versus contract or temporary.

WHAT ARE THE MAIN ELEMENTS IN THE COLD CHAIN?

Storage

The cold chain starts with the storage of the product at a refrigerated facility. If manufacturers of cold chain products don’t have storage equipment needed to keep their products regulated, they’ll have to outsource their cold chain operations to a partner who can provide the proper equipment.

Common cold storage equipment and facilities include refrigerated containers, cold rooms, chillers, cold boxes, blast freezers, and vaccine carriers.

Packaging

Temperature-controlled products need correct packaging to maintain their quality. Proper packaging helps reduce the risk of product contamination and ensures energy-efficient storage along the cold chain.

The most common refrigerants used in packaging are dry ice, gel packs, gel bricks, phase change material (PCM), and EPS panels (expanded polystyrene or Styrofoam).

Monitoring

Tracking certain information for specific cold chain products is a necessity. This includes temperatures and other environmental parameters, like humidity levels. Without monitoring, suboptimal conditions can happen and damage the quality of the product.

Cold chain monitoring often refers to the use of the Internet of Things (IoT) or other sensor software. These monitoring systems can detect temperature problems, keep track of all cold chain products on one platform, and improve predictive maintenance through the integration of sensor data with supply chain management software, like a transportation management system (TMS).

Delivery

Cold chain management also involves the delivery of shipments. Delivery is based upon the end-user consumers’ preferred methods for receiving cold deliveries.

WHY IS AN EFFICIENT COLD CHAIN PROCESS IMPORTANT?

Unlike shipping non-perishable products such as furniture, interruptions in the cold chain can result in damage to the quality of the product, making it unusable. An efficient cold chain process uses monitoring and reduces the amount of handling from end to end.

The cold chain industry has standardized temperature zones classified to maintain the quality of products. These classifications are:

Banana

Bananas and other tropical fruits like oranges, pineapples, or even potatoes have a temperature range of 12 degrees to 14 degrees Celsius (53 to 57 degrees Fahrenheit). This helps control ripening during transport.

Pharmaceutical

Most pharmaceutical products need temperatures between two and eight degrees Celsius (35 to 46 degrees Fahrenheit).

Chill

This classification is between two and four degrees Celsius (35 to 39 degrees Fahrenheit) for many other fruits, vegetables, and fresh meat.

Frozen

This temperature range is between minus 10 to minus 20 degrees Celsius (50 to 68 degrees Fahrenheit) for frozen meat, cakes, and bread.

Deep Frozen

Seafood, ice cream, and other frozen foods need colder temperatures at minus 25 to minus 30 degrees Celsius (minus 77 to minus 86 degrees Fahrenheit).

Ultra-Low

This is a new and growing temperature range often for pharmaceutical products that need temperatures reaching minus 70 degrees Celsius (minus 158 degrees Fahrenheit), like certain vaccines.

WHAT ARE SOME INDUSTRIES THAT USE COLD CHAIN?

Food and Beverage

Controlled temperatures are needed for transporting food and beverage products such as milk, produce, or meat. Interruptions in the cold chain can lead to spoilage or bacteria or mold growth. As mentioned above, many fruits like bananas ripen during their shipment.

Pharmaceutical

Many pharmaceutical products need temperature control. This includes products like vaccines, medication, or biologicals, like blood or plasma. Spoilage of these products can mean a loss in efficacy and can become a public health hazard if not caught.

Chemical

Temperature control is critical when it comes to some hazardous chemicals. Specifically, ones that can be susceptible to reactions due to heat release. If heat escapes from a chemical good that requires it to remain at a certain temperature, it can cause a spark, flame, or explosion to occur, not only damaging the product but potentially harming others.

Oil and Gas

This sector uses explosion-proof refrigerated containers on oil rigs, oil tankers, and offshore locations.

Military

The U.S. military must control the temperature of its medical supplies, which often travel long, hard-to-reach areas. Because of this, the cold chain process can become more complicated when handling products for the military.

WORK WITH AN EXPERIENCED PROVIDER

Not all temperature-controlled products are the same. Each product is unique and requires specialized solutions throughout the cold chain. Many cold chain manufacturers are turning to third-party logistics companies (3PLs) to handle their complex challenges in the cold chain process. For your cold chain to be successful, you need to be sure to work with a provider who understands your industry, regulations, and product requirements.

Luckily, you don’t have to look very far to find one. Here at Trinity, we have more than 40 years of experience in specialized industries such as cold chain.

Contact us today to find your customized logistics solution for your cold chain process.

