Trinity Logistics, a leading third-party logistics provider (3PL), is thrilled to share that its Technology Team has been recognized as one of the Top 10 Technology Teams by OnConferences. This prestigious award honors organizations that have demonstrated exceptional innovation, technical expertise, and a commitment to delivering leading solutions.

Trinity’s Technology Team plays a vital role in supporting the company’s operations and delivering exceptional service to its clients. The Team is responsible for developing and implementing cutting-edge technology solutions that enhance efficiency, improve customer service, and drive growth.

“The Trinity Technology Team continues to deliver innovative solutions driving business outcomes and effectively supporting our Team Members,” said Russ Felker, Chief Technology Officer at Trinity Logistics. “From cybersecurity to integrations to data availability to custom development, they consistently provide exemplary service and support for Team Trinity and its partners.”

OnConferences is a leading provider of educational conferences and networking opportunities for professionals across many industries. Its Top 10 Technology Teams award is determined through peer and community voting. Voters are instructed to select teams that they have seen make a significant impact on their own organization or within the broader industry, contribute to their professional community through thought leadership, drive innovation, and demonstrate exceptional leadership.

Trinity’s Technology Team and their dedication to excellence, innovative practices, and leadership have set them apart as a top-performing team. The Team has made remarkable achievements like a full migration to the cloud in only eight months, multiple new customer and vendor integrations, improved and differentiated functionality within Trinity’s custom Transportation Management System (TMS), and increased data availability for Team Members and the company’s Agent partners. These accomplishments helped them stand out from the rest of the submissions, distinguishing them as an outstanding Team.

Trinity Logistics is committed to investing in purposeful technology and great talent to ensure its respected culture and exceptional service stay at the forefront of its continued success. As the company continues to grow and evolve, this recognition serves as a testament to that ongoing promise.

LEARN MORE ABOUT TRINITY LOGISTICS TECHNOLOGY VIEW THE FULL LIST OF WINNERSAbout Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

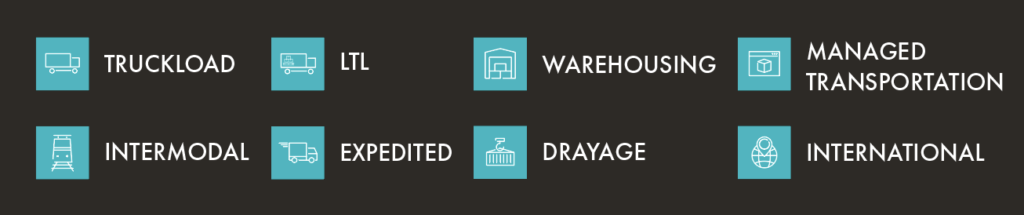

For the past 45 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized as a Top Freight Brokerage by Transport Topics, a Green Supply Chain Partner by Inbound Logistics, and a Top Company for Women to Work for in Transportation by the Women in Trucking Association.

About OnConferences

OnConferences is a leading organization that connects top professionals across various industries, promoting collaboration, innovation, and thought leadership. Through conferences, awards, and networking opportunities, OnConferences provides a platform for executives and organizations to exchange insights, fostering growth and development within their respective fields.

While many of us are soaking up the last of summer’s sun and fun, food manufacturing supply chains are readying for the upcoming holiday food rush.

Have you ever noticed a lot of our favorite memories are surrounded by food? When we go to celebrate something like a birthday, anniversary, or special achievement, it usually involves food. It’s no surprise then that over the holiday season, nearly 165 million consumers across the U.S. purchase food and beverages to celebrate, according to a study from Cornell. As the holidays soon approach, food consumption surges, with the average American indulging up to an extra 440 calories per serving!

The increased demand and tight holiday deadlines can present challenges for many food and beverage companies with their logistics. This is in addition to already facing a competitive peak shipping season! However, by understanding the dynamics of this unique period of time, shippers can ensure success is ahead of them. First, let’s dive into some fascinating facts and insights about food during the holiday season. Then, we’ll follow that with some essential tips so your company can be prepared for the holiday food rush!

Holiday Food Supply Timeline & Stats

The Holiday Food Surge Begins with Fall

The holiday food rush first begins with the arrival of fall flavors. Pumpkin spice, now seen as the quintessential flavor of fall, has seen a 47 percent increase in sales, as reported by The Guardian, within the past five years. In 2023 alone, Datassential reported 144 new limited-time offers that featured pumpkin on major restaurant menus. From the infamous Pumpkin Spice Lattes (PSLs) to pumpkin soups and ravioli, this flavor dominates the season. But we can’t forget another fall favorite – apple. Food and beverage items with caramel apple were one of the highest-indexing flavors last fall.

Halloween Signals Significant Holiday Food Consumption Increase

Halloween is a major milestone in the holiday food timeline, with 65 percent of consumers participating in the festivities. In fact, of all 172 million that celebrate the spooky season, 95 percent of them purchase candy. Even more staggering is that a quarter of all the candy sold annually comes from Halloween sales. It’s not all about the sweets, though! Pizza is the most popular dinner staple on All Hallow’s Eve, according to Grubhub. There’s also the annual tradition of carving a pumpkin, with Statista reporting roughly 154 million Americans partaking in the activity in 2023.

Dia de Los Muertos Celebrations Begin to Trend

Datassential reports that 10 percent of consumers in the U.S. report celebrating Dia de Los Muertos, or Day of the Dead. This holiday is gaining popularity, which means so are the celebratory foods associated with it! Pan de Muerto is one traditional sweet bread that’s essential to the celebration.

Thanksgiving Continues to Drive Food Supply Chain Demand

Thanksgiving remains the most popular fall holiday, with 83 percent of Americans celebrating the tradition. A whopping 46 million turkeys are consumed each year, according to the U.S. Department of Agriculture. Other top holiday staples include cranberry sauce, stuffing, green bean casserole, mashed potatoes, macaroni and cheese, sweet potatoes, and pumpkin and apple pies. That’s a lot of food to prepare for a meal, so 23 percent of consumers will buy a full, ready-made meal from a restaurant. Another 22 percent will supplement with some food from restaurants for part of their feasts.

Sweets, Candy & Chocolate Build Holiday Food Demand at Christmas & New Year’s

Leading up to Christmas, many enjoy hot cocoa, cookies, and other treats. 1.76 billion candy canes, a holiday staple, are made annually for this joyous time of the year. 70 percent of Americans make Christmas desserts, with frosted sugar cookies being the top ones consumed annually. Don’t forget the eggnog! 122 million pounds of it is poured and drunk each year.

When it comes to Christmas dinner, pork dishes are the most popular globally, but turkey still trumps all for the U.S. Other winter feast staples include roasted or mashed potatoes, roasted carrots, gravy, stuffing, shrimp, and lots of Christmas pudding, cookies, and pies. Sweet tooths rejoice as 83 percent of consumers fill stockings with treats like candy and chocolate.

Christmas and New Year’s are among the busiest holidays for restaurants. Both holidays also see a spike in alcohol consumption, with New Year’s Eve being the second most alcohol-associated holiday behind Mardi Gras. Champagne is the fan favorite for those ringing in the New Year.

Logistics & SHipping Tips for Holiday Food Shipping

The holiday season often brings those in logistics the gift of increased demand and decreased capacity. Like most Americans, truck drivers aim to be home for the holidays, trimming the number of available carriers down. Freight of all kinds can increase during the period, further cutting the number of trucks available. Shippers with more specialized requirements, like temperature control, can find even less capacity. Shippers also have tighter deadlines to meet at this time to make the most of the seasonal business.

Overall, the holiday season can be a time of heightened stress and disruption. Given these unique challenges, it’s crucial for food and beverage shippers to prepare thoroughly to appease customers.

Five Tips for the Best Holiday Food Shipping Logistics Outcomes

Tip 1: Keep Inventory Stocked

Running out of stock during the holiday season is a surefire way to lose customers. Track your inventory levels closely and replenish supplies early to ensure you’re well-stocked. By keeping orders moving consistently, you’ll be able to meet consumer demand and avoid causing any disappointment.

Tip 2: Have Backup Shipping Plans Ready

The chances of any disruptions or delays happening during this season are increased. Having backup shipping plans already prepared is essential to keep your goods moving.

