“Sense of urgency” is a term that is thrown around a lot in the business world today. And for good reason – the world around us is constantly changing, and we need to react right now! Trinity Logistics has made a sense of urgency a priority, and from what I’ve learned, most companies probably should.

In A Sense of Urgency, by John P. Kotter, the author very clearly defines the three stages of urgency and explains the importance of a true sense of urgency. We thought we would share his key points in the hopes that you are encouraged to put these ideas into place within your own organization.

The first stage of urgency is one of complacency.

Defined as “a feeling of contentment or self-satisfaction, especially when coupled with an unawareness of danger or trouble.”

When a person, department, or company is in a state of complacency, the general feeling is complete contentedness with the status quo. People tend to think: “I know what to do and I do it. If there is a problem, it’s not mine.” Their behavior is unchanging, opportunities and hazards are equally ignored, and their focus is purely internal.

The consequences? The world around you moves on while you stay the same. Competitors will change and innovate to meet your customer’s demands because for the complacent, change either doesn’t happen fast enough or it doesn’t happen at all.

The second stage of urgency is a false sense of urgency.

This is a flurry of energy and activity built out of failures.

Often, the failures are the result of complacency, leading management to put intense pressure on their team to perform exceedingly well and unrealistically fast. Someone in this stage is frantic, stressed, anxious, frustrated, and exhausted. There is a very high activity with very low productivity.

For these people, the problems still lie somewhere else, but now they will experience very defensive reactions. They will hold fast to what is being done right and will partake in finger-pointing attacks on others. The consequences of this are equally destructive to complacency. The unproductive activity and pressure are fueled by a team full of anxiety and anger. There are many wasted hours and lost opportunities.

The ideal stage is a true sense of urgency.

This is driven by a belief that “the world contains great opportunities and hazards” and “a gut-level determination to move, and win, now!”

There are four tactics laid out in the book that you can use to obtain a true sense of urgency in your organization, but I’m just going to touch on the one that I think is the easiest to implement right now.

We hear it all the time – your attitudes, feelings, and actions are contagious. The one thing you can do that will start a ripple effect of urgency is to behave with urgency every day.

In order to have a true sense of urgency and not slip into complacency, it’s important to remember that past successes tell us nothing about the future. Often, sports imitate life, and you don’t have to look too far to see prior success not resulting in success the following year… just look at the Super Bowl winners from 2008-2012.

| Year Won | Team | Following Year’s Result |

|---|---|---|

| 2012 | Giants | Missed playoffs |

| 2011 | Packers | Lost opening round playoffs |

| 2010 | Saints | Lost opening round playoffs |

| 2009 | Steelers | Missed playoffs |

| 2008 | Giants | Lost opening round playoffs |

Two didn’t qualify for the playoffs at all, and the three that did have a combined 0-3 record. I’m sure that complacency and the thought of “we did it this way last year, it’ll work again this year!” contributed to why these teams saw the results they did.

Winning today does not guarantee success tomorrow. We all have to work at it; we have to be better today than yesterday. Every day is an opportunity for you to win, so we must choose to do so and then make sure victory happens.

So where is your sense of urgency? Where is your department or your company? Where are your competitors, your customers, and your stakeholders?

We hope you will notice a difference when you call Trinity. Please do not hesitate to contact our team, as we want to show off our improved sense of urgency with your logistics!

Request a quoteOptimizing your logistics can make all the difference in your business’s bottom line. However, to fully understand your logistics processes you need to look at your logistics analytics.

To start, you’ll need access to the right technology. One such piece of technology is a transportation management system (TMS). A TMS is an excellent investment and according to Logistics Management Magazine, has been shown to reduce transportation costs by up to 30 percent.

Not interested in reading? Find out these priceless tips on improving your logistics processes.

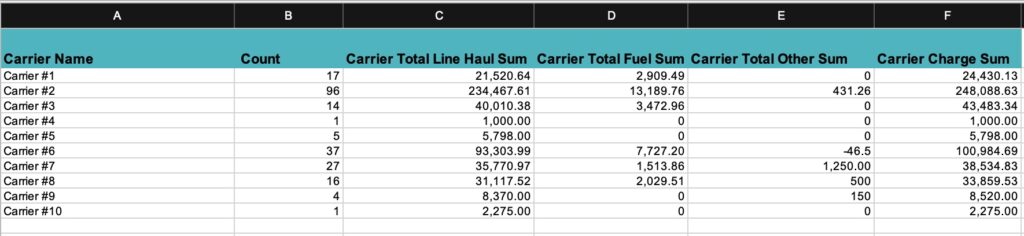

To get the most out of a TMS and your logistics, you’ve got to know what you should be watching. All the data a TMS provides can be overwhelming and the possibilities of what you could analyze are endless. Ultimately, sifting through that data can be complex and time-consuming. So, to make things easier for you, our Team of TMS experts found the top 5 reports you should be running so you can see your best return on investment (ROI).

Get started with a demo of Trinity's TMSTOP 5 LOGISTICS REPORTS YOU NEED

Getting the data you need for a good overview of your logistics processes doesn’t need to be complicated. These reports should give you a broad view of logistics analytics to help you reach your KPIs.

Freight Accruals

Freight accruals is a report used to keep track of the costs associated with transporting your goods to a customer. These costs begin accruing from the moment the goods deliver, and they get discharged once a freight invoice is paid.

Tracking freight accruals allows your company to calculate your true net revenue at any given time. As a result, you’ll gain a better insight into any outstanding balances accumulated during a specific timeframe, whenever you may need it.

Cost Allocation

A cost allocation report breaks down your freight charges by a mile, pound, or SKU.

For any multi-stop loads, or loads made up of many POs, freight charges can be allocated to each order based on the percentage of distance, weight, or quantity the individual order contributed to the whole. Therefore, tracking your cost allocations will give your company a better look into the true cost of transporting your goods. You can then use this report to identify your most costly SKUs or lanes.

