It’s a simple fact. People can’t survive without food. When times are tough, we can certainly make sacrifices in other parts of our lives, like our online shopping habits or a remodel we wanted, but not food. This makes food manufacturing a reliable and even diverse industry to run a business in. Yet, it doesn’t come without its own set of unique challenges, especially with its logistics.

Today, the demand for fast and reliable shipping is higher than ever. Food and beverage companies need to meet the rising pressure to provide quicker turnarounds and deliver their products at optimal freshness to stay competitive. With already complex supply chains, how can a company keep up? Not to mention, what if there’s an issue found or a delay? Don’t stress. We’ll cover logistics challenges that commonly hurt food manufacturing businesses and how working with a third-party logistics (3PL) company, like Trinity Logistics, can solve and simplify your processes for shipping food.

Common Shipping Challenges Faced by Food Manufacturing

Diversity in Scheduling Applications Introduces Challenges

One of the biggest headaches for food manufacturers is self-imposed. Each shipper or distributor could be using a different scheduling portal or application. Some even just use Excel spreadsheets. Because of this, scheduling conflicts and communication gaps are often seen when shipping food. This can be very frustrating to the logistics departments arranging the shipments.

Furthermore, the carriers they aim to work with may not know how to use the application or might not even have access to it. This inefficiency can cause issues with them scheduling their pickup or delivery appointments. It also can limit access to capacity, something that is truly needed for those requiring temperature control during peak produce season!

Plenty of Time-Sensitive Freight in Food Manufacturing – Beat Must Arrive by Dates

As previously mentioned, food manufacturers face a growing demand for products that are at peak freshness, especially for those needing temperature control. It’s not unusual for these time-sensitive shipments to be last-minute orders requiring immediate action. Some of these can come in just the day before or even the day before and need shipping right away. Sometimes to help manage the influx of shipments, freight can be assigned with a “Must Arrive by Date” (MABD). This can put pressure on food manufacturers, and missed delivery windows can result in costly penalties. These fees, called chargebacks, usually get pushed back onto the customer and impact your bottom line and service.

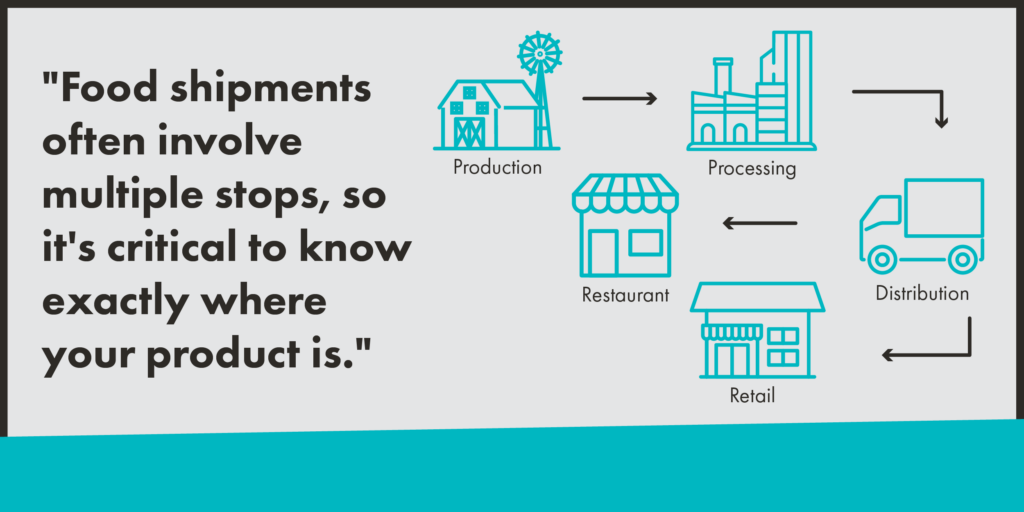

Identify Visibility Gaps When Shipping Food

With many time-sensitive and temperature-control requirements, it’s important for food manufacturers to have complete visibility into their shipments. Food shipments often involve multiple stops, so it’s critical to understand where your product is and when it’s expected to arrive. Even though it is valuable, many food manufacturers find they have limited visibility of their shipments. This creates a lot of uncertainty, causing additional gaps in communication and possible delays or disruptions. Most importantly, it can jeopardize the safety of your food product, an important piece to meet the Food Safety Modernization Act (FSMA) regulation.

Keeping Food Shipping Logistics Budget in Control

Carrier selection for shipping food products can be a puzzle for food manufacturers to figure out. On one hand, you want to work with high-quality carriers to ensure your food products arrive at peak freshness. On the other hand, they cost more. One certainly wants to budget and find balance. Look to pay too little, and you may not find the quality service your products need. Finding that balance between the two can be difficult.