Build relationships with multiple carriers and suppliers, or even a third-party logistics provider (3PL). This way, you’ll have known contacts ready in case you need any help.

Look at alternate modes of transportation and be prepared to quickly shift plans should something happen. Exploring multimodal options can be a great way to diversify risk, add capacity, and protect your freight budget. Having this flexibility available and ready can help you stay on track and your supply chain running smoothly.

Tip 3: Real-Time Visibility is Needed for Success

In today’s supply chains, having access to the visibility you need is crucial. You should either work with a provider that offers it or invest in your own technology, like a Transportation Management System (TMS).

A TMS can be very helpful during the holiday season. It can help you with routing decisions by matching your freight with the best carriers, lanes, and rates. In addition, it will allow you to optimize the in-house processes of your transportation network – which can be helpful during busy and slow seasons. By selecting the best carriers and optimizing your routes, you’ll not only increase your service but reduce your risk.

Using a TMS also gives you data-driven insights to better manage disruptions, reduce downtime, and budget your logistics spend. Data analytics can help you recognize which carriers are most likely to have the capacity, saving you time arranging your shipments.

Tip 4: Communication and Collaboration

Effective communication is key to a successful holiday season. Regularly communicate with all stakeholders, including suppliers, carriers, and customers. Collaborating with your partners during the seasonal planning phase can provide valuable insights and help you identify potential issues before they arise.

Tip 5: Partner with a 3PL

Working with a 3PL can be a game-changer during the holiday season. A 3PL offers access to a larger network of carriers, advanced technology, and expertise in managing complex logistics challenges. With their support, you can ensure your supply chain remains resilient, even in the face of unexpected disruptions.

Treat Yourself with Easier Logistics This Holiday Season

Navigating the holiday food rush can be overwhelming, and that’s why Trinity Logistics is here to be your guide. Like Santa, we’ve been around a while, with 45 years of experience handling logistics during holiday seasons.

Right away, you’ll gain access to our large network of vetted, quality carrier relationships to cover your shipments. But that’s just the start! There are many more benefits to working with Trinity, including:

- Multiple modes of transportation to find the best bang for your buck, support your business growth, or just have a backup plan ready

- Best-in-class technology and customized Managed Transportation solutions available, giving you the exact visibility and data you want

- 24/7/365 support, so no matter what day or time it is, you’ll have the help you need

One benefit that tends to shine above all else? Our exceptional People-Centric service. It’s the trait that makes Trinity different from other 3PLs and keeps our customers returning time and time again. It’s truly our care, compassion, and communication that you’ll notice and appreciate.

Everyone wants to enjoy the holiday season. Why not let Trinity focus on the logistics for your business, so you can go back to doing what you enjoy – helping consumers savor holiday treats and create memorable moments with your product.

Try out Trinity Logistics for Your Next Shipment Learn How Trinity Supports Food & Beverage Shippers Sample More of the Trinity Culture & Service – Join Our Mailing ListAre you a Freight Agent that stumbled across this article?

Freight Agents, Indulge in an Exceptional 3PL PartnerConsumers want more fruits and vegetables in their diets but produce shippers must face these common logistics challenges to keep up with their demand.

It’s hard to deny the nutritional value fruits and vegetables bring to our diets. It’s likely why there’s been substantial growth in consumer demand for produce over the past decade. While that’s great for businesses based in produce, there’s also greater pressure for produce shippers to deliver.

The journey from farm to table can be surprisingly complex for fruits and vegetables. Produce shippers face several hurdles that they need to overcome for their products to deliver fresh and meet the growing consumer demand. Let’s explore the intricacies of these difficulties and how they all can be taken care of by working with a third-party logistics (3PL) provider, like Trinity Logistics.

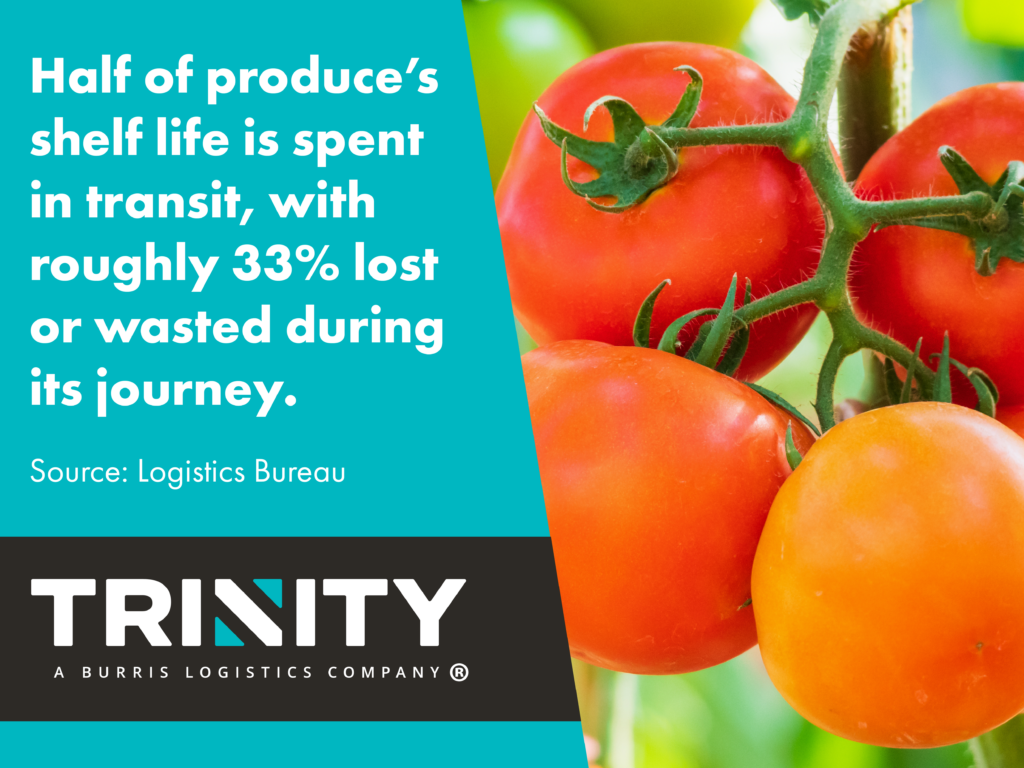

CHALLENGE 1: CHOOSING BEST TRANSPORTATION MODE

Produce shippers first face the challenge of determining what transportation mode to use for their shipments. With produce, half of its shelf life is spent in transit. It’s also reported that roughly 33 percent of produce is lost or wasted during its journey, according to the Logistics Bureau.

This is why produce shippers must ask themselves these questions to help determine the right transportation mode for their shipment.

What’s best for your product?

What can you afford?

How much time does your produce have?

Air is great for foods that have a very short shelf life and may need expedited shipping. However, air is often the most expensive of your options. Rail can offer you cost savings but requires more travel time, often two to three days. This option is often saved for produce with a longer shelf life. Lastly, there’s truckload shipping, which offers several shipping options and costs, depending on factors like whether you need a full truck, expedited shipping, or freight consolidation.

CHALLENGE 2: SELECTING THE RIGHT CARRIER PARTNER

The next challenge produce shippers need to tackle is choosing the right carrier to pick up and deliver their shipment. This may be the most crucial task of all because the carrier you choose can make or break your shipment. You need to trust the carrier you choose has experience in handling your specific cargo and meeting food safety regulations, especially for those that need temperature control.

CHALLENGE 3: MAINTAINING FRESHNESS/QUALITY

Maintaining freshness is one of the primary logistics challenges for produce shippers. Millions of dollars are wasted each year on produce that didn’t maintain freshness by delivery.

Produce begins to deteriorate the moment it’s harvested, so the risk of decomposition is equal to, or perhaps even greater, to produce shippers than those of theft or delay. Fresh or frozen produce needs to be stored and transported at specific temperatures to ensure its quality when bought and eaten by the consumer. Even the amount of humidity, light, or kind of packaging can affect a produce product, so produce shippers face this challenge in every segment of their shipping.