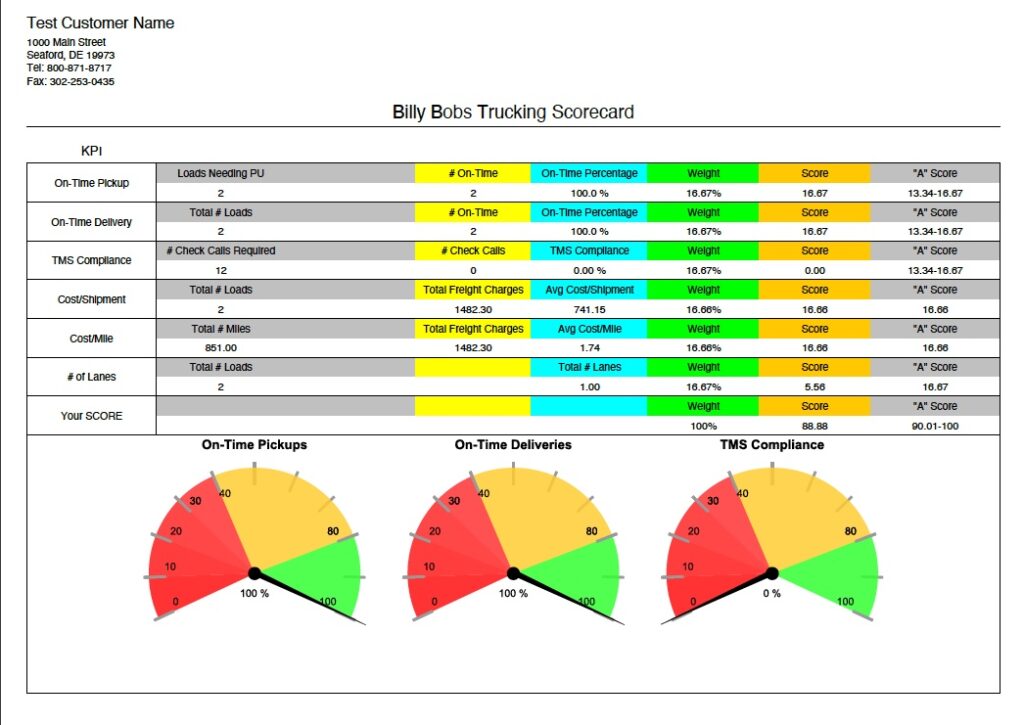

Carrier Scorecard

Carrier scorecard reporting helps you track a carrier’s performance. This will show data such as tender acceptance, on-time pickups, and on-time deliveries.

A carrier scorecard report can help you find which carriers are meeting your transportation needs and which are causing extra work. For example, carriers who bid low on a request-for-proposal (RFP), proceed to decline tenders, or provide poor service can cost your company. Without knowing how your selected motor carriers are doing, you could be facing thousands of dollars in extra expenses or, worse yet, lose customers.

By tracking your carriers’ performance, you can reevaluate your routing guide by selecting more reliable carriers on trouble lanes, improving both your costs and customer service. Additionally, this can help you set solid KPIs with your relationship carriers so you can better communicate your needs.

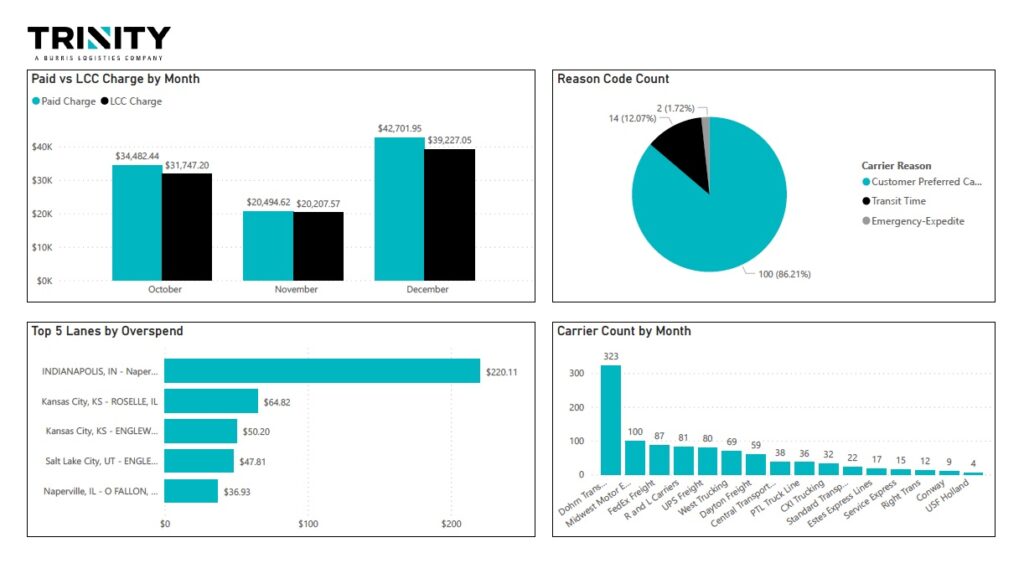

Least Cost Carriers

Least cost carrier reporting helps you identify loads where the carrier with the lowest cost didn’t haul the freight, the reason why, and the extra freight charges that occurred as a result.

This logistics report can help your company identify potential problem areas, resolve the underlying issues, and prevent unnecessary expenses from occurring in the future. If you’re looking to cut freight costs, this report clarifies where your missed opportunities are located.

Since cost isn’t the only factor when selecting a carrier, this report can also help you identify carriers that get repeatedly passed over despite offering lower rates. Therefore, these carriers provide you with the opportunity to work with them on a service-level agreement before you award business solely based on cost.

Power Lanes

Power lane reporting identifies new lanes and provides a benchmark for negotiating contracted rates with carriers.

You can identify a new lane as an origin-destination pairing that occurs a set number of times. Once a new lane is identified, the spot market rates paid to move that lane get broken down by load, mileage, pound, and more. This helps you have a point of reference when negotiating rates with carriers.

