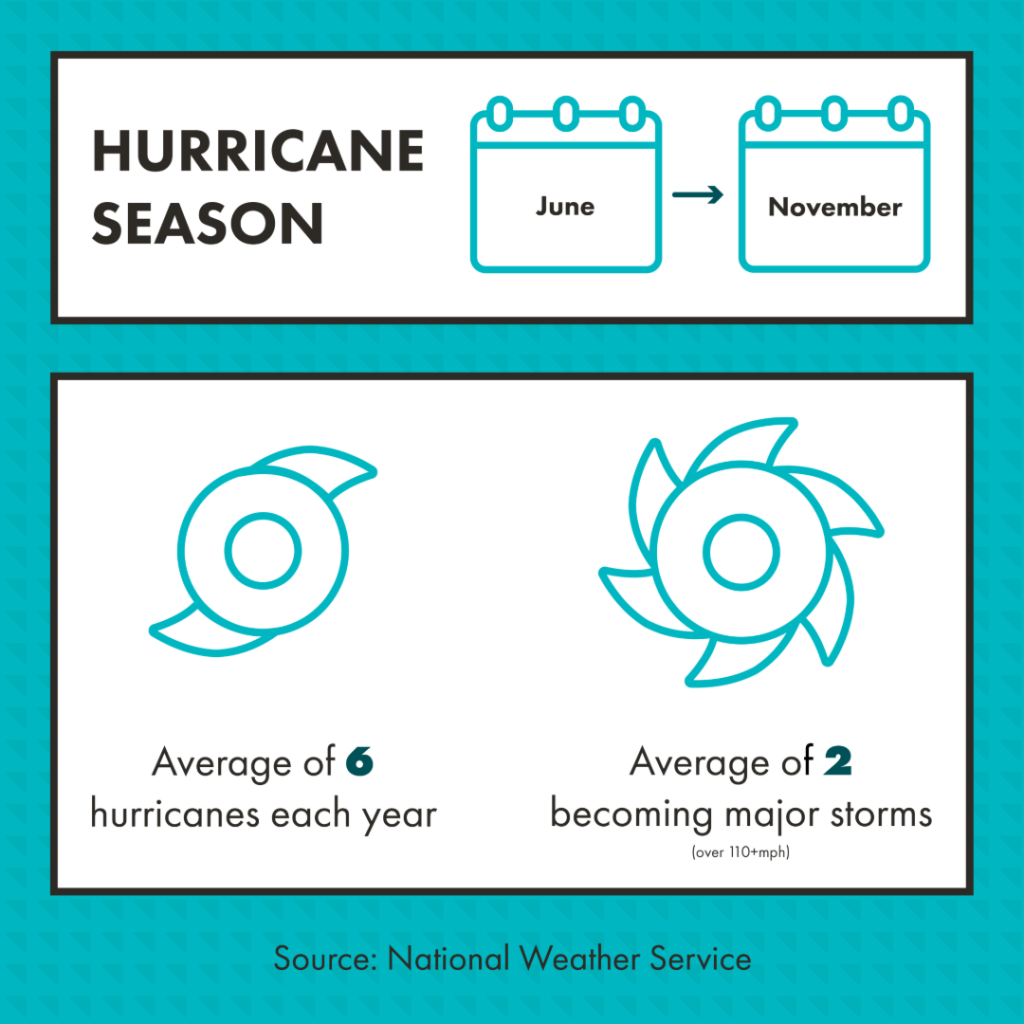

June 1st through the end of November is considered Hurricane Season for the Atlantic and Gulf Coast, with heightened chances of storms occurring from early August to October. According to the National Weather Service, there’s an average of six hurricanes each year, with two typically becoming major storms hosting winds of 110-plus mph.

Even on its best days, the logistics industry is considered complicated. Throw a hurricane in the mix, and you can have straight-up chaos. Hurricane Season means supply chains should prepare for the worst in weather, like heavy rain, dangerous gusts of wind, limited visibility, and flooding. Shipping setbacks such as impassable roadways, stranded trucks and drivers, loss of cargo, and extended deliveries are just some of what can be experienced. Here’s what your organization needs to know to prepare during peak Hurricane Season so your company can avoid delays and a loss in revenue.

Supply Chain Tips for Peak Hurricane Season

Stay Informed

A hurricane’s path and level of impact can change very quickly. It’s crucial you stay informed of potential storms that could impact your supply chain during Hurricane Season.

Set up alerts to be notified of newly formed storms and hurricanes. When a potential storm is in your path find a trusted weather news source and check it often for updates. Don’t just follow the updates before the storm, but also during and after. You may also adopt and use advanced weather tracking systems to get up-to-date information to make informed, real-time decisions.

Maintain Communication

Natural disasters, like hurricanes, can have a huge impact on your company’s supply chain. An easy way to stay ahead is to be transparent and communicate openly throughout. Transparency builds trust and helps manage expectations during a crisis.

If a potential hurricane threatens your business, acknowledge it immediately. Then, start communicating with your customers and partners about the potential effects. Regular updates on potential disruptions and recovery efforts can go a long way in maintaining strong business relationships.

Have an Emergency Plan Ready

You should have a company-wide plan that outlines its actions during a hurricane. Your emergency plan should include important details like;

- an evacuation route for buildings affected

- a crisis communication plan

- assigned employee emergency roles and responsibilities

- instructions on how to protect inventory and equipment

- where emergency supplies are located and how best to use them

- how capable facilities will support when others are affected

When planning, make safety your company’s top priority during a hurricane. Once established, your plan should be reviewed often and updated as needed to ensure it remains effective. Additionally, running practice drills can help everyone know their roles and responsibilities.

Consider Alternatives

Consider what alternative workspaces and methods of transport you could use in the event of a hurricane. Are there temporary warehouse solutions where inventory could be stored? Could intermodal replace a truckload shipment that’s in the path of the storm? Are there alternative routes? How can facilities outside of the storm’s path support those affected? These alternative options should be included in your emergency plan.

While you may not have all the answers when planning, the more you include, the quicker you can make strategic decisions when needed. Having room for flexibility and adaptability is key to minimizing disruptions.

Have Visibility in Your Supply Chain

Visibility is needed now more than ever for supply chains. Having visibility not only helps you on good days but especially during hurricane season.

A transportation management system (TMS) can provide the necessary visibility during a hurricane. It provides critical data about your shipments and orders in real-time, giving you an advantage should a problem arise. This can help you make quick decisions to reroute shipments, avoid affected areas, and keep your customers informed.

See how a TMS could help youThink About Recovery

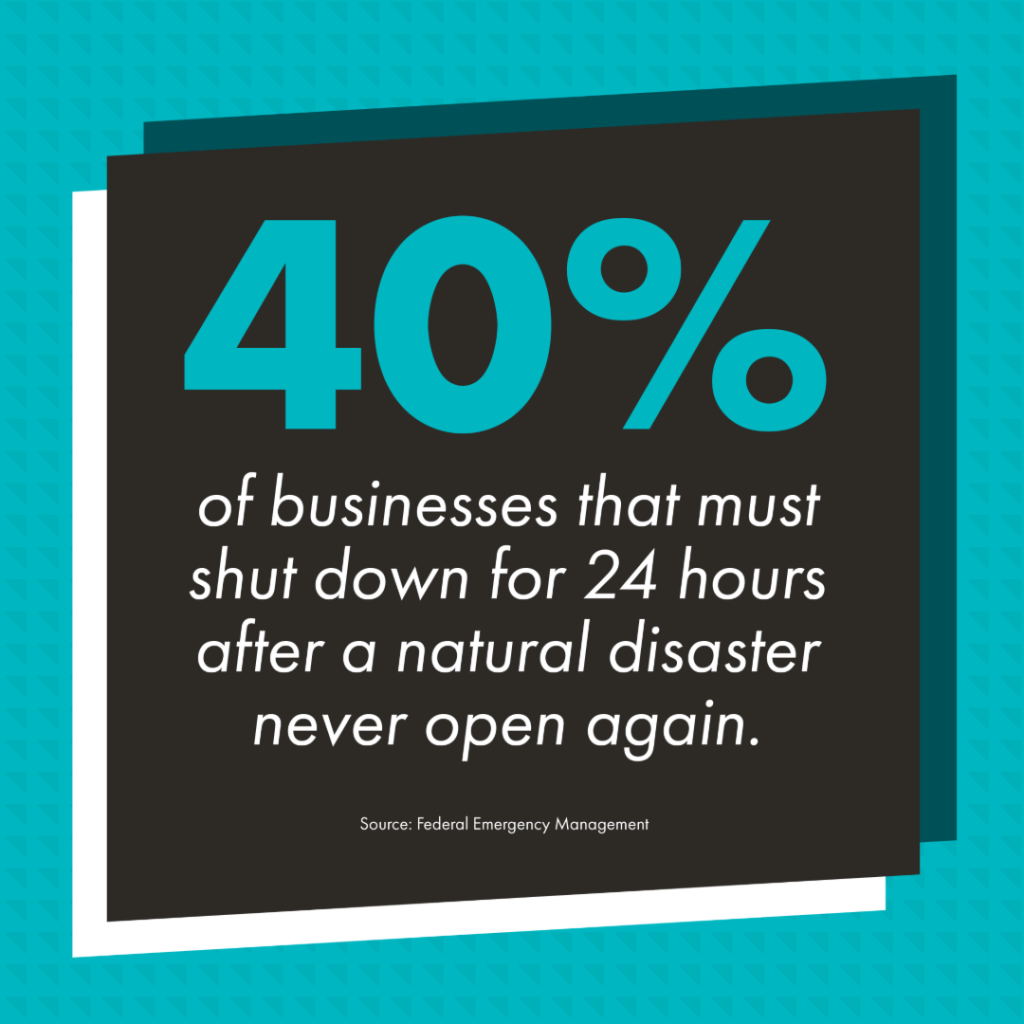

According to the Federal Emergency Management Agency (FEMA), almost 40 percent of businesses that have to shut down for 24 hours due to a natural disaster never open again.

Ensure your business won’t be in that 40 percent if it happens. Have a plan ready to roll for the aftermath of a hurricane. Prepare for the worst and then plan how to recover from it quickly. This will help prevent any potentially steep revenue loss.