Every kind of produce also has different needs. Some need very specific environments to maintain freshness. Others can stay at room temperature or take on more handling. Shelf life is also something to consider. Produce with short shelf lives will need quick transit from farm to store. This also means several kinds of produce often can’t ship together. Since there is no one-size-fits-all process for produce, it’s important for produce shippers and their logistics partners to understand what’s needed for the specific product to deliver at peak quality.

CHALLENGE 4: SHIPMENT VISIBILITY

Tracking and shipment visibility is essential for produce shippers to be able to reduce risk. Without a clear look into your shipments, you’re left in the dark and uncertain whether your product will arrive on time or in acceptable condition.

This can challenge more than just produce shippers, but all stakeholders in a company’s supply chain. Miscommunication can happen between retailers and sellers as well, causing miscalculations in capacity planning or undependable forecasts. Real-time visibility and data are absolutely needed for produce shippers to enhance transparency with their business partners and gain more control over their supply chains.

CHALLENGE 5: REGULATIONS

Navigating regulations is a huge challenge for produce shippers. Failure to meet those regulations can lead to severe and often costly consequences. For example, in the U.S., produce shippers must comply with the Food Safety Modernization Act (FSMA), which entails specific guidelines for food safety.

There are also quality standards and labeling requirements to be met. The U.S. Department of Agriculture (USDA) has a strict grading system to determine the quality of produce, considering its size, shape, color, and defects.

CHALLENGE 6: HANDLING ANY CLAIMS

There’s always a risk for claims in shipping, but claims can happen more often for produce shippers compared to other industries, due to its shorter shelf life. The majority of claims we see in produce shipping are the result of spoilage, which can happen for many different reasons.

Handling claims for produce is slightly more difficult due to the Perishable Agricultural Commodities Act (PACA). When handling produce claims, it’s important you and your transportation provider understand and follow PACA.

HOW TRINITY LOGISTICS HELPS PRODUCE SHIPPERS OVERCOME THEIR CHALLENGES

All those challenges listed above that you may face – we know how and are prepared to handle them.

After 45 years of serving shippers in the food and beverage industry, we’re experts in its logistics requirements and regulations. We also take part in industry organizations, like the International Fresh Produce Association, so we stay knowledgeable about what may affect produce shippers.

When it comes to choosing your transportation mode, we have a multitude of options available to support you, whether you’re looking for help with one shipment or a fully outsourced logistics solution.

Additionally, we work with trusted carrier relationships that have been fully vetted to ensure your product travels safely and delivers on time. This includes vetting that reefer equipment is not older than 2012 and a temp-reading or download can be made readily available for any refrigerated or frozen produce shipments.

No matter where your freight is in its journey, we provide you with several real-time tracking options to stay fully informed. Through our Managed Transportation service and the use of a transportation management system (TMS), you can find more visibility and data to improve your supply chain processes and communication.

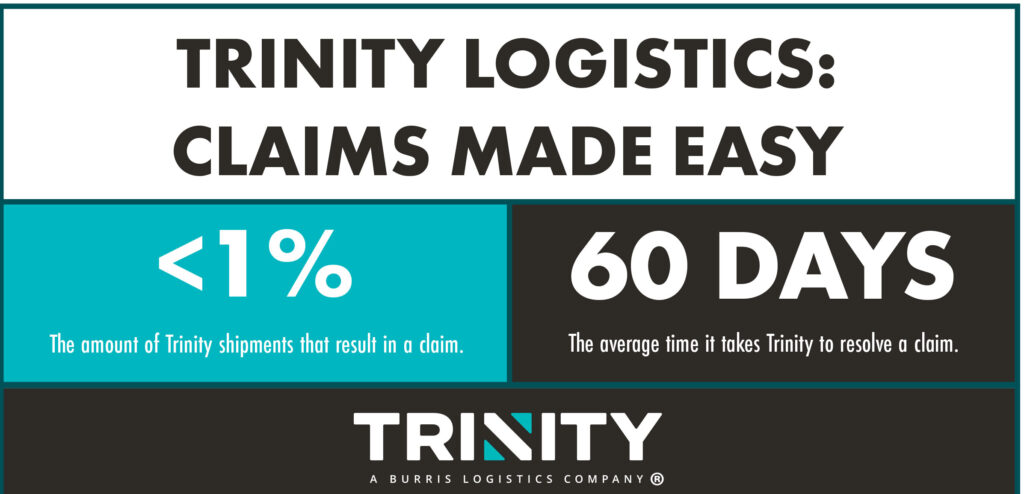

And then there are claims. While we wish every situation could go smoothly, there can still be mishaps. Even so, we’re proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. That’s likely because we work with shippers and receivers to monitor load and unload times, checking to ensure trailer doors are not left open, causing temperatures to fluctuate outside of any required ranges.

Now, fear not, because if something does happen, we’re able to help with that too. We have an in-house expert Claims Team to help negotiate any produce claims on your behalf, with an average rate of 60 days in resolving cargo claims.

By working with Trinity Logistics for your produce shipments, you’ll also gain an extra benefit – experiencing our acclaimed People-Centric service. It’s what our customers praise the most about our services and keeps them returning to Trinity Logistics for their logistics needs.

If you’re tired of tackling these produce shipping challenges alone, it may be time to get connected and join the thousands of shippers that choose to make their logistics easy with Trinity Logistics. You won’t be-leaf our exceptional service until you try it!

Get Out of Your Produce Shipping Pickle

Check Out Trinity's Solutions Request a Free Shipping QuoteOptimizing your logistics can make all the difference in your business’s bottom line. However, to fully understand your logistics processes you need to look at your logistics analytics.

To start, you’ll need access to the right technology. One such piece of technology is a transportation management system (TMS). A TMS is an excellent investment and according to Logistics Management Magazine, has been shown to reduce transportation costs by up to 30 percent.

Not interested in reading? Find out these priceless tips on improving your logistics processes.

To get the most out of a TMS and your logistics, you’ve got to know what you should be watching. All the data a TMS provides can be overwhelming and the possibilities of what you could analyze are endless. Ultimately, sifting through that data can be complex and time-consuming. So, to make things easier for you, our Team of TMS experts found the top 5 reports you should be running so you can see your best return on investment (ROI).

Get started with a demo of Trinity's TMSTOP 5 LOGISTICS REPORTS YOU NEED

Getting the data you need for a good overview of your logistics processes doesn’t need to be complicated. These reports should give you a broad view of logistics analytics to help you reach your KPIs.

Freight Accruals

Freight accruals is a report used to keep track of the costs associated with transporting your goods to a customer. These costs begin accruing from the moment the goods deliver, and they get discharged once a freight invoice is paid.

Tracking freight accruals allows your company to calculate your true net revenue at any given time. As a result, you’ll gain a better insight into any outstanding balances accumulated during a specific timeframe, whenever you may need it.

Cost Allocation

A cost allocation report breaks down your freight charges by a mile, pound, or SKU.

For any multi-stop loads, or loads made up of many POs, freight charges can be allocated to each order based on the percentage of distance, weight, or quantity the individual order contributed to the whole. Therefore, tracking your cost allocations will give your company a better look into the true cost of transporting your goods. You can then use this report to identify your most costly SKUs or lanes.