Market trends can also cause unexpected price fluctuations, further challenging their logistics budget. This can really hurt those needing to meet peak freshness as it’s not like they can’t ship their products as they may perish. Instead, they’ve got to adjust and pay the current price.

Food manufacturers must be creative and find solutions to keep their costs down but their quality up. They can consider other transportation modes as options to manage costs, but understanding which one makes the most sense for their product can be overwhelming.

Embracing Sustainability in Food Shipping

Sustainability is on everyone’s minds, including consumers. With global food and beverage production causing roughly 34 percent of greenhouse gas emissions, consumers are holding food manufacturing companies to higher standards. They’re researching more about the companies they purchase food products from. They want to know what positive practices they implement, such as sustainable fishing, the use of ecological pesticides, reforesting, fair trade, or the use of compostable packaging.

TRINITY Logistics SOLVEs Food Shipping PROBLEMS

With over 45 years of serving customized logistics solutions to thousands of food manufacturers, we’re fairly confident in our ability to help you overcome any of these challenges.

We Speak Your Food Shipping Scheduling Language

We’re in tune with most if not all, scheduling portals that food and beverage shippers use. You don’t have to worry about training us! Yes, we could even say we know how to navigate those scheduling apps “with our eyes closed.” Even if we have a newer Team Member who is unfamiliar with it, we can guarantee that at least one of our 400+ Team Members or 135+ Authorized Agents know it and can assist.

Time-Sensitive Titans: We Deliver Your Food Products When It Matters Most

At Trinity Logistics, we understand the urgency of time-sensitive food deliveries. Our Team excels in handling quick turnarounds, making us the “emergency room” for your time-critical freight. We are acutely aware of the potential repercussions of missed deliveries and leverage our strong carrier relationships to secure the capacity you need. These established partnerships allow for better planning and ensure that carriers are familiar with the specific needs of food commodities, pickup, and delivery locations.

Furthermore, in the unfortunate event that fees do arise due to carrier issues, Trinity acts as your advocate. We hold our carriers accountable and ensure that any associated charges are passed along to the responsible party. Our meticulous investigation process guarantees that only the root cause of the problem bears the financial burden.

Expand the View into Your Food Shipments

We’re champions of end-to-end visibility, great communication, and transparency because we know you deserve it. Our commitment to People-Centric service isn’t just our slogan; it’s our philosophy.

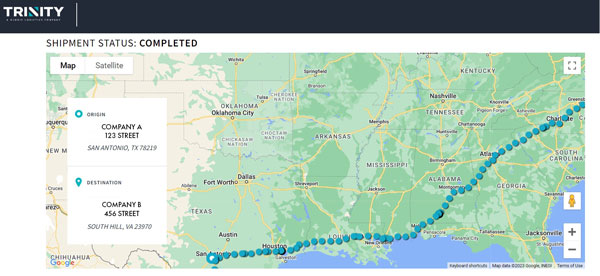

We leverage a combination of cutting-edge technology and a dedicated Team Member to keep you informed every step of the way. Use our Customer Portal to see real-time tracking of your shipments. If you’re looking for even more transparency, there’s our Managed Transportation service, offering you a customized Transportation Management System (TMS) solution that works for your business. Between our technology and our Team Members, you’ll find this proactive approach ensures you’re not left in the dark until delivery.

Find Balance in Your Logistics Budget

Starting out, our established carrier relationships not only gain you access to capacity but to leverage our competitive rates. Additionally, we have multiple modes to choose from and our Experts can help you explore which one suits your product and budget.

Now, we understand balance isn’t easy to obtain, so that’s why Trinity Logistics goes a step further in our service to help you find it. For those food manufacturers that build a shipping history with us, we’re able to review your data and conduct a comprehensive review of your logistics. This will give you a clearer insight into your logistics to find room for improvement. We won’t come empty-handed, either. We’ll make recommendations to add efficiencies and see if we’re on the right track for your company’s success.

Adding Sustainability into Your Logistics

We understand the importance of sustainability and are committed to helping you implement it throughout your supply chain. This includes connecting you with carriers that prioritize eco-friendly practices, finding sustainable shipping options, and exploring carbon offsetting programs. If you need further proof, Trinity currently holds a bronze medal rating by EcoVadis, the world’s largest and most trusted provider of sustainability ratings.

Learn more about Trinity's sustainability initiativesBonus Benefit for Food Manufacturers! Trinity’s Relationship with Honor Foods

As a Burris Logistics Company, we have a direct relationship with Honor Foods. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They have access to thousands of reputable brands and can simplify your purchasing process. Honor specializes in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers. Speed up your lead times and increase profitability with no extra storage space needed. Working with Trinity and Honor, you can get the best of both Burris Logistics brands and gain additional success in your business.