Recovery Team, assemble! It’s time to identify the key employees and providers to get your business back to normal operations. An initial assessment will need to take place and your team’s sole responsibility should be to restore and resume processes. Having those alternative solutions and backup suppliers or providers will be handy here.

Weather the Storm with a Reliable Logistics Partner

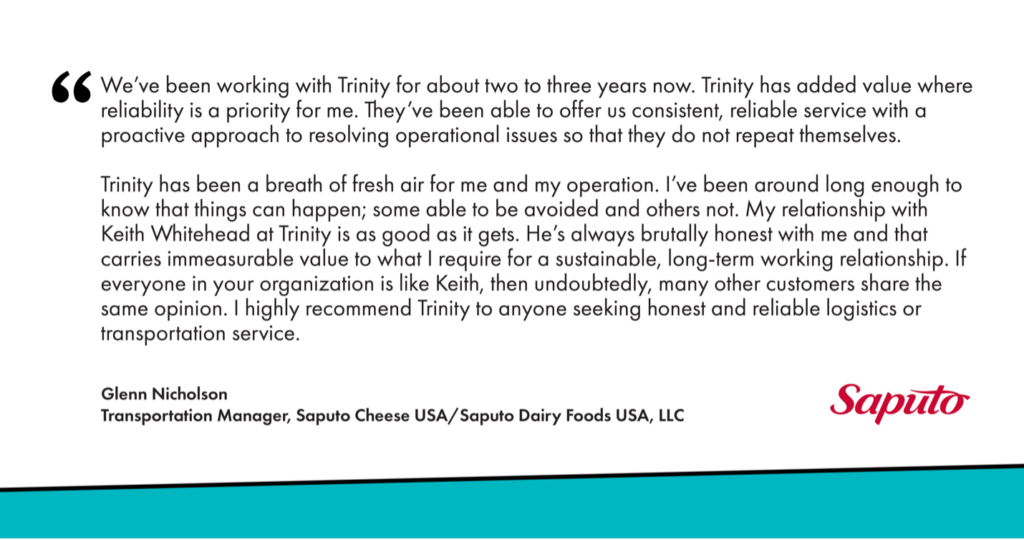

Sometimes, you just need extra help. A relationship with a reliable logistics provider, like Trinity Logistics, can help your supply chain overcome the threats of Hurricane Season.

Hurricanes can roll in a cloudy overcast of unknowns, but Trinity shines a light toward safety and security. We have over 45 years of experience helping thousands of supply chains through ups and downs. We thrive on problem-solving and handling issues like the ones hurricanes can bring. We also have a dedicated After-Hours Team to support and quickly resolve any potential challenges – no matter the time of night, holidays, or weekend.

Our nationwide network of trusted carrier relationships ensures your shipments arrive safely at their delivery locations. Additionally, multiple transportation options offer the flexibility to keep your goods moving. Lastly, we’ll help you find real-time visibility with our customizable Managed Transportation solutions. Our dedicated Team (comprised of six Regional offices across the nation) is ready to help you maintain continuity and resilience in your supply chain.

Partner with Trinity logistics so your supply chain can stay afloat, no matter the weather. (Our exceptional service might just blow you away, though!)

GET A FREE QUOTE ON YOUR NEXT SHIPMENT SUBSCRIBE & STAY IN THE KNOW LEARN MORE ABOUT TRINITY LOGISTICS

Do you feel like you could be spending less on your less-than-truckload (LTL) shipping rates? Most likely, you’re right. LTL shipping rates are affected by many different factors, so it can be pretty easy to make these simple changes and see your shipping costs decrease. While these tips may not be possible for everyone or every shipment, hopefully, you’ll find one you can start implementing to reduce your freight costs.

HOW LTL SHIPPING RATES ARE CALCULATED

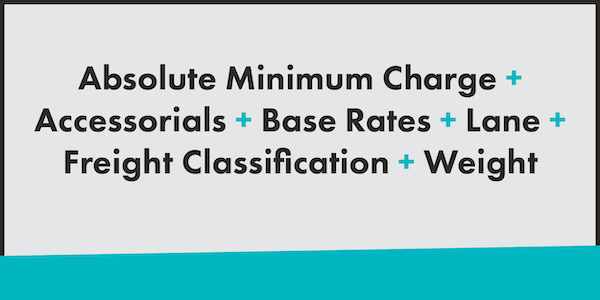

Compared to truckload rates, LTL shipping rates can be very confusing. To make it simpler, here’s what goes into your LTL costs.

Absolute Minimum Charge

This is the lowest rate a carrier will charge.

Accessorials

These are extra charges for any services provided by the carrier that are beyond simply shipping from one point to another. Examples of common accessorials include:

- Inside pickup or delivery

- Lift gate service

- Residential delivery

- Detention storage

Base Rates

Each LTL carrier sets its own base rate, often quoted per 100 lbs., and based on the freight classification, weight of the shipment, distance traveled, and the origin and destination zip codes.

Lane

The lane plays a role in the base rate. The further the distance traveled in the lane, the more costly the LTL shipping rate can be.

Freight Classification

The product you ship has its own classification based on the National Motor Freight Classification (NMFC). Freight that is dense and difficult to break is in a lower class, making it the least expensive. Lighter and more fragile freight is at a higher freight class and thus, costs more.

Weight

LTL shipping rates are based on the total weight and number of pallets. The heavier a shipment, the less it costs per hundred pounds, as factored by the base rate calculation.

HOW TO SAVE ON YOUR LTL SHIPPING RATES

Maximize Density

LTL carriers make a profit by fitting as many different LTL shipments into their trailers as safely as possible. So, which do you think they prefer – a shipment that takes up 25 percent of their trailer or a shipment that takes up 10 percent? The less space your shipment can take up, the less it could cost to ship it.

While the weight of your shipment may be out of your control, the density is not. Increasing density starts with how you pack your LTL freight. Experienced shippers know that doing everything they can to compactly pack their freight on pallets will reduce their LTL shipping rates.

So, do everything you can to make your shipment take up less space. If your current pallets are not stackable, find a way to make them, if possible. Reduce any empty space between cases or products on the pallet. If possible, stack an extra row on top of each pallet to eliminate using an extra pallet. Brainstorm all the ways to make your shipment take up less space, and you’ll likely see savings.

*It’s important to note that you should never negate safety or product quality to reduce your shipping rates!

Aim to Avoid Peak Shipping When Possible

While this may not always be possible, avoiding peak shipping times is an easy way to reduce your LTL shipping costs. When you can, plan and ship early or after peak times.

Evaluate Packaging and Product Design for Logistics

Now this tip is more of a hefty task, but it’s certainly one to consider. When in the early stages of product and packaging design, or even when re-evaluating, it’s ideal to get one of your logistics professionals involved. This will help your product and package designers consider details that can make your product easy to ship, stack, and organize. There’s nothing worse than having a great product only to end up with it being too cost-prohibitive to transport.

Consider “Economy Class” LTL Carriers

If your shipment isn’t time-sensitive, using “economy class” LTL carriers is an easy way to reduce your LTL shipping rates. Their rates are often cheaper but their transit times are longer, so you’re trading off higher costs for more time. If you have time to spare, this is a great option for savings.

Ship Larger Loads Less Often

As you likely know, it’s cheaper to ship several pallets at once than one at a time over a few weeks. However, to use this strategy, you’ll have to convince your customers to take on larger orders. You can offer them a price break or agree to share some of the savings you see in shipping to do so.

Consolidate to One Truckload

Eliminating a shipment altogether is a surefire way to reduce your freight costs.

Have you ever considered consolidating your LTL shipments into a multi-stop truckload shipment? Shipping a full truckload of freight is often far less expensive than shipping multiple LTL shipments.

Of course, it depends on where your shipments are delivering. For example, a multi-stop truckload picking up in Maine and delivering in Florida, Minnesota, and California might not make financial sense compared to shipping LTL. But if your delivery points are close to each other, or if they form a line across the country (at least vaguely), getting a quote on a consolidated truckload shipment would be very wise

If you don’t have enough for a full truckload, you could still consolidate and combine two or more LTL shipments into one. It’s worth it to see if any sort of consolidation can reduce your LTL shipping rates.

Negotiate with LTL Carriers

It never hurts to ask or negotiate for a discounted rate with your LTL carrier. Perhaps you can have an accessorial fee waived or reduced based on shipment frequency.

If you ship all kinds of freight, you may be able to negotiate freight of all kinds (FAK) for reduced LTL shipping rates. Rather than getting a rate for different classes of freight (which can be time-consuming and complicated), you negotiate to have all your LTL freight rated in the same class, with FAK, which not only saves you time but money.

You could also negotiate for Customer Specific Pricing (CSP). This is contracted pricing, which could include a FAK structure if needed. LTL CSP allows carriers to have a better picture of your freight which not only results in more efficient, but often cheaper, pricing since the rate contracts are ONLY based on your shipments.

Interested in LTL CSP? Let Trinity negotiate with LTL carriers on your behalf.

Avoid Accessorials When Possible

Accessorials in LTL shipping are common and some may be unavoidable, but many can be avoided when planning ahead. To avoid these extra charges, make sure to educate yourself on your LTL carrier’s guidelines and accessorial fees, aim to avoid weight, dimension, and oversizing adjustments, and ensure your bill of lading (BOL) is accurate. Taking these extra steps will ensure you don’t get hit with unexpected charges and keep your LTL shipping rates low.

Provide Accurate Information

Most shippers are aware that the rate for shipping their LTL freight is highly dependent on the size and weight. For this reason, some people are tempted to slightly underestimate the dimensions or weight of their shipment in the hopes it will result in a slightly lower shipping cost and the LTL carrier will be none the wiser.

Whatever you do, don’t do this! Rather than saving money, you may be opening yourself up to extra charges. Most carriers will double-check that the dimensions and weight of your shipment match what’s on the BOL. If it doesn’t match, you’ll be faced with extra, unexpected charges. Your shipment cost will be raised accordingly, but you’ll also be charged with an inspection or reweigh fee, and it’s possible the carrier will red flag your freight to be inspected every single time you ship with them, meaning you just caused increased LTL shipping rates for the future – the opposite of what you wanted.