Identifying power lanes will help you secure fixed rates and better predict future freight costs.

Note: Most transportation management software products have the ability to run the five reports listed above. If you’re missing out on these exclusive reports, or you’re interested in a TMS for your supply chain, request a special demo with our logistics experts, who can help assess your needs!

MAKE LOGISTICS ANALYTICS MEANINGFUL

The logistics part of your business is complex and dynamic. There are lots of moving parts with many potential bottlenecks, so it’s important the metrics you report on are meaningful.

The right logistics analytics will help you measure performance, optimize routes, and streamline functions. Without the proper data, your business growth will be stagnant. There’s no way to know what needs to be changed if you don’t have visibility.

Additionally, unfound inefficiencies can impact your customer service and carrier relationships and can lead to lost sales and higher costs. Having the right logistics analytics can be one of your most powerful tools and make a big difference in your everyday business activities.

START LEVERAGING YOUR LOGISTICS ANALYTICS

According to research, 93 percent of shippers believe logistics analytics are critical to making intelligent decisions. And 71 percent believe that data improves quality and performance. Yet, too many businesses continue to use manual, time-consuming processes to analyze their logistics.

Take advantage of logistics technology and innovative logistics analytics so you can find actionable insights with the right reporting. And if you need help with your logistics analytics, we can help.

Start hitting that easy button because a TMS with Trinity can make tracking your logistics data a breeze. Not only do we understand everyone’s needs are different and offer customized solutions, but you also have the option of as much or little support from our superusers as you want.

And if you’re looking for expert advice based on your logistics analytics, Trinity offers Quarterly Business Reviews so we can help you find efficiencies.

So what are you waiting for? Let’s get connected and see how we can optimize your processes.

I'm ready for a clearer insight into my logistics analytics.Trinity Logistics, a Burris Logistics company, is proud to share that Food Logistics has named the company as a recipient of the 2022 Top 3PL & Cold Storage Providers Award.

Food Logistics is the only publication exclusively dedicated to covering the movement of products and information through the cold food and beverage supply chain. The Top 3PL & Cold Storage Providers list recognizes leading third-party logistics and cold storage providers in the food and beverage industry. Companies on the list play a pivotal role in keeping the food and beverage industry’s products stored, transported, and stocked while maintaining the product’s quality.

“These past 18 months have been so challenging for U.S. supply chains. It’s the continuous bottlenecks that require fleets to re-tool and pivot accordingly. But it’s the drivers, the fleet, the warehouses, and software/technologies that really keep today’s supply chains in line,” says Marina Mayer, Editor-in-Chief of Food Logistics and Supply & Demand Chain Executive. “These 3PLs and cold storage providers have collaborated on all facets of their operations to achieve full visibility, complete forecasting, end-to-end leverage, and the ultimate in sustainability. Now is the time to honor and celebrate those companies making magic happen behind the frontlines.”

Trinity works with thousands of shippers in the food and beverage industry, making the company well-versed in its requirements and regulations. Equipped with state of industry technology and with Burris Logistics, one of the top cold storage providers in North America, as its parent company, Trinity provides exceptional service to those in the cold chain.

“We are honored to be named a Top 3PL & Cold Storage Provider, and very fortunate to be part of the Burris Logistics family,” said Mark Peterson, SVP of Sales at Trinity Logistics. “Having a parent company with 90+ years of cold storage & food distribution experience gives us a distinct advantage. From the 3PL viewpoint, our focus is on optimizing the efficiency of our distribution network. The pillars of that effort are gathering and analyzing the right data; clear and consistent communication with our partners; and the highly educated and motivated team of professionals at Trinity Logistics.”

The full list of 2022’s Top 3PL & Cold Storage Providers will appear in Food Logistics’ August issues, as well as online at www.FoodLogistics.com.

Learn how Trinity supports food and beverage companies.About Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 40 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized on Transport Topics’ Top 100 Freight Brokerage List, a Top 3PL and Cold Storage Provider by Food Logistics, and a Top Company for Women to Work for in Transportation by Women in Trucking.

If you’re a company that ships products, you need to learn about all shipping options available to you. This allows you to manage your costs better while keeping your product moving. When applicable, freight consolidation is an option that can save on your shipping. There are also many other benefits to consolidation. We’re here to help you better understand what freight consolidation is and what it can offer your logistics.

WHAT IS FREIGHT CONSOLIDATION?

Freight consolidation is when a shipper combines multiple shipments within a region into a single load hauled by a carrier to a destination region. The load gets broken down into smaller parts and delivered by a regional carrier to their many destinations. Or vice versa, they get picked up by a regional carrier to merge into a single shipment and delivered to their destination. Freight consolidation is ideal for shippers who frequently move a few pallets or smaller amounts of product.

WHAT ARE THE BENEFITS?

Savings

Often, shippers will only use half or two-thirds of a trailer but still pay for the entire space. Whereas, with freight consolidation, you can earn preferred rates and optimize your logistics. Most importantly, you save time and money.

By consolidating your smaller, regional freight, you can avoid paying a higher rate. By shipping your freight all at once instead of sending loads individually, you’re able to pay bulk rates.

You can also avoid the costs that come along with using storage sites, inventory management facilities, and your own fleet of vehicles. Freight consolidation providers can provide these for you to better manage your shipment until its delivered. You won’t have to store your shipment on your own. Instead, you’ll be able to send it to the facility where it will ship to your retailers. This will help streamline the process should you need more inventory.

Taking it a step further, you’ll also have fewer trucks on the road. As a result, you’ll be spending less on fuel and spending less per mile since it will be on one truck instead of many. The savings can be significant enough to make a big difference in your company’s bottom line. This can be a real difference for mid-sized and smaller businesses that see their profits cut by their shipping costs.