Operating in food manufacturing can be complex, but it doesn’t have to be. Try Trinity Logistics for your shipping and see just how easy it can be.

Discover how Trinity exceptionally serves those in food and beverage Get a quote to see if our solutions are right for your businessThere are some common misconceptions out there about less-than-truckload (LTL) shipping. If you fall victim to any of these LTL shipping myths, you could end up thinking this mode isn’t for your freight. Or worse, spending extra time or money that you could have saved with your LTL shipping.

Here are some of the most popular misunderstandings about LTL shipping and why they’re simply not true.

LTL SHIPPING IS DIFFICULT

Many companies actually find this mode of shipping to be the most flexible and easy to book. As long as you’re working with a quality LTL carrier or third-party logistics (3PL) provider, you’ll find that LTL shipping can be one of the easier modes of transportation to work with.

LTL SHIPPING RATES ARE NON-NEGOTIABLE

Some believe that there’s no room for negotiation when it comes to rates for this mode. In reality, you can negotiate your LTL shipping rates but you’ll need a solid relationship with your carrier to see any benefit. You can also negotiate outside of peak shipping season when companies are more likely to offer lower rates. When you choose to work with Trinity for your LTL, you can trust that our experts negotiate on your behalf to get you the best rate for your specific shipping needs.

ALL LTL ACCESSORIAL FEES ARE THE SAME

In reality, accessorial charges in LTL shipping can fluctuate between carriers by as much as 50 percent.

To determine the accessorial fees charged by a specific carrier, you can look at their rules tariff. This will give you a breakdown of all the accessorials they charge. Some of the most common accessorial charges include liftgates, residential delivery, hazardous material fees, and limited access charges.

One reason these charges vary between carriers is whether they calculate the fee based on cents-per-hundred-pounds or by a flat rate. They can also vary based on different pricing agreements or contracts already in place.

“I’VE BEEN SHIPPING THE SAME FREIGHT FOR YEARS, AND MY CLASS HAS NEVER CHANGED, SO I DON’T HAVE TO WORRY ABOUT IT CHANGING IN THE FUTURE.”

It’s important to always double-check to confirm your freight class hasn’t changed. The National Motor Freight Classification (NMFC) board meets twice a year and revises the freight classes for dozens of different commodities, so there’s always a chance that your freight class could change without warning.

Even if you’ve never had issues with re-classifications in the past, LTL carriers remain strict about having accurate classifications on the bill-of-lading (BOL). Carriers often equip their drivers with tape measures and scanning devices to determine dimensions and double-check your freight’s class.

LTL SHIPPING TIMES ARE GUARANTEED

Unless specified as guaranteed, LTL shipping times are estimates. Due to LTL’s flexible service offerings, carriers cannot truly guarantee specific times.

This means both your pick-up and delivery times are never guaranteed (unless specified). Even with a specified guarantee, there can sometimes be a delay or missed window.

The good news is that you can receive tracking notifications from the carrier, so you know once they have picked up. The same goes for your delivery. You’ll receive an estimated delivery date but should be able to track and trace through your provider and receive any notifications if there’s a delay.

You can check with your LTL carrier or provider if they can offer guaranteed LTL shipping as an additional service – meaning there’s an extra charge for this. In this case, it’s imperative that you list the delivery time clearly on the BOL.

A guaranteed delivery time only takes effect once the shipment is picked up from the shipper’s address, and delays in pick-up will not be factored into that time. Transit time does not include the day of pickup or weekends and holidays. It’s also good to note that added requirements at the delivery location, like delivery appointments, can also void the guarantee.

TEMPERATURE-CONTROLLED SHIPMENTS CAN’T GO WITH LTL SHIPPING

Many businesses assume that freight like produce or ice cream can’t ship via LTL because of their need for temperature control. LTL’s flexibility often gets overlooked. With refrigerated LTL, your temperature-controlled freight will be on the same truck as another customer’s freight that needs a similar temperature range. While there are a limited number of LTL providers that can offer this service, it isn’t true that you can’t use LTL for your temperature-controlled shipments. Refrigerated LTL can be a great way to ship any temperature-controlled goods without having to pay full truckload prices.

WORKING WITH A 3PL FOR LTL SHIPPING ISN’T WORTH IT

This is the common misconception we come across when it comes to LTL shipping. Many companies don’t realize all the benefits that come with using a 3PL for their LTL.

Working with a 3PL like Trinity Logistics gives you the competitive edge of working with an expert in LTL who has a network of strong and trustworthy carrier relationships. What does this mean for you?