REQUEST A QUOTEAuthor: Christine Morris

Interruptions to the cold chain create problems such as spoilage, changes in the appearance, taste, or smell of a product, growth of harmful bacteria, or lost potency. Preventing any interruption of the cold chain is one of the main responsibilities of a logistics manager. Let’s look at some of the significant cold chain challenges you may have to face, and how you can keep issues at bay.

REGULATIONS

Regulations for the cold chain are ever-changing and complex, which is why they are one of the major challenges faced today. If your cold chain is worldwide, it can be more complicated as there is no one entity to regulate on a global scale. Each region has its own regulations, compliance mandates, and enforcement agencies. Some examples of these are:

U.S. Food and Drug Administration (FDA)

In the U.S., the federal regulatory agency for food and pharmaceuticals is the FDA.

Most cold chain food regulations come from the FDA’s Food Safety Modernization Act (FSMA) of 2017. This regulation covers the cleanliness and function of equipment, protocols set in place for transportation, employee training on the proper handling of food in cold chains, and records of all FSMA compliance.

When it comes to pharmaceutical products, many regulations affect the cold chain. Some of those include:

- 21 CFR 203.32

- Addresses the need for maintaining drugs under stable conditions and meeting manufacturer’s specifications.

- 21 CFR 211.150

- Provides guidance on the written procedures for managing expirations and a reliable system for identifying the distribution of drug samples in the event of a recall.

- 21 CFR 203.36

- Outlines the responsibilities of manufacturers and authorized distributors.

- 21 CFR 205.50

- Minimum requirements for storage and handling of prescription drugs and maintenance of distribution records

Canadian Food and Drugs Act

In Canada, the regulatory authority is the Government of Canada. The Canadian Food and Drugs Act was passed in 1920 and revised in 1985. It regards the production, import, export, and transport across provinces for food, drugs, and cosmetics including products like soap and toothpaste. It ensures products are safe, ingredients disclosed, and drugs are effective.

International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH)

Many other countries, refer to ICH guidelines gathering data on a product’s safety and efficacy to establish a cold chain strategy. ICH brings together many regulatory authorities to discuss data and establish those guidelines. Gathered data is used to consider the duration of temperature excursions that can occur across distribution channels.

Regulations can be complex and demanding at times, but they all have the same goals of retaining the safety, quality, transparency, and efficacy of cold chain commodities. The biggest key to keeping compliance with cold chain regulations is increasing end-to-end visibility in your cold chain. Keeping proper documentation of data throughout your supply chain can seem difficult but modern technology like a transportation management system (TMS), can simplify this cold chain challenge. Current technology applications like GPS tracking, ELD data, Internet of Things (IoT), and a TMS can give you advanced analytics and reporting that would otherwise be comprised of manual processes. Not only does technology offer you savings in time but of human error as many processes become automated.

SUSTAINABILITY

Another significant cold chain challenge is the increasing spotlight on sustainability. The distribution and transportation of temperature-controlled products have shown to be major causes of greenhouse gas emissions. In comparison to other supply chain transportation, cold chain transport consumes 20 percent more fuel than other heavy vehicle types due to the refrigeration equipment. The biggest issue facing sustainability is the high-power consumption or combustion of fossil fuels necessary to power the cold chain’s cooling systems.

There are also growing issues and increasing regulations on refrigerant gases used in cooling systems like hydrofluorocarbons (HFCs) as they are responsible for high greenhouse gas emissions. In 2015, the European Union set strict limits on the production and sale of high global warming potential HFC refrigerants. In the U.S., the Manufacturing Act of 2019 was passed which established a timeline of phasing down the use of HFCs by 2036.

Because of the increasing pressure of sustainability and its regulations enacted on the cold chain, many large food and pharmaceutical companies have plans in place to reduce their carbon emissions. In 2015, more than 150 businesses in the U.S. signed the Business Act on Climate Pledge which launched for private sector businesses to express their support on international action on climate change. Also, in 2015, the Paris Agreement was created, signed by 195 countries at the United Nations climate change summit. This agreement aims to reduce greenhouse gas emissions to prevent the planet from warming by more than 2 degrees Celsius.