Reduce Risk

You’ll also see increased security. Damaged freight continues to remain a lingering issue for shippers. Things happen in shipping and can be the reality of doing business. Consolidated shipping is not only more cost-efficient, but it reduces the on-again, off-again handling of your freight. Ultimately, when using an experienced shipper and consolidating your freight, your products will be in safer hands.

And not only that — it will be in those hands less often. Having your freight consolidated also means that it will be on fewer trucks, making the odds smaller of it being in an accident.

It goes beyond safety too. Freight consolidation also benefits through added reliability. Because your product is handled less, there is a lower risk of something going missing or delivering to the wrong place. There’s also less of a chance that something will interrupt your delivery, causing it to be late. This all adds up to you gaining peace of mind and having happy customers on the other end of your shipment.

Improved Flexibility and Time Management

Freight consolidation will improve the flexibility of your shipping needs and make your orders more timely. Freight consolidation often offers faster transit times and reduces wait times for transporting small loads. By storing your freight at a consolidation facility, your products will be ready to go when needed. This improves your timeline and inventory flexibility, which your customers will appreciate.

Changes happen in orders and can throw things into a real mess sometimes. Yet, freight consolidation will not hinder your ability to get your products to your customers on a short turnaround. Through a consolidation strategy, you can get your freight delivered on your schedule. Expert providers will help you put a plan into place so your freight gets on a truck and the road while better utilizing truck space and time.

Better Visibility and Control

With consolidated shipping, your visibility improves, as does your control. Let’s say for some reason, quality control alerts you that there’s a problem with your shipment and it’s already been shipped. Normally, you would have to wait for the supplier to send a replacement, meaning your delivery timeline is now out of your hands. In contrast, consolidation allows you to perform quality control measures as soon as the product reaches the warehouse. This reduces the chances of losing time and control due to unforeseen problems.

Using freight consolidation also gives you more control over your due dates and production schedules. You’ll be able to manage the entire distribution chain on your own or with a logistics partner.

Improved Relationships

This process not only benefits you but your customer or retailer too. By shipping smarter, you’ll be able to build better relationships with other companies, customers, and your carriers.

First, you can establish relationships with other businesses that use LTL shipping. If you find another company that ships a similar product or sized load on the same schedule to a shared retailer, you can establish a shipping partnership. This partnership can help reduce costs for both of you and build smarter loads through shared freight consolidation shipments.

As for your customers, they’ll appreciate that you’ve gotten together for more efficient shipping since they work with both companies. They’ll also appreciate the savings that freight consolidation provides.

Having the right carrier relationships will make it all happen for you. You’ll need a carrier relationship you can rely on to manage your orders and make sure products deliver on time. Perhaps your products have special needs that your carrier will have to accommodate. Not having a good relationship established won’t reassure you that your shipment will turn out fine. Having consistent relationships with carriers can also lead to you receiving better pricing.

CHALLENGES WITH CONSOLIDATION

Finding Carriers

Because freight consolidation can seem complicated, not all carriers are willing to haul them. Even when you can find a carrier willing to transport your consolidated shipments, be sure that you are well-informed and charged appropriately. Partnering with a third-party logistics company (3PL) can help assure you find a carrier to haul your shipment and get a fair rate for it.

More Time Planning

Although it can save you time transporting, consolidated shipping does need some extra time spent organizing and planning. You’ll need to be aware of factors such as pricing, dimensions, timing, and other specifics to guarantee that your shipments arrive both safely and on time.

WHAT’S HOLDING YOU BACK?

Freight consolidation can save you headaches. There are many businesses using freight consolidation to help streamline their shipping process, get products to their customers faster, and help to build and maintain relationships. However, it’s crucial you have a complete understanding of how consolidation works to ensure proper delivery.

One of the best practices of consolidated shipping is to use an experienced provider. By working with an experienced provider, you’ll be able to overcome the challenges that come with freight consolidation and solely reap the benefits.

Luckily, here at Trinity, we’re experts in freight consolidation. By working with Trinity, you’ll gain peace of mind knowing your shipments are taken care of. Our Team of experts can help you plan and organize your shipments, recommend freight consolidation when it’s suitable, and you’ll gain access to our vast network of carrier relationships.

If freight consolidation is a shipping method you’re interested in but need guidance on, we’re here to help.

Learn more about People-Centric Freight Solutions®.AUTHOR: Christine Morris

It’s no surprise that one of the hottest topics in the world lately is the pain felt at the pump. Rising fuel prices have been at an all-time high, surpassing the costs since 2008, and these prices will only continue to climb. As a result, businesses are being forced to pay more to operate, causing a ripple effect for everyone.

Wait, How Did This Even Start?

You may be wondering how fuel prices even got to this all-time high. Well, they can’t be blamed on any specific event or occurrence as many different factors caused fuel prices to surge.

World Conflict

World conflict is one issue affecting fuel prices, specifically those in Western Europe. The Russia-Ukraine war has been brewing for some time now, and due to attacks, the United States among others has stopped imports, like oil, coming from Russia.

Russia is one of the world’s largest oil exporters, exporting nearly eight million barrels in one month. The drastic change in accepting oil imports from Russia has caused the price of fuel to rise because it’s not as available as it once was.

The Dreaded “C” Word

Another catalyst for the spike in fuel prices is the continual effect of Covid-19. I’m sure you’re tired of hearing it, but the world is still feeling the pains of the virus while we aim to return to life. Recently, Covid forced Chinese ports to close for a brief period and now that the ports are opening back up, supply cannot keep up with demand.

As people try to live alongside Covid-19, office workers are going back to in-person work and people are returning to travel after two years of staying put. With more people leaving their homes, it’s causing a greater demand for fuel while our supply is limited.

The Effects of These Issues

Fuel prices are affecting everyone, including consumers, and businesses, but those in the logistics industry are seeing greater challenges. That’s because the logistics sector has seen disruption after disruption. First, with the issues started by the pandemic, then the port congestion once businesses began to reopen, and so on to now with increased fuel prices. This industry has barely had a moment to catch its breath.