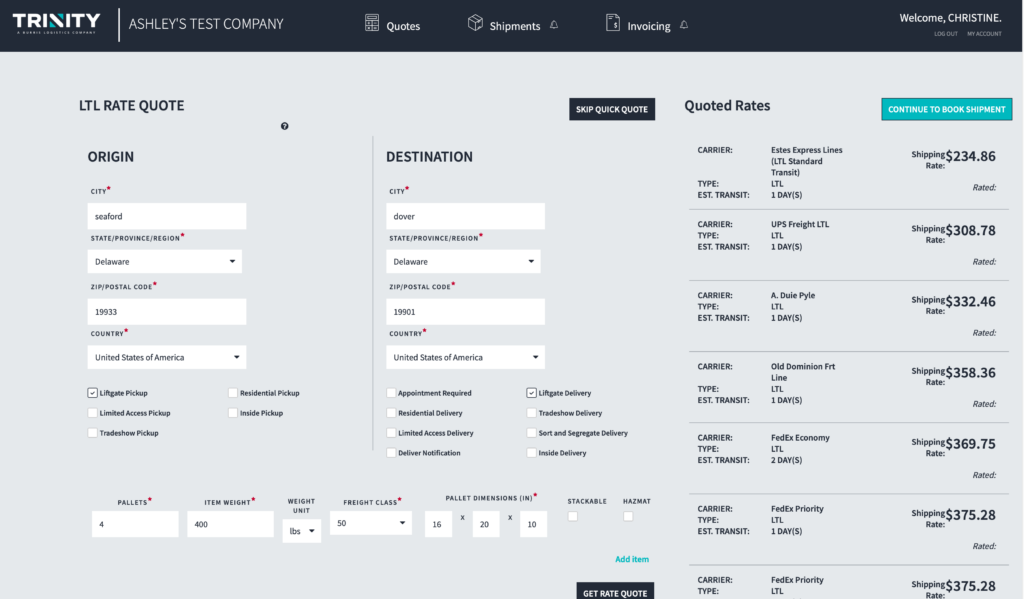

Getting LTL shipping quotes and booking shipments with quality LTL carriers is even easier. Especially through Trinity’s Customer Portal, with our LTL Quick Quote feature available. You’ll also have full transparency over your shipment’s transit.

And if your freight is temperature-controlled? No problem. We can help you with any refrigerated LTL shipments.

Additionally, through our relationships with both large and small LTL carriers, we’re able to negotiate accessorial charges and LTL shipping fees to get you the best service at an ideal rate.

Keep in mind, too, that LTL shipping is about more than just rates. If you experience any service failures or frequent lapses in communication with your current LTL provider, switching to a best-in-class 3PL with top-notch People-Centric service such as ours can save you time and money, even if the rates are the same as before.

See how Trinity Logistics can offer you a better LTL shipping solution.

DISCOVER TRINITY'S LTL SERVICE SEE HOW TRINITY HELPED MW SUPPLY WITH THEIR LTL SHIPPINGTrinity Logistics, a Burris Logistics company, is proud to share that Food Logistics has named the company as a recipient of the 2022 Top 3PL & Cold Storage Providers Award.

Food Logistics is the only publication exclusively dedicated to covering the movement of products and information through the cold food and beverage supply chain. The Top 3PL & Cold Storage Providers list recognizes leading third-party logistics and cold storage providers in the food and beverage industry. Companies on the list play a pivotal role in keeping the food and beverage industry’s products stored, transported, and stocked while maintaining the product’s quality.

“These past 18 months have been so challenging for U.S. supply chains. It’s the continuous bottlenecks that require fleets to re-tool and pivot accordingly. But it’s the drivers, the fleet, the warehouses, and software/technologies that really keep today’s supply chains in line,” says Marina Mayer, Editor-in-Chief of Food Logistics and Supply & Demand Chain Executive. “These 3PLs and cold storage providers have collaborated on all facets of their operations to achieve full visibility, complete forecasting, end-to-end leverage, and the ultimate in sustainability. Now is the time to honor and celebrate those companies making magic happen behind the frontlines.”

Trinity works with thousands of shippers in the food and beverage industry, making the company well-versed in its requirements and regulations. Equipped with state of industry technology and with Burris Logistics, one of the top cold storage providers in North America, as its parent company, Trinity provides exceptional service to those in the cold chain.

“We are honored to be named a Top 3PL & Cold Storage Provider, and very fortunate to be part of the Burris Logistics family,” said Mark Peterson, SVP of Sales at Trinity Logistics. “Having a parent company with 90+ years of cold storage & food distribution experience gives us a distinct advantage. From the 3PL viewpoint, our focus is on optimizing the efficiency of our distribution network. The pillars of that effort are gathering and analyzing the right data; clear and consistent communication with our partners; and the highly educated and motivated team of professionals at Trinity Logistics.”