Use a TMS for Efficiencies

Controlling your shipping costs can be difficult without having full visibility of your freight spend. So, if you’re really looking to take control of your freight costs, a transportation management system (TMS) is what you need. A TMS can give you clear insight into your logistics with comprehensive reporting so you can find more ways to save on your LTL shipping rates while also finding efficiencies in your operations.

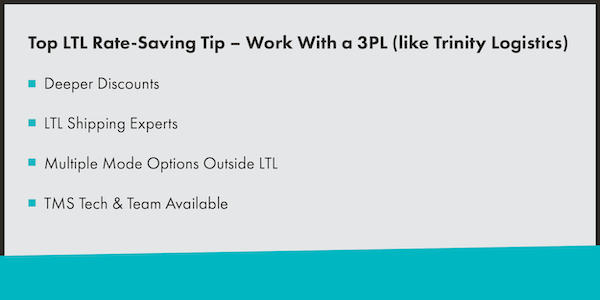

WORK WITH A 3PL

Probably the quickest and easiest way to save on your LTL shipping rates and your time is working with a third-party logistics company (3PL), like Trinity Logistics.

Because of the high volume of freight that 3PLs arrange for all their customers, means we have lower contracted rates (aka deeper discounts) available that you otherwise wouldn’t be able to access. This will result in significant cost savings, especially over time.

Working with Trinity Logistics also gives you the benefit of working with logistics experts who can help you not only with your LTL shipping but any other modes you may need or be interested in. We’ll help you determine what other modes make sense and what other benefits or savings they could offer your business. We also have a dedicated Team to assist you with Managed Transportation or implementing a TMS if that’s something you may need now, or in the future as you grow.

Whether you simply need help saving on your LTL shipping rates or would like a valuable logistics partner on your side for all your logistics needs, our Team is ready to help you and your business succeed.

LEARN HOW TRINITY CAN HELP YOU WITH LTL SHIPPING START SAVING ON LTL SHIPPING RATES-GET A FREE QUOTECraft Beer Logistics: Navigate Complexity, Grow Your Business

Beer, a beloved and timeless beverage. It’s a staple in many cultures and continues to be one of the world’s most popular drinks. A growing subset in beer is the craft beer industry, known for its robustness, variety of flavors, and highlighting regional tastes. According to the Brewers Association, in 2022, craft beer sales increased five percent and now account for almost a quarter of the U.S. beer market. While the demand for craft beer grows, the logistics behind its distribution is increasingly complex.

Craft brewery owners often wear many hats and have lots of tasks to hop on. This can include handling their logistics. This includes more than just the shipping of their beer but the many ingredients and equipment that go into making it. From start to finish, these beer supply chains involve numerous stages and stakeholders, including ingredient manufacturers, distributors, and retailers.

Having effective logistics planning and processes is crucial for craft brewers to meet their growing demand and provide great service to their stakeholders. Managing their supply chains can be difficult to do alone, which is why a third-party logistics (3PL) provider can be a valuable resource to growing craft breweries.

LOGISTICS CHALLENGES FACING THE CRAFT BEER INDUSTRY

Knowing how to legally and efficiently manage their shipping networks is a crucial part of running a successful craft brewery business. There are several challenges craft brewers face such as keeping temperature control throughout transportation, meeting state regulations, and meeting customer demand.

PERISHABLE INGREDIENTS AND PRODUCTS

The need for temperature control in the logistics of craft beer is paramount to preserve the integrity of any needed ingredients or finished products.

Craft brewers also often experiment with ciders, mead, and other malt beverages with specialized flavors, which can include perishable ingredients like fruit. The shelf life of the raw materials and craft beer brings along the element of urgency, placing even more importance on on-time deliveries. Coordinating these shipments to ensure quality beer adds an additional layer of complexity to the logistics process.

REGULATORY COMPLIANCE

Navigating the web of regulations for shipping beer in logistics can be a considerable challenge. Regulations for shipping alcohol vary from state to state, meaning you’ll need to be compliant based on where you are shipping to and from. Additionally, state laws will often change every few years, making it even more difficult.

Craft brewers must also find carriers with the correct licensing, knowledge, and experience to handle the unique requirements of transporting alcoholic beverages. It’s important to work with a logistics provider that knows all the ins and outs of meeting your product’s requirements and state regulations to prevent costly disruptions due to non-compliance.

MEETING CUSTOMER DEMAND

As craft brewers reach more customers, the more need there is for effective logistics planning. Having to juggle keeping track of supplies, determining the most efficient distribution methods, and preparing for any supply chain disruption can be overwhelming. Having a successful craft brewery goes beyond just brewing great beer, but ensuring it reaches the consumer when and where they want it.

Managing costs is on top of rolling out new beverages can be a significant challenge for craft breweries. Having efficient strategies, such as freight consolidation or finding the most cost-effective mode of transportation, can help keep costs in check. This is where an expert third-party logistics company (3PL) can assist with strategy and technology, like a transportation management system (TMS) for visible reporting.

3PL BENEFITS: BREWING SUCCESS WITH TRINITY LOGISTICS

While there may be difficulties to face in the dynamic world of craft brewing, partnering with a 3PL like Trinity Logistics can alleviate the burden. Here’s why working with us for your craft beer shipping and supply chain is the perfect recipe for success:

Our Only Job is Logistics

Logistics is what we handle day in and day out. When you trust us with your freight, you get more time to focus on what you do best – brewing exceptional beer and growing your business.

Experts in Specialized Shipments

Understanding the nuances of transporting freight with specialized requirements, such as temperature control, is our expertise. Whether it’s raw materials or the final product, we ensure everything arrives in optimal condition.

Regulation Compliance

Our dedicated Team and compliance department work diligently to ensure the necessary regulations are meant to provide you peace of mind and reduced risk.

Tracking and Tracing

We understand transparency is key to your success, so we offer several ways to view and keep track of your freight, no matter the time of day.

Effective Logistics Strategies

Whether you need help with something as simple as finding the most cost-effective mode of transportation to freight consolidation, we can help you find and implement strategies to optimize your supply chain and manage costs. It doesn’t matter if it’s just one or 20 pallets of freight, we can arrange full truckload, less-than-truckload (LTL), expedited, or any other mode you may need.

Reduced Risk

At Trinity, we meticulously verify all carrier relationships that we work with, not just during the initial setup but for every shipment. We’re also proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. If something does happen, we have a Cargo Claims Department at the ready to assist you in navigating any issues.

24/7/365 Support

No matter what happens, we’re ready to support you around the clock. We have a dedicated After-Hours Team to continue the monitoring of your freight and are ready to quickly resolve potential challenges, no matter the time of night, holidays, and every weekend.

Trustworthy Carrier Relationships

We treat and respect our carrier relationships just as much as our shipper ones. We aim to build a strong partnership with each one to help their businesses be successful. Because of that, we’ve built strong and trusted partnerships with those in our carrier network, providing you further confidence that your freight will arrive safely.

Managed Transportation

Whether you solely need a TMS for your transportation management, you’re looking for a fully outsourced solution, or something in between, we can help. We understand companies don’t come one-size-fits-all, and neither should the services you need to optimize your logistics. Our Managed Transportation services cater to businesses of all sizes and needs, capable of growing right alongside your brewing venture.

Partnering with Trinity Logistics offers you more than just transportation services. We’re a trusted, strategic ally that’s invested in seeing your business succeed. Leave the logistics to the seasoned experts, so you can focus on creatively and passionately brewing while we ensure your craft brews reach your consumers right when they want it.

LET US HELP WHAT ALES YOU IN LOGISTICSConsumers want more fruits and vegetables in their diets but produce shippers must face these common logistics challenges to keep up with their demand.

It’s hard to deny the nutritional value fruits and vegetables bring to our diets. It’s likely why there’s been substantial growth in consumer demand for produce over the past decade. While that’s great for businesses based in produce, there’s also greater pressure for produce shippers to deliver.

The journey from farm to table can be surprisingly complex for fruits and vegetables. Produce shippers face several hurdles that they need to overcome for their products to deliver fresh and meet the growing consumer demand. Let’s explore the intricacies of these difficulties and how they all can be taken care of by working with a third-party logistics (3PL) provider, like Trinity Logistics.

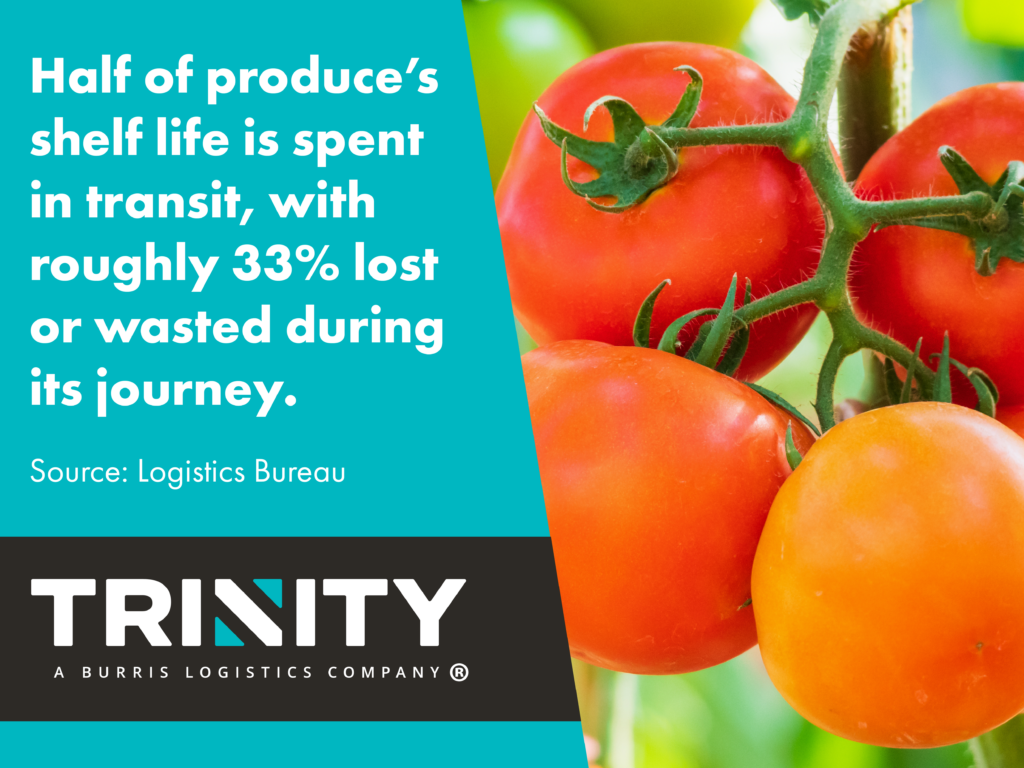

CHALLENGE 1: CHOOSING BEST TRANSPORTATION MODE

Produce shippers first face the challenge of determining what transportation mode to use for their shipments. With produce, half of its shelf life is spent in transit. It’s also reported that roughly 33 percent of produce is lost or wasted during its journey, according to the Logistics Bureau.