Logistics is at a crossroads; with the United States economy looking at a recession, and world conflicts yet to improve, it’s going to be hard for fuel prices to drop back to normal levels until everything balances out.

How Bad is it Actually?

Even though everyone has been hearing and seeing the high fuel prices, how bad are these prices? Well, in June, the U.S. national average price per gallon topped $5, which is 50 percent higher than it was this time last year. Even pre-pandemic prices were at $2.55 average for that month, showing the direct impact that covid and other issues have caused.

These prices only continue to rise when we talk about the cost of diesel fuel. This type is often more expensive than regular gas, and this is what truck drivers use to fill up their tanks. In June, diesel fuel averaged $5.50 per gallon in the U.S., which is a .50-cent increase from regular fuel. While this increase seems small, when truckers are driving over 500 miles per day, the extra cost can add up quickly.

President Joe Biden has tried to take steps to lower fuel prices in the United States. He has called on Congress to do a Federal Gas Tax Holiday, releasing the charges that the federal government has on fuel. Typically, the government charges an 18-cent tax per gallon on gasoline and a 24-cent tax per gallon on diesel, but President Biden has called for the Tax Holiday to give Americans breathing room as they battle other economic issues like inflation.

High fuel prices are not an issue solely faced by the United States. In fact, gas prices in the United States are on the lower end of the spectrum compared to other countries. For example, while the average in June for the United States was $5 per gallon, in Germany, it averaged $8.26 per liter, while one of the highest fuel prices was in Hong Kong, where gas was $10.71 per liter in June.

How Do High Fuel Prices Impact You?

So, how do the rising fuel prices affect those in the logistics industry? Well, let’s take a look.

Shippers

Increased fuel prices mean higher logistics costs because it’s now more expensive to move their products from point A to point B.

Consumers

Consumers see a direct cost increase on products due to fuel prices. Because it now costs more for shippers to move their products to their destinations, they must also raise the price of their products to continue to make a profit.

Carriers

The biggest issue carriers are seeing with the high fuel prices is the impact on their income. Their operating costs have increased due to the rising fuel and product prices. And with rates lower than they’ve been throughout the pandemic, many carriers have decided to put a pause on driving until the market return to normal. This could cause added chaos to the market. Should more carriers halt their work, there could be an imbalance in the industry, causing more backlogs and shipping delays as a result.

Trinity is Here to Help

As an experienced third-party logistics company with over 40 years in business, we’ve worked with many shippers and motor carriers through the ups and downs faced in this industry, including this one. We’ve seen it all and are here to help you through these troubling times.

Whether you’re a shipper looking for better logistics management or a motor carrier looking for dedicated freight to keep you consistently moving, you can find all the solutions you need with our People-Centric approach.

Get connected with us today so you can start having Trinity Logistics, a Burris Logistics Company, by your side, no matter the state of the market.

Learn more about Trinity Logistics Join our mailing listHello there. I’m Holly, Trinity’s friendly neighborhood freight Agent Recruiter.

Every day I have the privilege of working with our Authorized Agents as well as finding new freight agent businesses to welcome into the Trinity family. This has given me a bird’s eye view of what it takes to run a successful freight agent business. And I can tell you, IT’S HARD!!! It’s a grind. It’s a hustle. It requires a BIG dose of grit and determination. But it’s in our blood! We thrive on the fast pace, the opportunity for unlimited income, and the flexibility of running our own show.

With all that being said, I’m extremely proud of the tools, resources, and personalized support Trinity provides to our Authorized Agents daily. While I could go into all the things we can do to help support your freight agent business, today, I’ll settle for the opportunity to introduce you to four unique resources we provide our Authorized Agent network to make their days easier and their businesses more profitable.

SAVE TIME WITH RFPs

Do you find Requests For Proposals (RFPs) an annoying time suck? Not anymore! At Trinity, we take care of the heavy lifting for you.

Trinity’s Authorized Agents have full access to our in-house Pricing Team for RFPs both large and small. Our Team works hard to combine data from many market sources plus our extensive internal lane history to compare a total of nine data points. That’s some impressive wizardry, I tell you! This will not only save you time from figuring out the right pricing but also give you confidence that the pricing details you share with your customer are spot on.

And that’s not all! We also provide you with real-time market-specific rates focused on your customer’s needs. This way, you can be as hands-on or hands-off in the process as you choose.

AND DON’T WORRY ABOUT CAPACITY

You’ve just saved time on the pricing aspect of your RFP. It’s complete, and you’ve won your lanes, but what happens next?

You get on the phone with your relationship carriers for their rates and volume commitments. In an ideal world, the rates are great and there’s plenty of capacity. Awesome! Time to get back to helping your customers and growing your freight agent business.

But how often does that really happen? Often, your relationship carriers don’t run those new lanes, don’t have the capacity to commit, or ask for rates above the market. So, what do you do then? Most likely, head on to those dreaded load boards.

Here comes Trinity to save the day. Our Authorized Agents have full access to our Carrier Procurement and Development Team. This Team of Trinity experts will take the data from your RFP, find you capacity using our proprietary lane matching technology and then get rate agreements in place for COMMITTED capacity to service your customer’s needs.

So, if you often work with RFPs for your customers, go ahead and press the easy button with Trinity!

WORK SMARTER, NOT HARDER

Are you looking for a deeper dive to uncover your most profitable freight? We’re here to help you with that! By using your load history, our Pricing Team will provide you with a Network Analysis to give valuable insight into your most profitable lanes. With this data in mind, you’ll be able to focus your sales efforts on the markets that produce the highest margin to help you reach your freight agent business goals. We’ll help you work smarter, not harder!

EASILY DIVERSIFY YOUR FREIGHT AGENT BUSINESS

One more thought for the day; let’s say you specialize in full truckload freight. In fact, you’re such an expert that you can almost move it with your eyes closed.

But in this constantly evolving freight market, your customers ask you for help with all kinds of other weird stuff like less-than-truckload (LTL), intermodal, drayage, ocean or air, expedited freight, technology solutions, warehousing, e-commerce…maybe even a total outsource!