The full list of 2022’s Top 3PL & Cold Storage Providers will appear in Food Logistics’ August issues, as well as online at www.FoodLogistics.com.

Learn how Trinity supports food and beverage companies.About Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 40 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized on Transport Topics’ Top 100 Freight Brokerage List, a Top 3PL and Cold Storage Provider by Food Logistics, and a Top Company for Women to Work for in Transportation by Women in Trucking.

With cold chain logistics, every product that you deal with has very specific temperature requirements that you need to adhere to. These products are ending up on tables across the entire country, so you want to make your product arrives precisely the way it needs to be so it’s safe for human consumption. Because of this, cold chain logistics can be challenging to manage, and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. It would undoubtedly be helpful to find one provider that could offer you end-to-end cold chain management, from production to delivery. And that’s what we’re here to talk about today. Burris Logistics and Trinity Logistics working together could be the solutions you’ve been looking for to simplify your cold chain management. Keep reading to find out how we work better together to serve your complete cold chain.

BURRIS LOGISTICS CAPABILITIES

Let’s start with Burris Logistics. What do they offer that can enable cold chain shippers and their businesses to thrive in the face of its complexities?

Quick Background

Burris Logistics has been around for 96 years. The company started as a produce hauler from southern Delmarva to Philadelphia. They quickly grew and expanded into the frozen food business and found their purpose as a driven food logistics provider. Today, they own 14 cold storage sites up and down the east coast and out into Midwest. Burris Logistics currently has a family of brands including Burris PRW Plus, Honor Foods, and Trinity Logistics.

Burris Logistics offers you logistics technology solutions that never sleep. With a Technology Team of over 100 Team Members, they work around the clock to provide you with technology resources designed to meet your specific needs.

From a Burris asset standpoint, they’re able to track all their trailers with ELD and reefer tracking, with the ability to ping the tractor and trailers to see where each of their assets are in real time. In addition, they have access to technology that can start and stop the units, reset them, or check temps on them, no matter the distance. With the complexities of cold chain transit and the current driver shortage, Burris works hard to put in place any technology that can make a driver’s job easier. They want to cut any obstacles drivers may face on the road while having any data be transparent to help both them and ultimately, any customers.

Burris also has technology for their cold storage warehouses. They focus on providing their customers with freshness, clarity, and visibility. They offer real-time monitoring and any differentiation from setpoints gets recorded. They make sure to get real-time data to those who need it should meaningful decisions need action, and have secondary and tertiary backups available.

Some of their other logistics technology offered are:

· Warehouse management system software

· Enterprise resource management

· Produce inspection tool

· External integrations

· Supply chain portal

· Demand planning

· Order status

· Delivery status

Burris Logistics works with you to create the best possible warehousing and distribution solutions. They’ll support you with a network of strategically located warehouses, 96 years of expertise, and a solution customized for your unique needs.

In a reflection of national trends, the newest and fastest-growing business line within Burris Logistics is their direct-to-consumer to support those in the cold chain e-commerce space. Through current resources and expertise in temperature-controlled logistics, Burris can deliver a premier frozen fulfillment network with cutting-edge technology, thought leadership, and warehouses across the country. Burris’s knowledge of shipping supplies, coolant technology, and two-day parcel shipping capability ensures quality is delivered with every package.

Facility Design is the process of considering new construction via greenfield facility sites or the re-purposing of an existing operation. Many companies are facing changing business needs, including the need for multi-channel execution. This makes the ability to scale up and scale down with various capabilities an essential part of planning. With partners who increase their dependency on Burris Logistics, they’ve been able to scale their operations to accommodate their programs with new locations, modifications to existing assets, and technology to keep the supply chain efficient.

Your customers desire the right products, in place, at the right time. Honor Foods, a Burris Logistics company understands how important it is to have on-menu and on-shelf products available while also minimizing food waste. They can help you plan inbound and outbound freight, using logistics technology and their warehouses to maintain food quality and safety.

With one of their other brands, Honor Foods, Burris offers Private Label In-house brands that have developed into trusted names amongst food service operators. These products undergo scrutinous selection and quality assurance knowing that our restaurant partners only accept the best. Your customers want what is trending, and Burris can help you meet this demand. Their brands come sourced from trusted shippers and can be a noticeable cost saving for you.

Burris Logistics understands that products need different environments, which is why their facilities can provide different temperatures and humidity, depending on your product. Newer warehouses are purposefully being built with ambient/dry storage space to accommodate increased partner needs. Additionally, their warehouses and distribution centers are in strategic locations near major transportation hubs and ports, making it easy to get your freight on the move quickly.