This is why produce shippers must ask themselves these questions to help determine the right transportation mode for their shipment.

What’s best for your product?

What can you afford?

How much time does your produce have?

Air is great for foods that have a very short shelf life and may need expedited shipping. However, air is often the most expensive of your options. Rail can offer you cost savings but requires more travel time, often two to three days. This option is often saved for produce with a longer shelf life. Lastly, there’s truckload shipping, which offers several shipping options and costs, depending on factors like whether you need a full truck, expedited shipping, or freight consolidation.

CHALLENGE 2: SELECTING THE RIGHT CARRIER PARTNER

The next challenge produce shippers need to tackle is choosing the right carrier to pick up and deliver their shipment. This may be the most crucial task of all because the carrier you choose can make or break your shipment. You need to trust the carrier you choose has experience in handling your specific cargo and meeting food safety regulations, especially for those that need temperature control.

CHALLENGE 3: MAINTAINING FRESHNESS/QUALITY

Maintaining freshness is one of the primary logistics challenges for produce shippers. Millions of dollars are wasted each year on produce that didn’t maintain freshness by delivery.

Produce begins to deteriorate the moment it’s harvested, so the risk of decomposition is equal to, or perhaps even greater, to produce shippers than those of theft or delay. Fresh or frozen produce needs to be stored and transported at specific temperatures to ensure its quality when bought and eaten by the consumer. Even the amount of humidity, light, or kind of packaging can affect a produce product, so produce shippers face this challenge in every segment of their shipping.

Every kind of produce also has different needs. Some need very specific environments to maintain freshness. Others can stay at room temperature or take on more handling. Shelf life is also something to consider. Produce with short shelf lives will need quick transit from farm to store. This also means several kinds of produce often can’t ship together. Since there is no one-size-fits-all process for produce, it’s important for produce shippers and their logistics partners to understand what’s needed for the specific product to deliver at peak quality.

CHALLENGE 4: SHIPMENT VISIBILITY

Tracking and shipment visibility is essential for produce shippers to be able to reduce risk. Without a clear look into your shipments, you’re left in the dark and uncertain whether your product will arrive on time or in acceptable condition.

This can challenge more than just produce shippers, but all stakeholders in a company’s supply chain. Miscommunication can happen between retailers and sellers as well, causing miscalculations in capacity planning or undependable forecasts. Real-time visibility and data are absolutely needed for produce shippers to enhance transparency with their business partners and gain more control over their supply chains.

CHALLENGE 5: REGULATIONS

Navigating regulations is a huge challenge for produce shippers. Failure to meet those regulations can lead to severe and often costly consequences. For example, in the U.S., produce shippers must comply with the Food Safety Modernization Act (FSMA), which entails specific guidelines for food safety.

There are also quality standards and labeling requirements to be met. The U.S. Department of Agriculture (USDA) has a strict grading system to determine the quality of produce, considering its size, shape, color, and defects.

CHALLENGE 6: HANDLING ANY CLAIMS

There’s always a risk for claims in shipping, but claims can happen more often for produce shippers compared to other industries, due to its shorter shelf life. The majority of claims we see in produce shipping are the result of spoilage, which can happen for many different reasons.

Handling claims for produce is slightly more difficult due to the Perishable Agricultural Commodities Act (PACA). When handling produce claims, it’s important you and your transportation provider understand and follow PACA.

HOW TRINITY LOGISTICS HELPS PRODUCE SHIPPERS OVERCOME THEIR CHALLENGES

All those challenges listed above that you may face – we know how and are prepared to handle them.

After 45 years of serving shippers in the food and beverage industry, we’re experts in its logistics requirements and regulations. We also take part in industry organizations, like the International Fresh Produce Association, so we stay knowledgeable about what may affect produce shippers.

When it comes to choosing your transportation mode, we have a multitude of options available to support you, whether you’re looking for help with one shipment or a fully outsourced logistics solution.

Additionally, we work with trusted carrier relationships that have been fully vetted to ensure your product travels safely and delivers on time. This includes vetting that reefer equipment is not older than 2012 and a temp-reading or download can be made readily available for any refrigerated or frozen produce shipments.

No matter where your freight is in its journey, we provide you with several real-time tracking options to stay fully informed. Through our Managed Transportation service and the use of a transportation management system (TMS), you can find more visibility and data to improve your supply chain processes and communication.

And then there are claims. While we wish every situation could go smoothly, there can still be mishaps. Even so, we’re proud to share that less than one percent of all shipments coordinated with Trinity Logistics end up in a claim. That’s likely because we work with shippers and receivers to monitor load and unload times, checking to ensure trailer doors are not left open, causing temperatures to fluctuate outside of any required ranges.

Now, fear not, because if something does happen, we’re able to help with that too. We have an in-house expert Claims Team to help negotiate any produce claims on your behalf, with an average rate of 60 days in resolving cargo claims.

By working with Trinity Logistics for your produce shipments, you’ll also gain an extra benefit – experiencing our acclaimed People-Centric service. It’s what our customers praise the most about our services and keeps them returning to Trinity Logistics for their logistics needs.

If you’re tired of tackling these produce shipping challenges alone, it may be time to get connected and join the thousands of shippers that choose to make their logistics easy with Trinity Logistics. You won’t be-leaf our exceptional service until you try it!

Get Out of Your Produce Shipping Pickle

Check Out Trinity's Solutions Request a Free Shipping QuoteWhether your product is coming straight from the farm, is moving between processing, or heading off to the consumer, the dairy industry needs first-rate cold chain solutions to meet their complex supply chains.

Dairy products such as milk, cheese, and butter are household staples and essential in many people’s diets. It’s no surprise that the dairy industry is considered one of the fastest-growing industries, almost doubling in value every five years. To keep up with consumer demand, the dairy industry needs exceptional cold chain solutions to keep their products cold and safe for consumption.

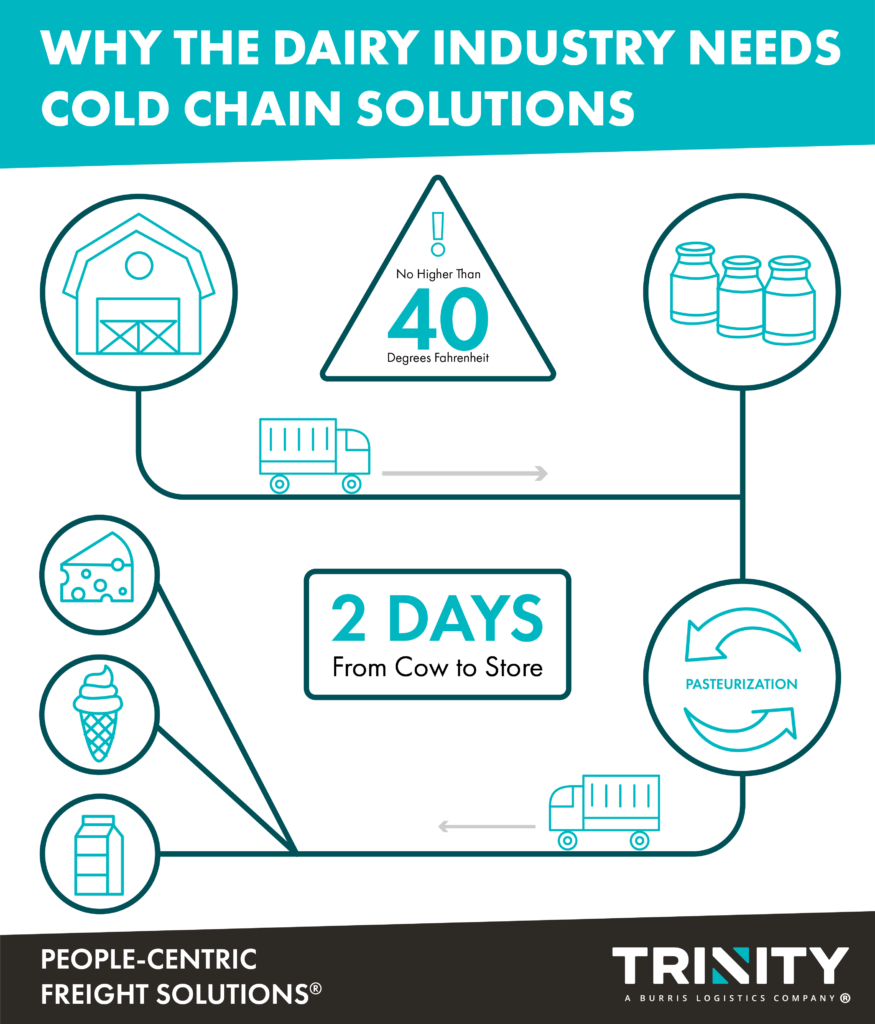

Why the Dairy Industry Needs Cold Chain Solutions

Dairy products all start with milk, and it has a short shelf life. After the cows have been milked, it immediately transports to cooling storage tanks or a chilled trailer. To ensure the milk doesn’t spoil, it must be stored at a temperature no higher than 40 degrees Fahrenheit. It’s then transported to a processing facility, pasteurized, and transported again to consumers.