Being sustainable in the cold chain is also something you can be recognized for now with awards such as the Supply & Demand Chain Executive Green Supply Chain Award or the Council of Supply Chain Management Professionals’ Supply Chain Sustainability Award. Some ways to consider in adding sustainability to your cold chain is improving your cold chain management to reduce waste and your carbon footprint or considering alternative transportation modes like intermodal versus truckload when shipping your products. While you’re working on improving sustainability in your cold chain, make sure the providers you work with are equally interested in sustainability as well. Here at Trinity, we are proud of our sustainability efforts and to be recognized as a SDCE Green Supply Chain Award winner and as a Food Logistics’ Top Green Provider.

TEMPERATURE VARIANCES

It’s one of the biggest and most common cold chain challenges: maintaining the required temperature of the product throughout the entire supply chain. Any temperature that is higher than the set temperature can affect a product’s quality. Not all products that get exposed to a temperature past their threshold will spoil right away, as it depends on how steep and frequent the exposure was. Once a product has begun to thaw, it is considered contaminated. Depending on the product and temperature, that window of time can be very short. There are many times during cold chain in which a product can be exposed to a temperature variance: during unloading and loading of the product, from poor packaging, handling, or broken equipment.

Loading and Unloading

As your product moves through the cold chain, it can get exposed to temperatures outside its set temp. Whenever loading and unloading your product, handling should be as quick as possible. Preventing prolonged exposure to temperature changes prevents having problems with quality.

Poor packaging or handling

There are many different ways to package your cold chain freight so it can keep its cool. If it’s not done right or in mind of your transit time, your goods can spoil before arrival. When handled poorly, they can become damaged, causing lost product.

Equipment problems

One way the cold chain can be interrupted is when your equipment breaks down. Refrigeration equipment can malfunction due to damage, inadequate maintenance, or losing power.

In cold storage, doors becoming damaged are one of the common challenges they face. When cold storage doors become damaged, they can’t maintain their specified temperatures.

Due to inadequate maintenance, there can be a buildup of condensation in coolers and freezers, causing slippery surfaces and unsafe conditions for workers, as well as a spoiled product. Another maintenance challenge is handling the growth of mold or mildew, which can happen with poorly maintained temperatures. Should this happen, the freezer will need to be cleaned thoroughly and inspected for any problems.

Transportation Breaks Down

Vehicles can break down at any time. Any hold-up in your cold chain shipment could mean more than just a time delay, it can mean a spoiled product. Make sure you’re working with a qualified carrier who inspects their truck or other modes of freight before the journey begins.

Keeping track of the temperature throughout your cold chain is another way to combat having your products exposed to changes in temperature. Temperature monitoring systems are quickly replacing any manual processes of collecting temperature information, saving time, and preventing spoiled products. This also allows cold chain managers insight into their problem areas and being able to fix them.

Some of these temperature monitoring systems are RFID or wireless sensor network, thermal imaging, and temperature loggers. RFID or other wireless sensor networks are the most common in the cold chain. These sensors capture the location and temperature, communicating the information back to a database and allowing parameters like an estimated shelf life to be calculated. You’ll often find these in warehousing and cold storage. Thermal imaging is exactly what you think it is; imaging that is taken showing the different temperatures of everything in the photo. Thermal imaging uses a sensor to convert the radiation given off at different temperatures into a visible light picture. This is also often used in warehousing and cold storage. Lastly, temperature loggers are another type of sensor placed next to cargo in transportation. They can be set to record as frequently as every second, minute, or hour. Once removed, they can be plugged into a computer so the temperature data can be transferred and analyzed.

TEMPERATURE-CONTROLLED SHIPPING CAPACITY

Another significant cold chain challenge is available capacity. Capacity is always a challenge for any industry, but even more so for the cold chain, especially right now. With freight in high demand across all industries and capacity slim, drivers can pick and choose what shipments they want to take based on (already) high rates. Reefer trailers are already limited with the increased demand on cold chain, but when rates for moving other high-demand commodities such as lumber or retail keep increasing, those drivers can choose to utilize their reefer trailer as a dry van to haul should those rates be better paying, further reducing cold chain capacity. Cold storage warehousing is seeing the strain as well because of the growing freight demand. More storage space is needed in the supply chain and new buildings are being built, but those currently in production or needing their building supplies (which are also in high demand), puts yet another strain on shipping capacity until that demand has decreased. With the cold chain demand increasing and available equipment and drivers doing quite the opposite, can the logistics sector keep up? Read more in our current whitepaper.

DON’T LET THE COLD CHAIN SCARE YOU

There is a lot of juggling to do when managing the cold chain. If even one ball is dropped, it can affect the whole cold chain. You can prepare as best as you can for these cold chain challenges, but sometimes it’s nice to know you have backup when you need it most.