With you being a full truckload shipping expert, this may sound intimidating! And the last thing you want to do is send them somewhere else and risk that “other guy” poaching your freight.

There’s no longer a need to worry! Trinity Logistics has you covered. We offer full operations teams for our Authorized Agents to handle ALL other modes besides full truckload. Pair that with our parent company, Burris Logistics, and their opportunities, and it’s simple. You bring the opportunity, and we do the rest. All you need to do is sit back and collect the extra margin for your growing freight agent business.

Additionally, we provide you with monthly mode training classes so you can learn and be confident in what you are selling. There’s no need to be the subject matter expert on all modes when you have Trinity Team Members to support you and your freight agent business.

JOIN THE TRINITY FAMILY AND BEGIN GROWING YOUR FREIGHT AGENT BUSINESS

Trinity Logistics has over 30 years of experience aiding in the success of our freight agent businesses, with many of our newer businesses seeing a 50 percent increase over a two-year period from joining. Consider joining our Authorized Agent Network today so you can gain more time to focus on your customers, generate more revenue, and we’ll focus on everything else.

To learn more about our Authorized Agent program and all the ways we can save you time and help you build a successful freight agent business, feel free to contact our Agent Team phone at 800-846-3400 x 1908 or click the button below!

I'd like to connect with TrinityAs more shippers look to reduce freight costs and their carbon footprint, intermodal logistics continues to see rapid growth. The Intermodal Freight Transportation Market has predicted a Compound Annual Growth Rate (CAGR) of 8.27 percent from 2021 to 2026 for intermodal logistics. And with intermodal peak season on the way, shippers using this mode must have the right shipping strategies in place.

Intermodal can be a very effective mode when it matches up with the right customers, but with the rapid growth of customers choosing intermodal logistics, we often hear a similar question from our shipping customers: “What should I expect during intermodal peak season?” So, let’s learn more about what peak season for intermodal is, how it may affect you, and what you can do to stay ahead.

WHEN IS INTERMODAL PEAK SHIPPING SEASON?

Peak shipping season refers to the time of year when freight volumes see an influx. For most modes, this falls in line with the time of year when retailers begin pushing inventory for back-to-school and the holiday season. During this time, shippers try to keep up with demand and manage inventories while fulfilling a high volume of orders, and motor carriers are busier than usual trying to deliver freight on time.

Historically, the peak shipping season for intermodal logistics is around June to December. While June may seem a bit early, many shippers are rushing to get their goods through West Coast ports before June 30th, and rail is a popular way for shippers to transport their West Coast imports. According to the Alameda Corridor Transportation Authority, since 2006, the number of goods imported and then loaded into intermodal equipment through Los Angeles and Long Beach ports has grown 25 percent.

With roughly two-thirds of intermodal containers coming off the West Coast from import traffic during peak season, this limits the supply of 53’ containers heading East.

Even though June is the typical start of peak season for intermodal, it can fluctuate. Some years it can be later or earlier. But since the start of the pandemic, intermodal logistics have been greatly affected by capacity, making peak season more year-round than in former years. This is because of the rapid increase in online shopping year-round for consumers, which the pandemic only heightened.

“The past two years since the beginning of covid-19 has greatly impacted intermodal capacity,” says Jennifer Fritz, Trinity intermodal expert. “Historically peak season for intermodal logistics usually starts June through December, but with capacity affected by the change in supply chains from covid-19, it’s been tight year-round, making peak season pressure felt year-round instead of a few months of the year.”

CHALLENGES OF INTERMODAL PEAK SEASON

Expected or unexpected, any time there is a major shift in supply chains, it can throw off your operation. So, how does peak season affect intermodal logistics? Well, it’s not much different than peak season shipping for any other mode.

You’ll see tightened capacity because of the increased freight volumes and demand. And anytime we see tightened capacity, we see increased prices as well. So, the more in demand something is with less supply, it equals higher rates.

You’re also bound to see some shipping delays and need to give longer lead times. Your usual service levels may also drop because of the overwhelming volumes of freight needing to be moved during peak season shipping. Especially lately with the continued covid-19 pandemic still affecting the market, West Coast ports, and ultimately, intermodal logistics.

Take Control of Your Intermodal Logistics During Peak Season

Make sure you’re not unprepared for intermodal peak season. Each peak season is variable, rarely unlike another, and planning is more critical than ever with it being more frequent and extreme. Here are some tips to help you take control of intermodal peak season.

Give Even More Lead Time

Book your intermodal shipments as far in advance as possible. Prices are volatile during intermodal peak season, and the rate to move a shipment through intermodal logistics can increase by hundreds of dollars over a single day. In addition, available equipment can often be an issue. This is not the season to wait until the last minute.

Stay Updated on the Industry

Ever since the start of the pandemic, it’s more important than ever to know what’s going on in intermodal logistics. As we’ve seen over the past few years, supply chain disruption can happen at any time, so make sure you check the news daily or have a good resource to give you all the information you need.

Try Shipping Later

Perhaps all your items don’t need to arrive during peak season. Great. If possible, schedule those shipments to ship after intermodal peak season, when there is more capacity and you’ll likely get a better shipping rate, or at least stagger them. So, if part of your shipment needs to arrive right away, have that delivered faster. And for any freight that doesn’t need to deliver quickly, schedule that shipment for a later date.

Plan for Extra Time

As noted, with the influx of freight needing to be moved, there are bound to be delays. Many intermodal carriers have fully planned days and if they get delayed, it affects the rest of their movements. So, make sure you allow plenty of time for your products to get to their destination. This will help keep a delay from happening and possibly get you a better freight rate.

Shop Around

Prices can fluctuate between providers and from day to day. If you have the time, try getting prices from a few different providers or being more flexible with your dates to see if you can find a better value. For example, the difference between a 15-day delivery time and a 20-day delivery time could be significant. Check out all avenues and find what works best for your budget and freight.