Usually, this process alone, from cow to store, takes place in about two days. Now, milk is often a starting point for the many diverse dairy products available. Depending on the final product, dairy supply chains have more steps and complexities added.

Common Issues Requiring Cold Chain Solutions

- Temperature Control Needed for Most Dairy Products

- Capacity During Peak Shipping Seasons

- Managing Milk Production with Dairy Demand

- Supply Chain Disruptions

- Dairy is Highly Regulated

- Supply Chain Visibility

- Potential High Value Dairy Products

Temperature Control Needed for Most Dairy Products

Most dairy products need storage at specific temperatures to keep from spoiling. Dairy products need strict attention because of the risk posed to consumers if the cold chain is broken. If not consistently kept cold and free of humidity, bacteria in the dairy can cultivate and dairy products can become harmful.

Capacity During Peak Shipping Seasons

While some dairy products can seek out alternative transportation modes, most find shipping truckload is the most viable option. It’s usually the fastest and cheapest way to move the product because of its weight. It’s also the most viable due to freight security and nature of the product, and because it reduces the risk of claims due to temperature fluctuations or shifting. Since most dairy products need refrigerated trucks for their shipments this can make capacity an issue at times, such as produce season, when reefer capacity can be tighter. It can not only be more difficult to secure a refrigerated truck, but more expensive to do so.

Managing Milk Production with Dairy Demand

Dairy product demand can fluctuate. Yet, even when consumers want fewer dairy products, the cows don’t stop making milk. They can’t be turned on and off like machines, giving the dairy industry a unique balancing act to handle.

Additionally, when it comes to shipping milk, most of that is kept regional given the short shelf life and cost to ship, making dairy demand management even trickier.

Supply Chain Disruptions

As we’ve learned in recent years, there’s always the chance for supply chain disruption to happen. Whether that’s a truck breaking down, a roadblock, or some other instance that would cause delays. With several dairy products (like milk) having a short shelf life, any delays can risk product spoiling and going to waste. Companies in the dairy industry need to be able to act quickly if any disruption happens.

Dairy is Highly Regulated

Dairy products are associated with foodborne illnesses, so it’s no surprise that they’re highly regulated. Right from the start, milk is tested to ensure it’s of safe quality to consume and make other products from. There’s also the Food Safety Modernization Act (FSMA), which places strict requirements on sanitary transportation and the handling of dairy products.

Supply Chain Visibility

Because of so many factors mentioned above, it’s important for dairy companies to have full, real-time visibility of their supply chains. Additionally, many wholesale food distributors and grocery warehouses hold very strict requirements for appointments with very strict product quality inspections to be accepted into their inventory. Without it, dairy companies are at risk of losing products and money due to spoilage, disruptions, delays, or regulation requirements.

Potential High Value Products

Certain dairy products can be high value, like some cheeses for example. This can make the overall value of the load to be costly should there be any potential claims. It’s best for shippers to work with expert providers who have the experience and knowledge to handle any high value dairy products.

Leading Cold Chain Solutions from Trinity Logistics

Shippers in the dairy industry looking for first-rate cold chain solutions can find all they need with Trinity Logistics. We’re a leading third-party logistics (3PL) provider with over 40 years of experience serving logistics solutions to some of the top-known brands in the food and beverage sector.

Standard Operating Procedures for Temperature-Controlled Shipments

One of the reasons we excel in cold chain solutions is our standard operating procedures in place for every temperature-controlled shipment we arrange. This includes:

- Only working with carrier relationships that have downloadable reefer units

- Requiring carriers to pre-cool trailers a minimum of one to two hours before pickup

- Requiring carriers to run their reefer units on continuous

- If necessary, requiring carriers to pulp product before loading

- Requiring carriers to use one of our tracking and tracing partners for real-time shipment visibility

- Only using carriers that have refrigerated trailers that are 2015 or newer

We understand just how critical it is that your product stays at its required temperature. That’s why we work with our trusted, experienced carrier relationships to ensure your product arrives fresh.

Multi-Modal Cold Chain Solutions

No matter what transportation mode you need your product to ship, we have the logistics solutions to support your business now and in the future, including;

- Truckload

- Expedited

- International

- Cross-broder

- Air or ocean shipping

- Drayage

- Less-than-truckload

- Managed Transportation

This enables your business to seamlessly run regardless of what change or growth you experience.

In-Depth Transportation Management

Whether you need a transportation management system (TMS), to fully outsource your logistics, or your own customized managed transportation solution, we can help. We know each business is unique, which is why our system is highly configurable so we can meet your exact needs. Our Trinity experts will work as part of your business, offering in-depth reporting and data to help get you ahead of your competitors.

No Need to Worry About Disruptions

Did I mention that Trinity has been serving cold chains for over 40 years? We’ve seen it all when it comes to supply chain disruptions and delays. We know how to quickly adapt plans to keep your freight moving. While you’ll have your sole Trinity relationship to lean on for updates, we also have a 24/7 Team in case we need any additional support. You can learn to rest easy whenever your shipment is in our care.

Experts in Temp-Controlled Logistics and Dairy

Trinity Logistics has been serving cold chains for 40-plus years, in addition to our parent company, Burris Logistics, that was built on its expertise of handling temperature-controlled commodities.

There’s also Honor Foods, another Burris Logistics company you can lean on for food redistribution if needed. Honor Foods is a leading foodservice redistributor with locations throughout the Northeast, Mid-Atlantic, and Southeast regions of the U.S. They specialize in frozen, refrigerated, dairy, and dry products with over 3,000 stocked items from 300+ trusted suppliers.

Our People-Centric Service

What makes Trinity unique from other 3PLs and what our customers praise the most is our exceptional People-Centric service. We’re a company built on a culture of family and servant leadership, and that culture shines through in our service to you. It’s our care, compassion, and communication that you’ll notice and appreciate.

I’D LIKE LEARN MORE ABOUT TRINITY'S COLD CHAIN SOLUTIONSMotor carriers aren’t the only ones affected by deadheading.

While every mile driven takes a toll on the environment, research shows that deadhead miles account for over a third of carbon emissions in trucking. In fact, 36 percent of trucks travel empty in the U.S. every day, averaging roughly 61 billion miles deadheading every year.

Simply put, deadheading is an inefficiency problem within the logistics industry, one that we all know we need to improve. According to a survey by Convoy, 69 percent of respondents said reducing deadhead miles is important to them. By reducing deadhead miles, both shippers and carriers can slash their supply chain costs while also making an environmental impact.

WHAT IS DEADHEADING IN TRUCKING?

Deadheading, deadhead miles, or empty miles – they all mean the same thing – that a truck is driving empty. Usually, this happens once a driver has made a delivery to the receiver, and they don’t have freight to pick up until their next destination. This means they drive empty back to the original shipping point or to their next pickup location. Empty miles waste time for a carrier by failing to generate revenue. It also causes them to incur extra operating costs and contribute more emissions into our atmosphere.

Ideally, the most efficient use of a carrier’s time is finding a backhaul shipment. This is a nearby shipment that needs to be picked up and delivered close to or at their next destination, so either their pickup origin or next pickup.

HOW DEADHEADING POSES PROBLEMS

We’ve already discussed how deadheading contributes to C02 emissions and how carriers lose money running deadhead miles, but what about shippers? How are they affected?

Well, those carriers need to make up the money and time they lost deadheading somehow. They’re likely to charge a higher rate on their following shipments to do so.

Also, driving empty miles can be dangerous when severe weather occurs. A truck can weigh about half its weight empty than when it’s full, making it more susceptible to accidents. While truck drivers are trained in managing high winds and road safety, that’s often with a full truck and not an empty one. The same winds that shake a passenger car have been known to flip an empty truck.

WHY IS DEADHEADING SO COMMON?

It’s often difficult for a carrier to find their own backhauls, nor do shippers have the time to focus and invest their time in them. They need the truck to pick up and deliver and return to pick up the next shipment, not thinking of the in-between. Other carrier relationships and contracted shipments can get in the way, making it difficult to arrange or find backhauls.

HOW TO REDUCE DEADHEADING

It’s possible for shippers to keep backhauls for carriers in mind to both help keep carrier relationships moving and make headway on sustainability initiatives.

Make Use of Technology

Technology makes it much easier to match a truck with an available shipment. You can make use of digital freight matching (DFM) tools like Trucker Tools or DAT, which give shippers and carriers an easier way to find each other and match up based on suitable capacity for a shipment. Automation and machine learning in those applications help quickly find and create those matches.

A transportation management system (TMS) can also be helpful here. A TMS brings together information on all shipments and digital freight networks to help make sure trailers are utilized fully and backhauls gain the coverage they need. A TMS also gives you the opportunity to optimize your routes to reduce any deadheading.

Consider Consolidating Your Freight

Combining your partial shipments into a full truckload to one distribution point to then be delivered by a regional carrier or vice versa can allow for fewer empty miles and trucks on the road, saving you money and reducing your emissions.

Consider Continuous Move Planning

This plan involves stringing loads together to make the most of fleet utilization and driver time by bundling low-volume and high-volume lanes together. Carriers will add lanes across many customers, creating closed-loop routes to keep freight moving constantly. As a benefit, shippers often receive per-mile rates since they are making use of a carrier’s empty miles. This can be a bit more complex, but with a TMS and proper communication, can be an effective way to reduce deadheading.

TRINITY CAN HELP YOU REDUCE DEADHEAD MILES

Deadheading is an industry-wide problem that we all need to work on together to resolve. Carriers need to dedicate time for searching and finding backhauls, just as shippers need to work with carriers to reduce their empty miles. That’s one way an intermediary, a 3PL like Trinity Logistics, can step in and help. We can work with both parties to arrange shipments so that each company has its unique needs met.

We have over 40 years of experience arranging shipments between shippers and carriers. Our Team of experts can help shippers plan and organize their shipments and recommend freight consolidation strategies when it’s suitable. We also have a Carrier Development Team dedicated to growing our carrier relationships by learning their wants and needs. We reach out and gather their preferred lanes and capacity to better match them to available shipments to keep them moving and generating revenue.

Trinity Logistics is also recognized as a Green Supply Chain partner for its sustainability initiatives and solutions available to offer shippers more options for their logistics that can reduce their carbon emissions.