Luckily here at Trinity, we’re experts in complex situations. In fact, I would say it’s our specialty. We’ve seen every possible problem there could be and are happy to help. By working with Trinity, you can gain access to the data you need to improve your performance and output, find equipment and capacity when you’re finding it difficult, and work with someone who understands current regulations, no matter the region or type of commodity you work with. We’re here to have your back regardless of what cold chain challenge comes your way.

Simplify your cold chain challenges.Not ready to request a quote? Subscribe to our YouTube channel and watch our latest State of the Industry and Freight Market Update videos to stay on top of what’s going on in cold chain.

Author: Christine Morris

If you haven’t already noticed, cold chain logistics is currently a hot topic. The demand for fresh products and quality supply chain processes are at an all-time high. Recognizing these trends in cold chain and taking action will help you fulfill your customer’s needs. Let’s look at five trends going on in the cold chain industry.

1. An Increased Demand on Quality Products

Big trends in cold chain, specifically the food industry, has been the demand for fresher and higher-quality products. Consumers want their peaches to be juicier and their avocados to be riper. To satisfy the customers’ wants, you need to make sure the carrier that is shipping your product is well versed in cold chain management. They need to know how to avoid changes in the texture and taste of the produce when a shipment fluctuates beyond the required temperature. The focus on quality products means that refrigerated warehouses will need to maintain temperature zones.

Quality products don’t stop at fresh food. With the COVID-19 vaccine being administered, people want to make sure that what they’re getting injected into their bodies is safe. In addition, the amount of biological drugs and gene therapies is growing. Because of this, logistics companies are also widening their capacity for temperature-controlled transportation to meet the demand.

As we’ve stated in our Shipping Pharmaceuticals blog, cold chain logistics play significant role in the pharmaceutical supply chain. Manufacturers of these vaccines and medications need the cold chain to run smoothly to prevent any damage to the expensive drugs. Pharmaceuticals also need to arrive as good as new because medicine that has sat in incorrect temperatures for an extended period can be ineffective or detrimental to a patient’s health.

2. The Global Cold Chain Market is Booming

A recent report by Grand View Research shows that the global cold chain market size is expected to grow 14.8 percent from 2021 to 2028. Many nations have recognized a rising need to avoid food waste and loss of healthcare products due to spoilage. Moreover, the demand for fresher products is on the rise. Nations such as China and India are boosting their global cold chain efforts to meet the demand for their exports. International trade liberalization has also boosted the use of cold chain, globally. Because it is the global cold chain is rising, manufacturers need to become more specialized in their products so they can ship their goods to a wider variety of customers across the globe.

3. Stronger Regulations

Another trend in the cold chain has been stricter regulations on shipped products. Both globalization and the recent rise of food and pharma counterfeit incidences have caused production and cold chain rules to be reevaluated. The beginning of these rules started with the Food and Drug Administration’s Food Safety Modernization Act. This act requires anyone in the food supply chain to document every step of the process. Certain products like fruit must be traced all the way back to the point of origin.

Being proactive with these firm rules and regulations has also been a common trend across cold chain logistics. Manufacturers are strengthening their processes in-house to help mitigate any issues with their cold chain. Safety should be a top priority for the manufacturer when shipping through cold chain.

4. Innovative Packaging

Specialized packaging has been a trending topic in the cold chain industry. Whether it be for pharmaceuticals or food and beverages, manufacturers have been more specific on how they want their products packaged.

For pharmaceutical companies, there has been a conflict between packaging and transportation costs. For smaller shipments moving through the supply chain, a company can choose either a 24, 48, or 72-hour packaging that will protect the products from becoming ineffective. The more insulated the packaging is, the higher the cost. Globalization is also a major factor in this dilemma. If the U.S. ships cold chain products like pharmaceuticals overseas, it is imperative that the carrier knows to re-ice the shipment if any delays occur.

Companies that specialize in temperature-controlled packaging are making single-use or reusable packaging for all your cold chain needs. There are new refrigerated shipping systems that don’t require gel coolants, and they weigh much less than typical cold chain packages. These systems use evaporative, reactive cooling technology that responds and adjusts to fluctuating temperatures.

Whether it be significant innovations such as evaporative cooling technology or something as simple as adding handles and straps to your packaging, traditional packaging is starting to become a thing of the past. Companies are trying to gain that competitive advantage of being the most innovative packaging company for your cold chain needs.

5. Outsourcing to a Third-Party Logistics Company

Another demand in the cold chain has been for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the transportation of their products. That is why a 3PL provides a wide range of technology services to promote transparency within the supply chain.