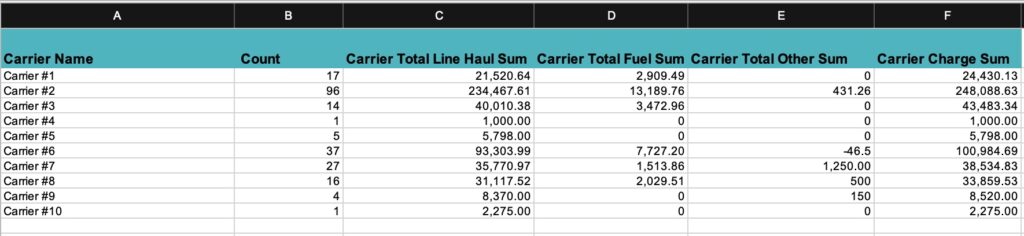

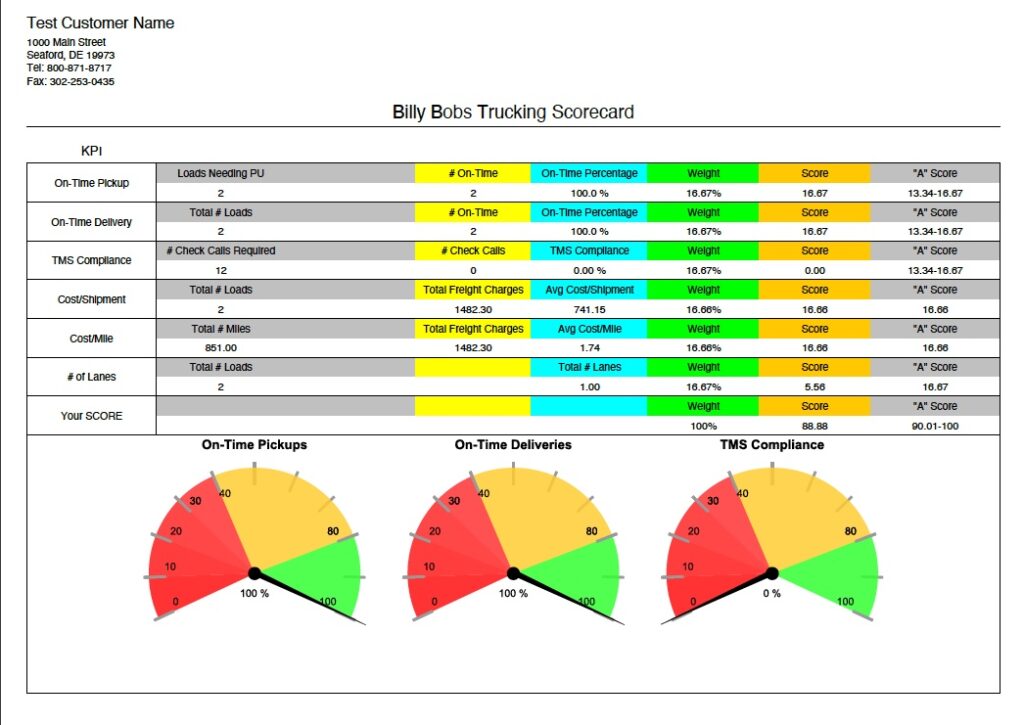

Carrier Scorecard

Carrier scorecard reporting helps you track a carrier’s performance. This will show data such as tender acceptance, on-time pickups, and on-time deliveries.

A carrier scorecard report can help you find which carriers are meeting your transportation needs and which are causing extra work. For example, carriers who bid low on a request-for-proposal (RFP), proceed to decline tenders, or provide poor service can cost your company. Without knowing how your selected motor carriers are doing, you could be facing thousands of dollars in extra expenses or, worse yet, lose customers.

By tracking your carriers’ performance, you can reevaluate your routing guide by selecting more reliable carriers on trouble lanes, improving both your costs and customer service. Additionally, this can help you set solid KPIs with your relationship carriers so you can better communicate your needs.

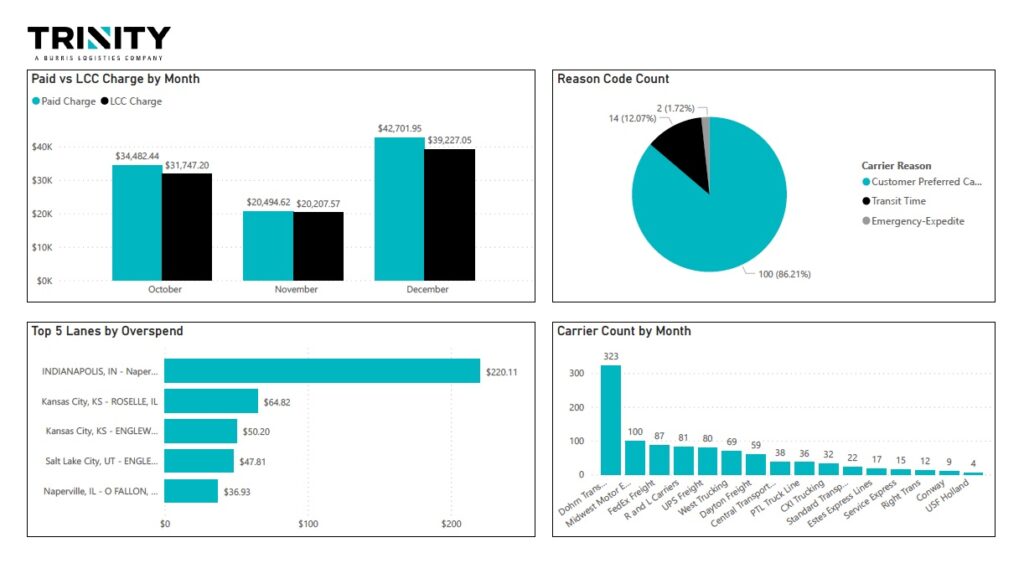

Least Cost Carriers

Least cost carrier reporting helps you identify loads where the carrier with the lowest cost didn’t haul the freight, the reason why, and the extra freight charges that occurred as a result.

This logistics report can help your company identify potential problem areas, resolve the underlying issues, and prevent unnecessary expenses from occurring in the future. If you’re looking to cut freight costs, this report clarifies where your missed opportunities are located.

Since cost isn’t the only factor when selecting a carrier, this report can also help you identify carriers that get repeatedly passed over despite offering lower rates. Therefore, these carriers provide you with the opportunity to work with them on a service-level agreement before you award business solely based on cost.

Power Lanes

Power lane reporting identifies new lanes and provides a benchmark for negotiating contracted rates with carriers.

You can identify a new lane as an origin-destination pairing that occurs a set number of times. Once a new lane is identified, the spot market rates paid to move that lane get broken down by load, mileage, pound, and more. This helps you have a point of reference when negotiating rates with carriers.

Identifying power lanes will help you secure fixed rates and better predict future freight costs.

Note: Most transportation management software products have the ability to run the five reports listed above. If you’re missing out on these exclusive reports, or you’re interested in a TMS for your supply chain, request a special demo with our logistics experts, who can help assess your needs!

MAKE LOGISTICS ANALYTICS MEANINGFUL

The logistics part of your business is complex and dynamic. There are lots of moving parts with many potential bottlenecks, so it’s important the metrics you report on are meaningful.

The right logistics analytics will help you measure performance, optimize routes, and streamline functions. Without the proper data, your business growth will be stagnant. There’s no way to know what needs to be changed if you don’t have visibility.

Additionally, unfound inefficiencies can impact your customer service and carrier relationships and can lead to lost sales and higher costs. Having the right logistics analytics can be one of your most powerful tools and make a big difference in your everyday business activities.

START LEVERAGING YOUR LOGISTICS ANALYTICS

According to research, 93 percent of shippers believe logistics analytics are critical to making intelligent decisions. And 71 percent believe that data improves quality and performance. Yet, too many businesses continue to use manual, time-consuming processes to analyze their logistics.

Take advantage of logistics technology and innovative logistics analytics so you can find actionable insights with the right reporting. And if you need help with your logistics analytics, we can help.

Start hitting that easy button because a TMS with Trinity can make tracking your logistics data a breeze. Not only do we understand everyone’s needs are different and offer customized solutions, but you also have the option of as much or little support from our superusers as you want.

And if you’re looking for expert advice based on your logistics analytics, Trinity offers Quarterly Business Reviews so we can help you find efficiencies.

So what are you waiting for? Let’s get connected and see how we can optimize your processes.

I'm ready for a clearer insight into my logistics analytics.Hello there. I’m Holly, Trinity’s friendly neighborhood freight Agent Recruiter.

Every day I have the privilege of working with our Authorized Agents as well as finding new freight agent businesses to welcome into the Trinity family. This has given me a bird’s eye view of what it takes to run a successful freight agent business. And I can tell you, IT’S HARD!!! It’s a grind. It’s a hustle. It requires a BIG dose of grit and determination. But it’s in our blood! We thrive on the fast pace, the opportunity for unlimited income, and the flexibility of running our own show.

With all that being said, I’m extremely proud of the tools, resources, and personalized support Trinity provides to our Authorized Agents daily. While I could go into all the things we can do to help support your freight agent business, today, I’ll settle for the opportunity to introduce you to four unique resources we provide our Authorized Agent network to make their days easier and their businesses more profitable.