If you’d like to talk to one of our experts about your shipping needs and find more sustainable options, click the button below so we can get started.

GET A FREE, NO-OBLIGATION SHIPPING QUOTEHVAC contractors and plumbers continue to face supply chain woes like material shortages and rising costs.

Battling these issues is making it tougher for HVAC contractors and plumbers to meet their customer’s demands in the short term and perhaps even longer. Here’s what HVAC contractors and plumbers can do to rise above.

WORK WITH MANY SUPPLIERS

If current suppliers can’t meet your needs, then it’s a good time to explore other ones. Many suppliers are ready to strike up new relationships and may be willing to be more flexible with contracts. Shopping with multiple suppliers will not only gain you access to more resources but can offer you more varied pricing options to consider.

CONSIDER ALTERNATIVE MATERIALS

It might be worth checking into other materials as they may be easier to get your hands on. Considering other brands of materials or equipment can keep your projects from staying stagnant.

COMMUNICATION IS KING

In difficult times like these, communication can be something that gives your company a competitive edge. Not only is it a vital aspect of a successful business, but it helps build trust and long-lasting relationships. While no one likes delivering bad news about backorders or delays, keeping your customers informed will go far, as they’ll appreciate your honesty and transparency.

IMPROVING CUSTOMER SERVICE

While material shortages and delays are out of your hands, great customer service will keep your current customers and help you gain new ones. In addition, extra attention to customer service can help address any frustrations among your customers. While these challenges may not last forever, your reputation will, so make sure yours remains good, if not great.

PRE-ORDER MATERIALS AND EQUIPMENT

Many HVAC contractors and plumbers often only order the materials and equipment as needed. Instead, plan and stock up on the materials you most often use for your projects. This way, you’ll have what you need ready instead of waiting for materials to deliver.

CONSIDER MODE DIVERSIFICATION

Trying different modes of transportation could help you offset your increased costs. Keep an eye on transportation costs across the different modes available. Being more flexible with your freight shipping can give you some financial benefits.

INVEST IN TECHNOLOGY

Logistics technology, like a transportation management system (TMS), has tools available to help you stay on top of your supply chain and plan efficiently. One example is helping you with your routing decisions by matching your freight with the best carriers, lanes, rates, and transit service. It will also enable you to better track and manage any service disruptions or shipment delays in real-time, thus increasing your service levels and improving your customer relationships.

THINK ABOUT ONSHORING

Onshoring is a strategy that HVAC contractors and plumbers can use to mitigate supply chain woes and improve competitiveness. Onshoring strategy can ensure resilience in your supply chain and give your company a competitive edge.

Onshoring refers to the overall practice of moving manufacturing operations from foreign soil back to the United States or outsourcing to domestic contract manufacturers rather than overseas. An example of onshoring would be having operations moved to Mexico versus China.

Onshoring allows your supply chain shorter travel times since materials and products are much closer than if they were overseas. This not only keeps your projects moving that much quicker but reduces your transportation costs. Additionally, you’ll also have the benefit of being greener due to less fuel being used.

CONSIDER OUTSOURCING YOUR LOGISTICS

According to the 2020 Annual Third-Party Logistics Study, 67 percent of shippers stating using a 3PL contributed to reducing their logistics cost, while 83 percent said it improved their service. By outsourcing to a 3PL, like Trinity Logistics, you won’t have to spend hours worrying about your logistics and get the help you may need to be more flexible with your shipping options.

“In this market where it’s difficult to meet demand and project deadlines due to material and product shortages, it may not be the best option to send it via LTL as you may save a few dollars on the front end but pay for it with extended estimated transit times, and the possibility of the parts being damaged as they go from terminal to terminal throughout transit. Working with a 3PL, like Trinity Logistics, can bring you other possibilities on how to move your freight efficiently, such as dedicated full truck options, expedited (straight trucks/sprinter vans), partial, and hot shot options to keep your freight moving to arrive on time so you can achieve your project deadlines.”

– Michael Whitaker, Business Development Representative at Trinity Logistics

If you’re looking for a reliable 3PL provider to help with your HVAC supply chain, consider Trinity Logistics. With Trinity, you gain a Team of experts to help optimize your supply chain, help arrange shipping using other modes, and end-to-end visibility through our available technology.

DISCOVER TRINITY LOGISTICSOptimized load planning is fundamental to improving your service and revenue.

Could your company be wasting money on a logistics strategy that doesn’t work? Efficient load planning is more critical than ever and a key performance area for any supply chain. Ideally, you want to be able to move your product to your customers while maintaining desired service levels in the most efficient way. Logistics optimization strategies such as improving your load planning processes can be an effective way to reduce freight costs by as much as 10 to 40 percent.

While this sounds great, load planning can be a very manual and time-consuming process. A transportation management system (TMS), specifically one that includes a freight optimization tool, is one way to analyze and take your load planning process from hours of manual work to minutes through automation and technology.

Start saving time and get your free supply chain analysis with Trinity Logistics.COMMON LOAD PLANNING TMS MISCONCEPTIONS

Before we dive into how a TMS can help you with your load planning, perhaps you’ve thought of one of these common misconceptions.

A TMS Optimizes on Its Own

First off, not all TMS platforms are the same. Some may not even offer load planning tools. It’s also important to see what kind of support is offered, as having an expert available can help provide you with more insight than the software alone.

The Optimized Load Plan Will Be Perfect Every Time

Technology is a great tool to make your logistics processes more efficient. The word to remember here is “tool”. Even a TMS with a freight optimization tool can overlook certain opportunities for freight consolidation, so it’s important to always treat your transportation technology as an aid to your load planning process and not as a full replacement for it.

BENEFITS OF OPTIMIZED LOAD PLANNING

- Cost Savings

- Higher profitability

- Improved logistics performance

- Improved logistics collaboration

- Improved customer service

HOW A TMS HELPS OPTIMIZE YOUR LOAD PLANNING

A TMS is a powerful tool for optimizing your load planning. A TMS provides you visibility into your entire logistics process. This allows you to monitor performance and create efficient plans. It helps you with your forecasting and planning so you can find cost-saving options. A TMS can help give you a clearer picture of your entire freight network by housing all your transportation information in one system.

Now, there is a lot of transportation management software out there. To gain the most benefit for your load planning process, you’ll want to make sure you select one with a freight optimization tool.

New to transportation management software? Download our FREE Guide to Transportation Management Software.WHY WOULD I NEED A FREIGHT OPTIMIZATION TOOL?

Anyone who has gone through the process of figuring out how to reduce shipping costs for each of their loads knows how much of a pain it can truly be. The process starts with tracking down all your open shipments, deciding what loads should be moved together, and then building, rating, and tendering those loads manually. For those who have not implemented a TMS, this is usually done with paper and pencil or an Excel spreadsheet.

Many factors go into optimizing shipments, including the number of pallets and weight of each shipment (taking trailer size into consideration), delivery availability for locations, and special services needed.

Perhaps one of the most important dynamics of building a shipment is delivery deadlines. It’s imperative to take note of whether a truck can deliver to single or multiple locations and arrive on time, factoring in the drivers’ hours of service (HOS) and loading and unloading times.

In sum, it’s a like a complex jigsaw puzzle made up of your freight, and trying to figure it out alone can be difficult.

HOW CAN A FREIGHT OPTIMIZATION TOOL HELP ME?

The freight optimization tool in a TMS will take your list of open shipments and consolidate them into loads based on the criteria specified by you. The software’s criteria encompass ship and delivery date flexibility, maximum weight per shipment, the maximum number of pieces, the number of picks and drops, driver hours, and more.

You’re also able to choose which carriers you want to include for consideration. Once these parameters are set and the optimizer has been run, you also have the capability to auto-create loads in the TMS based on the optimizer’s results.

The optimizer tool accomplishes in minutes what usually takes a person hours to calculate and configure, with the likelihood of saving money in the meantime. The top benefits here translate to both time and money saved. Gone are the days of sitting at your desk for hours with a calculator and a headache.

In summary, our TMS (and other similar products) allow you to enter all your shipments, whether it’s 20 or 1000, and will automatically calculate the most efficient way to route your shipments by combining smaller shipments into multi-drop truckloads, keeping other shipments separate, and configuring the way it all gets routed across the country. The results of the freight optimization tool include the reported cost savings and a detailed report of the loads proposed.

START OPTIMIZING YOUR LOAD PLANNING WITH TRINITY’S TMS

Logistics optimization never ends. It is a continuous process only limited by your time, technology, and commitment to improvement. And ensuring your company has access to a best-in-class TMS is the key to starting that process and finding efficiencies.

Discover how Trinity’s TMS, including its freight optimization tool, can improve your logistics processes, like load planning, helping you offer better customer service and reduce costs while increasing revenue.

SIGN UP FOR A FREE SUPPLY CHAIN ANALYSIS AND TMS DEMOOptimizing your logistics can make all the difference in your business’s bottom line. However, to fully understand your logistics processes you need to look at your logistics analytics.

To start, you’ll need access to the right technology. One such piece of technology is a transportation management system (TMS). A TMS is an excellent investment and according to Logistics Management Magazine, has been shown to reduce transportation costs by up to 30 percent.

Not interested in reading? Find out these priceless tips on improving your logistics processes.

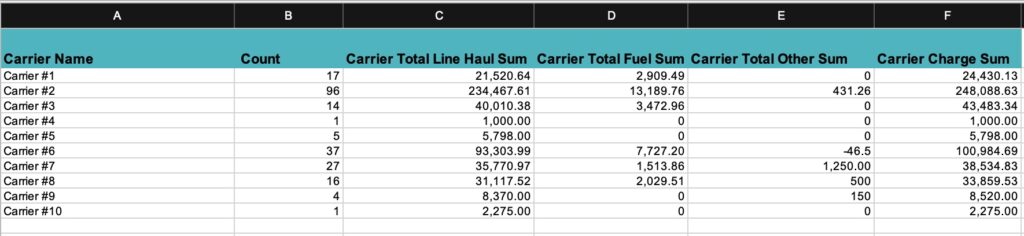

To get the most out of a TMS and your logistics, you’ve got to know what you should be watching. All the data a TMS provides can be overwhelming and the possibilities of what you could analyze are endless. Ultimately, sifting through that data can be complex and time-consuming. So, to make things easier for you, our Team of TMS experts found the top 5 reports you should be running so you can see your best return on investment (ROI).