Have Modal Flexibility

Sometimes a mode will max out on capacity. If capacity is reached for intermodal logistics, ensure you have relationships with over-the-road carriers or a third-party logistics company as a backup. This ensures no matter what, you’ll be able to get your freight from point A to point B.

Leverage Partnerships

Partnering with an experienced 3PL can make navigating peak season for intermodal logistics, or any logistics mode, more accessible. Companies, like Trinity Logistics, often have longstanding relationships with carriers for all modes, plus logistics technology and well-trained teams ready to help you. A reputable 3PL will have seen it all during peak shipping seasons and be able to help you manage your logistics without batting an eyelash.

GET HELP WITH YOUR INTERMODAL LOGISTICS, NO MATTER THE SEASON

While we can’t look into a crystal ball and predict how long this never-ending peak season for intermodal logistics will last, we can tell you that many logistics providers and shippers are adapting. Intermodal peak season shipping can be stressful, but these tips can help you better navigate your intermodal logistics during the peak shipping season.

If you’re looking for help, Trinity Logistics is here to support you. We have a full Team of Intermodal Experts, experienced and ready to assist you with your intermodal logistics. Simply click the button below and let’s get connected.

Learn about our Intermodal serviceTrinity Logistics is proud to share that it has received Comparably’s 2022 Best CEOs for Women Award.

“I wouldn’t be receiving this recognition if it weren’t for the great effort and feedback of the Team Members at Trinity,” said Donnie Burris, CEO of Burris Logistics, the parent company of Trinity Logistics. “At any of the Burris Logistics companies, every Team Member is empowered to pursue excellence within their careers here. I’m very happy to hear that the Team Members at Trinity feel that empowerment and I look forward to continuing that great company culture they have for years to come.”

“To date, 54 percent of Trinity’s Team Members are women and 23 percent of those women, hold a management or leadership role, including Trinity’s President, Sarah Ruffcorn.

“We are blessed to have Donnie Burris as the leader of our organization,” said Sarah Ruffcorn, Trinity Logistics President. “He listens, supports, and encourages all Team Members in our organization to be their best each day. He doesn’t just believe in our purpose of ‘Improving people’s lives by constantly striving to be our best’; he lives it.”

Comparably Awards are based solely on sentiment feedback provided by employees who anonymously rate their employer throughout the year. Comparably Awards showcases the leaders and leadership teams who are driving positive culture change across companies large and small. The Best CEOs for Women for 2022 represents the top-ranked CEOs as rated by female employees on Comparably.com throughout the previous 12 months. Every CEO on the list is in the Top five percent of all CEOs rated by female employees.

“The top-rated leaders on our annual Best CEOs for Women list have fostered inclusive company cultures that make everyone feel supported and heard,” said Comparably CEO Jason Nazar. “Donnie Burris’ high ratings from Trinity’s female employees is a testament to his commitment in this arena.”

Stay in the know. Join our mailing list.Interested in working with an organization that is committed to you and your career growth?

Become A Team MemberAbout Trinity Logistics

Trinity Logistics is a Burris Logistics Company, offering People-Centric Freight Solutions®. Our mission is to deliver creative logistics solutions through a mix of human ingenuity and innovative technology, enriching the lives of those we serve.

For the past 40 years, we’ve been arranging freight for businesses of all sizes in truckload, less-than-truckload (LTL), warehousing, intermodal, drayage, expedited, international, and technology solutions.

We are currently recognized on Transport Topics’ Top 100 Freight Brokerage List, a Top 3PL and Cold Storage Provider by Food Logistics, and a Top Company for Women to Work for in Transportation by Women in Trucking.

About Comparably

Comparably is a leading workplace culture and corporate brand reputation platform with over 15 million anonymous employee ratings on 70,000 companies. With the most comprehensive data on large and SMB organizations in nearly 20 different workplace categories – based on gender, ethnicity, age, experience, industry, location, education – it is one of the most used SaaS platforms for employer branding and a trusted third-party site for workplace culture and compensation. For more information on Comparably’s studies and annual Best Places to Work Awards, visit Comparably News.

Have you ever wondered what a freight broker is, what they do, and why they exist?

To put it in simple terms, freight brokers are simply matchmakers. They are the middleman between the shipper (the maker or owner of the product) and the trucking company that moves the freight.

Freight brokers perform a valuable service for both ends of the spectrum, however, they do not function as an actual motor carrier. Instead, they arrange for the transport of goods.

Freight broker activities are under the jurisdiction of the Federal Motor Carrier Safety Administration (FMCSA) which defines a broker as “a person who, for compensation, arranges, or offers to arrange, the transportation of property by an authorized motor carrier”. -49 C.F.R. Part 371

Brokerages

Freight brokerages provide assistance to motor carriers by filling their trucks and providing assistance along the route to help the truck driver deliver the order on time.

Not every motor carrier has a private sales force working to secure loads for their fleet and needs help accessing a network of shippers quickly to keep them rolling. Freight brokers also provide great financial service to truckers, providing fuel advances to help with cash flow and offering quick payment plans. Oftentimes, the carrier is paid before the freight broker collects payment from the shipper! Bottom line, a freight broker exists to help the motor carriers relocate their equipment to a better freight market, or in many cases, back to their home base.

Many companies find the services provided by freight brokers to be an important link in their supply chain. The importance of a freight broker is easy to understand; the freight broker makes sure that the shipments are arranged to deliver on time at a fair price with reputable providers. Without freight brokers, shippers would encounter an enormous investment of time and money trying to find the right motor carrier to transport their products, tracking the shipment, and auditing freight bills.

Frustrated with your shipment tracking? Check out Trinity’s Customer Portal and see how easy it is to track your shipments, view and pay your invoices online, and request freight quotes.