SAVE TIME WITH RFPs

Do you find Requests For Proposals (RFPs) an annoying time suck? Not anymore! At Trinity, we take care of the heavy lifting for you.

Trinity’s Authorized Agents have full access to our in-house Pricing Team for RFPs both large and small. Our Team works hard to combine data from many market sources plus our extensive internal lane history to compare a total of nine data points. That’s some impressive wizardry, I tell you! This will not only save you time from figuring out the right pricing but also give you confidence that the pricing details you share with your customer are spot on.

And that’s not all! We also provide you with real-time market-specific rates focused on your customer’s needs. This way, you can be as hands-on or hands-off in the process as you choose.

AND DON’T WORRY ABOUT CAPACITY

You’ve just saved time on the pricing aspect of your RFP. It’s complete, and you’ve won your lanes, but what happens next?

You get on the phone with your relationship carriers for their rates and volume commitments. In an ideal world, the rates are great and there’s plenty of capacity. Awesome! Time to get back to helping your customers and growing your freight agent business.

But how often does that really happen? Often, your relationship carriers don’t run those new lanes, don’t have the capacity to commit, or ask for rates above the market. So, what do you do then? Most likely, head on to those dreaded load boards.

Here comes Trinity to save the day. Our Authorized Agents have full access to our Carrier Procurement and Development Team. This Team of Trinity experts will take the data from your RFP, find you capacity using our proprietary lane matching technology and then get rate agreements in place for COMMITTED capacity to service your customer’s needs.

So, if you often work with RFPs for your customers, go ahead and press the easy button with Trinity!

WORK SMARTER, NOT HARDER

Are you looking for a deeper dive to uncover your most profitable freight? We’re here to help you with that! By using your load history, our Pricing Team will provide you with a Network Analysis to give valuable insight into your most profitable lanes. With this data in mind, you’ll be able to focus your sales efforts on the markets that produce the highest margin to help you reach your freight agent business goals. We’ll help you work smarter, not harder!

EASILY DIVERSIFY YOUR FREIGHT AGENT BUSINESS

One more thought for the day; let’s say you specialize in full truckload freight. In fact, you’re such an expert that you can almost move it with your eyes closed.

But in this constantly evolving freight market, your customers ask you for help with all kinds of other weird stuff like less-than-truckload (LTL), intermodal, drayage, ocean or air, expedited freight, technology solutions, warehousing, e-commerce…maybe even a total outsource!

With you being a full truckload shipping expert, this may sound intimidating! And the last thing you want to do is send them somewhere else and risk that “other guy” poaching your freight.

There’s no longer a need to worry! Trinity Logistics has you covered. We offer full operations teams for our Authorized Agents to handle ALL other modes besides full truckload. Pair that with our parent company, Burris Logistics, and their opportunities, and it’s simple. You bring the opportunity, and we do the rest. All you need to do is sit back and collect the extra margin for your growing freight agent business.

Additionally, we provide you with monthly mode training classes so you can learn and be confident in what you are selling. There’s no need to be the subject matter expert on all modes when you have Trinity Team Members to support you and your freight agent business.

JOIN THE TRINITY FAMILY AND BEGIN GROWING YOUR FREIGHT AGENT BUSINESS

Trinity Logistics has over 30 years of experience aiding in the success of our freight agent businesses, with many of our newer businesses seeing a 50 percent increase over a two-year period from joining. Consider joining our Authorized Agent Network today so you can gain more time to focus on your customers, generate more revenue, and we’ll focus on everything else.

To learn more about our Authorized Agent program and all the ways we can save you time and help you build a successful freight agent business, feel free to contact our Agent Team phone at 800-846-3400 x 1908 or click the button below!

I'd like to connect with TrinityThe chemical industry serves as support for many other industries, like agriculture, automotive, construction, and pharmaceuticals. According to an American Chemistry Council report, 96 percent of all manufactured goods trace back to chemical manufacturers. Chemical manufacturers often process raw materials into refined products used in other industries or within the chemical industry. However, raw materials costs have been rising recently, along with additional operating costs in the chemical industry.

As chemical manufacturers face increased expenses, many find it more challenging to remain profitable. How can chemical manufacturers better manage their operating costs? In this blog, we’ll take a walk through what chemical manufacturers are currently facing and how they can better manage their operating expenses.

Rising Raw Material Costs

Raw materials costs have been rising in recent years. Part of the cause for increased prices is because they’ve gotten scarcer as the demand has risen for them. For example, raw agricultural materials have increased 117 percent since 2000, rubber has seen an increase of 359 percent, and steel is up 167 percent.

Crude oil, which many chemical companies use for energy and other materials, is up 250 percent since 2000. Crude oil prices are the most important ones to watch because it affects so many different markets. For example, many basic ingredients originate in the oil and gas fields and then travel through a global supply chain to make materials like plastics, packaging, fertilizers, lubricants, paints, and much more. Additionally, higher energy costs mean higher operating costs for the chemical industry.

Logistics Operating Costs in the Chemical Industry

The strength of long, global supply chains continue to be tested. From the start of the Covid-19 pandemic to battling intense weather and labor shortages, prices for logistics operating costs in the chemical industry have skyrocketed. Chemical supply chains have had their weaknesses exposed, from their dependence upon the volatile oil and gas sector to their global shipping networks. It’s caused additional cost as many of the materials needed to operate are out of stock due to shipping congestion and backlogs. According to a survey done by the National Association of Chemical Distributors, 85 percent of chemical industry distributors reported at least one imported item out of stock.

How to Better Manage Operating Costs in the Chemical Industry

Interestingly enough, skyrocketing logistics costs are beginning to outweigh other operating expenses for chemical manufacturers. Finding better management and control in your logistics may be the thing to keep your chemical company cost competitive. As a result, a growing trend among chemical manufacturers is turning to outside help for their logistics. Many chemical companies find that using a third-party logistics company (3PL) makes a lot of sense. It helps them free up resources to focus on other aspects of their business. Here are some ways working with a 3PL can help you manage your operating costs.

Find the Right Carrier – In Less Time

We all know the stress and workload of finding a carrier to move your freight, especially for chemical manufacturers who need carriers that know how to handle their products safely. Capacity can be limited when looking for a hazmat certified, or tanker endorsed carrier for a decent shipping rate. Outsourcing your transportation is one solution to that problem.

3PLs will take over the responsibilities of finding and vetting qualified carriers. A 3PL should make sure carriers have the proper credentials, insurance, and experience for your freight. Take control of your time and let someone else take on the workload so you can gain time for the rest of your business.

Create Efficiency With A 3PL’s Technology

Working with a 3PL also offers you access to their technology services, like shipment tracking, automated workflows, and detailed reporting. By replacing your manual processes with logistics technology, you’ll find more visibility into your supply chain. And that visibility can help you find efficiencies to help you manage your operating costs. While the technology itself can be an extra cost alone, most 3PLs offer you technology applications along with freight arrangements. Additionally, you’ll have experts you can rely on to help you navigate those applications.

Transportation Management Systems

All chemical companies are focusing on streamlining their operations, whether they choose to outsource their logistics or not. Many companies are turning to transportation management systems (TMS) to optimize their transportation networks.

A TMS can help your business gain visibility into your supply chain, create new efficiencies, and automate your manual workload, so you can better manage operating costs.

When using a 3PL, you often have options to choose how you want to integrate your TMS. Trinity Logistics offers you customer integration and a specialist to work with you every step of the way. No matter what option you choose, you gain the visibility and automation you’re looking.

Control Your Logistics Costs

In business and life, there are certain aspects that you can manage and control. As a chemical manufacturer, you must manage those costs that you can control and plan for those variances in costs for those you cannot. Logistics is one operating cost you can manage when you choose to partner with a 3PL.

And you don’t have to look too far to find one. Trinity Logistics is well-versed in the chemical industry and understands your complicated market. Our Team of experts is here to help you find the quality carrier you need while offering technology to help you create efficiencies. We can help you gain control over your logistics costs, so you can make room for those other unknowns.

If you’re ready to get a handle on your operating costs in the chemical industry, let’s get connected.