TRINITY LOGISTICS CAPABILITIES

Quick Background

Trinity Logistics has been around for over 40 years. The company was started by the Banning family in Cambridge, Maryland. Throughout the years, the company grew and expanded as a non-asset-based third-party logistics company (3PL) and was acquired by Burris in 2019. The two companies saw similarities in company culture and future goals, deciding to unite for greater opportunities and offer more supply chain solutions for our customers.

Burris + Trinity = Better TogetherURRIS

What’s great for Trinity being part of the Burris Logistics family of brands is being able to offer more help to Burris customers. Trinity’s support helps Burris better assist some of the existing freight business they have for customers either coming back into their buildings or going to other places.

The addition of Trinity also offers Burris customers a wider variety of options in modes and technology, or even help outside of the cold chain. Trinity is very experienced in heavy haul moves or more complicated hazardous moves for the chemical industry. So, no matter the size of your company or freight, we have a solution for you. But, we’re here to talk about the cold chain, so let’s focus on refrigerated and frozen freight.

While it’s not always hard to find a refrigerated carrier, you do want to be selective. There are a lot of carriers out there, but Trinity has a robust vetting process in place. We make sure carriers hauling your freight have the right amount of insurance, requirements, and experience. In addition, we make sure these drivers are representing Burris and Trinity the way we need to and that our customers are getting their products delivered safely.

You might ask, how do we guarantee safety with our carrier network? Well, these carriers mean as much to us as our shipper customers do, so we build just as strong carrier relationships. We offer our carriers many different kinds of technologies for location tracking, temperature tracking, and so on. We make sure to continue to evolve our technology solutions to keep the shipping process easy and safe for both carriers and customers. Additionally, we have our communication. Our communication is one of our strongest assets to ensure both parties have their needs and solutions met. Our bottom line is bringing value and if we can do that, we’ll be successful.

We offer and use several different technologies like Macropoint or Fourkites, so we can ping shipments and know exactly where they are and what the temperature of the product is, giving our customers instant access to look at their freight. That’s just one piece of the technology puzzle.

Even with the technology available, we never lose contact with our customers. We strive to stay very People-Centric. Our technology only helps make it easier for our customers to view information, especially with our Customer Portal, giving them the ability to trace loads without having to reach out. It gives them access to see updates at any time of day and offers backend access to their invoices to answer billing questions, make payments online, or provide them with a breakdown of what each load costs, lumper fees, accessorials, or pallet exchanges. Our Customer Portal allows you to manage that piece of business on your own time and at your own speed. We’ll always be available, but the Portal and any of our technologies are there to bring you even more value and efficiency.

Current logistics technology available:

· Carrier Portal

· My Carrier Packet

· TriumphPay

· FourKites

· Trucker Tools

· MacroPoint

· Customer Portal

· Customized Transportation Management Solutions

· Banyan LTL

· DAT Book Now

· Trucker Tools Book It Now

WAREHOUSING

We know that one size does not fit all when it comes to warehousing. That’s why we have warehouse providers with locations across the nation to allow you to scale your business at your own pace, plus our cold storage solutions with Burris Logistics. Our growing network supports reliable service and premier dry, refrigerated, or frozen solutions so you can focus on what you do best.

TRUCKLOAD

Our truckload service provides you with the means to get your freight moving quickly. Truckload is faster than traditional LTL or intermodal shipments which means your shipments can arrive on time and on schedule.

LESS-THAN-TRUCKLOAD (LTL)

Our LTL service provides you with the means to get your freight hauled through a range of options. By leveraging our volume and extensive network of LTL carriers, we can provide you with lower rates for LTL shipments consisting of 1-10 pallets of either dry or temperature-controlled products.

INTERMODAL

You can add value to your supply chain by using this cost and environmentally-friendly shipping option. By shipping intermodal, you’ll reduce your carbon footprint and have reliable and consistent capacity when over-the-road capacity can be tight.

EXPEDITED

Sometimes your freight is time-sensitive or needs less handling. When this happens, we can arrange over-the-road or air-expedited shipping. We’ll make sure your freight arrives on time and without stopping at terminals in between.

DRAYAGE

Your freight can be delivered from the port or rail right to your door, or from your door to the port or rail. Either way, we’ll save you money in the process. From servicing imports and exports, returning empty or full containers, helping you avoid unnecessary fees, long drayage options, or more, our Team is ready to help.

INTERNATIONAL

Arranging international shipments can be tricky and requires a lot of communication. If you are looking for help with arranging your Full Container Load, Less Than Container Load, door-to-door, or port-to-port services, we can help. We’ll be your intermediary with freight forwarders to arrange your air and ocean freight international shipments.