Consumers today are becoming more conscientious about their needs. No one wants to settle for spoiled milk or ineffective pharmaceuticals. It is imperative that manufacturers stay up to date on these current trends in the cold chain in order to satisfy their customers. Doing research and staying in the know are both imperative ways for your business to be successful. Being proactive and listening to what customers want is the best way to stay on top in the cold chain industry.

Interested in learning more about Trinity’s experience in cold chain?

Speak With an expertFrozen food is considered one of the safest forms of food preservation because the freezing temperatures prevent harmful bacteria. This doesn’t necessarily mean that frozen food is foolproof. Several situations that could cause your frozen food to go bad and ways to prevent them from happening. If you’re new to shipping frozen food, or you’re a seasoned veteran staying up to date with the ever-changing world of cold chain logistics, here are a few things to keep in mind that can impact your company’s bottom line.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

Improper Packaging

Improper packaging is the most common mistake in frozen food shipping. It may also be the most involved part of your process. Multiple layers of packaging and ensuring an airtight seal to eliminate any heat or humidity penetration is critical. Your packaging’s inner layer should be waterproof to prevent any leakage from melting refrigerant causing damage to your outer packaging.

The person responsible for packaging your frozen food should have a strong understanding of dry ice and how to store it in proper containers. Although it a great source for cold chain packaging, it could be detrimental to your shipment if misused. If dry ice is packaged in an airtight container, there could be a pressure build up and cause that entire container to burst.

Package your frozen food with the proper amount of dry ice or frozen gel packs to prevent temperature fluctuations from happening. You should also ensure that you have the proper sized box to store your products. Too large with extra space means your goods could become damaged in the process of moving.

To prevent improper packaging, ensure that you have full knowledge of the temperatures required for that shipment and what type of insulation you want to use. Partnering with a 3PL that works with vetted carriers that have a strong understanding of how to transport frozen food will also save your shipment from spoiling or getting damaged.

Underestimating Shipping Times

When you underestimate shipment times, the result could impact your bottom line. If your product arrives to its destination melted or spoiled, you’ll end up with rejected products. This means money lost.

Plan your frozen food shipments ahead and research estimated transit times so you can pack enough coolant material. This will also provide insight on which refrigerant choice would work better for that shipment. One to two blocks of dry ice will last between 18-36 hours in a small Styrofoam shipping container. In a larger shipping container, dry ice can last between two to three days. It’s never a bad idea to make sure you have enough refrigerant packed so that it could last an extra day or two should your shipment have some unforeseen delay. Communicate the estimated transit time with your third-party logistics provider to ensure that the carrier shipping your frozen food has all the necessary information.

Not Properly Recording Information

Keep record of every detail about your shipment. This is paramount to staying compliant with the Food Safety Modernization Act (FSMA) and proving that your business has done everything possible to prevent the spread of foodborne illness. This includes the proper labeling of packaging, any providers used, and temperature records from before, during, and after transit.

The FDA Food Safety Modernization Act (FSMA) is transforming the nation’s food safety system into one that is based on the prevention of foodborne illnesses. Our team stays updated on these regulations and have processes in place to stay compliant.

Not Using a Qualified Provider

Maintaining the correct temperatures when shipping frozen food means maintaining its quality. You should make sure you choose a provider who is experienced with your frozen food product. Don’t make the mistake in trying to lower shipping costs by shipping mixed temperature goods together, which if not done properly, can compromise their quality and result in rejection of your product. Shipping mixed loads can be done, but you need to make sure it’s with a provider that has trucks with separate compartments capable of holding different temperatures, and the experience to handle it.

Finding and building a relationship with a qualified, experienced carrier to haul your frozen food products can be a long and time-consuming process. At Trinity, we have a network of over 70,000 qualified carrier relationships to help you.

Why not choose to save some time?

Request a QuoteIf you find it difficult to juggle multiple providers for your cold chain logistics, there’s a better, even seamless, way of doing business. Cold chain logistics can be difficult to manage and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. Often you may find yourself with many providers and contacts to sort through. What if you could reduce all your cold chain logistics companies down to one? What if you could replace the rest by finding one with a range of modes for your cold chain freight, including warehousing, transportation management, and more? Sound too good to be true? Keep reading.

RISKS OF MULTIPLE PROVIDERS

When you ship and manage temperature-controlled freight, you often find yourself working with more than one logistics provider. This means there can be more handling, which can become a cause for safety concerns.