Get started with a demo of Trinity's TMSTOP 5 LOGISTICS REPORTS YOU NEED

Getting the data you need for a good overview of your logistics processes doesn’t need to be complicated. These reports should give you a broad view of logistics analytics to help you reach your KPIs.

Freight Accruals

Freight accruals is a report used to keep track of the costs associated with transporting your goods to a customer. These costs begin accruing from the moment the goods deliver, and they get discharged once a freight invoice is paid.

Tracking freight accruals allows your company to calculate your true net revenue at any given time. As a result, you’ll gain a better insight into any outstanding balances accumulated during a specific timeframe, whenever you may need it.

Cost Allocation

A cost allocation report breaks down your freight charges by a mile, pound, or SKU.

For any multi-stop loads, or loads made up of many POs, freight charges can be allocated to each order based on the percentage of distance, weight, or quantity the individual order contributed to the whole. Therefore, tracking your cost allocations will give your company a better look into the true cost of transporting your goods. You can then use this report to identify your most costly SKUs or lanes.

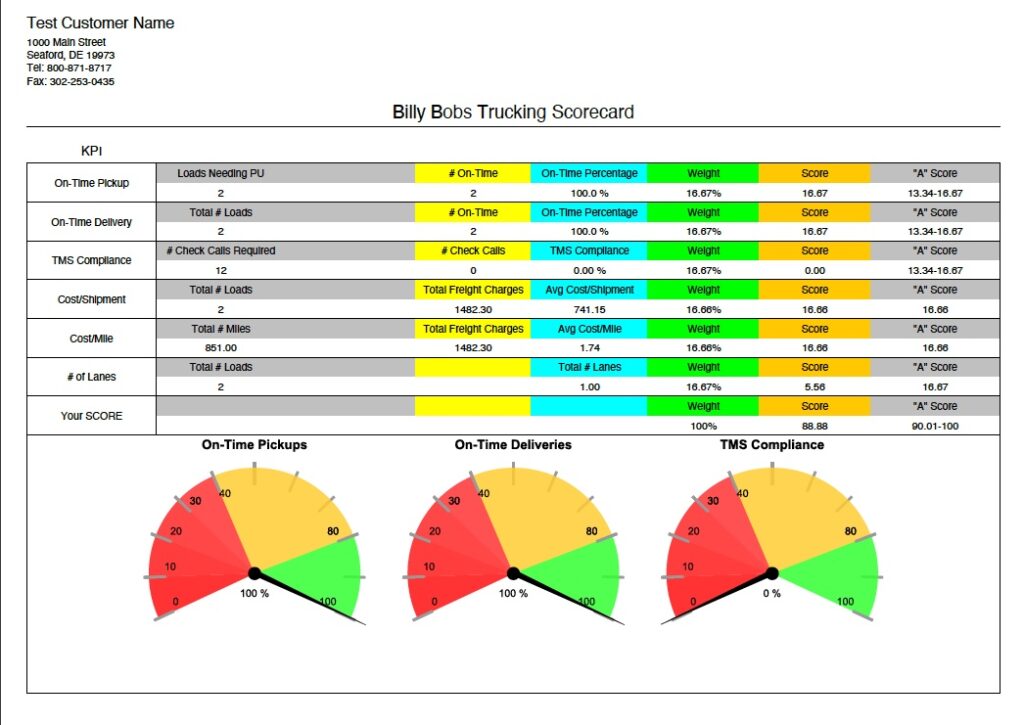

Carrier Scorecard

Carrier scorecard reporting helps you track a carrier’s performance. This will show data such as tender acceptance, on-time pickups, and on-time deliveries.

A carrier scorecard report can help you find which carriers are meeting your transportation needs and which are causing extra work. For example, carriers who bid low on a request-for-proposal (RFP), proceed to decline tenders, or provide poor service can cost your company. Without knowing how your selected motor carriers are doing, you could be facing thousands of dollars in extra expenses or, worse yet, lose customers.

By tracking your carriers’ performance, you can reevaluate your routing guide by selecting more reliable carriers on trouble lanes, improving both your costs and customer service. Additionally, this can help you set solid KPIs with your relationship carriers so you can better communicate your needs.

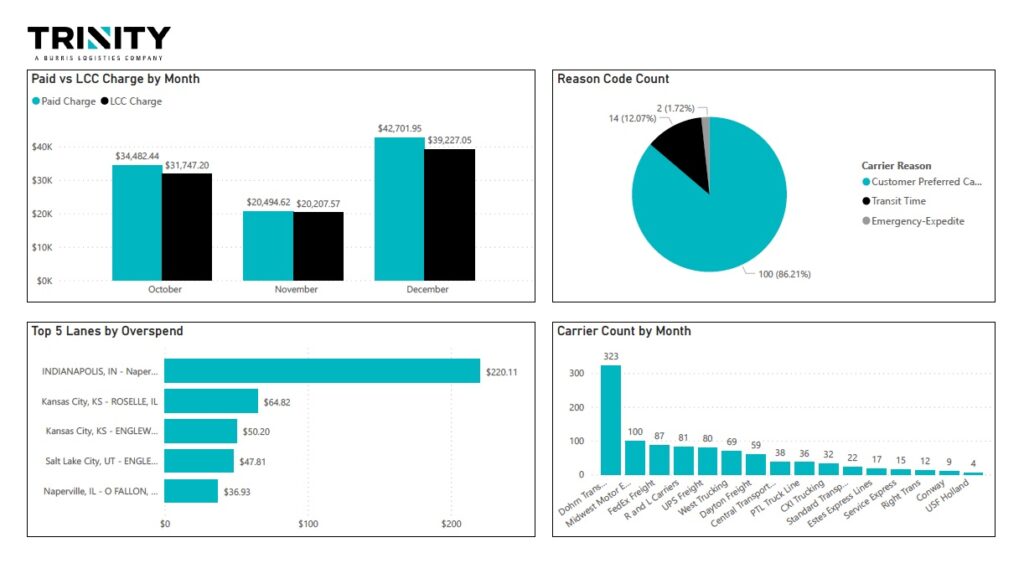

Least Cost Carriers

Least cost carrier reporting helps you identify loads where the carrier with the lowest cost didn’t haul the freight, the reason why, and the extra freight charges that occurred as a result.

This logistics report can help your company identify potential problem areas, resolve the underlying issues, and prevent unnecessary expenses from occurring in the future. If you’re looking to cut freight costs, this report clarifies where your missed opportunities are located.

Since cost isn’t the only factor when selecting a carrier, this report can also help you identify carriers that get repeatedly passed over despite offering lower rates. Therefore, these carriers provide you with the opportunity to work with them on a service-level agreement before you award business solely based on cost.

Power Lanes

Power lane reporting identifies new lanes and provides a benchmark for negotiating contracted rates with carriers.

You can identify a new lane as an origin-destination pairing that occurs a set number of times. Once a new lane is identified, the spot market rates paid to move that lane get broken down by load, mileage, pound, and more. This helps you have a point of reference when negotiating rates with carriers.

Identifying power lanes will help you secure fixed rates and better predict future freight costs.

Note: Most transportation management software products have the ability to run the five reports listed above. If you’re missing out on these exclusive reports, or you’re interested in a TMS for your supply chain, request a special demo with our logistics experts, who can help assess your needs!

MAKE LOGISTICS ANALYTICS MEANINGFUL

The logistics part of your business is complex and dynamic. There are lots of moving parts with many potential bottlenecks, so it’s important the metrics you report on are meaningful.

The right logistics analytics will help you measure performance, optimize routes, and streamline functions. Without the proper data, your business growth will be stagnant. There’s no way to know what needs to be changed if you don’t have visibility.

Additionally, unfound inefficiencies can impact your customer service and carrier relationships and can lead to lost sales and higher costs. Having the right logistics analytics can be one of your most powerful tools and make a big difference in your everyday business activities.

START LEVERAGING YOUR LOGISTICS ANALYTICS

According to research, 93 percent of shippers believe logistics analytics are critical to making intelligent decisions. And 71 percent believe that data improves quality and performance. Yet, too many businesses continue to use manual, time-consuming processes to analyze their logistics.

Take advantage of logistics technology and innovative logistics analytics so you can find actionable insights with the right reporting. And if you need help with your logistics analytics, we can help.

Start hitting that easy button because a TMS with Trinity can make tracking your logistics data a breeze. Not only do we understand everyone’s needs are different and offer customized solutions, but you also have the option of as much or little support from our superusers as you want.

And if you’re looking for expert advice based on your logistics analytics, Trinity offers Quarterly Business Reviews so we can help you find efficiencies.

So what are you waiting for? Let’s get connected and see how we can optimize your processes.

I'm ready for a clearer insight into my logistics analytics.With cold chain logistics, every product that you deal with has very specific temperature requirements that you need to adhere to. These products are ending up on tables across the entire country, so you want to make your product arrives precisely the way it needs to be so it’s safe for human consumption. Because of this, cold chain logistics can be challenging to manage, and finding reliable providers can be frustrating. There are many moving parts of the cold chain that can be hard to follow and track. It would undoubtedly be helpful to find one provider that could offer you end-to-end cold chain management, from production to delivery. And that’s what we’re here to talk about today. Burris Logistics and Trinity Logistics working together could be the solutions you’ve been looking for to simplify your cold chain management. Keep reading to find out how we work better together to serve your complete cold chain.

BURRIS LOGISTICS CAPABILITIES

Let’s start with Burris Logistics. What do they offer that can enable cold chain shippers and their businesses to thrive in the face of its complexities?

Quick Background

Burris Logistics has been around for 96 years. The company started as a produce hauler from southern Delmarva to Philadelphia. They quickly grew and expanded into the frozen food business and found their purpose as a driven food logistics provider. Today, they own 14 cold storage sites up and down the east coast and out into Midwest. Burris Logistics currently has a family of brands including Burris PRW Plus, Honor Foods, and Trinity Logistics.