Author: Christine Morris

If you work in logistics, you’ve likely heard the term TMS before. TMS is the acronym of a transportation management system. A TMS is a software program that allows you to manage your entire supply chain, including your internal logistics department, suppliers, warehouses, carriers, vendors, etc. Having a TMS for your supply chain can help provide your company with greater visibility, better reporting, and improved performance through automating many manual processes. Many companies use a TMS for their logistics management, like e-commerce companies, retail businesses, manufacturers, distributors, even logistics service providers such as 3PLs (like us!). If you’re reading this article, more than likely you’re interested in a TMS but are hesitant. Let’s talk through some of those hesitancies and see if we can help resolve them.

TMS HESITANCY 1: I WANT TO KEEP CONTROL. I FEAR OF LOSING MY ROLE IN LOGISTICS MANAGEMENT.

Most fear losing control of their logistics operations or that it won’t be done correctly. However, a best-in-class TMS allows you to decide the amount of control you would like to have. You can opt for a TMS that integrates with your current system, using your own carriers and rates. Or if you want to be more “hands-off” you can outsource your TMS with a 3PL that provides software, account management, and use of their carrier relationships and rates. If you’re in between, you can have help with account management but still be involved and a mix of your own carriers and rates and your 3PL’s carriers.

Even with all those options, no matter your role in logistics management, a TMS isn’t going to do it all for you. Instead, technology like a TMS simply helps you do your job more efficiently by automating those very manual and time-consuming tasks that we do every day!

TMS HESITANCY 2: IT COSTS TOO MUCH

This is often a misconception. With software as a service (Saas) and a cloud-based or web-based TMS, sometimes there are no costly up-front investments. It also means you won’t have to worry about having software installed on company servers and continuously managing updates.

It really depends on your logistics needs and the solutions your provider can offer you. At Trinity, we offer technology solutions for companies of all sizes and with different levels of services. A TMS can often end up saving you money in the long term by helping you better manage your freight spend and performance.

TMS HESITANCY 3: MY BUSINESS IS TOO SMALL. WE DON’T WANT TO MAKE ANY CHANGES.

No business is too small! And even if you don’t want anything to change in your process, change is inevitable as it will happen in your industry and business. Will your business be ready for when that happens?

It’s vital to adopt technology, like a TMS, into your business before you grow too fast rather than waiting until while you are growing quickly. What you have in place may work for now, but when your business really starts growing, the cost and time to manage your workload will be growing too. Can your process handle that?

We all know change can come quickly and unexpectedly, causing disruptions in our processes.

A TMS can help you be better prepared and ready for any changes.

TMS HESITANCY 4: IT’S TOO COMPLICATED TO USE. WE TRIED IT BEFORE AND NO ONE WOULD USE IT.

Some TMS’s can be difficult to navigate and if there’s not a lot of support, you may abandon it. But a best-in-class TMS should be user-friendly and configurable to the needs of each individual user. You should also have access to a support system that can help you when needed.

There’s a big difference between purchasing software to use from a company and working with a 3PL that offers it as a solution. Considering a 3PL often uses their own TMS, they’ll know how to use it and help you. Quality TMS providers will work with you to make sure the TMS meshes well with your other systems.

ARE YOU EXPERIENCING ANY OF THESE CHALLENGES?

Struggling With Keeping Your Quotes Organized

If you work with several different shipments, it can be time-consuming and overwhelming to be on the phone or going from website to website asking for rates from carriers in your network. Contacting all those carriers for your different shipments and keeping track of those quotes can take you away from the other important aspects of your business.

Managing and Selecting the Best Carriers

We know that not all shipment is the same. Some shipments need temperature control, require special delivery services, or need to be handled with extreme care. Because of that, not all shipments are handled by the same carrier. There are carriers best suited to handle all your shipment needs. However, managing them all can be difficult.

Keeping Track of Your Shipments

As mentioned above, most often all your freight is not hauled by the same carrier. It can be common for several different shipments to be in transit aboard different company trucks all over the country/world. Because of this, freight tracking can be challenging. Without a TMS, there will have to be someone entering shipment numbers into forms on several different carrier sites.

Not Getting Insight into Your Logistics

Without proper reporting from a TMS, it can be hard to gather data to determine which carrier was the cheapest throughout this past year. Or analyze which carrier had the best performance. Or find out what your freight costs were on certain lanes.

Not all TMS’s may generate the reporting you need, but a best-in-class TMS can off you advanced reporting to go into specific logistics metrics. Without TMS technology to offer you data-driven insight into your business, can you really know how you are doing year after year?

STILL NOT READY TO COMMIT TO A TMS?

Say Hello to Trinity’s Customer Portal

We understand. Committing to a TMS can be a big change. We listened and heard you.

That’s why we now offer our Customer Portal for shippers working with Trinity. There’s no commitment, no additional charges, with a sample of TMS technology right at your fingertips.

Track your shipments, request quotes, view and pay invoices, or view and duplicate historical quotes. See how easy it is.

Start shipping with us today to gain access.

REQUEST A QUOTE I ALREADY SHIP WITH TRINITY, SIGN ME UPLOOKING FOR MORE?

Trinity’s Managed Transportation

We’re here and ready to help you with your logistics management. Our combination of experienced account management and best-in-class TMS technology offers you a customized solution to help achieve your unique supply chain goals. Through Trinity’s Managed Transportation, there’s no need to worry about an out-of-the-box solution that doesn’t fully meet your needs.

Whether you’re looking for Saas, a Managed TMS, a fully Integrated Outsource, or something in between, we’ll work with you to design a solution unique to your business, not the other way around. You’ll gain control, visibility, improved performance, reduce costs, and eliminate manual, time-consuming processes.

So, what do you have to lose?

GET MY FREE SUPPLY CHAIN ANALYSISLooking to learn more about Trinity’s unique TMS solutions? Schedule a risk-free live demo with Ryan O’Halloran to learn more about our customizable solutions.

SCHEDULE A RISK-FREE LIVE DEMOAUTHOR: CHRISTINE MORRIS

When was the last time you reviewed your logistics network and technology? If it’s been more than six months, then you’ve stumbled upon the right article. Now, you might be thinking, “I don’t feel like our process is necessarily broken. Is it really worth trying to fix it? Do I really need a transportation management system?” Yet, what if you could strategically reduce your overall spend while transforming your team from being reactive and task-oriented to proactive and customer-oriented. What kind of impact would that have on your company’s bottom line?

If your business;

- has a freight spend of $1M or more,

- utilizes a mix of transportation modes,

- has multiple locations that utilize their own mix of broker and asset providers,

- procures a majority of freight via the spot market, or

- manages most of your data via Excel spreadsheets;

Then keep reading as we’re going to take a look at some common areas of improvement you could see with a Managed Transportation approach.

You’ll learn how Trinity’s unique solutions focus on finding the right mix of people, process, and technology. Through this, we can help leverage your supply chain into a competitive advantage for your organization.

Let’s dive in.

PAIN POINT 1: LACK OF EFFICIENCY

Lack of efficiency in your business is a direct result of a decentralized and very manual approach. Programs like Outlook and Excel were just never intended to handle a freight spend of $1M or more. If your freight spend is $1M or more, you’re probably working with a couple of hundred orders a month, with who knows how many stakeholders to help micromanage quotes, tenders, tracking, and tracing of shipments.

How much time is being wasted across your organization with overwhelming manual processes?

Does this process save you any money when it comes to freight spend?

Do you know if you are utilizing the right carriers?

Would contract pricing cost you less than the spot market in the long run?

The bottom line is this is a reactive strategy focused on individuals’ tasks. To optimize your team and freight, you need a major shift towards being more proactive and customer-focused. This is where Trinity’s technology can help you. All of our Managed Transportation features a cloud-based TMS platform that creates a centralized freight command center, replacing your redundant manual processes with automation. Our TMS helps you manage the entire life cycle of an order and we can even integrate with your order management system to truly optimize your workflow. This means no more phone calls, typing out shipment details, or wondering where your freight is or when it’s going to deliver. Technology is one of the critical aspects of our solutions here at Trinity and also a major catalyst to transforming your supply chain.

PAIN POINT 2: PERFORMANCE

Efficiency isn’t just about getting faster; it’s about getting better. Finding and creating better team performance, better carrier performance, and ultimately improving your bottom-line company performance. So, is there room for improvement in these areas for you? Are your current strategies effective? Can they be measured? You may have answers to these questions that vary from location to location. You’ll usually find some of your distribution centers are better at procuring freight than others.