Discover Trinity Logistics AS YOUR FREIGHT BROKER PARTNER

Trinity Logistics, ranked by Transport Topics as one of the Top Freight Brokerages for the 20th consecutive year, moves an average of over 40,000 loads per month. With that amount of volume, we carry significant buying power and relationships with our carrier network. That translates into savings on each shipment that many shippers may not be able to obtain based on their volume alone.

Trinity Logistics saves shippers and motor carriers a great deal of time playing matchmaker. Our goal is not only to deliver your product on time but also to deliver time itself so that you can perform at your best without having to become experts in matching loads to trucks or vice versa.

Learn more about our solutions.There are several shipping options available for your freight. Sometimes it can be difficult to determine which mode of transportation will suit your needs best. One mode to consider for your freight is intermodal shipping.

If this mode has been one you’ve been interested in learning more about, we’re here to help. First, we’ll walk you through what intermodal shipping is, when you should consider this mode, its benefits, and how intermodal rates work, so you can be on your way to transporting your freight in a new way!

What is Intermodal Shipping?

Intermodal shipping is the use of two or more modes to get the product from shipper to receiver. This could include any combination of ocean, air, rail, or truck transportation. However, in North America, intermodal often refers to the combination of using trucks and rail to move freight in shipping containers.

Drayage

Another good term to know when talking about intermodal shipping is drayage. Drayage describes the trucking service from an ocean port or rail ramp. Drayage carriers are power only, meaning they only supply the truck or power unit. They pick up and drop off any equipment (the container and chassis) owned by the railroad, an intermodal provider, or ocean freight liners. Most often, drayage carriers will complete multiple loads in a day respective to their region.

When Should I Consider Intermodal Shipping?

Almost anything that can ship via truckload can be shipped intermodal. Here are some qualifiers on whether your shipments make sense to ship intermodal:

· You are looking to reduce shipping costs.

· You want to reduce risk during travel and have less handling of your product.

· You want your company to be more environmentally considerate with your shipping.

· You have long-distance shipments, over 750 miles.

· You have a lot of freight to move and a flexible delivery timeline.

· You have frequent shipments going to the same locations in similar quantities.

If any of the above qualifiers sound like you and your freight shipments, read on to learn about some of the benefits of switching up to intermodal shipping for your transportation.

Benefits of Intermodal Shipping

Moves a Lot of Product

A single train can move a load size equal to 280 truckloads. Essentially, you have an entire fleet at your disposal. As a result, high-volume shipments meet maximum efficiency when shipping intermodal. This can save you time and money by reducing fuel and labor costs.

Quick(er) Shipping

Most people wouldn’t imagine intermodal shipping being quick enough. Not too long ago, a coast-to-coast shipment would take about two weeks. Now, it only takes about seven to 10 days, depending on the lane. If your delivery date is more flexible and not immediate, intermodal can make sense for your shipments. Additionally, intermodal sees fewer disruptions, making it more reliable than truckload. Intermodal does not have to worry about traffic patterns, weigh stations, checkpoints, or other issues compared to trucking.

Stay Green

Intermodal is more fuel-efficient than trucking since more products can be moved almost 500 miles on a single gallon of diesel fuel. According to the Environmental Protection Agency (EPA), replacing Over-The-Road shipments exceeding 1,000 miles with intermodal shipping reduces greenhouse gas emissions by 65 percent. Additionally, better fuel efficiency means savings on shipping costs.

Reduced Risk

When choosing to ship intermodal, shippers have far less exposure to roadway collisions, which means less chance of damage to your product. The risk of damage is also lowered because freight is loaded onto containers and not directly handled when changing between truck and rail. In addition, theft concerns are reduced as railyards are constantly monitored and no one can go in or out without documentation.

Understanding Intermodal Rates

Intermodal shipping rates have three basic parts: an origin drayage rate, a rail linehaul, and a destination drayage rate. However, door-to-door rates are typically an all-in rate comprised of those three components.

Drayage Rates

Drayage carriers offer consistent rates since they start and/or end every load at a consistent location, the intermodal rail ramp. Like truckload, drayage rates are a flat rate plus a fuel surcharge. Drayage carriers often provide a point-to-point pricing matrix including pick-up and delivery rates from every intermodal ramp to dozens of destinations within their region. Unlike truckload spot rates, drayage rates are much less volatile because drayage carriers often update their pricing matrix once a year, unlike the spot market which fluctuates daily.

It’s important to note that when using drayage as a stand-alone service, you see other surcharges such as chassis fees or charges for port congestion or wait time at the rail or port.

Rail Rates

There are seven Class I railroads in North America:

- Union Pacific (Western U.S)

- BNSF (Western U.S)

- CSX (Eastern U.S)

- Norfolk Southern (Eastern U.S.)

- Canadian Pacific (Canada and Northern U.S.)

- Canadian National (Canada and Northern U.S.)

- Kansas City Southern (South Central U.S. and Mexico)

Your intermodal marketing company (IMC) will get pricing matrixes from these railroads, which include rates from their intermodal ramps to other ramps. Rail rates are a flat fee plus a fuel surcharge.

Important to note: Shippers cannot access intermodal rates directly from the railroads. You MUST work with an intermodal marketing company or third-party logistics company (3PL), like Trinity.

Don’t Forget About Accessorials

Because intermodal shipping depends on efficiency, accessorials are much more common than shipping truckload. Since intermodal shipping is very predictable and competitive, intermodal providers present shippers with the most efficient pricing, expecting to be compensated for any accessorials should they occur.

Because of this, ensure you understand your provider’s accessorial policy and find out how those fees are factored into their rates. Even still, there’s no need to fear intermodal shipping because of the accessorial fees. In the long-term, intermodal shipping, even with accessorials, makes the overall cost savings of the mode worth it.

Trinity Can Help With Your Intermodal Shipping

If you’re seeking to increase efficiencies in your supply chain logistics and transportation, intermodal is one mode to highly consider. The idea of using intermodal shipping over truckload can be intimidating, but choosing an experienced and knowledgeable provider, such as Trinity Logistics, can make the change an easy one.

Find out more about Trinity's intermodal option.