Manual processes in the transportation of cold chain freight can cause decreased visibility along your freight’s journey. The majority exists within the food industry due to the Food Safety Modernization Act (FSMA). Because of this, shippers need to practice diligence when selecting and vetting the carriers they choose move their freight. They must make sure to communicate responsibilities such as required temperature requirements, having access to temperature readings, and making sure equipment is inspected before moving.

When you work with more than one carrier the process becomes more complicated. Each one adds complexity to your cold chain and every handling adds risk. Take time to map out your supply chain end-to-end, identify gaps, simplify your processes, and reduce the number of providers that move your freight. This can reduce your cold chain safety risks.

Shipping temperature-sensitive items? Check out our Temperature Shipping Guide.

HOW WORKING WITH TRINITY CAN BENEFIT YOUR COLD CHAIN

This is where partnering with Trinity Logistics can help. As a Burris Logistics Company, we’re uniquely qualified to arrange solutions across your entire cold chain. Working with us means you can feel at ease knowing your cold chain products are well taken care of during transportation. Stop searching for and working with multiple cold chain logistics companies. We vet every carrier in our network, reducing your risk and time spent finding providers. Some of the benefits of working with one 3PL include:

…INCREASED FLEXIBILITY

The ability to be flexible and quickly adapt to change is important for your cold chain business to stay competitive. When you partner with Trinity it gives you that flexibility of having a whole network of vetted, qualified carriers at the ready. And because we’re under the Burris Logistics umbrella, should you need other logistics solutions outside of our range, we can still support you by working with Burris to arrange those cold chain solutions that fit. We can help you stay flexible as one sole provider, instead of working with several.

…REDUCED WASTE

When you work with only one cold chain logistics provider, you can reduce your waste. At Trinity, you’ll build a relationship with a logistics expert. We can help you reduce supply chain inefficiencies through transportation management or reduce emissions by finding better routes. We can help you use trucks efficiently, such as reducing deadhead miles or suggesting intermodal when it makes sense.

…SAVE MONEY

When you work with a cold chain logistics company, such as Trinity Logistics, you can save money. With more flexibility, increased efficiencies, and reduced waste, you’ll be able to use your money better and reduce your logistics costs. By working with one provider instead of several, you’ll save time in billing and invoices. We provide a Team of dedicated, knowledgeable, and flexible experts, bringing you increased productivity and workflows within your logistics. Working with a provider such as Trinity, is a great way to cut costs without losing quality, time, or deadline requirements when it comes to your freight management and transportation.

WORKING WITH A COMPANY LIKE TRINITY, A BURRIS LOGISTICS COMPANY

When choosing to work with Trinity Logistics, you’re choosing to cut complexity. Cold chain logistics is complicated in itself and trying to do it alone can be frustrating. Choose to reduce your frustration with cold chain logistics companies by choosing the right one.

With Trinity, you’ll gain end-to-end supply chain management. Trinity is one part of the Burris Logistics umbrella, so working with us offers you access to other Burris options such as cold storage or direct-to-consumer fulfillment should you need it.

With Trinity and Burris combined, you’ll gain a greater level of flexibility in your cold chain with customized solutions. You’ll have a greater level of agility in your logistics execution while reducing cost. Since we focus on how you operate as a shipper, we make sure we fit your mold and help to solve your problems, not the other way around. You can count on Trinity Logistics to be able to serve and support your cold chain all the way from production to delivery.

Simplify your cold chain logistics today.

REQUEST A QUOTENeed more info?

WATCH OUR COLD CHAIN WEBINARRoses are red. Violets are blue. How do flowers get delivered in perfect condition to you? With Valentine’s Day approaching, the surge of flower orders and deliveries is increasing. The process of shipping flowers from nurseries to florists requires time sensitivity and attention to detail. With the Day of Love nearly here, let’s dive into the cold chain logistics in flower delivery.

The Import of Flowers

While running to the florist to pick up a dozen roses is a simple task, the process to get those roses to the United States wasn’t so simple. Most flowers sold in the U.S. come from abroad. California is the main domestic flower producer in the U.S., but it only accounts for a small percentage of the flowers sold here. Flowers that end up in our grocery stores primarily come from South America, Africa, and Europe.

The journey that flowers take to the U.S. is a long one. Experience in cold chain is necessary for the carriers that haul this delicate freight. Flowers must be maintained in the proper environment for quality purposes. Healthy, beautiful flowers won’t survive their long journey without a proper cold chain solution.

From Field to Florist