MANAGED SERVICES

In this service, we combine our experienced account management and best-in-class transportation management technology to deliver you a customized solution that helps your company achieve its unique supply chain goals.

HOW WE CAN SERVE YOUR COLD CHAIN BETTER TOGETHER

Experience in Cold Chain

For many reasons, Burris Logistics and Trinity work well together for cold chain shippers. First off is our combined years of experience. There are certain things in cold chain you can only learn from the experience of working with temperature-controlled shipments. For example, things like picking and loading fresh produce, understanding what those temperatures are and what they need to be for storage and transit, and keeping track of those temperatures. Or understanding how to move ice cream from the West Coast and knowing that you can’t go over the mountains; that you must travel around them so as not to cause shrinkage. By having years of experience and understanding of those complex situations and small details that make or break a cold chain shipment, you can trust your temperature-controlled freight is handled safely and correctly with Burris and Trinity.

Technology

Between both Burris and Trinity, we have incredible logistics technology available, but what differentiates us from others is that we keep in mind that logistics is still a “people” business. Technology will always be a tool for our Teams to use and bring logistics solutions to other people who need them. Therefore, we try to stay away from technology just for technology’s sake and make sure what we use and offer is always a valuable solution.

Communication

Because of our years of experience, we are well-versed and experienced in many different situations. We know when and how to pivot quickly and keep business moving forward. When issues arise, we work until they are resolved and keep open communication every step of the way. Having a solid relationship with experts like Burris and Trinity will prove to be your largest asset no matter what supply chain bottlenecks you may face

Flexible, Customized Solutions

Because our two businesses offer many options while keeping business People-Centric, it means you can find a solution that’s customized for your growing business and needs and your solution can be flexible. We know the cold chain and solutions aren’t static, they are ever-changing, so you need a provider that can keep up. By working with Burris and Trinity, you’ll never have to worry about changing up your logistics plan as we’re readily equipped to accommodate any changes you may need. In addition, we can help you stay flexible as one sole provider instead of working with several.

Visibility and End-to-End Cold Chain Management

As the cold chain sector continues to grow, there’s been a growing demand for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the logistics of their temperature-controlled freight. Working with Burris and Trinity can not only give you a wide range of technology to gain visibility and provide you with all the logistics services you may need, thus making your cold chain efficient and transparent. We’ll provide you with dedicated, knowledgeable experts, increased productivity and workflows, and reduced complexity by working with Burris Logistics and their family of brands instead of several different providers.

HAVE YOUR COLD CHAIN LOGISTICS TAKEN CARE OF, END-TO-END

Between Trinity and Burris, we have a substantial Team with a lot of experience in cold chain and knowledge about its potential pitfalls. As a result, we’ve created processes and different services so that we get it right the first time, every time we handle a cold chain shipment.

You can find value in our combined companies’ sizes and services offered. Cold chain logistics can be complicated and trying to do it all alone can be frustrating. That’s why we’re here to help you simplify it. You can count on Burris Logistics and Trinity to serve and support your cold chain all the way from production to delivery, and every step between.

FIND YOUR END-TO-END SOLUTION WITH BURRIS LOGISTICS GET A SHIPPING QUOTE FROM TRINITY LOGISTICSHow does the cold chain process differ from your typical supply chain? The cold chain is a variation of your standard supply chain. It involves the movement of refrigerated or frozen products from temperatures of two degrees Celsius (35 degrees Fahrenheit) all the way down to negative 70 degrees Celsius (158 degrees Fahrenheit). The cold chain involves industries such as food and beverage, pharmaceuticals, and chemicals.

WHAT IS THE COLD CHAIN PROCESS?

The cold chain process is a logistics management process for perishable products that need refrigerated temperatures to maintain quality and safety from end to end. It involves performing a chain of tasks to prepare, store, and transport products in the cold supply chain.

Logistical planning and management protect the integrity of cold chain shipments. This involves using proper packaging, proper transportation equipment, carefully chosen transportation routes, perfect timing, and visibility throughout to ensure that what’s expected is what happens. The cold chain process is best done by using technology and data at every point of the process.

WHY IS THE COLD CHAIN IMPORTANT?

The cold chain ensures perishable products are safe, of high quality, or potency at the point of consumption or use. Failure to keep those products at correct temperatures results in degradation, discoloring, bruising, or microbial growth. When you have quality cold chain products, you’ll have satisfied customers, meaning greater demand, and the protection of public health.

Additionally, cold chain providers contribute a great deal to the economy and workforce. According to GCCA, approximately $6.1 billion is generated by the refrigerated warehousing industry annually. Not to mention, the North American refrigerated warehousing industry employs more than 62,774 people annually on a full-time basis, with 92 percent being permanent employees versus contract or temporary.