Burris Logistics offers you logistics technology solutions that never sleep. With a Technology Team of over 100 Team Members, they work around the clock to provide you with technology resources designed to meet your specific needs.

From a Burris asset standpoint, they’re able to track all their trailers with ELD and reefer tracking, with the ability to ping the tractor and trailers to see where each of their assets are in real time. In addition, they have access to technology that can start and stop the units, reset them, or check temps on them, no matter the distance. With the complexities of cold chain transit and the current driver shortage, Burris works hard to put in place any technology that can make a driver’s job easier. They want to cut any obstacles drivers may face on the road while having any data be transparent to help both them and ultimately, any customers.

Burris also has technology for their cold storage warehouses. They focus on providing their customers with freshness, clarity, and visibility. They offer real-time monitoring and any differentiation from setpoints gets recorded. They make sure to get real-time data to those who need it should meaningful decisions need action, and have secondary and tertiary backups available.

Some of their other logistics technology offered are:

· Warehouse management system software

· Enterprise resource management

· Produce inspection tool

· External integrations

· Supply chain portal

· Demand planning

· Order status

· Delivery status

Burris Logistics works with you to create the best possible warehousing and distribution solutions. They’ll support you with a network of strategically located warehouses, 96 years of expertise, and a solution customized for your unique needs.

In a reflection of national trends, the newest and fastest-growing business line within Burris Logistics is their direct-to-consumer to support those in the cold chain e-commerce space. Through current resources and expertise in temperature-controlled logistics, Burris can deliver a premier frozen fulfillment network with cutting-edge technology, thought leadership, and warehouses across the country. Burris’s knowledge of shipping supplies, coolant technology, and two-day parcel shipping capability ensures quality is delivered with every package.

Facility Design is the process of considering new construction via greenfield facility sites or the re-purposing of an existing operation. Many companies are facing changing business needs, including the need for multi-channel execution. This makes the ability to scale up and scale down with various capabilities an essential part of planning. With partners who increase their dependency on Burris Logistics, they’ve been able to scale their operations to accommodate their programs with new locations, modifications to existing assets, and technology to keep the supply chain efficient.

Your customers desire the right products, in place, at the right time. Honor Foods, a Burris Logistics company understands how important it is to have on-menu and on-shelf products available while also minimizing food waste. They can help you plan inbound and outbound freight, using logistics technology and their warehouses to maintain food quality and safety.

With one of their other brands, Honor Foods, Burris offers Private Label In-house brands that have developed into trusted names amongst food service operators. These products undergo scrutinous selection and quality assurance knowing that our restaurant partners only accept the best. Your customers want what is trending, and Burris can help you meet this demand. Their brands come sourced from trusted shippers and can be a noticeable cost saving for you.

Burris Logistics understands that products need different environments, which is why their facilities can provide different temperatures and humidity, depending on your product. Newer warehouses are purposefully being built with ambient/dry storage space to accommodate increased partner needs. Additionally, their warehouses and distribution centers are in strategic locations near major transportation hubs and ports, making it easy to get your freight on the move quickly.

TRINITY LOGISTICS CAPABILITIES

Quick Background

Trinity Logistics has been around for over 40 years. The company was started by the Banning family in Cambridge, Maryland. Throughout the years, the company grew and expanded as a non-asset-based third-party logistics company (3PL) and was acquired by Burris in 2019. The two companies saw similarities in company culture and future goals, deciding to unite for greater opportunities and offer more supply chain solutions for our customers.

Burris + Trinity = Better TogetherURRIS

What’s great for Trinity being part of the Burris Logistics family of brands is being able to offer more help to Burris customers. Trinity’s support helps Burris better assist some of the existing freight business they have for customers either coming back into their buildings or going to other places.

The addition of Trinity also offers Burris customers a wider variety of options in modes and technology, or even help outside of the cold chain. Trinity is very experienced in heavy haul moves or more complicated hazardous moves for the chemical industry. So, no matter the size of your company or freight, we have a solution for you. But, we’re here to talk about the cold chain, so let’s focus on refrigerated and frozen freight.

While it’s not always hard to find a refrigerated carrier, you do want to be selective. There are a lot of carriers out there, but Trinity has a robust vetting process in place. We make sure carriers hauling your freight have the right amount of insurance, requirements, and experience. In addition, we make sure these drivers are representing Burris and Trinity the way we need to and that our customers are getting their products delivered safely.

You might ask, how do we guarantee safety with our carrier network? Well, these carriers mean as much to us as our shipper customers do, so we build just as strong carrier relationships. We offer our carriers many different kinds of technologies for location tracking, temperature tracking, and so on. We make sure to continue to evolve our technology solutions to keep the shipping process easy and safe for both carriers and customers. Additionally, we have our communication. Our communication is one of our strongest assets to ensure both parties have their needs and solutions met. Our bottom line is bringing value and if we can do that, we’ll be successful.

We offer and use several different technologies like Macropoint or Fourkites, so we can ping shipments and know exactly where they are and what the temperature of the product is, giving our customers instant access to look at their freight. That’s just one piece of the technology puzzle.

Even with the technology available, we never lose contact with our customers. We strive to stay very People-Centric. Our technology only helps make it easier for our customers to view information, especially with our Customer Portal, giving them the ability to trace loads without having to reach out. It gives them access to see updates at any time of day and offers backend access to their invoices to answer billing questions, make payments online, or provide them with a breakdown of what each load costs, lumper fees, accessorials, or pallet exchanges. Our Customer Portal allows you to manage that piece of business on your own time and at your own speed. We’ll always be available, but the Portal and any of our technologies are there to bring you even more value and efficiency.

Current logistics technology available:

· Carrier Portal

· My Carrier Packet

· TriumphPay

· FourKites

· Trucker Tools

· MacroPoint

· Customer Portal

· Customized Transportation Management Solutions

· Banyan LTL

· DAT Book Now

· Trucker Tools Book It Now

WAREHOUSING

We know that one size does not fit all when it comes to warehousing. That’s why we have warehouse providers with locations across the nation to allow you to scale your business at your own pace, plus our cold storage solutions with Burris Logistics. Our growing network supports reliable service and premier dry, refrigerated, or frozen solutions so you can focus on what you do best.

TRUCKLOAD

Our truckload service provides you with the means to get your freight moving quickly. Truckload is faster than traditional LTL or intermodal shipments which means your shipments can arrive on time and on schedule.

LESS-THAN-TRUCKLOAD (LTL)

Our LTL service provides you with the means to get your freight hauled through a range of options. By leveraging our volume and extensive network of LTL carriers, we can provide you with lower rates for LTL shipments consisting of 1-10 pallets of either dry or temperature-controlled products.

INTERMODAL

You can add value to your supply chain by using this cost and environmentally-friendly shipping option. By shipping intermodal, you’ll reduce your carbon footprint and have reliable and consistent capacity when over-the-road capacity can be tight.

EXPEDITED

Sometimes your freight is time-sensitive or needs less handling. When this happens, we can arrange over-the-road or air-expedited shipping. We’ll make sure your freight arrives on time and without stopping at terminals in between.

DRAYAGE

Your freight can be delivered from the port or rail right to your door, or from your door to the port or rail. Either way, we’ll save you money in the process. From servicing imports and exports, returning empty or full containers, helping you avoid unnecessary fees, long drayage options, or more, our Team is ready to help.

INTERNATIONAL

Arranging international shipments can be tricky and requires a lot of communication. If you are looking for help with arranging your Full Container Load, Less Than Container Load, door-to-door, or port-to-port services, we can help. We’ll be your intermediary with freight forwarders to arrange your air and ocean freight international shipments.

MANAGED SERVICES

In this service, we combine our experienced account management and best-in-class transportation management technology to deliver you a customized solution that helps your company achieve its unique supply chain goals.

HOW WE CAN SERVE YOUR COLD CHAIN BETTER TOGETHER

Experience in Cold Chain

For many reasons, Burris Logistics and Trinity work well together for cold chain shippers. First off is our combined years of experience. There are certain things in cold chain you can only learn from the experience of working with temperature-controlled shipments. For example, things like picking and loading fresh produce, understanding what those temperatures are and what they need to be for storage and transit, and keeping track of those temperatures. Or understanding how to move ice cream from the West Coast and knowing that you can’t go over the mountains; that you must travel around them so as not to cause shrinkage. By having years of experience and understanding of those complex situations and small details that make or break a cold chain shipment, you can trust your temperature-controlled freight is handled safely and correctly with Burris and Trinity.

Technology

Between both Burris and Trinity, we have incredible logistics technology available, but what differentiates us from others is that we keep in mind that logistics is still a “people” business. Technology will always be a tool for our Teams to use and bring logistics solutions to other people who need them. Therefore, we try to stay away from technology just for technology’s sake and make sure what we use and offer is always a valuable solution.

Communication

Because of our years of experience, we are well-versed and experienced in many different situations. We know when and how to pivot quickly and keep business moving forward. When issues arise, we work until they are resolved and keep open communication every step of the way. Having a solid relationship with experts like Burris and Trinity will prove to be your largest asset no matter what supply chain bottlenecks you may face

Flexible, Customized Solutions

Because our two businesses offer many options while keeping business People-Centric, it means you can find a solution that’s customized for your growing business and needs and your solution can be flexible. We know the cold chain and solutions aren’t static, they are ever-changing, so you need a provider that can keep up. By working with Burris and Trinity, you’ll never have to worry about changing up your logistics plan as we’re readily equipped to accommodate any changes you may need. In addition, we can help you stay flexible as one sole provider instead of working with several.

Visibility and End-to-End Cold Chain Management

As the cold chain sector continues to grow, there’s been a growing demand for efficiency and visibility throughout the supply chain. Companies don’t like to be left in the dark when it comes to the logistics of their temperature-controlled freight. Working with Burris and Trinity can not only give you a wide range of technology to gain visibility and provide you with all the logistics services you may need, thus making your cold chain efficient and transparent. We’ll provide you with dedicated, knowledgeable experts, increased productivity and workflows, and reduced complexity by working with Burris Logistics and their family of brands instead of several different providers.

HAVE YOUR COLD CHAIN LOGISTICS TAKEN CARE OF, END-TO-END