While a siloed strategy may have made sense for you at one point, companies grow and change. Considering change is a constant, a more wholistic approach will typically yield a better overall cost and carrier performance for you. This is what we consider to be the process part of our solutions. Data is a key driver for the strategy on this one.

On the surface level, it will appear that you simply are spreading your freight too thin across too many carriers or brokers. At Trinity, our Team of Logistics Consultants can quickly diagnose if you are leveraging your overall volumes to the best of your ability. Through strategic sourcing and customer-specific pricing, you can yield savings of six to ten percent, sometimes even more. It can also have a significant effect on improving on-time performance. Best of all, with Trinity’s Managed Transportation, you’ll always be able to track these metrics. You’ll be able to know exactly how your teams compare to the market and are able to adapt quickly when things change.

PAINT POINT 3: VISIBILITY

It’s hard to overstate the importance of real-time visibility in today’s supply chain. When a customer or sales rep asks for a delivery ETA or if the warehouse needs to know what trucks are scheduled to come in; that can all fall back on your outdated and manual processes. Things like picking up the phone, back and forth emails, creating and sharing spreadsheets, that’s just your day-to-day visibility. What about those overall performance metrics and being able to measure your team or your carriers? Unfortunately for many shippers, there can be too many roadblocks for effective communication and a lack of overall supply chain awareness.

However, with the right strategy and technology, visibility can shift from a challenge to a strength. Having access to a TMS takes over a lot of the heavy lifting for you, acting as a virtual control tower for all logistics updates and communication. With Trinity’s solutions, we included unlimited users who can access updates and data 24/7 via the cloud. We can even create push notifications where your team, your warehouse, and your customers can receive updates for their specific tasks automatically. For most shippers, real-time visibility has fully transitioned from an optional benefit to a business necessity – which is why Trinity brings all of this valuable information right to your fingertips.

PAIN POINT 4: BUSINESS INTELLIGENCE

Data has quickly become one of the world’s most valuable resources. In order to make effective decisions, proper data and analysis are needed, especially for logistics strategy or more enterprise-level decisions that reach far beyond the supply chain.

Now let’s say you do have access to good, tangible data. Even still, most likely your data is spread out among various laptops, email accounts, and carrier portals. Trying to compile complete and accurate information is difficult in itself this way, but the greater challenge is what can you do with this data?

That’s where working with Trinity comes in hand. We help compile and present a key analysis in a way that is easy for you to understand and collaborate on action steps for your company’s continuous improvement. Our customers are able to successfully leverage their data to lower costs, improve performance, and drive their company forward. There are many types of helpful reports you can expect to see such as carrier scorecards, customer profitability reports, to network analysis, and distribution projects.

From Surviving to Thriving

Whether or not your challenges have already been identified, through a Managed Transportation Discovery Call with our people-centric approach, you can learn how to take your business from surviving to thriving. Your consultation is free and the only thing you have to learn is how your business can operate more efficiently and strategically.

What do you have to lose?

Intrigued?

Request a consultationNot quite ready for a consultation but still interested in learning more about Trinity’s TMS? Register for a brief presentation specifically focused on our TMS.

Register

Interruptions to the cold chain create problems such as spoilage, changes in the appearance, taste, or smell of a product, growth of harmful bacteria, or lost potency. Preventing any interruption of the cold chain is one of the main responsibilities of a logistics manager. Let’s look at some of the significant cold chain challenges you may have to face, and how you can keep issues at bay.

REGULATIONS

Regulations for the cold chain are ever-changing and complex, which is why they are one of the major challenges faced today. If your cold chain is worldwide, it can be more complicated as there is no one entity to regulate on a global scale. Each region has its own regulations, compliance mandates, and enforcement agencies. Some examples of these are:

U.S. Food and Drug Administration (FDA)

In the U.S., the federal regulatory agency for food and pharmaceuticals is the FDA.

Most cold chain food regulations come from the FDA’s Food Safety Modernization Act (FSMA) of 2017. This regulation covers the cleanliness and function of equipment, protocols set in place for transportation, employee training on the proper handling of food in cold chains, and records of all FSMA compliance.

When it comes to pharmaceutical products, many regulations affect the cold chain. Some of those include:

- 21 CFR 203.32

- Addresses the need for maintaining drugs under stable conditions and meeting manufacturer’s specifications.

- 21 CFR 211.150

- Provides guidance on the written procedures for managing expirations and a reliable system for identifying the distribution of drug samples in the event of a recall.

- 21 CFR 203.36

- Outlines the responsibilities of manufacturers and authorized distributors.

- 21 CFR 205.50

- Minimum requirements for storage and handling of prescription drugs and maintenance of distribution records

Canadian Food and Drugs Act

In Canada, the regulatory authority is the Government of Canada. The Canadian Food and Drugs Act was passed in 1920 and revised in 1985. It regards the production, import, export, and transport across provinces for food, drugs, and cosmetics including products like soap and toothpaste. It ensures products are safe, ingredients disclosed, and drugs are effective.

International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH)

Many other countries, refer to ICH guidelines gathering data on a product’s safety and efficacy to establish a cold chain strategy. ICH brings together many regulatory authorities to discuss data and establish those guidelines. Gathered data is used to consider the duration of temperature excursions that can occur across distribution channels.

Regulations can be complex and demanding at times, but they all have the same goals of retaining the safety, quality, transparency, and efficacy of cold chain commodities. The biggest key to keeping compliance with cold chain regulations is increasing end-to-end visibility in your cold chain. Keeping proper documentation of data throughout your supply chain can seem difficult but modern technology like a transportation management system (TMS), can simplify this cold chain challenge. Current technology applications like GPS tracking, ELD data, Internet of Things (IoT), and a TMS can give you advanced analytics and reporting that would otherwise be comprised of manual processes. Not only does technology offer you savings in time but of human error as many processes become automated.

SUSTAINABILITY

Another significant cold chain challenge is the increasing spotlight on sustainability. The distribution and transportation of temperature-controlled products have shown to be major causes of greenhouse gas emissions. In comparison to other supply chain transportation, cold chain transport consumes 20 percent more fuel than other heavy vehicle types due to the refrigeration equipment. The biggest issue facing sustainability is the high-power consumption or combustion of fossil fuels necessary to power the cold chain’s cooling systems.

There are also growing issues and increasing regulations on refrigerant gases used in cooling systems like hydrofluorocarbons (HFCs) as they are responsible for high greenhouse gas emissions. In 2015, the European Union set strict limits on the production and sale of high global warming potential HFC refrigerants. In the U.S., the Manufacturing Act of 2019 was passed which established a timeline of phasing down the use of HFCs by 2036.

Because of the increasing pressure of sustainability and its regulations enacted on the cold chain, many large food and pharmaceutical companies have plans in place to reduce their carbon emissions. In 2015, more than 150 businesses in the U.S. signed the Business Act on Climate Pledge which launched for private sector businesses to express their support on international action on climate change. Also, in 2015, the Paris Agreement was created, signed by 195 countries at the United Nations climate change summit. This agreement aims to reduce greenhouse gas emissions to prevent the planet from warming by more than 2 degrees Celsius.

Being sustainable in the cold chain is also something you can be recognized for now with awards such as the Supply & Demand Chain Executive Green Supply Chain Award or the Council of Supply Chain Management Professionals’ Supply Chain Sustainability Award. Some ways to consider in adding sustainability to your cold chain is improving your cold chain management to reduce waste and your carbon footprint or considering alternative transportation modes like intermodal versus truckload when shipping your products. While you’re working on improving sustainability in your cold chain, make sure the providers you work with are equally interested in sustainability as well. Here at Trinity, we are proud of our sustainability efforts and to be recognized as a SDCE Green Supply Chain Award winner and as a Food Logistics’ Top Green Provider.

TEMPERATURE VARIANCES

It’s one of the biggest and most common cold chain challenges: maintaining the required temperature of the product throughout the entire supply chain. Any temperature that is higher than the set temperature can affect a product’s quality. Not all products that get exposed to a temperature past their threshold will spoil right away, as it depends on how steep and frequent the exposure was. Once a product has begun to thaw, it is considered contaminated. Depending on the product and temperature, that window of time can be very short. There are many times during cold chain in which a product can be exposed to a temperature variance: during unloading and loading of the product, from poor packaging, handling, or broken equipment.