WHAT ARE THE MAIN ELEMENTS IN THE COLD CHAIN?

Storage

The cold chain starts with the storage of the product at a refrigerated facility. If manufacturers of cold chain products don’t have storage equipment needed to keep their products regulated, they’ll have to outsource their cold chain operations to a partner who can provide the proper equipment.

Common cold storage equipment and facilities include refrigerated containers, cold rooms, chillers, cold boxes, blast freezers, and vaccine carriers.

Packaging

Temperature-controlled products need correct packaging to maintain their quality. Proper packaging helps reduce the risk of product contamination and ensures energy-efficient storage along the cold chain.

The most common refrigerants used in packaging are dry ice, gel packs, gel bricks, phase change material (PCM), and EPS panels (expanded polystyrene or Styrofoam).

Monitoring

Tracking certain information for specific cold chain products is a necessity. This includes temperatures and other environmental parameters, like humidity levels. Without monitoring, suboptimal conditions can happen and damage the quality of the product.

Cold chain monitoring often refers to the use of the Internet of Things (IoT) or other sensor software. These monitoring systems can detect temperature problems, keep track of all cold chain products on one platform, and improve predictive maintenance through the integration of sensor data with supply chain management software, like a transportation management system (TMS).

Delivery

Cold chain management also involves the delivery of shipments. Delivery is based upon the end-user consumers’ preferred methods for receiving cold deliveries.

WHY IS AN EFFICIENT COLD CHAIN PROCESS IMPORTANT?

Unlike shipping non-perishable products such as furniture, interruptions in the cold chain can result in damage to the quality of the product, making it unusable. An efficient cold chain process uses monitoring and reduces the amount of handling from end to end.

The cold chain industry has standardized temperature zones classified to maintain the quality of products. These classifications are:

Banana

Bananas and other tropical fruits like oranges, pineapples, or even potatoes have a temperature range of 12 degrees to 14 degrees Celsius (53 to 57 degrees Fahrenheit). This helps control ripening during transport.

Pharmaceutical

Most pharmaceutical products need temperatures between two and eight degrees Celsius (35 to 46 degrees Fahrenheit).

Chill

This classification is between two and four degrees Celsius (35 to 39 degrees Fahrenheit) for many other fruits, vegetables, and fresh meat.

Frozen

This temperature range is between minus 10 to minus 20 degrees Celsius (50 to 68 degrees Fahrenheit) for frozen meat, cakes, and bread.

Deep Frozen

Seafood, ice cream, and other frozen foods need colder temperatures at minus 25 to minus 30 degrees Celsius (minus 77 to minus 86 degrees Fahrenheit).

Ultra-Low

This is a new and growing temperature range often for pharmaceutical products that need temperatures reaching minus 70 degrees Celsius (minus 158 degrees Fahrenheit), like certain vaccines.

WHAT ARE SOME INDUSTRIES THAT USE COLD CHAIN?

Food and Beverage

Controlled temperatures are needed for transporting food and beverage products such as milk, produce, or meat. Interruptions in the cold chain can lead to spoilage or bacteria or mold growth. As mentioned above, many fruits like bananas ripen during their shipment.

Pharmaceutical

Many pharmaceutical products need temperature control. This includes products like vaccines, medication, or biologicals, like blood or plasma. Spoilage of these products can mean a loss in efficacy and can become a public health hazard if not caught.

Chemical

Temperature control is critical when it comes to some hazardous chemicals. Specifically, ones that can be susceptible to reactions due to heat release. If heat escapes from a chemical good that requires it to remain at a certain temperature, it can cause a spark, flame, or explosion to occur, not only damaging the product but potentially harming others.

Oil and Gas

This sector uses explosion-proof refrigerated containers on oil rigs, oil tankers, and offshore locations.

Military

The U.S. military must control the temperature of its medical supplies, which often travel long, hard-to-reach areas. Because of this, the cold chain process can become more complicated when handling products for the military.

WORK WITH AN EXPERIENCED PROVIDER

Not all temperature-controlled products are the same. Each product is unique and requires specialized solutions throughout the cold chain. Many cold chain manufacturers are turning to third-party logistics companies (3PLs) to handle their complex challenges in the cold chain process. For your cold chain to be successful, you need to be sure to work with a provider who understands your industry, regulations, and product requirements.

Luckily, you don’t have to look very far to find one. Here at Trinity, we have more than 40 years of experience in specialized industries such as cold chain.

Contact us today to find your customized logistics solution for your cold chain process.

REQUEST A QUOTEAuthor: Christine Morris