Loading and Unloading

As your product moves through the cold chain, it can get exposed to temperatures outside its set temp. Whenever loading and unloading your product, handling should be as quick as possible. Preventing prolonged exposure to temperature changes prevents having problems with quality.

Poor packaging or handling

There are many different ways to package your cold chain freight so it can keep its cool. If it’s not done right or in mind of your transit time, your goods can spoil before arrival. When handled poorly, they can become damaged, causing lost product.

Equipment problems

One way the cold chain can be interrupted is when your equipment breaks down. Refrigeration equipment can malfunction due to damage, inadequate maintenance, or losing power.

In cold storage, doors becoming damaged are one of the common challenges they face. When cold storage doors become damaged, they can’t maintain their specified temperatures.

Due to inadequate maintenance, there can be a buildup of condensation in coolers and freezers, causing slippery surfaces and unsafe conditions for workers, as well as a spoiled product. Another maintenance challenge is handling the growth of mold or mildew, which can happen with poorly maintained temperatures. Should this happen, the freezer will need to be cleaned thoroughly and inspected for any problems.

Transportation Breaks Down

Vehicles can break down at any time. Any hold-up in your cold chain shipment could mean more than just a time delay, it can mean a spoiled product. Make sure you’re working with a qualified carrier who inspects their truck or other modes of freight before the journey begins.

Keeping track of the temperature throughout your cold chain is another way to combat having your products exposed to changes in temperature. Temperature monitoring systems are quickly replacing any manual processes of collecting temperature information, saving time, and preventing spoiled products. This also allows cold chain managers insight into their problem areas and being able to fix them.

Some of these temperature monitoring systems are RFID or wireless sensor network, thermal imaging, and temperature loggers. RFID or other wireless sensor networks are the most common in the cold chain. These sensors capture the location and temperature, communicating the information back to a database and allowing parameters like an estimated shelf life to be calculated. You’ll often find these in warehousing and cold storage. Thermal imaging is exactly what you think it is; imaging that is taken showing the different temperatures of everything in the photo. Thermal imaging uses a sensor to convert the radiation given off at different temperatures into a visible light picture. This is also often used in warehousing and cold storage. Lastly, temperature loggers are another type of sensor placed next to cargo in transportation. They can be set to record as frequently as every second, minute, or hour. Once removed, they can be plugged into a computer so the temperature data can be transferred and analyzed.

TEMPERATURE-CONTROLLED SHIPPING CAPACITY

Another significant cold chain challenge is available capacity. Capacity is always a challenge for any industry, but even more so for the cold chain, especially right now. With freight in high demand across all industries and capacity slim, drivers can pick and choose what shipments they want to take based on (already) high rates. Reefer trailers are already limited with the increased demand on cold chain, but when rates for moving other high-demand commodities such as lumber or retail keep increasing, those drivers can choose to utilize their reefer trailer as a dry van to haul should those rates be better paying, further reducing cold chain capacity. Cold storage warehousing is seeing the strain as well because of the growing freight demand. More storage space is needed in the supply chain and new buildings are being built, but those currently in production or needing their building supplies (which are also in high demand), puts yet another strain on shipping capacity until that demand has decreased. With the cold chain demand increasing and available equipment and drivers doing quite the opposite, can the logistics sector keep up? Read more in our current whitepaper.

DON’T LET THE COLD CHAIN SCARE YOU

There is a lot of juggling to do when managing the cold chain. If even one ball is dropped, it can affect the whole cold chain. You can prepare as best as you can for these cold chain challenges, but sometimes it’s nice to know you have backup when you need it most.

Luckily here at Trinity, we’re experts in complex situations. In fact, I would say it’s our specialty. We’ve seen every possible problem there could be and are happy to help. By working with Trinity, you can gain access to the data you need to improve your performance and output, find equipment and capacity when you’re finding it difficult, and work with someone who understands current regulations, no matter the region or type of commodity you work with. We’re here to have your back regardless of what cold chain challenge comes your way.

Simplify your cold chain challenges.Not ready to request a quote? Subscribe to our YouTube channel and watch our latest State of the Industry and Freight Market Update videos to stay on top of what’s going on in cold chain.

Author: Christine Morris

Chemical manufacturers collect and use a lot of data in their supply chain. They deal with data on their products, customers, transportation, storage, operations and more. Acquiring that data is not hard but managing and utilizing that information to be able to analyze your business is the challenge. Taking advantage of a Managed Services solution can assist in better managing and using your data in your chemical supply chain.

Managed Services

Managed Services is when you outsource your freight and logistics processes to a third-party logistics (3PL) provider, such as Trinity Logistics. You can find ways to manage your data in one place using a 3PL’s Transportation Management System (TMS). By better managing, using, and analyzing your data, an organization can reduce costs, improve margins, generate revenue, and make smarter business decisions. How does a TMS offer you all this?

Supply Chain Visibility

A TMS can provide visibility into your supply chain data in many ways. Best-in-class TMS’s, such as Trinity Logistics’, can provide better insight into your logistics processes.

Executives can combine this improved visibility with robust reporting to help guide their decision making. You can also provide system access to your outside supply chain members such as suppliers, carriers, and vendors. Each partner can better plan for their part, having the potential to reduce expensive production costs, limit excessive accessorial charges, and improve customer service.

Freight spend visibility has many benefits within itself. By analyzing freight spend by lane, companies can learn which of their lanes are not profitable based on transportation costs. Identifying company-wide shipment volumes and rates can provide you leverage when negotiating your carrier contracts.

Reporting & Analyzing

Not all TMS’s can generate the reporting you may need. Most generate basic reports that summarize your transportation information. Examples of basic reports include freight spend totals, shipment statuses, and shipment volume reports. But a best-in-class TMS can generate advanced reports that go into specific logistics metrics. Advanced reports can include accountability, analyzed freight spend, lane analysis, and carrier performance to name a few. The reports are dynamic, and you can filter, summarize, or graph information based on what you want to see.

The above-mentioned offers:

Accountability Reports

Accountability reports offer companies the opportunity to hold core members of their supply chain accountable for controlling costs. For example, with carriers you can view costs of carriers used, late fees accrued, any unnecessary detention charges and more.

Analyzed Freight Spend Reports

Analyzed freight spend reports allow a company to track their freight spend based on parameters. Having the ability to track it in this way ensures that potential causes of lost profits are identified and addressed right away.

Lane Analysis Reports

Analyze changes in rates by lane and predict trends in your freight costs with a lane analysis report. You can prepare for changes up front or try to prevent them altogether through carrier rate negotiations.

Carrier Performance Reports

Carrier performance reports can help you identify which carriers are best meeting your transportation needs.

Reports are an important tool to use to find areas of successes and setbacks. Once identified, companies can take advantage of this information by adjusting their practices. They can find ways to create more successes and overcome shown setbacks. Yet, most companies don’t have the technology needed to analyze their processes in such a manner. Money is often wasted on unknown and unnecessary expenses.

Quarterly Business Reviews

When choosing to work with Trinity’s Managed Services team, you gain a relationship with a specialist. Our Team analyzes, produces, and presents Quarterly Business Reviews (QBR), making it easier for you to digest your data. We help you understand what is working, what is not, and what can be done to further escalate your company’s growth.

The importance of data doesn’t revolve around how much data you have, but what you do with it. Managing and analyzing your data effectively is what will take your chemical company even farther. Take it from one of our largest chemical customers, Albaugh;

““We have had tremendous growth over the last 3-4 years. This would not have been possible without the level of service and expertise Trinity Logistics provides. They are a true strategic partner in a very dynamic environment.”

Click here to read our case study on how Managed Services helped Albaugh with their growth.

When you combine your data with our Managed Services solutions, you can,

- gain visibility into your supply chain,

- generate advanced reporting to look into specific metrics,

- analyze reports to create efficiencies, successes, and overcome setbacks,

- and see how your company can grow with our Quarterly Business Review presentations.

Do you want to see what you will find when you manage and analyze your data with Trinity Logistics?